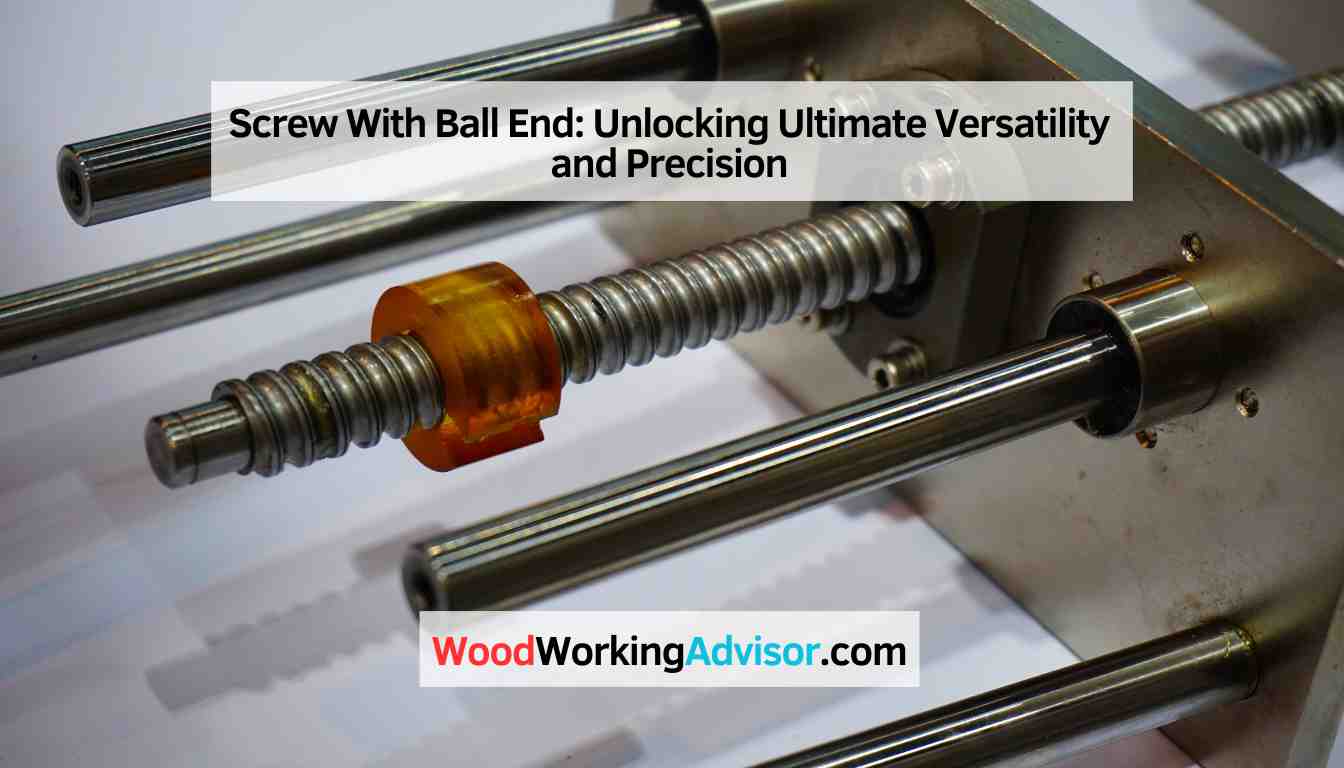

A screw with a ball end has a rounded tip for easier insertion and stress distribution. It enhances grip and reduces marring during tightening.

In the world of fasteners, screws with ball ends are a game-changer. With a rounded tip, they provide better grip and minimize damage when tightening. Using a ball end screw can make your project smoother and more effective by ensuring a secure fit without the risk of slipping or stripping.

This innovative design feature is especially useful in industries where precision and durability are paramount, such as automotive, aerospace, and manufacturing. Let’s delve deeper into the benefits and applications of screws with ball ends to understand why they are a valuable addition to your toolkit.

The Evolution Of Screw With Ball End

The design of Screw With Ball End has come a long way over time, revolutionizing fastening solutions with its distinctive features. Let’s delve deeper into its journey of innovation.

Origins And Development

- Origin: Initially introduced in the industrial sector.

- Development: Evolved from traditional screws to precision-engineered ball-end design.

- Applications: Widely adopted in various industries for enhanced functionality.

Advantages Over Traditional Screws

- Improved Maneuverability: Ball-end design allows for easier access in confined spaces.

- Enhanced Torque Transfer: Provides a more secure grip and reduces the risk of slippage.

- Reduced Damage: Minimizes surface damage with precise positioning.

Applications In Various Industries

Screw with Ball End finds extensive usage across a wide range of industries due to its unique design and functionality.

Automotive And Engineering

In the automotive sector, Screw with Ball End is ideal for precision tasks such as assembly of engine parts.

Screw with Ball End is also commonly employed in various engineering applications requiring precise fastening and accessibility in tight spaces.

Aerospace And Manufacturing

The aerospace industry relies on Screw with Ball End for assembling intricate components in aircraft and spacecraft.

In the manufacturing sector, this screw type is favored for its ability to reach fastening points that are challenging to access with traditional screws.

Choosing The Right Screw With Ball End

Choosing the right screw with ball end can make a significant difference in the success of a project. These specialized screws with a rounded ball shape at one end are commonly used in various industries, including automotive, aerospace, and manufacturing. To ensure you select the most suitable screw with a ball end for your specific application, consider key factors such as material considerations, size, and compatibility.

