Woodworking machines come in various types, including saws, planers, and routers, each designed for specific woodworking tasks. Woodworking is a craft that requires skill, precision, and the right tools.

While craftsmanship plays a crucial role, having the correct woodworking machines can greatly enhance productivity and efficiency. These machines are specifically designed to perform various woodworking tasks, such as cutting, shaping, and smoothing wood. We will explore the different types of woodworking machines, their uses, and how they contribute to creating high-quality wooden products.

Whether you are a professional woodworker or an avid DIY enthusiast, understanding the various woodworking machines available will help you choose the right equipment for your projects. So, let’s dive into the wide array of woodworking machines and discover their capabilities.

2. Beginner-friendly Woodworking Machines

If you’re new to woodworking, it’s important to start with the right tools. Investing in beginner-friendly woodworking machines can help you gain confidence and achieve better results. These machines are designed with simplicity and ease of use in mind, making them perfect for those who are just starting out on their woodworking journey. In this section, we will explore three essential woodworking machines that are perfect for beginners: the power drill, circular saw, and random orbital sander.

2.1 Power Drill

The power drill is a versatile tool that no woodworking enthusiast should be without. It is ideal for drilling holes, driving screws, and even sanding and polishing surfaces when fitted with the appropriate attachments. With its adjustable speed settings and easy-to-use ergonomic design, the power drill allows beginners to handle a wide range of projects with precision and control.

2.2 Circular Saw

The circular saw is a must-have woodworking machine for any beginner looking to make straight cuts in wood. Its compact size and powerful cutting capabilities make it suitable for a variety of projects, from cutting boards to building furniture. Equipped with safety features such as blade guards and easy depth adjustments, the circular saw ensures that beginners can work confidently and safely.

2.3 Random Orbital Sander

The random orbital sander is an essential machine for achieving smooth and professional-looking finishes. Unlike traditional sanders, the random orbital sander moves in both a rotary and orbital motion, reducing the risk of leaving visible sanding marks on the surface of the wood. Its lightweight design and ergonomic grip make it easy for beginners to handle, allowing them to achieve desired results without much effort.

3. Intermediate-level Woodworking Machines

Once you have gained some experience and feel more confident in your woodworking skills, it’s time to step up to the intermediate-level woodworking machines. These machines offer more versatility and capabilities than the beginner-level machines, allowing you to tackle more complex woodworking projects with ease.

3.1 Table Saw

The table saw is an essential woodworking machine for intermediate-level woodworkers. It features a circular blade that is mounted on an arbor, and it is designed to make precision cuts in wood. The table saw’s large and flat surface provides a stable platform for cutting larger pieces of wood with accuracy.

With a table saw, you can make a wide variety of cuts, including rip cuts, crosscuts, and miter cuts. It is also commonly used for cutting dados and grooves, making it a versatile machine for various woodworking tasks. Some table saws even come with additional features like tilting arbor for bevel cuts and a sliding table for cutting larger panels.

When using a table saw, safety is of utmost importance. Always wear safety goggles and use push sticks or featherboards to keep your fingers away from the blade. Read the manufacturer’s instructions and follow all safety guidelines to ensure a safe and productive woodworking experience.

3.2 Router

The router is another indispensable woodworking machine that adds versatility to your projects. It is a handheld power tool or a mounted tool with a rotating bit and is used to hollow out an area in a piece of wood. Routers are mainly used for decorative purposes, such as creating intricate designs, adding decorative edges, and making joints.

With different router bits, you can achieve various effects and shapes, including dado cuts, rabbet cuts, chamfers, and fluting. Routers can be used for both straight cuts and curved cuts, making them suitable for a wide range of applications in woodworking.

Using a router requires some practice and precision. Make sure to secure your workpiece firmly and move the router in the right direction to achieve desired results. Keep the router base flat against the wood and move it smoothly to avoid any mistakes or hiccups during the routing process.

3.3 Bandsaw

The bandsaw is a versatile woodworking machine that uses a continuous band of teethed metal, mounted on two large wheels, to make cuts in wood. This machine is particularly useful for making curved cuts, irregular shapes, and intricate designs that are challenging to achieve with other machines.

