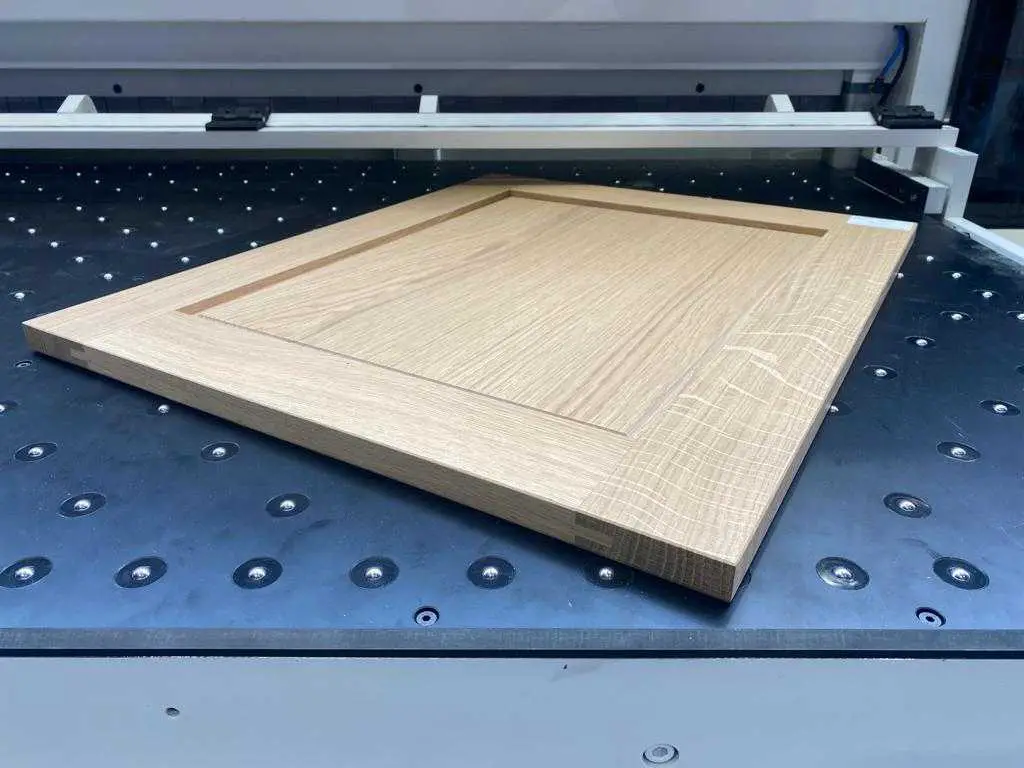

A wood flooring machine is a specialized tool for cutting, sizing, and shaping wood flooring materials efficiently. It is designed for precision and productivity in creating high-quality wood flooring products.

Investing in a wood flooring machine can significantly improve production output and quality, making it an essential asset for businesses in the flooring industry. With advanced features and automation capabilities, these machines streamline the manufacturing process, reducing manual labor and increasing operational efficiency.

By incorporating a wood flooring machine into your production line, you can achieve consistent results, reduce waste, and meet the demands of a competitive market.

Credit: sanyimachinery.en.made-in-china.com

Benefits Of Wood Flooring Machine

Wood flooring machines offer several advantages that can significantly benefit businesses in the wood flooring industry. Let’s explore the key benefits of utilizing a wood flooring machine.

Increased Efficiency

Wood flooring machines enhance production speed and accuracy, leading to efficient manufacturing processes.

Improved Quality

When using a wood flooring machine, businesses can achieve higher precision and consistency in the finished products, ensuring improved overall quality.

Cost Savings

Utilizing a wood flooring machine can result in cost savings through reduced wastage and enhanced productivity.

Types Of Wood Flooring Machines

Wood flooring machines play a vital role in the manufacturing process, ensuring precision and quality in the production of different types of wood flooring. Let’s delve into the various types of wood flooring machines:

Solid Wood Flooring Machine

A solid wood flooring machine is designed specifically to process solid wood planks or boards into precise flooring pieces.

Engineered Wood Flooring Machine

An engineered wood flooring machine is specialized in manufacturing engineered wood flooring, which is composed of layers of wood glued together to form a durable and stable product.

