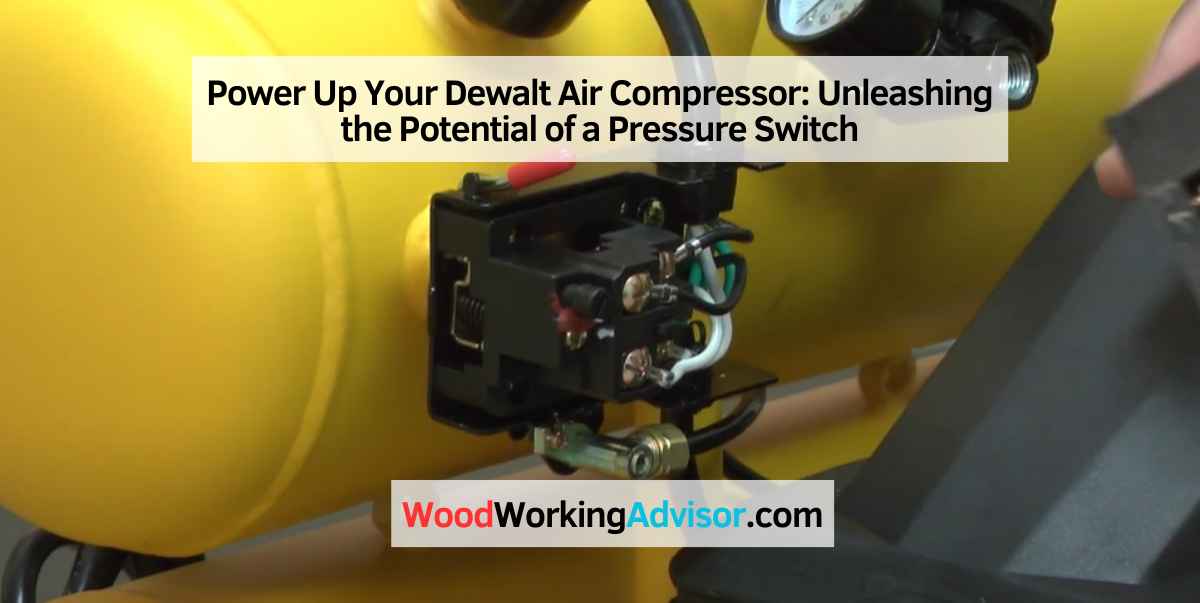

The pressure switch for a Dewalt air compressor regulates air pressure and allows the compressor to turn on and off as needed. It is a crucial component for maintaining optimal performance and preventing damage.

When it comes to operating your Dewalt air compressor efficiently, ensuring the pressure switch is functioning properly is key. This small but essential part plays a significant role in controlling the air pressure levels, safeguarding the compressor from overloading, and extending its lifespan.

Regularly checking and maintaining the pressure switch will help you avoid costly repairs and downtime while ensuring that your air compressor operates smoothly for years to come. Let’s explore the importance of the pressure switch for a Dewalt air compressor and how you can ensure it remains in top condition.

Understanding The Pressure Switch

A pressure switch for a DeWalt air compressor is a critical component that helps regulate the air pressure within the compressor system. It plays a crucial role in ensuring the compressor operates efficiently and safely.

Function Of A Pressure Switch

- Regulates Pressure: Controls the pressure levels in the air compressor.

- Turns On and Off: Activates the compressor when the pressure is low and shuts it off when the desired pressure is reached.

- Protects the Compressor: Prevents the compressor from over pressurizing, which can lead to malfunctions or safety hazards.

Signs Of A Faulty Pressure Switch

- Inconsistent Pressure: Fluctuations in pressure levels during operation.

- Compressor Not Turning On/Off: Fails to start or stop as intended.

- Air Leaks: Noticeable leaks around the pressure switch area.

Choosing The Right Pressure Switch

Choosing the right pressure switch for your Dewalt air compressor is crucial to ensure optimal performance and longevity. A pressure switch acts as a control mechanism that automatically stops the compressor when the desired air pressure level is reached and starts it again when the pressure drops. Here’s what you need to know about selecting the right pressure switch for your Dewalt air compressor.

Compatibility With Dewalt Air Compressor

When choosing a pressure switch for your Dewalt air compressor, ensure that it is specifically designed to be compatible with your model. Check the manufacturer’s recommendations to avoid any potential issues.

Key Features To Consider

- Pressure Rating: Opt for a pressure switch that has adequate pressure rating to meet the requirements of your Dewalt air compressor.

- Adjustability: Look for a switch that offers adjustable pressure settings for flexibility in operation.

- Durability: Choose a pressure switch made of high-quality materials to ensure longevity.

- Electrical Rating: Confirm that the switch meets the necessary electrical requirements for your Dewalt air compressor.