With a bandsaw, you can create precise cuts, resaw thick lumber into thinner pieces, and make intricate scrollwork. The bandsaw’s narrow blade allows for tighter-radius curves and finer cuts, providing you with more creative possibilities in your woodworking projects.

When using a bandsaw, it is vital to maintain proper blade tension and select the right blade for the task at hand. This will ensure clean and accurate cuts while keeping safety a priority. Remember to wear safety goggles and always keep your hands a safe distance away from the blade to prevent accidents.

4. Advanced Woodworking Machines

Discover the world of advanced woodworking machines, each specialized in different tasks and techniques. These devices offer efficient and precise woodworking, catering to craftsmen of various skill levels and project requirements.

Woodworking is a versatile craft that requires precision and finesse. To achieve the highest level of craftsmanship, advanced woodworking machines come into play. These machines possess advanced features designed to enhance efficiency, accuracy, and productivity. In this article, we will explore three essential advanced woodworking machines that every woodworker should be familiar with: the Jointer, Planer, and Lathe.

4.1 Jointer

The Jointer is an indispensable tool for woodworking enthusiasts. Its primary purpose is to straighten and flatten rough lumber, ensuring a smooth and level surface. With its rotating cutterhead and infeed/outfeed tables, the Jointer accurately eliminates twists, warps, and bows from boards. This machine can transform irregular pieces of wood into perfectly flat and squared stock, essential for creating furniture, cabinetry, and other fine woodworking projects.

4.2 Planer

Next in line is the Planer—an advanced machine that plays a crucial role in woodworking workshops. This machine complements the Jointer by further refining lumber thickness and ensuring consistent dimensions. As timber is fed into the Planer, its rotating cutterhead expertly shaves off precise amounts of wood, resulting in a uniformly thick and smooth surface. This enables woodworkers to create perfectly sized boards for specific projects, allowing for seamless joinery and precise assembly.

4.3 Lathe

Finally, we have the Lathe, a versatile woodworking machine that adds creativity and artistic flair to projects. This machine allows woodworkers to shape wood in various rotational forms, such as bowls, vases, and spindles. By spinning the wood rapidly against a cutting tool, the Lathe enables intricate carving, turning, and detailing. This advanced woodworking machine empowers craftsmen to unleash their imagination, creating stunning pieces that capture attention and admiration.

In summary, advanced woodworking machines such as the Jointer, Planer, and Lathe elevate the quality and precision of woodworking projects. Whether it’s achieving a flat and smooth surface, ensuring consistent dimensions, or exploring artistic possibilities, these machines are essential for any serious woodworker. By incorporating these advanced machines into their workshops, woodworkers can unlock their full potential and take their craftsmanship to new heights.

5. Specialized Woodworking Machines

Woodworking involves the use of various machines that are specifically designed to perform specialized tasks with precision and efficiency. These machines not only make woodworking easier but also allow craftsmen to create intricate designs and achieve high levels of accuracy. In this section, we will explore three types of specialized woodworking machines: CNC Router, Mortiser, and Scroll Saw.

