The concrete calculator is a tool used to estimate the amount of concrete needed for a project. It takes into account the dimensions of the area to be filled and calculates the required quantity of concrete.

Concrete Calculator

Planning a construction project requires accurate estimations, and knowing exactly how much concrete will be needed is essential. The concrete calculator provides a quick and convenient way to determine the amount of concrete required for a specific job. By inputting the dimensions of the space to be filled, including length, width, and depth, the calculator can provide an accurate estimate.

This not only helps in budgeting for the project but also ensures that there is neither wastage nor shortage of concrete. Using a concrete calculator saves time and effort, allowing for efficient planning and execution of construction projects.

Why Use A Concrete Calculator

Using a concrete calculator can greatly benefit both DIY enthusiasts and professionals in the construction industry. This powerful tool allows users to quickly and accurately determine the amount of concrete needed for a project. By saving time on manual calculations and ensuring accuracy in estimations, a concrete calculator becomes an indispensable asset for any concrete-related project.

Saves Time On Manual Calculations

Manual calculations can be tedious and time-consuming, especially when dealing with complex measurements or large-scale projects. Using a concrete calculator eliminates the need for manual calculations, reducing the risk of errors and saving substantial amounts of time in the process. Instead of spending valuable hours crunching numbers, users can input their project’s dimensions into the calculator, and within seconds, receive the precise amount of concrete required.

Ensures Accuracy In Estimations

Estimating the correct amount of concrete is crucial for both financial and practical reasons. Using too little concrete can lead to weak structures, while using too much can result in unnecessary wastage. By relying on a concrete calculator, users can be confident that their estimations are accurate and reliable. This helps avoid overordering materials, reducing project costs and minimizing waste. The precision provided by a concrete calculator ensures that the project proceeds smoothly, without any unexpected delays due to insufficient or excess concrete.

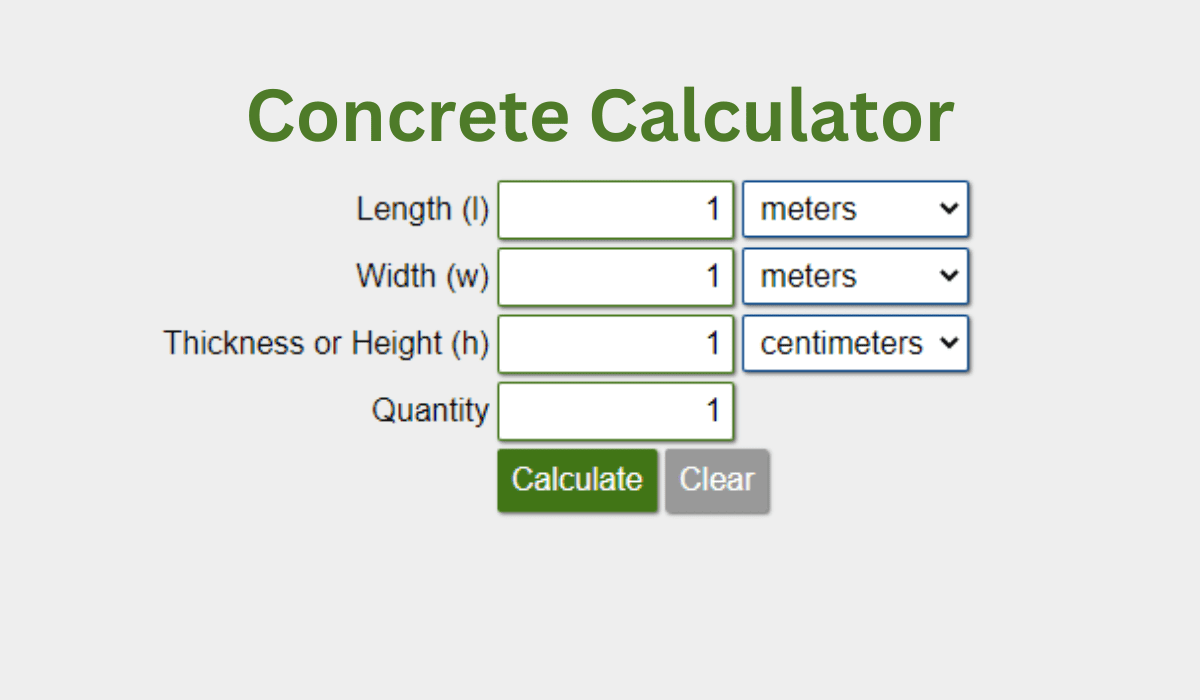

Types Of Concrete Calculators

Volume Calculators

Volume calculators for concrete are designed to calculate the cubic yards or cubic meters of concrete required for a project. These calculators make it easy to determine the amount of concrete needed based on the dimensions of the area to be filled. By inputting the length, width, and depth of the area, the calculator provides an accurate measurement for ordering the right amount of concrete. This ensures there is neither excess nor shortage of concrete for the project.

