The wood calculation formula is a method used to determine the amount of wood required for a specific project. It helps in estimating the quantity of wood needed accurately.

By using this formula, you can save time, money, and avoid unnecessary waste. Proper wood calculation is crucial for construction projects, carpentry work, and woodworking tasks. It ensures that the right amount of wood is ordered, minimizing the chances of shortages or excess material.

Whether you are building furniture or constructing a house, understanding the wood calculation formula is essential for efficient planning and execution. This article will explain the wood calculation formula, guiding you through the process step by step.

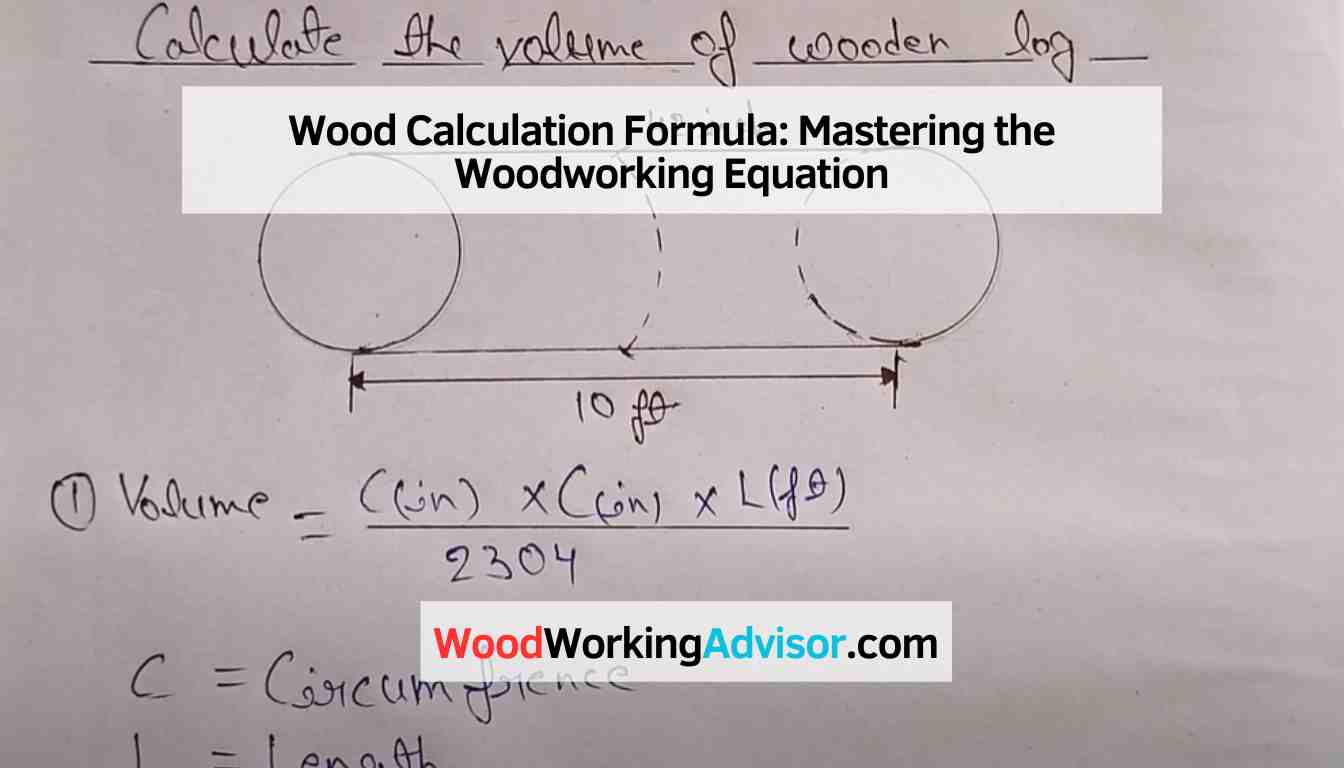

Credit: m.youtube.com

Basic Principles

Understanding the principles of wood calculation is essential for any woodworking project. By having a solid grasp of the basic principles involved, you can accurately calculate the amount of wood needed for your project, saving you time and money in the process. In this article, we will explore the fundamental concepts of wood calculation, including woodworking measurement units and key variables.

Understanding Woodworking Measurement Units

Before delving into the wood calculation formula, we need to grasp the different measurement units commonly used in woodworking. Wood is typically measured in board feet (BF) or cubic feet (CF).

In woodworking, a board foot represents a piece of lumber that measures one foot in length, one foot in width, and one inch in thickness. To calculate the board footage, simply multiply the length (in feet) by the width (in feet) and the thickness (in inches).

