Yes, a miter saw can cut metal efficiently and accurately, making it a versatile tool for various applications. A miter saw is a powerful tool that is commonly used for cutting wood at precise angles.

However, it is also equipped to handle metal cutting tasks effectively. The ability to cut metal with a miter saw is attributed to the use of the appropriate blade and the saw’s high-speed spinning motion, which allows for clean and precise cuts.

Whether it’s aluminum, steel, or stainless steel, the miter saw, with the right blade, can effortlessly slice through metal, making it a valuable addition to any workshop or construction site. It provides a convenient option for professionals and DIY enthusiasts who frequently work with metal, offering speed, accuracy, and ease of use, all in one tool.

Understanding Miter Saws And Their Capabilities

A miter saw is an indispensable tool commonly used in woodworking and construction projects. With its ability to make angled cuts with precision, it offers versatility and efficiency. But what about cutting metal? Can a miter saw handle the challenge? In this section, we will delve into the world of miter saws, exploring what they are, their key features and uses, and the materials they are typically used for.

What Is A Miter Saw?

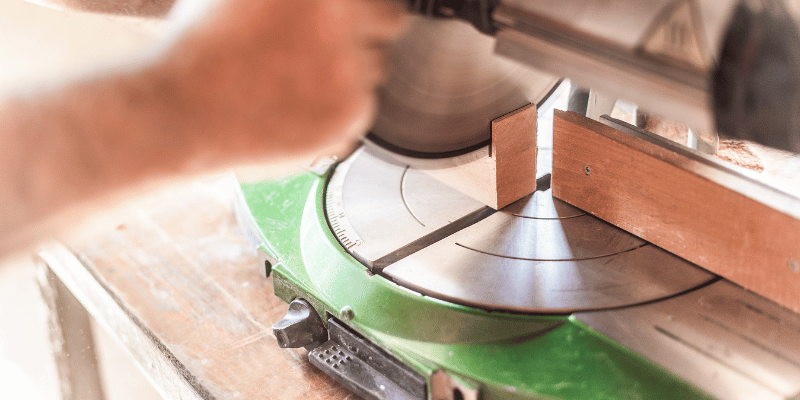

A miter saw, also known as a chop saw or a drop saw, is a specialized power tool designed to make accurate crosscuts, bevel cuts, and miter cuts. Its primary distinguishing feature is its circular blade mounted on a swing arm, which pivots to get the desired angle for cutting. This functionality allows precision and ease in creating angled cuts for various woodworking and construction tasks.

Key Features And Uses Of A Miter Saw

A miter saw comes equipped with several features that enhance its functionality and ease of use. Some of the key features include:

- Beveling Capability: A miter saw can tilt its blade to make bevel cuts, which are angled cuts made through the thickness of the material. This feature enables the tool to create compound cuts, essential for tasks like framing, molding, and trim work.

- Sliding Action: Some miter saws offer the additional feature of a slide mechanism that allows the blade to move forward and backward. This sliding action increases the cutting capacity of the tool, making it suitable for wider materials.

- Laser Guides: Many modern miter saws have laser guides that project a beam onto the working surface, providing a visual reference for aligning the cut. This feature ensures greater accuracy and precision.

- Dust Collection System: To maintain a clean and safe work environment, miter saws often include a dust collection system to capture the sawdust produced during cutting.

With their versatility and precision, miter saws have a wide range of uses in various applications:

- Trim work: Miter saws excel in creating clean, accurate miter cuts for molding, baseboards, and other decorative trims.

- Framing: Whether it’s building frames for doors, windows, or constructing roof trusses, a miter saw is an excellent tool for producing precise cutting angles.

- Furniture Making: From cutting angled joints to creating complex crosscuts for furniture pieces, miter saws are ideal for woodworking projects.

- Construction: Miter saws are indispensable in construction projects that require angled or bevel cuts, such as decking, roofing, and installation of crown molding.

Materials A Miter Saw Is Typically Used For

While miter saws excel at cutting various types of wood, their capabilities are not limited to that. They can also cut through other materials, such as:

- MDF (Medium-Density Fibreboard): Miter saws can effortlessly handle MDF, allowing for precise cuts in carpentry projects.

- Laminate: Whether for flooring or countertop installations, a miter saw can make clean, accurate cuts in laminates.

- Plastic: From PVC pipes to acrylic sheets, a miter saw can effortlessly cut through various types of plastic.