Weight Calculators

Weight calculators for concrete are essential for estimating the weight of concrete, especially when dealing with large quantities. These calculators are useful for determining the total weight of concrete needed, which is important for transportation and load-bearing considerations. By inputting the density and volume of the concrete, these calculators provide an accurate weight measurement, assisting in planning and execution of construction projects.

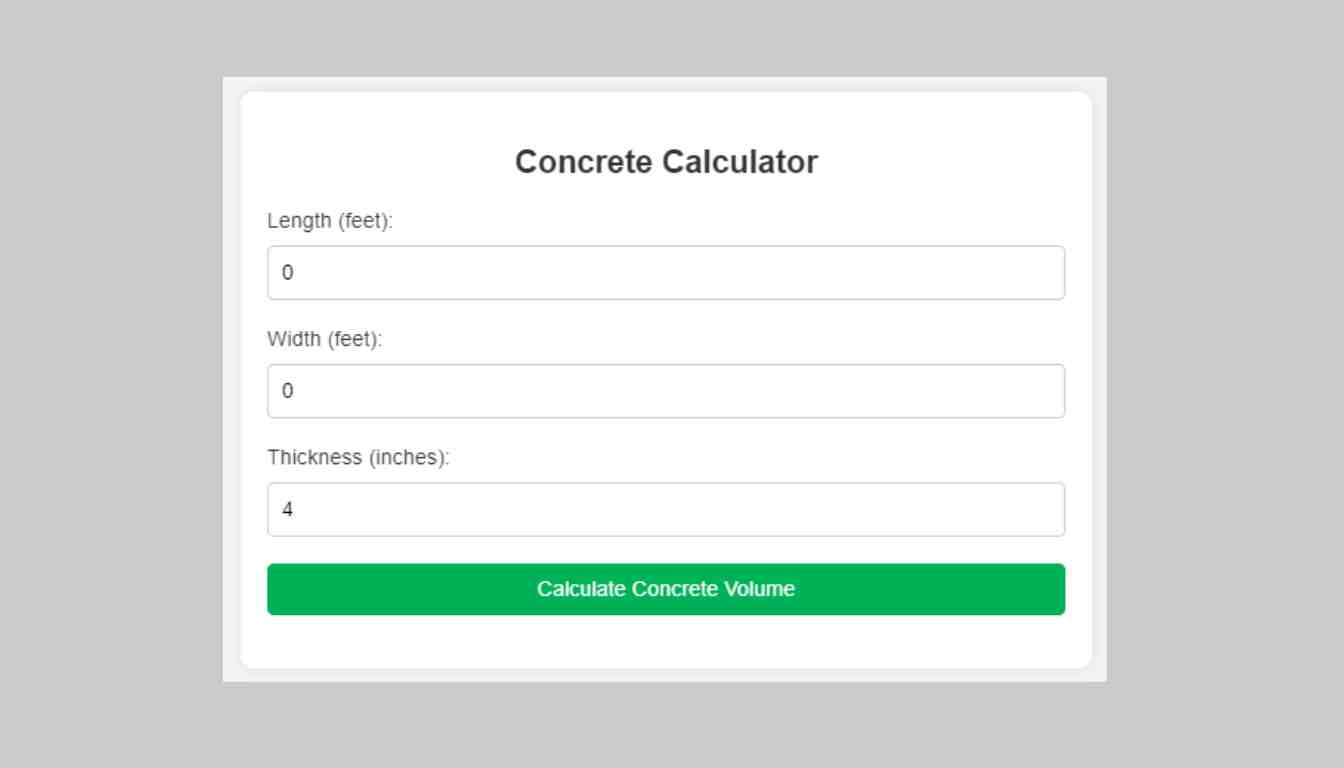

Key Input Parameters

When calculating the amount of concrete needed for a project, certain key input parameters play a crucial role. These parameters include the length, width, and depth of the concrete required, as well as the specific gravity of the concrete mix.

Length

The length of the area where the concrete will be poured must be accurately measured in feet before using the concrete calculator tool to ensure precise calculations.