On the other hand, cubic feet (CF) is used to measure wood in its solid or bulk form. It is commonly employed when calculating the volume of logs or wooden blocks. To compute the cubic footage, multiply the length (in feet) by the width (in feet) and the height (in feet).

Key Variables In Wood Calculation

When calculating the amount of wood required for a project, several key variables come into play. These variables include the length, width, and thickness of each wood piece. Additionally, the number of pieces needed is a crucial factor to consider.

Using the wood calculation formula, you can determine the total volume of wood required by multiplying the dimensions of each piece (length, width, and thickness) and then multiplying that by the number of pieces needed.

Furthermore, it is important to account for potential waste or scraps that may be generated during the woodworking process. Including a waste factor during your wood calculation ensures that you have enough material to complete your project without running short.

In summary, understanding the basic principles of wood calculation is the foundation for accurately determining how much wood you need for your woodworking project. By comprehending the woodworking measurement units and considering key variables such as dimensions and waste factors, you can ensure your project progresses smoothly without any unexpected hiccups along the way.

The Wood Calculation Formula Explained

Woodworking projects require accurate measurements to ensure materials are utilized efficiently. A crucial aspect of this process is understanding the wood calculation formula. By comprehending this formula and its components, you can make precise calculations and avoid costly mistakes. In this article, we will break down the formula components and explore the factors that can influence the woodworking equation.

Breaking Down The Formula Components

To properly calculate the required amount of wood, we need to understand the formula’s key components. These include:

- Length: The measurement of the wood piece from one end to the other.

- Width: The measurement of the wood piece from side to side.

- Thickness: The measurement of the wood piece from top to bottom.

- Quantity: The number of identical wood pieces needed for the project.

By considering these components, we can easily determine the amount of wood required for a specific project. Let’s dive deeper into the factors that can affect this woodworking equation.

Factors Affecting The Woodworking Equation

Several factors can influence the wood calculation formula, and it’s essential to take them into account when planning your woodworking project. These factors include:

- Wastage: Whether due to measurement errors, cutting inefficiencies, or knots in the wood, there will always be some degree of wastage. It’s crucial to estimate and incorporate this factor into your calculations to ensure you have enough wood on hand.

- Design complexity: Intricate designs may require additional wood to account for complex cuts, joinery, or overlapping components. Consider the complexity of your project when calculating the required wood quantity.

- Add-ons and allowances: If your project includes add-ons, such as trim or decorative elements, or requires allowances for expansion or shrinkage, make sure to factor them into your calculations.

By considering these factors, you can accurately determine the amount of wood needed for your project and minimize the risk of running out of materials mid-way through construction.

Applications In Woodworking

Wood calculation formula plays a vital role in woodworking, providing the necessary precision for material estimation and project planning. Understanding how to utilize this formula is essential for optimizing resources and ensuring efficient woodworking projects.

Utilizing The Formula For Project Planning

Utilizing the wood calculation formula is crucial for effectively planning woodworking projects. By accurately calculating the amount of wood required for a specific project, woodworkers can ensure that they have the appropriate materials on hand, minimizing wastage and reducing costs.

Precision In Material Estimation

The wood calculation formula facilitates precise material estimation, allowing woodworkers to determine the exact quantities of wood needed for different aspects of their projects. This level of precision is essential for avoiding shortages or excess supplies, streamlining the production process.

Credit: schoolofwoodwork.com

Common Mistakes And How To Avoid Them

Learn how to avoid common mistakes in wood calculation. Discover a simple formula to accurately measure wood, ensuring you have the right amount for your project.

Misinterpreting Measurement Units

Using the wrong units can lead to errors. Ensure to clarify units beforehand.

Overlooking Environmental Factors

Ignoring environmental impact can disrupt accuracy. Consider factors such as humidity.

Advanced Techniques And Adjustments

Advanced Techniques and Adjustments:

Adapting The Formula For Different Wood Types

Consider varying densities and characteristics of different wood types.

Accounting For Wood Wastage

Factor in wastage due to cuts, imperfections, and errors in measurements.