However, when it comes to cutting metal, not all miter saws are created equal. While some models may come with blades suitable for cutting through non-ferrous metals, a miter saw is generally not the first choice for cutting metal due to its limitations in terms of blade speed and power. For metal cutting purposes, specialized tools like metal chop saws or abrasive saws are typically used.

Exploring The Limitations Of iter Saws

In woodworking projects, a miter saw is an indispensable tool for making precise angled cuts. While miter saws are primarily designed for use with wood, many hobbyists and DIY enthusiasts wonder if they can be used to cut metal as well. In this section, we will explore the limitations of miter saws when it comes to cutting metal and discuss the factors that affect their ability to do so. We will also provide some safety precautions to keep in mind when using a miter saw for metal cutting.

Why Metal May Pose A Challenge For Miter Saws

Miter saws are typically equipped with a circular blade that is specifically designed for cutting wood. While this blade can make clean and precise cuts through wood, it may struggle with cutting through metal. One of the main reasons metal poses a challenge for miter saws is its hardness. Metal is much harder and more rigid than wood, which means that the blade may not be able to make effective cuts without the right modifications or accessories.

Factors That Affect A Miter Saw’s Ability To Cut Metal

Several factors come into play when determining a miter saw’s ability to cut metal. First and foremost is the type of blade being used. While a standard wood-cutting blade may work for softer metals like aluminum, it may struggle with harder metals like steel. Upgrading to a specialized metal-cutting blade can help improve the performance and efficiency of the miter saw.

Another important factor is the power and RPM (revolutions per minute) of the miter saw. Cutting through metal requires more power and higher RPM compared to cutting through wood. A miter saw with a higher horsepower motor and adjustable speed settings can provide the necessary power and speed for cutting metal.

The thickness and type of metal being cut also play a role. Thicker and harder metals will require more power and a stronger blade to make clean cuts. Additionally, certain metals like stainless steel may generate a significant amount of heat during the cutting process, which can affect the blade’s performance and lifespan.

Safety Precautions When Using A Miter Saw For Metal Cutting

Cutting metal with a miter saw can be hazardous, so it’s crucial to take the necessary safety precautions. Here are some guidelines to follow:

- Always wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and hearing protection.

- Secure the metal workpiece firmly using clamps or a vise to prevent it from shifting during the cutting process.

- Make sure the metal-cutting blade is correctly installed and tightened before starting the saw.

- Utilize a slow and steady cutting approach to prevent the blade from overheating or getting jammed.

- Allow the blade to come to a complete stop before lifting it from the workpiece or making any adjustments.

By adhering to these safety precautions, you can minimize the risk of accidents and ensure a safer metal cutting experience with your miter saw.

Enhancing A Miter Saw’s Ability To Cut Metal

While miter saws are primarily designed for woodworking tasks, with the right blade and techniques, they can also be effective in cutting metal. This opens up a whole new world of possibilities for DIY enthusiasts and professionals alike. In this section, we will discuss how to enhance a miter saw’s ability to cut metal through careful consideration of blade selection, implementing specific techniques for improved performance, and utilizing accessories that can further enhance metal cutting capabilities.

Blade Selection For Cutting Metal With A Miter Saw

Choosing the right blade is crucial when it comes to cutting metal with a miter saw. Not all blades are designed to withstand the demands of metal cutting, so it is essential to select one that is specifically labeled for this purpose. These specialized blades feature a tooth geometry and hardness that allows them to cut through various metals with ease.

When selecting a blade for cutting metal, consider the type and thickness of the metal you will be working with. Thin-gauge metals require fine-tooth blades, while thicker metals may necessitate coarser-tooth blades. Carbide-tipped blades are often recommended for their durability and longer lifespan.

Furthermore, using a blade with a negative hook angle can help prevent the saw from pulling the metal as it cuts, resulting in a smoother and more controlled cutting experience. It is important to note that blades designed for cutting non-ferrous metals, like aluminum or brass, differ from those intended for cutting ferrous metals like steel or iron.

Techniques For Improving Metal Cutting Performance

While the right blade is essential, employing proper cutting techniques can greatly enhance a miter saw’s metal cutting performance.

- Secure the workpiece: When cutting metal, it is crucial to securely fasten the workpiece to prevent movement during the cut. This can be achieved using clamps or a vice to ensure stability.

- Appropriate cutting speed: Unlike woodworking, slower cutting speeds are usually recommended for metal cutting. This allows the blade to maintain control and reduces the risk of overheating or blade damage.

