Yes, a miter saw can indeed cut metal, but it requires the use of a specialized cutting blade. A miter saw is a versatile power tool commonly used by carpenters and DIY enthusiasts for making precise angled cuts in various materials.

While primarily designed for cutting wood, many people wonder if a miter saw can be used to cut metal as well. The answer is yes, but with a few important considerations. In order to cut metal effectively and safely, it is necessary to use a specific type of cutting blade designed for metal applications.

These blades are constructed with durable materials and teeth specifically designed to handle the toughness and hardness of different metals. So, if you’re considering using a miter saw to cut metal, let’s delve deeper into the process and everything you need to know to ensure successful and accurate cuts.

Understanding The Basics Of A Miter Saw

When it comes to cutting angles in wood, a miter saw is an essential tool for any woodworking enthusiast or professional. With its ability to create precise and accurate cuts at various angles, this versatile power tool can elevate your woodworking projects to the next level.

How Does A Miter Saw Work?

A miter saw operates on a simple yet efficient mechanism that allows it to make angled cuts in wood effortlessly. The basic principle behind a miter saw is the ability to pivot the saw blade on its axis, enabling it to move horizontally and vertically. By adjusting the angle and the height of the blade, you can achieve angled cuts that are essential for creating precise joints and corners in woodworking.

The blade of a miter saw is mounted on a rotating arm, known as the miter arm, which is attached to a base. This base, also known as the fence, provides support and stability to the workpiece during cutting.

Key Components Of A Miter Saw

A miter saw consists of several key components that work together to ensure accurate and efficient cuts. These components include:

- Blade: The blade is the cutting tool of the miter saw. It is typically made of carbide-tipped steel, which ensures durability and precision.

- Miter Arm: The miter arm allows the blade to pivot horizontally, enabling the saw to make angled cuts.

- Fence: The fence is the base of the miter saw that provides stability and support to the workpiece during cutting.

- Miter Gauge: The miter gauge is a guide that helps you achieve precise and accurate angled cuts by allowing you to adjust the angle of the blade.

- Bevel Adjustment: Many miter saws also have a bevel adjustment feature that allows the blade to tilt vertically. This feature is particularly useful for making compound cuts or creating beveled edges.

What Materials Can A Miter Saw Cut?

While miter saws are primarily designed for cutting wood, they can also handle other materials, expanding their versatility and functionality. Some of the materials that a miter saw can cut include:

- Wood and Plywood: Miter saws excel at cutting through different types of wood, including softwood and hardwood, as well as plywood.

- Plastic and PVC: Miter saws can make clean and precise cuts in plastic materials and PVC pipes, making them suitable for various DIY projects.

- Aluminum: With the right blade and proper technique, a miter saw can effectively cut through aluminum extrusions and sheets.

It’s important to note that when using a miter saw to cut materials other than wood, you should use specialized blades designed for that specific material. This ensures optimal performance and safety.

In conclusion, understanding the basics of a miter saw is crucial before engaging in any woodworking or DIY projects. By grasping its workings and key components, you can confidently make precise cuts and create professional-looking finishes. Whether you’re a woodworking enthusiast or a professional carpenter, a miter saw is an indispensable tool in your workshop.

Credit: www.protoolreviews.com

Exploring The Limitations Of A Miter Saw

Miter saws are highly versatile power tools that are commonly used for making precise crosscuts and miter cuts in various materials such as wood, plastic, and metal. However, while a miter saw can easily handle wood and plastic, cutting metal with this tool can be a bit more challenging. In this article, we will delve into the limitations of a miter saw when it comes to cutting metal and discuss the important factors to consider for a successful metal cutting experience.

Overview Of The Standard Blade Types For Miter Saws

Understanding the different blade types available for miter saws is crucial when it comes to cutting metal effectively. While most standard miter saws come with blades specifically designed for cutting wood and other non-metal materials, there are specialized metal cutting blades that can be used as well. These blades are typically made from strong and durable materials such as carbide-tipped or high-speed steel, specifically formulated to withstand the rigors of cutting metal. They feature teeth with a different tooth count and tooth shape, allowing for more efficient cutting across metal surfaces.