Installation And Calibration

The installation and calibration of the pressure switch are crucial steps to ensure the proper functioning of a Dewalt air compressor. Proper installation ensures the safety and efficiency of the compressor, while accurate calibration helps maintain the desired pressure levels for various applications.

Step-by-step Installation Guide

Follow these steps for a seamless installation of the pressure switch for your Dewalt air compressor:

- Turn off the power supply to the air compressor to ensure safety during the installation process.

- Locate the existing pressure switch and carefully disconnect the electrical wires connected to it.

- Using the appropriate tools, remove the old pressure switch from the compressor’s housing.

- Mount the new pressure switch in place and reconnect the electrical wires following the manufacturer’s wiring diagram.

- Double-check all connections and ensure the switch is securely attached before restoring power to the compressor.

Calibrating The Pressure Switch

Proper calibration is essential to maintain the desired pressure levels for your air compressor. Here’s how to calibrate the pressure switch:

- Use a pressure gauge to measure the current pressure in the air compressor tank.

- Adjust the pressure switch settings according to the specific PSI requirements for your application.

- Turn the adjustment screw clockwise to increase the cut-in pressure or counterclockwise to decrease it.

- Monitor the pressure gauge as you make adjustments and stop when the desired pressure level is reached.

- Verify the pressure switch’s functionality by observing the compressor’s operation at the set pressure levels.

Maximizing Performance

One of the crucial components of a Dewalt air compressor is the pressure switch. It plays a vital role in ensuring that the compressor operates at optimum performance levels. By understanding how to maximize the performance of your pressure switch, you can enhance the overall efficiency and longevity of your Dewalt air compressor.

Optimizing Air Pressure Settings

Properly setting your air pressure is essential for the effective operation of your Dewalt air compressor. By optimizing the air pressure settings, you can achieve better performance and avoid unnecessary strain on the compressor components.

To optimize your air pressure settings, follow these steps:

- Refer to the user manual of your Dewalt air compressor to understand the recommended air pressure range.

- Use a reliable pressure gauge to measure the current air pressure in the tank.

- Adjust the pressure switch settings based on the desired pressure range mentioned in the manual.

- Ensure that the pressure relief valve is functioning correctly to prevent over-pressurization.

By following these steps, you can optimize your air pressure settings and ensure that your Dewalt air compressor operates at its maximum potential.

Maintenance Tips For Prolonged Durability

To maximize the performance and prolong the durability of your Dewalt air compressor, regular maintenance is crucial. Here are some maintenance tips to keep in mind:

- Regularly inspect and clean the pressure switch to prevent dust and debris buildup.

- Check the switch contacts for any signs of wear or damage and replace them if necessary.

- Inspect the electrical connections and wiring to ensure they are secure and free from corrosion.

- Regularly check and replace the air filter to prevent clogs and ensure proper airflow.

- Inspect the tank for any signs of corrosion or leaks and address them promptly.

By following these maintenance tips, you can prolong the durability of your Dewalt air compressor and ensure its optimal performance for years to come.

Frequently Asked Questions On Pressure Switch For Dewalt Air Compressor

What Is A Pressure Switch For Dewalt Air Compressor?

A pressure switch for Dewalt air compressor is a device that automatically controls when the compressor starts and stops based on the set pressure levels. It ensures the compressor operates within safe pressure limits and prevents damage or accidents.

How Does A Pressure Switch Work In A Dewalt Air Compressor?

A pressure switch in a Dewalt air compressor works by monitoring the air pressure inside the tank. When the pressure drops below a certain level, the switch activates the compressor to pump air into the tank. Once the pressure reaches the desired level, the switch shuts off the compressor.

Why Is The Pressure Switch In My Dewalt Air Compressor Not Working?

The pressure switch in your Dewalt air compressor may not be working if you notice issues like the compressor not turning on or off at the appropriate pressure range. This could be due to a faulty switch, electrical issues, or a problem with the pressure adjustment mechanism.

It’s best to consult a professional for troubleshooting and repair.

How To Adjust The Pressure Switch On A Dewalt Air Compressor?

To adjust the pressure switch on a Dewalt air compressor, you can follow these steps:

1. Disconnect the power supply.

2. Locate the pressure switch and find the adjustment screw.

3. Use a screwdriver to turn the adjustment screw clockwise to increase the pressure or counterclockwise to decrease it.

4. Ensure the desired pressure setting is within the recommended range for your compressor model.

5. Reconnect the power supply and test the compressor.

Conclusion

Choosing the right pressure switch for your Dewalt air compressor is crucial for optimal performance. By understanding the specific requirements of your compressor, you can make an informed decision. Whether it’s for industrial or personal use, finding the right pressure switch is essential for efficiency and longevity.