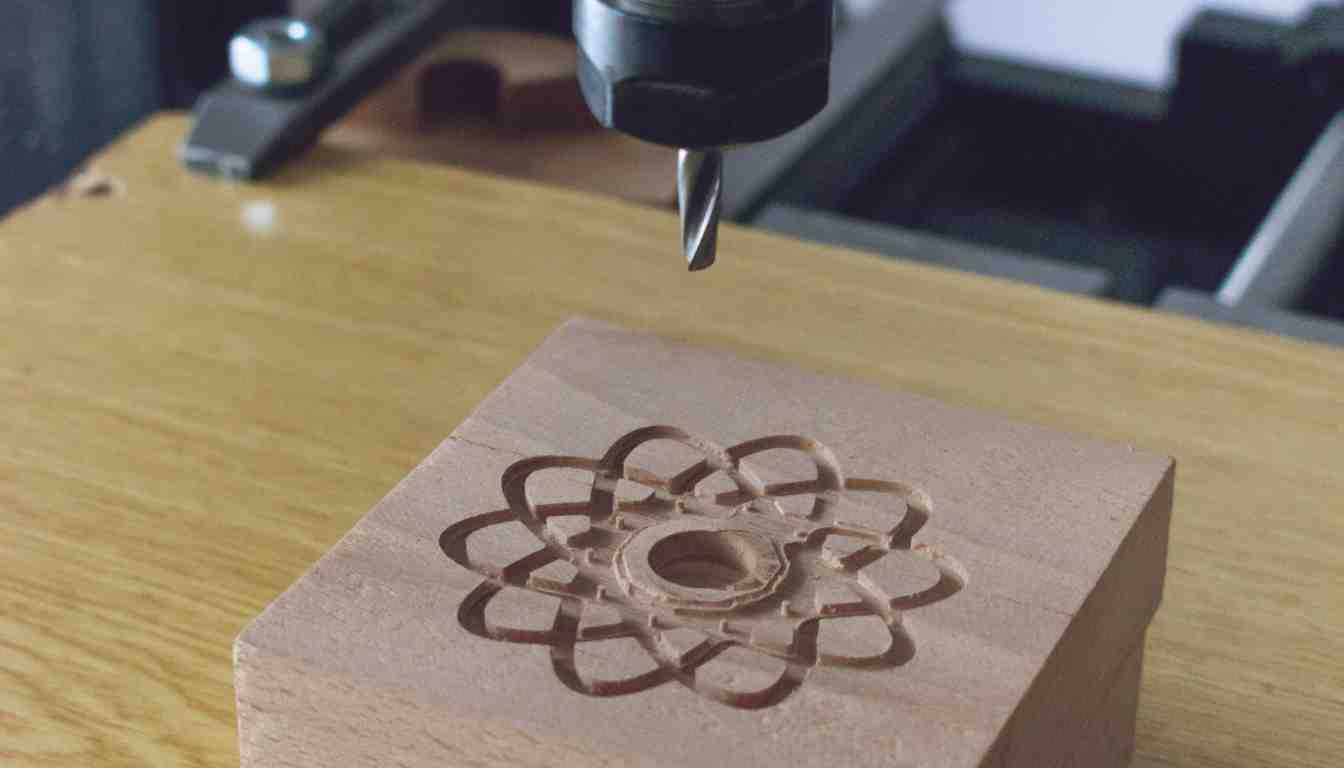

5.1 Cnc Router

A CNC Router is a computer-controlled cutting machine that is widely used in the woodworking industry. It operates on the principle of subtractive manufacturing, where material is cut away to create the desired shape. The CNC router uses a rotating cutting tool to remove material from the workpiece, guided by a computer program that controls its movement. This allows woodworkers to create intricate designs, carve out detailed patterns, and produce precise cuts with ease. With a CNC router, woodworking projects can be completed in less time, and the results are often of higher quality.

5.2 Mortiser

A Mortiser is a specialized woodworking machine used for cutting rectangular or square holes, called mortises, in wooden workpieces. It is commonly used for making joints in furniture and cabinetry. The mortiser consists of a chisel-like cutting tool called a mortising bit, which is powered by a motor. The workpiece is held securely in place, and the mortising bit is guided to create the desired hole. This machine greatly simplifies the process of creating mortise and tenon joints, which are essential for strong and durable woodworking projects.

5.3 Scroll Saw

A Scroll Saw is a specialized woodworking machine that is perfect for intricate and detailed cutting. It features a thin, reciprocating blade that moves up and down rapidly. This allows woodworkers to create precise cuts and curves in delicate materials, such as thin wood, plastic, or metal. The scroll saw is often used for crafting decorative items, making intricate fretwork, and creating detailed scrollwork designs. Its fine blade and precise control make it an indispensable tool for woodworkers who work on projects that demand intricate patterns and high levels of detail.

Conclusion

To sum up, understanding the different types of woodworking machines is vital for any woodworking enthusiast or professional. From table saws, bandsaws, planers, to jointers and routers, each machine has its unique capabilities and functions. By utilizing these machines effectively, woodworkers can enhance their productivity and the quality of their craft.

Exploring and mastering these various machines opens up endless opportunities for creativity and precision in woodworking projects. Happy woodworking!