When choosing a blade for metal cutting, it is important to consider factors such as the type of metal you will be cutting, the thickness of the material, and the desired cut quality. Always refer to the miter saw manufacturer’s guidelines and consult with experts or professional metalworkers for advice on selecting the right blade for your specific metal cutting needs.

Understanding The Risks And Safety Precautions

Cutting metal with a miter saw can pose certain risks and hazards. The high-speed rotation of the blade combined with the hardness of metal can lead to flying debris, sparks, and potential injury if not approached with caution. Therefore, it is essential to follow proper safety precautions to minimize any potential risks.

Some important safety measures to consider when cutting metal with a miter saw may include:

- Wearing appropriate personal protective equipment (PPE) such as safety goggles, gloves, and hearing protection.

- Ensuring the workpiece is securely clamped or held in place to prevent it from moving during cutting.

- Using a metal cutting lubricant or coolant to reduce heat and friction, ensuring smoother cutting and prolonging blade life.

- Being mindful of the blade’s position, ensuring proper clearance between the blade and the material to prevent binding or kickback.

The Importance Of Choosing The Right Blade For Metal Cutting

Choosing the right blade for metal cutting with a miter saw is crucial for achieving clean and precise cuts while prolonging the lifespan of the blade. Without the appropriate blade, you may experience increased blade wear, slower cutting speeds, and overall poor cutting performance.

Factors to consider when selecting the right blade for metal cutting include:

- The type of metal you will be cutting (steel, aluminum, etc.)

- The thickness of the material

- The desired cut quality (smooth, rough, etc.)

- The tooth count and shape of the blade

- The durability and strength of the blade material

By understanding these factors and choosing the appropriate blade accordingly, you can optimize the cutting process and ensure accurate and efficient metal cuts using your miter saw.

Unlocking The Ultimate Cutting Power: Tips And Tricks

When it comes to cutting metal, a miter saw might not be the first tool that comes to mind. However, with the right set of techniques and a bit of knowledge, you can unlock the ultimate cutting power of your miter saw and achieve precision cuts in various types of metal. In this guide, we’ll explore some valuable tips and tricks to help you get the most out of your miter saw when cutting metal.

Ensuring The Right Blade Speed And Tooth Count For Metal Cutting

Choosing the correct blade speed and tooth count is crucial for successful metal cutting with a miter saw. Since metal is a much tougher material than wood, using the wrong speed or tooth count may result in damaged blades or unsatisfactory cuts. Here’s what you need to keep in mind:

- Speed: Make sure your miter saw is equipped with a blade designed for metal cutting. These blades typically have a lower rotation speed than those for wood cutting, allowing them to handle the toughness of metal. Refer to the manufacturer’s guidelines or consult a professional to determine the ideal speed for your specific miter saw model.

- Tooth Count: Metal cutting blades have a higher tooth count compared to wood cutting blades. This is because more teeth equate to smoother, cleaner cuts in metal. Look for a blade with a tooth count around 60 to ensure efficient cutting and reduce the chances of blade dullness.

Using Lubricants And Cooling Techniques To Enhance Cutting Efficiency

When it comes to cutting metal with a miter saw, heat and friction can be your biggest enemies. The good news is that you can overcome this challenge by implementing lubrication and cooling techniques. Here are a few methods to consider:

- Lubricant: Applying a lubricant to the blade can help reduce friction and minimize heat build-up during the cutting process. A common lubricant choice is cutting oil or even a simple lubricant spray. Ensure you apply the lubricant to both sides of the blade before starting the cut.

- Coolant Systems: Some miter saws come with built-in coolant systems that spray a cooling substance onto the blade while cutting. If your miter saw doesn’t have this feature, you can manually spray a coolant onto the blade or use a cooling block, such as a damp sponge, to keep the blade temperature in check.

How To Secure The Metal And Achieve Precise Cuts

Securing the metal during cutting is vital for achieving accurate and precise cuts. Without proper clamping or support, the metal can vibrate or move, leading to uneven cuts or even accidents. Follow these steps to securely hold your metal in place:

- Clamping: Use clamps or a vice to firmly secure the metal piece to the miter saw’s work surface. This will ensure stability and minimize any unwanted movement during the cut.