Width

Similarly, the width of the area where the concrete will be placed also needs to be measured accurately in feet for accurate calculations.

Depth Of Concrete Required

Measuring the required depth of the concrete is crucial for determining the total amount of concrete needed. The depth is typically measured in inches or feet depending on the project requirements.

Specific Gravity Of Concrete Mix

The specific gravity of the concrete mix refers to the ratio of the density of the concrete mix to the density of water. This parameter helps in determining the weight of the concrete, which is essential for various construction and engineering aspects. It is an important factor in the calculation process.

Factors Affecting Concrete Calculations

Ensuring accurate concrete calculations is crucial when using a concrete calculator. Factors such as the type of concrete mix, dimensions, and desired strength affect the final result. Other influencing factors include the nature of the project, the location’s climate, and the presence of reinforcement.

Calculating the amount of concrete needed for a project is crucial to ensure a successful outcome. However, several factors come into play when determining the right amount of concrete to use. Understanding these factors will help you accurately estimate the quantity of concrete required for your project. In this section, we will explore two important factors that affect concrete calculations: Aggregate Size and Shape and Water-Cement Ratio.

Aggregate Size And Shape

The size and shape of aggregates used in concrete have a significant impact on the overall strength and workability of the mixture. Aggregates are the inert materials, such as sand, gravel, or crushed stone, that make up the bulk of concrete. The following points highlight the importance of aggregate size and shape:

1. Size Matters: The size of aggregates can vary from fine sand particles to large rocks. Using the right aggregate size is crucial for achieving maximum strength and durability in concrete. Generally, larger aggregates result in greater strength, but finer aggregates enhance workability.

2. Shape Influence: The shape of aggregates also affects the workability of concrete. Angular and rough aggregates lock together better, resulting in improved strength. On the other hand, rounded or smooth aggregates tend to reduce the strength of the concrete mix.

3. Proportions and Void Content: The proportion of different aggregate sizes in the mix impacts the void content. An appropriate balance of coarse and fine aggregates is essential to reduce voids and achieve optimal concrete density.

Water-cement Ratio

The water-cement ratio is another critical factor that significantly influences the strength and durability of concrete. It refers to the amount of water needed to provide adequate hydration to the cement. Here’s why the water-cement ratio is important:

1. Strength and Workability: The water-cement ratio directly affects both the compressive strength and workability of concrete. A lower ratio (less water) results in higher strength but may reduce workability, requiring additional effort during placement. Conversely, a higher ratio (more water) improves workability but can lead to weakened concrete.

2. Durability and Shrinkage: The water-cement ratio plays a vital role in determining the durability of the concrete. Excess water in the mixture can result in increased shrinkage and cracking over time, compromising the structure’s longevity.

3. Consistency Control: Maintaining consistency in the water-cement ratio is crucial for producing uniform concrete throughout the project. As weather conditions and other factors can affect the moisture content in aggregates, it is essential to adjust the ratio accordingly to maintain the desired consistency.

Understanding the relationship between aggregate size and shape, as well as the water-cement ratio, is key to accurate concrete calculations. By considering these factors, you can ensure the right amount of concrete is used, resulting in a successful and durable project. So, before you begin your next concrete construction venture, make sure to take these factors into account in order to optimize and streamline your calculations.

Benefits Of Using A Concrete Calculator

A concrete calculator simplifies project planning by accurately estimating the required concrete volume, ensuring cost-effectiveness and minimizing material wastage. By inputting measurements and specifics, you can swiftly determine the exact amount of concrete needed for diverse applications, such as slabs, columns, or footings, streamlining the construction process and minimizing errors.

Minimizes Waste

Using a Concrete Calculator minimizes the waste of materials and accurately estimates the amount needed for your project.

Optimizes Material Costs

This tool helps optimize material costs by ensuring you only purchase the exact amount required, saving you money.

Concrete Calculators simplify the process and increase efficiency by providing precise measurements.

Avoid overordering and excessive spending by using a Concrete Calculator for your projects.

Plan your project effectively by knowing the exact amount of materials needed.

Streamline your construction process by using a Concrete Calculator for accurate measurements.

Ensure optimal utilization of resources with the help of a Concrete Calculator.

A Concrete Calculator reduces the risk of running out of materials or having excess leftover.

Enhance your construction activities by making informed decisions based on accurate calculations.

Maximize your project efficiency by utilizing a Concrete Calculator for precise estimates.