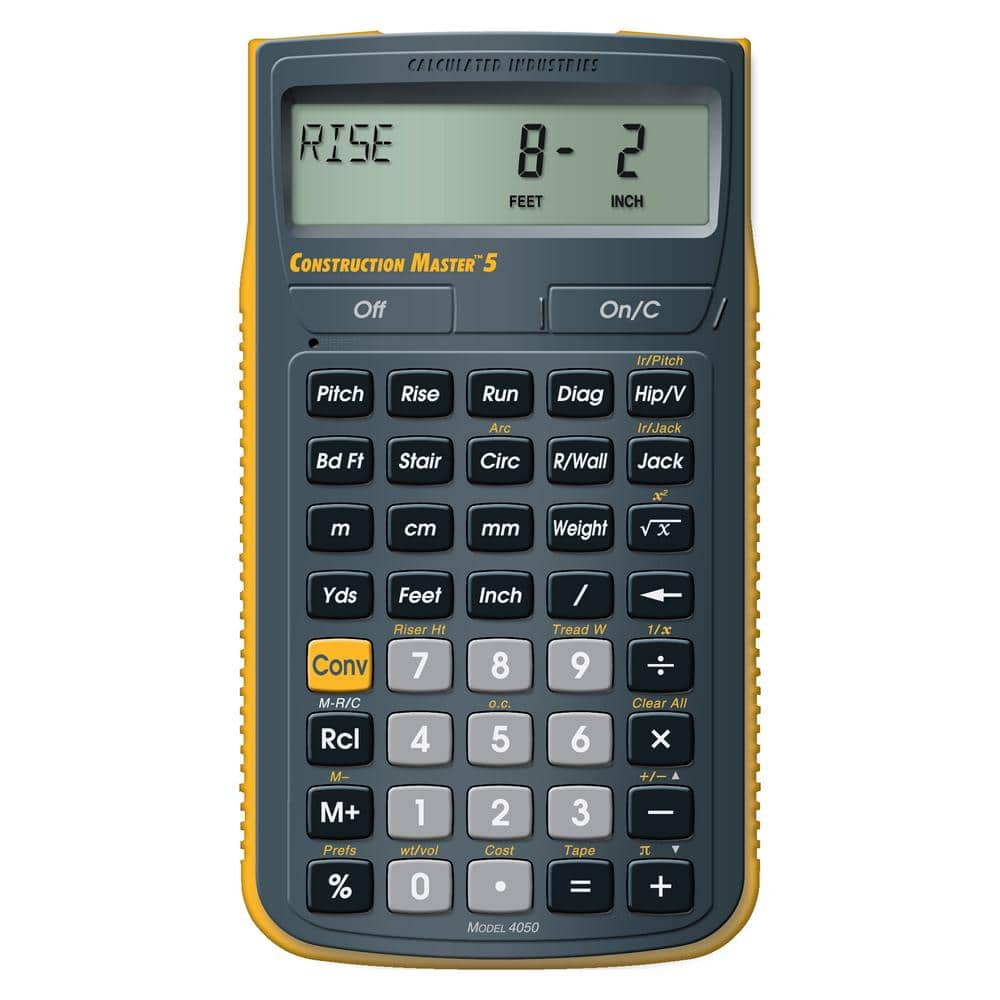

Credit: www.homedepot.com

Tools For Wood Calculation

Wood calculation is an essential part of any woodworking project. To accurately estimate the amount of wood required, various tools and software have been developed to simplify the process. In this section, we will explore the different tools available for wood calculation and their benefits.

Digital Calculators And Mobile Apps

Digital calculators and mobile apps provide a convenient way to calculate wood requirements on-the-go. They offer features such as basic wood measurement calculations, unit conversion, and real-time estimations, making it easier for woodworking enthusiasts to plan their projects effectively.

Benefits Of Using Specialized Software

Specialized software for wood calculation offers advanced features like 3D modeling, material optimization, and cost estimation. These tools enable users to create detailed project plans, visualize the end result, and minimize material wastage, ultimately leading to cost savings and efficient utilization of resources.

Frequently Asked Questions Of Wood Calculation Formula

What Is The Basic Wood Calculation Formula?

Wood calculation formula helps estimate the amount of wood required for a project based on specific dimensions.

How To Calculate Board Feet Of Wood?

Board feet are calculated by multiplying thickness, width, and length of the wood, then divided by 144.

Why Is Accurate Wood Calculation Essential?

Accurate wood calculation ensures you purchase the correct amount of materials, avoiding excess or shortage.

Can Wood Calculation Formulas Vary For Different Projects?

Yes, wood calculation formulas can vary based on the project complexity and specific requirements. It’s essential to adapt accordingly.

Conclusion

To sum up, understanding the wood calculation formula is crucial for any woodworking project. By knowing the volume and density of the wood, you can accurately estimate the quantity needed. This empowers you to plan efficiently and minimize waste, ultimately saving time and money.

Embracing this formula contributes to a successful and sustainable woodworking practice.