Laminate Wood Flooring Machine

Laminate wood flooring machines are utilized in the production of laminate flooring, a cost-effective option that mimics the look of hardwood while providing durability and easy maintenance.

Key Features To Consider

When it comes to choosing the right wood flooring machine for your needs, it is crucial to consider the key features that will impact the overall performance and efficiency of the machine. By understanding these key features, you can make an informed decision that will ultimately lead to better quality and productivity in your wood flooring projects.

Precision Cutting

Precision cutting is an essential feature to consider when choosing a wood flooring machine. This feature ensures that the machine is capable of cutting wood accurately and consistently, resulting in precise and seamless joints. Look for a machine that offers cutting mechanisms with advanced technology, such as laser guides or digital displays, which facilitate accurate cuts every time.

Versatility

When investing in a wood flooring machine, it’s essential to consider its versatility. A versatile machine can handle a wide range of wood types, thicknesses, and sizes, allowing you to tackle various flooring projects effortlessly. Look for features such as adjustable cutting depths and widths, multiple blade options, and the ability to handle different wood species, including hardwood and softwood.

Automation And Integration

In today’s fast-paced world, automation and integration play a significant role in increasing productivity and efficiency. When selecting a wood flooring machine, ensure that it offers automation features, such as automated blade changing or feeding systems, which can save you time and effort. Integration capabilities with other equipment or software can also streamline your workflow, making it easier to manage and track your wood flooring projects.

Credit: www.ebay.com

Choosing The Right Wood Flooring Machine

When it comes to efficiently producing high-quality wood flooring, choosing the right wood flooring machine is crucial. The perfect wood flooring machine can significantly impact the production process, quality of the flooring, and the overall cost-effectiveness. Therefore, assessing production needs, evaluating quality and durability, and considering budget and ROI play a pivotal role in making the optimal selection.

Assessing Production Needs

Before investing in a wood flooring machine, it’s essential to assess the production needs. This includes evaluating the volume of wood flooring required to be produced within a specific timeframe, the desired level of automation, and the types of wood and finishings to be used. These factors will dictate the type and specifications of the wood flooring machine needed for the operation.

Evaluating Quality And Durability

High-quality wood flooring machines are designed to deliver precise and consistent results, ensuring the durability and aesthetic appeal of the flooring. When choosing a wood flooring machine, it’s vital to evaluate the built quality, precision of cutting and finishing, and the overall durability of the machine. Investing in a durable and reliable wood flooring machine can significantly minimize maintenance costs and enhance the longevity of the equipment.

Considering Budget And Roi

When considering the purchase of a wood flooring machine, it’s crucial to weigh the initial investment against the potential return on investment (ROI). While it’s tempting to opt for the most advanced and feature-rich machine, it’s important to consider whether the additional features align with the production needs and justify the cost. Analyzing the long-term benefits and operational cost savings can aid in making a financially prudent decision.

Credit: www.ebay.com

Frequently Asked Questions On Wood Flooring Machine

What Is The Best Way To Run Wood Flooring?

The best way to run wood flooring is to start with a clean and level subfloor. Next, lay down moisture barrier and underlayment. Then, lay the wood planks perpendicular to the floor joists. Finally, leave space for expansion and finish with proper sealing.

What Is The Best Machine To Refinish Hardwood Floors?

The best machine for refinishing hardwood floors is a drum sander. It efficiently removes the old finish and levels the surface, providing a smooth and even result. Drum sanders are widely available for rent and deliver professional-grade performance.

What Is Machined Wood Flooring?

Machined wood flooring is made through precise cutting techniques for a uniform and smooth finish. It offers durability and a polished look to any space.

Do Carpenters Do Wood Flooring?

Yes, carpenters can install wood flooring. It is a common service offered by many carpenters for residential and commercial spaces.

Conclusion

To sum up, the wood flooring machine is a game-changer for anyone involved in the flooring industry. Its efficiency, precision, and versatility make it a valuable asset for both small and large-scale projects. With the ability to handle various types of wood and deliver flawless results, this machine ensures a smooth and seamless flooring installation process.

Investing in this technology is a wise move to stay ahead of the competition and provide high-quality flooring solutions to clients.