- Sacrificial Backing: For improved precision, consider using a sacrificial backing material behind the metal. This backing can be a piece of wood or any other sacrificial material, helping to prevent chipping and provide additional support.

With these tips and tricks, you can efficiently cut metal with your miter saw and achieve clean, precise results. Remember to always prioritize safety and consult the manufacturer’s guidelines for your specific miter saw model.

Pros And Cons Of Using A Miter Saw For Metal Cutting

Miter saws are commonly used for precision cutting in woodworking projects, but can they be used for metal cutting as well? In this article, we will explore the pros and cons of using a miter saw for metal cutting, helping you decide whether it’s the right tool for your metalworking needs.

Advantages Of Using A Miter Saw For Metal Cuts

Using a miter saw for metal cutting offers several advantages that make it a viable option for certain projects. Here are some of the main benefits:

- Precision Cutting: Miter saws are designed for precise and accurate angle cuts, making them suitable for creating clean and precise cuts in metal.

- Speed and Efficiency: Miter saws are powered tools that can make quick work of metal cutting tasks, helping you save time and effort.

- Versatility: Many miter saws come with adjustable angle settings, allowing you to make beveled cuts or compound cuts in metal, expanding your creative possibilities.

- Ease of Use: Miter saws are relatively easy to operate, even for beginners. With proper safety precautions, you can quickly master the technique of using a miter saw for metal cutting.

Limitations And Drawbacks Of Using A Miter Saw For Metal

While miter saws can be handy for metal cutting in some situations, they also have certain limitations and drawbacks that you should be aware of:

- Material Compatibility: Miter saws are primarily designed for cutting wood, so their ability to cut through metal may be limited. Depending on the thickness and hardness of the metal, you may encounter difficulties or even damage the tool.

- Blade Selection: Miter saw blades designed for metal cutting are less common and may be more expensive than wood-cutting blades. It’s essential to ensure you have the correct blade for cutting metal to minimize the risk of accidents.

- Spark and Debris: Metal cutting with a miter saw can create sparks and debris. It is crucial to have proper safety measures in place, such as wearing protective goggles and working in a well-ventilated area to reduce the risk of injury.

- Limited Cutting Capacity: Miter saws have a limited cutting capacity in terms of the size and thickness of the material they can handle. If you need to cut large or thick metal pieces, a miter saw may not be the most suitable option.

Before attempting to cut metal with a miter saw, always consult the manufacturer’s guidelines and recommendations. Assess the specific project requirements, including the type and thickness of the metal, to ensure the miter saw is suitable for the task at hand. Additionally, consider alternative tools and cutting methods, such as a metal-cutting band saw or an angle grinder, for more specialized metal cutting needs.

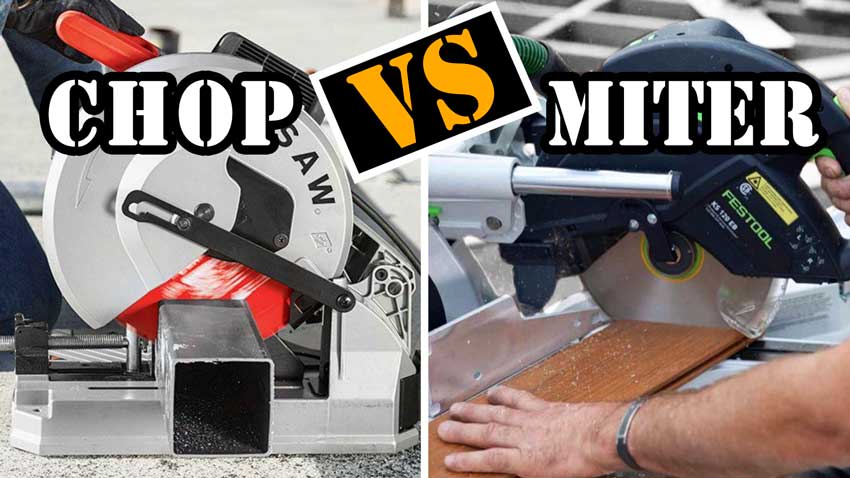

A Comparison With Other Metal Cutting Tools

When it comes to cutting metal, there are several tools available in the market. Each tool has its own advantages and limitations, offering different levels of cutting precision and versatility. Two popular tools often considered for cutting metal are the miter saw and the angle grinder. While the miter saw is primarily designed for making angled cuts in wood, it can also be used for cutting metal with the right blade. On the other hand, the angle grinder is specifically designed for metal cutting and offers powerful performance. Let’s dive into a comparison between the miter saw and the angle grinder to determine which tool is best for metal cutting.