Material Considerations

When choosing a screw with a ball end, the material of both the screw and the workpiece should be a critical consideration. Stainless steel screws are ideal for applications requiring excellent corrosion resistance, while alloy steel screws offer high strength. For projects involving non-ferrous materials such as aluminum or brass, specialized aluminum or titanium screws may be preferred for their lightweight and non-corrosive properties.

Size And Compatibility

The size of the screw with a ball end should match the dimensions of the workpiece and the intended application. Selecting the appropriate thread size and length is crucial for achieving a secure and precise fit. Additionally, ensuring compatibility with the receiving end or nut is essential to prevent any misalignment or instability. Consider the thread pitch, diameter, and overall length of the screw carefully to ensure a proper match with the application’s requirements.

Techniques For Maximum Performance

When it comes to using a Screw With Ball End, proper handling and regular maintenance are crucial for achieving maximum performance. This blog post will provide you with essential tips to ensure you get the most out of your screw. By following these techniques, you can optimize the functionality and lifespan of your screw, ultimately saving time and effort.

Proper Handling And Usage

It is important to handle and use the Screw With Ball End correctly to prevent any damage or accidents. Here are some guidelines for proper handling:

- Align the screw properly: Before tightening or loosening any fasteners, make sure the ball end of the screw is aligned with the screw head or socket. This will help maintain a secure grip and prevent slipping or stripping.

- Apply steady pressure: When using the screw, apply steady pressure while turning to maintain control and ensure a smooth operation. Avoid excessive force, as it can lead to wear and tear on the screw or the items being fastened.

- Use the right screwdriver: Ensure you use the appropriate size and type of screwdriver for the screw you are working with. Using an ill-fitting screwdriver can result in poor performance and potential damage to the screw or surrounding materials.

Maintenance And Care

To keep your Screw With Ball End in optimal condition, regular maintenance and care are essential. Here are some maintenance tips:

- Keep it clean: After each use, remove any dirt, debris, or residue from the screw to prevent buildup. You can use a soft cloth or brush and a mild cleaning agent if necessary.

- Inspect for damage: Regularly inspect the screw for any signs of wear, such as bent or damaged threads, rust, or corrosion. If any damage is detected, replace the screw to ensure continued performance.

- Apply lubrication: Lubricating the screw periodically can help reduce friction, extend its lifespan, and improve its performance. Use a suitable lubricant recommended by the manufacturer and apply it according to the instructions provided.

By following these maintenance and care techniques, you can enhance the longevity and efficiency of your Screw With Ball End. Remember, proper handling and regular maintenance are key to achieving maximum performance. Implement these tips, and you’ll enjoy smooth operation and reliable results with your screw, whether you’re working on DIY projects or professional applications.

Future Innovations And Potential Impact

The screw with ball end has come a long way since its initial introduction. Manufacturers are continually pushing the boundaries of design and functionality to meet the ever-evolving needs of precision engineering. With advancements in materials and engineering techniques, these screws now offer enhanced performance and increased durability.

One significant advancement in design is the incorporation of a ball at one end of the screw. This simple yet ingenious addition allows for improved access and maneuverability in hard-to-reach spaces, making it ideal for precision engineering applications. The ball end provides a pivot point, giving the user greater control and reducing the risk of slippage.

Moreover, manufacturers are experimenting with different materials and surface treatments to optimize the performance of these screws. By utilizing high-strength alloys and coatings that enhance corrosion resistance, the screws can withstand extreme conditions and provide reliable performance in harsh environments.

Implications For Precision Engineering

The introduction of screw with ball end brings forth several implications for precision engineering. These innovations have the potential to revolutionize the way engineers approach their work, offering increased efficiency and accuracy in various applications.

1. Enhanced Accessibility: The ball end allows engineers to access tight spaces and angles that were previously difficult to reach. This increase in accessibility simplifies intricate and complex tasks, improving overall productivity.

2. Precision Alignment: The pivot point provided by the ball end enables precise alignment during assembly and installation processes. This leads to improved accuracy, reducing the chances of errors and ensuring a higher quality end product.

3. Reduced Damage: The use of the screw with ball end minimizes the risk of damage to delicate components during fastening. The ball acts as a buffer, preventing excessive force or slippage, which can potentially cause damage to the workpiece or surrounding areas.

Credit: www.temu.com

Frequently Asked Questions On Screw With Ball End

What Is A Screw With A Ball End Used For?

A screw with a ball end is commonly used in hard-to-reach areas where a standard screwdriver doesn’t have enough clearance. The ball end allows you to insert and turn the screw at an angle, making it ideal for tight spaces and awkward positions.

How Does A Screw With A Ball End Work?

A screw with a ball end has a rounded tip instead of a traditional flat one. This round tip allows for more flexibility in angling the screwdriver, allowing you to reach screws that would otherwise be difficult to access. Simply insert the ball end into the screw head and turn as usual.

Can I Use A Screw With A Ball End With Any Screwdriver?

Yes, you can use a screw with a ball end with any screwdriver that is compatible with the screw head. The ball end provides additional flexibility in awkward positions, but it does not require a specialized screwdriver. As long as the screwdriver matches the screw head shape, you can use it with a screw with a ball end.

Are Screws With Ball Ends Secure?

Screws with ball ends provide a secure fastening solution when used correctly. The rounded tip of the screw allows for better torque transmission, reducing the chance of slippage during installation. However, it is important to ensure that the screwdriver is firmly seated in the ball end to maximize security and prevent stripping or damage.

Conclusion

The screw with ball end is a versatile and efficient tool for various applications. Its design allows for easy insertion and removal and provides a secure grip, making it a valuable addition to any toolkit. Whether working on mechanical or DIY projects, the screw with ball end offers reliability and convenience.