Tips For Accurate Calculations

When using a concrete calculator, accurate measurements are crucial for a successful project. Here are some essential tips to ensure precision and efficiency:

Double-check Inputs

Always verify your measurements before entering them into the concrete calculator. A simple mistake could lead to costly errors in the final estimate. Take your time to double-check and ensure the accuracy of the inputs.

Use Calculators From Reputable Sources

Opt for calculators from trusted and reliable sources to guarantee accurate results. Avoid using unknown or questionable tools that may provide inaccurate or misleading calculations.

Best Practices For Concrete Mixing

Mixing concrete correctly is a crucial step in any construction or DIY project. To ensure the best results, it’s important to follow industry-approved methods and techniques. In this article, we’ll discuss two key aspects of concrete mixing: uniform mixing techniques and proper curing methods.

Uniform Mixing Techniques

When it comes to achieving a consistent and durable concrete mix, applying uniform mixing techniques is essential. Here are a few best practices to follow:

- 1. Measure ingredients accurately: Before starting the mixing process, it’s crucial to measure the ingredients accurately. This step helps maintain the correct ratios required for a strong and durable concrete mix.

- 2. Use a concrete calculator: To ensure precise measurements, use a reliable concrete calculator. It helps you calculate the amount of cement, aggregates, and water needed for the desired concrete strength.

- 3. Combine dry ingredients first: Start by combining the dry ingredients, including cement and aggregates, thoroughly. This initial mixing helps distribute the cement evenly throughout the mixture, which ultimately contributes to the concrete’s strength and durability.

- 4. Gradually add water: Slowly add the calculated amount of water while continuously mixing the concrete. Avoid adding too much water, as it can weaken the mixture and negatively affect the final strength of the concrete.

- 5. Mix thoroughly: Use a concrete mixer or a sturdy wheelbarrow and mix the ingredients thoroughly. Make sure to scrape the sides and bottom of the mixer or wheelbarrow to ensure all the materials are properly blended.

- 6. Avoid overmixing: While it is essential to mix the concrete thoroughly, overmixing can lead to the formation of air pockets. These air pockets can weaken the concrete, so it’s important to avoid excessive mixing.

Proper Curing Methods

Proper curing is another crucial aspect of achieving strong and durable concrete. Here are some recommended curing methods:

- 1. Moisture retention: After the concrete is placed, it’s essential to retain moisture. This can be achieved by covering the concrete with a plastic sheet or using a curing compound. Moisture retention allows the concrete to properly hydrate, leading to increased strength.

- 2. Adequate curing time: Concrete requires sufficient time to fully cure and achieve its optimal strength. It is recommended to cure concrete for at least seven days under favorable curing conditions. However, the curing time may vary depending on the specific project requirements and environmental factors.

- 3. Avoid premature drying: Protect the freshly poured concrete from drying out too quickly, as this can weaken the final structure. Preventing premature drying can be done by using plastic sheeting, misting the concrete surface with water, or utilizing specialized curing blankets.

- 4. Temperature control: Extreme temperatures can impact the curing process and the final strength of the concrete. Whenever possible, maintain a moderate temperature by avoiding exposure to direct sunlight or extreme cold.

- 5. Regular inspection: Throughout the curing process, it’s essential to inspect the concrete regularly for any signs of cracks, shrinkage, or other issues. Early detection allows for timely intervention and remediation if required.

By adhering to these best practices for concrete mixing and curing, you can ensure the longevity and durability of your construction projects. Remember, consistent and proper mixing techniques, combined with appropriate curing methods, are key factors in achieving high-quality concrete.

Credit: housing.com

Frequently Asked Questions Of Concrete Calculator

What Is A Concrete Calculator Used For?

A concrete calculator helps estimate the amount of concrete needed for a project, ensuring accurate budgeting and planning.

How To Use A Concrete Calculator Effectively?

Input dimensions like length, width, and thickness to calculate concrete volume needed, considering factors like wastage and reinforcement.

Why Is Calculating Concrete Essential For Construction?

Accurate concrete calculation prevents wastage, controls costs, ensures structural integrity, and simplifies project management.

Conclusion

The concrete calculator is an invaluable tool for anyone involved in construction or DIY projects. Its ability to accurately determine the quantity of concrete needed saves time and money, while also reducing waste. By utilizing this user-friendly tool, you can ensure the success and cost-effectiveness of your project.

Don’t overlook the benefits of the concrete calculator – it’s a must-have resource for every builder.