3D-printed batteries are a new innovation revolutionizing energy storage and power supply. This technology combines the versatility of 3D printing with the benefits of battery technology, resulting in compact, customizable, and high-performance batteries.

The ability to create batteries in various shapes and sizes opens up numerous possibilities for energy storage in different applications. From wearable electronics to electric vehicles, 3D-printed batteries offer a scalable and efficient solution for powering our modern world. By leveraging the flexibility of 3D printing, manufacturers can optimize battery designs for specific devices, improving the overall energy density and performance.

As the demand for portable and sustainable power sources continues to grow, 3D-printed batteries offer a promising solution for meeting these needs.

How 3d Printing Is Transforming Battery Technology

3D printing technology is revolutionizing battery design and functionality, paving the way for innovative advancements in energy storage. Let’s delve into how 3D printing is reshaping battery technology.

Customization

Customization: With 3D printing, batteries can be tailored to meet specific needs and requirements.

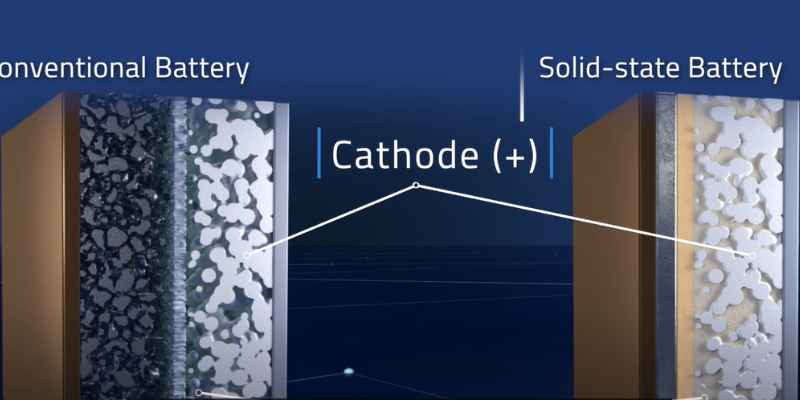

Complex Designs

Complex Designs: 3D printing enables intricate and elaborate battery designs that were previously impossible to achieve with traditional manufacturing methods.

Integration Of Multiple Functions

Integration of Multiple Functions: Through 3D printing, batteries can now incorporate various functions within a single structure, optimizing space and efficiency.

Applications Of 3d-printed Batteries

Batteries are an essential component in many devices and industries, and advancements in 3D printing technology have opened up a world of possibilities for battery production. With the ability to create intricate and customized designs, 3D-printed batteries are finding applications in various fields.

Consumer Electronics

In the world of consumer electronics, 3D-printed batteries offer significant advantages. Their small size and customizable shapes allow for more efficient use of space within devices, enabling manufacturers to create slimmer and sleeker designs. For example, smartwatches and wireless earphones often rely on compact batteries, and 3D printing technology makes it easier and more cost-effective to produce these small power sources.

Electric Vehicles

One of the most promising applications of 3D-printed batteries is in the electric vehicle (EV) industry. As the demand for EVs continues to rise, manufacturers are looking for ways to enhance their performance and reduce their weight. 3D-printed batteries offer solutions by allowing the production of lightweight, custom-shaped batteries that can fit into the nooks and crannies of an EV’s chassis. With 3D printing, EV manufacturers can optimize battery placement and achieve better weight distribution, ultimately improving the vehicle’s overall efficiency.

Medical Devices

The medical field also benefits greatly from 3D-printed batteries. Medical devices, such as pacemakers and hearing aids, require small and reliable power sources. 3D printing allows manufacturers to customize battery designs to perfectly fit the needs of these devices, ensuring optimal performance and longer-lasting functionality. Additionally, the ability to print batteries with biocompatible materials ensures that they are safe for use in medical implants and devices, reducing the risk of adverse reactions.

Challenges And Limitations

When it comes to the application of 3D printing in battery technology, there are several challenges and limitations that need to be addressed. Although 3D-printed batteries offer numerous advantages, such as custom shapes and sizes, efficient use of materials, and rapid prototyping, there are certain obstacles that currently limit their widespread adoption and effectiveness.

Production Scalability

Producing 3D-printed batteries at a large scale presents a significant challenge, especially in terms of ensuring consistency and quality. While additive manufacturing offers customization, it is important to develop standardized processes to enable mass production without compromising performance. Achieving the scalability required for commercial applications remains a priority for further advancements in 3D-printed battery technology.

Safety Concerns

Ensuring the safety and reliability of 3D-printed batteries is a critical concern. The intricate and layered nature of 3D-printed components can introduce potential weaknesses and vulnerabilities, which must be thoroughly evaluated and mitigated. Additionally, the use of new materials and manufacturing techniques requires comprehensive testing and validation to meet regulatory standards and ensure user safety.