- Minimize blade deflection: High tooth counts and slower cutting speeds are effective in minimizing blade deflection, which can be a common issue when cutting metal. This helps to ensure accuracy and a clean cut.

- Use a lubricant: Applying a lubricant such as cutting oil or wax to the blade and the workpiece can reduce friction, heat buildup, and prolong the lifespan of the blade. It also helps achieve smoother cuts.

Accessories That Can Enhance A Miter Saw’s Metal Cutting Capabilities

There are several accessories available that can further enhance a miter saw’s ability to cut metal effectively.

| Accessory | Description |

|---|---|

| Metal Cutting Blade Stabilizers | These stabilizers can be attached to the miter saw’s blade, reducing vibrations and increasing stability during the metal cutting process. |

| Blade Coolant Systems | These systems provide a continuous flow of coolant to the blade, keeping it cool and reducing the risk of overheating. |

| Workpiece Holders | These accessories securely hold the metal workpiece and provide additional support, minimizing the chances of movement and increasing safety. |

By utilizing these accessories, you can optimize your miter saw’s metal cutting capabilities, improving both performance and safety.

Alternatives To Miter Saws For Metal Cutting

While miter saws are commonly used for cutting wood, they may not always be the best tool for cutting metal. Fortunately, there are several alternative tools available that are specifically designed to cut through metal with ease. In this section, we will explore some of these alternatives and discuss their pros and cons.

Introduction To Other Tools Suitable For Cutting Metal

When it comes to cutting metal, there are several tools that are better suited for the job than a miter saw. These alternatives include:

- Angle Grinder: An angle grinder is a versatile tool that can be used for various tasks, including cutting metal. It is equipped with a spinning disc that can easily slice through metal sheets, pipes, and bars. This tool offers excellent maneuverability and is ideal for cutting curves or intricate shapes.

- Metal Shears: Metal shears are designed specifically for cutting metal sheets and are available in both manual and electric versions. They feature sharp blades that can make straight or curved cuts in metal with precision.

- Plasma Cutter: A plasma cutter utilizes an electrically conductive gas to create a high-temperature plasma arc that can cut through metal like a hot knife through butter. This tool is perfect for cutting thick metal plates and is commonly used in industrial applications.

- Nibbler: A nibbler is a handheld tool that uses a punch and die mechanism to cut through metal. It is particularly useful for making intricate cuts and can easily handle tight curves and corners.

Pros And Cons Of Using Alternative Tools

When considering alternatives to miter saws for metal cutting, it is essential to understand the pros and cons of each tool:

| Tool | Pros | Cons |

|---|---|---|

| Angle Grinder |

|

|

| Metal Shears |

|

|

| Plasma Cutter |

|

|

| Nibbler |

|

|

Considerations When Choosing Between A Miter Saw And Alternative Tools For Metal Cutting

When choosing between a miter saw and alternative tools for cutting metal, several factors should be considered:

- Material Thickness: If you primarily work with thin metal sheets, a miter saw may suffice. However, for thicker materials, it is recommended to opt for alternative tools like plasma cutters or metal shears.

- Precision Requirements: Different metal cutting tools offer varying levels of precision. If you need to make intricate cuts with tight tolerances, a nibbler or metal shears may be the better choice.

- Portability: Miter saws are generally more portable and easier to transport compared to larger tools like plasma cutters. Consider the portability aspect if you frequently work on-site or have limited space.

- Budget: Depending on your budget, some tools may be more affordable or cost-effective than others.

By considering these factors, you can make an informed decision on whether to use a miter saw or opt for one of the alternative tools for cutting metal that better suits your specific needs.

Tips For Efficient And Effective Metal Cutting With A Miter Saw

Efficient and effective metal cutting with a miter saw is possible with these helpful tips. Discover how to properly use a miter saw for cutting metal and achieve accurate results.

Best Practices For Achieving Clean And Precise Metal Cuts

When it comes to cutting metal with a miter saw, following the right techniques and best practices can make all the difference in achieving clean and precise cuts. Whether you’re a seasoned DIY enthusiast or a professional carpenter, these tips will help you maximize the efficiency and accuracy of your metal cutting projects:

- Choose the right blade: The type of blade you use plays a crucial role in the quality of your metal cuts. Opt for a high-quality, carbide-tipped blade specifically designed for cutting metal. Ensure the blade has a fine-tooth configuration with at least 80 teeth for optimal performance.