Miter Saw Vs. Angle Grinder: Which Is Best For Metal Cutting?

Both the miter saw and the angle grinder have their own unique features that make them suitable for various cutting applications. Let’s compare these tools based on their cutting abilities and overall performance when it comes to cutting metal:

| Tool | Cutting Precision | Versatility | Power |

|---|---|---|---|

| Miter Saw | Good | Limited | Less |

| Angle Grinder | High | High | High |

As the table shows, the miter saw offers decent cutting precision but has limited versatility when it comes to cutting different types of metal. It lacks the power and speed of an angle grinder. On the other hand, the angle grinder provides high cutting precision, excellent versatility, and a powerful motor to handle various metal cutting tasks efficiently.

Miter Saw Vs. Circular Saw: Which Provides Better Cutting Precision?

While the miter saw and the circular saw share some similarities, they have distinct features that set them apart in terms of cutting precision. The circular saw is known for its ability to make straight and precise cuts in various materials, including metal. However, it requires a steady hand and a guide to achieve the desired accuracy. On the contrary, the miter saw offers better cutting precision, especially for angled cuts, thanks to its adjustable miter and bevel angles. It provides a stable cutting platform, allowing you to make accurate cuts without the need for extra support.

Additional Tips And Safety Precautions For Cutting Metal With A Miter Saw

If you decide to use a miter saw for cutting metal, here are some additional tips and safety precautions to ensure a successful and safe cutting experience:

- Always wear protective gear, including safety goggles, gloves, and a dust mask, to protect yourself from metal shards and debris.

- Choose a suitable blade for cutting metal, such as a carbide-tipped or an abrasive cutting wheel, based on the thickness and type of metal you are working with.

- Secure the metal firmly using clamps or a vise to prevent slipping or movement during the cutting process.

- Take your time and let the blade do the work. Avoid applying excessive force or rushing the cut, as it can lead to inaccuracies and potential hazards.

- Use a slow cutting speed to reduce heat buildup and prevent damage to the blade and the metal.

By following these tips and precautions, you can enhance your cutting accuracy and ensure a safer metal cutting experience with a miter saw.

Frequently Asked Questions For Can You Cut Metal With A Miter Saw

Can You Cut Metal With A Miter Saw?

Yes, you can cut metal with a miter saw. However, it’s important to use the right blade, such as a carbide-tipped blade or an abrasive blade. Additionally, you may need to slow down the cutting speed and use proper safety precautions, like wearing eye protection and clamping down the metal securely.

What Type Of Blade Should I Use To Cut Metal With A Miter Saw?

To cut metal with a miter saw, you should use a specific blade designed for cutting metal. Look for a carbide-tipped blade or an abrasive blade. These blades have the strength and durability to handle metal cutting tasks. Make sure to choose the right blade based on the thickness and type of metal you’re cutting.

Can I Cut Any Type Of Metal With A Miter Saw?

While a miter saw can cut through various types of metal, it’s important to consider the thickness and hardness of the metal. A miter saw is most suitable for cutting thin or soft metals, such as aluminum or thin sheets of steel.

For thicker or harder metals, a different type of saw or cutting tool may be more appropriate.

Conclusion

A miter saw can indeed be used to cut metal, but it requires the right blade and some safety precautions. With a metal-cutting blade and the proper technique, you can make accurate and clean cuts in metal materials. However, it’s essential to remember that miter saws are primarily designed for woodworking, so using them for metal should be approached with caution.

Always prioritize safety and consult the manufacturer’s guidelines before attempting any unconventional cuts with your miter saw. Happy cutting!