Material Constraints

The availability of suitable materials for 3D printing battery components is another limiting factor. While there is ongoing research into developing advanced materials for energy storage, the current options may not fully meet the performance and durability requirements of traditional battery technologies. Overcoming material constraints and ensuring compatibility with 3D printing processes is essential for unlocking the full potential of 3D-printed batteries.

Current Research And Innovations

The current research and innovations in 3D-printed batteries have propelled the industry into a new era of energy storage. Scientists and engineers are continually exploring avenues to enhance the energy density, improve charging speeds, and develop biodegradable materials for 3D-printed batteries.

Enhanced Energy Density

Recent advancements in 3D-printing technology have led to the development of batteries with enhanced energy density, allowing for longer-lasting power in smaller, lightweight designs. This breakthrough has paved the way for more efficient energy storage and extended device usage between charges, offering unparalleled convenience for various applications.

Improved Charging Speeds

With ongoing research, breakthroughs in 3D-printed battery design have resulted in improved charging speeds. This innovation has the potential to revolutionize the way devices are powered, as it significantly reduces the time required to replenish energy reserves, enhancing overall user experience and promoting sustainable energy consumption.

Biodegradable Materials

Researchers are actively focusing on the use of biodegradable materials in 3D-printed batteries, aiming to mitigate environmental impact and support sustainable practices. By leveraging biodegradable components, these batteries offer a promising solution to reduce electronic waste and promote eco-friendly energy storage alternatives.

Environmental Impact Of 3d-printed Batteries

When it comes to the environmental impact of 3D-printed batteries, sustainability and recycling initiatives play a crucial role in minimizing the negative effects on our planet.

Sustainability

One of the key advantages of 3D-printed batteries is their contribution to sustainability. These batteries are designed with a focus on reducing waste and energy consumption during production. By using additive manufacturing techniques, 3D printers can minimize material waste compared to traditional battery manufacturing processes.

Additionally, 3D-printed batteries can be optimized for energy efficiency, allowing devices to operate for longer periods of time without the need for frequent charging. This not only enhances user convenience but also helps in reducing energy consumption and carbon emissions.

Recycling Initiatives

Another vital aspect of the environmental impact of 3D-printed batteries is recycling initiatives. As battery usage continues to grow, proper disposal and recycling of old batteries become crucial to prevent hazardous materials from polluting the environment.

With 3D-printed batteries, recycling is made easier due to their modular design. These batteries can be disassembled into their individual components, making it simpler to separate and recycle various materials such as metals, plastics, and electrolytes. This modular approach improves the overall recyclability of the batteries, reducing waste and allowing for the recovery of valuable raw materials.

In addition, 3D-printing technology enables the creation of customizable battery designs, which means that old batteries can be recycled to produce new batteries with different specifications. This circular economy approach not only minimizes waste but also contributes to resource conservation.

Conclusion

Considering the sustainability features and recycling initiatives associated with 3D-printed batteries, it is evident that these innovative technologies have a positive environmental impact. By reducing waste, conserving resources, and enabling efficient recycling, 3D-printed batteries are a step forward in the development of sustainable and eco-friendly energy storage solutions.

Future Outlook

The future outlook for 3D-printed batteries is promising with the potential for significant market growth and technological advancements.

Market Growth

The market for 3D-printed batteries is projected to experience considerable expansion due to increasing demand.

Technological Advancements

Ongoing research and development efforts are driving technological advancements in 3D printing technology for batteries.

Frequently Asked Questions On 3d-printed Battery

What Is A 3d-printed Battery?

A 3D-printed battery is a rechargeable battery manufactured using 3D printing technology. It is compact and customizable, offering unique design possibilities and applications in various industries.

How Does 3d Printing Impact Battery Technology?

3D printing revolutionizes battery technology by enabling the creation of custom-shaped batteries, improving energy density, and enhancing performance while reducing manufacturing costs.

What Are The Advantages Of 3d-printed Batteries?

3D-printed batteries offer design flexibility, enhanced energy storage capacity, lightweight construction, and the potential for integration into complex devices and structures.

Are 3d-printed Batteries Suitable For Consumer Electronics?

Yes, 3D-printed batteries are ideal for consumer electronics, providing compact and high-performance power solutions for devices such as smartphones, wearables, and IoT gadgets.

Conclusion

3D-printed batteries offer a range of advantages, paving the way for groundbreaking innovations in various industries. Their compact size, customizable shape, and improved energy storage capacity make them a game-changer. As technology continues to evolve, it’s exciting to think about the possibilities that lie ahead.

With further advancements and refinements, 3D-printed batteries have the potential to shape a more sustainable and efficient world. So, get ready to witness the power of this revolutionary technology!