- Secure your workpiece: Before making any cuts, make sure your workpiece is securely clamped or held in place. Metal can be stubborn and prone to movement, so using a sturdy vise or clamp will provide stability and prevent any unwanted shifting during the cutting process.

- Mark your cut line: Taking the time to mark a clear and precise cut line on your metal workpiece will guide your sawing motions and ensure accuracy. Use a metal marker or scribe to create a visible line that won’t easily rub off during the cutting process.

- Slow and steady: Metal cutting requires a different approach compared to cutting wood. To prevent blade damage and achieve cleaner cuts, it’s important to take your time and maintain a slow, steady cutting pace. Avoid pushing the saw too forcefully or rushing through the cutting process.

- Apply appropriate pressure: Applying too much or too little pressure while cutting metal can negatively impact the quality of the cuts. Find the right balance by allowing the blade to do the work and applying gentle, consistent pressure throughout the cut. Let the blade’s teeth bite into the metal gradually.

- Use lubrication: Lubricating the blade and workpiece can significantly improve the cutting process. Applying a cutting fluid or lubricant directly to the blade reduces friction and heat, preventing blade dulling and helping you achieve smoother and cleaner cuts.

Maintenance Tips For Prolonging The Lifespan Of Your Miter Saw Blade

Maintaining your miter saw blade properly is essential for both its longevity and its cutting performance. By following these maintenance tips, you can ensure that your blade stays sharp and effective for as long as possible:

- Keep the blade clean: After each use, clean off any debris and metal shavings that may have accumulated on the blade. Use a stiff brush to remove any residue and prevent it from dulling the blade prematurely.

- Inspect for damage: Regularly inspect your miter saw blade for any signs of wear, damage, or dullness. Look for missing or chipped teeth, warping, or excessive wear. Replace any damaged blades promptly to prevent compromised cutting performance and potential safety hazards.

- Sharpen or replace as needed: If you notice reduced cutting performance or dullness, sharpening the blade can restore its effectiveness. However, sharpening should be done by a professional to ensure proper blade alignment. Additionally, if your blade is nearing the end of its lifespan, it’s best to replace it with a new one.

- Store properly: When not in use, store your miter saw and blade in a clean, dry area away from moisture and excessive heat. Proper storage prevents corrosion and damage to the blade, extending its lifespan.

Troubleshooting Common Issues When Cutting Metal With A Miter Saw

While a miter saw is a versatile tool for cutting various materials, including metal, it’s not uncommon to encounter some challenges along the way. Here are a few common issues and troubleshooting tips to help you overcome them:

- Poor cutting performance: If you’re experiencing poor cutting performance, the first step is to check the blade’s sharpness and condition. Dull or damaged blades can affect cutting efficiency. If the blade is in good condition, ensure that you’re using the appropriate cutting speed and technique for the specific metal you’re working with.

- Blade binding or getting stuck: If the blade binds or gets stuck during the cutting process, make sure that the workpiece is properly secured and clamped. Additionally, check for any irregularities or deformities in the metal that may cause the blade to bind. Lubricating the blade and workpiece can also alleviate binding issues.

- Excessive heat or burning: If you notice excessive heat or burning during the cutting process, it may be an indication of a dull blade or inappropriate cutting speed. Check the blade’s sharpness and replace if necessary. Adjusting the cutting speed and using cooling lubricants can also help dissipate heat and reduce burning.

By implementing these tips and troubleshooting techniques, you can enhance your metal cutting experience with a miter saw and achieve the desired precision and efficiency. Remember to prioritize safety, maintain your equipment, and continually improve your cutting skills for optimal results.

Frequently Asked Questions For Can A Miter Saw Cut Metal

Can A Miter Saw Cut Metal?

Yes, a miter saw can cut metal with the right blade. However, it’s important to use a blade specifically designed for cutting metal, such as a carbide-tipped blade. The cutting capacity of the miter saw will depend on the blade, so make sure to check the manufacturer’s recommendations before attempting to cut metal.

Always wear appropriate safety gear and take necessary precautions when working with metal.

Conclusion

A miter saw can indeed cut metal with the right blade and technique. While it may not be its primary purpose, this versatile tool can be a valuable addition to any DIYer or professional’s arsenal. By following safety precautions and using the appropriate saw blade, you can achieve clean and accurate cuts on various metal materials.

So, don’t hesitate to explore the possibilities of your miter saw beyond woodworking projects.