Reciprocating saw blades are not universal as they come in different shapes and sizes to fit specific saws and cutting tasks. Reciprocating saw blades are essential components for cutting through various materials such as wood, metal, and plastic.

However, it is important to note that these blades are not universal. They are designed in diverse shapes and sizes to fit specific reciprocating saw models and cater to different cutting tasks. This means that compatibility between blades and saws is crucial for effective and safe cutting.

Choosing the right blade for your reciprocating saw is essential for achieving optimal cutting performance and ensuring the longevity of both the blade and saw. By understanding the unique requirements of your reciprocating saw, you can select blades that match its specifications and the materials you intend to cut.

Credit: www.ebay.com

Factors Influencing Blade Compatibility

When it comes to reciprocating saw blades, one important consideration is their compatibility with different saws. While reciprocating saws are widely used for various applications, it is crucial to understand the factors that influence blade compatibility before making a purchase. This article will explore three key factors that determine whether a reciprocating saw blade is universal or not: blade shank design, blade length and width, and tooth configuration.

Blade Shank Design

Blade shank design is a critical factor in determining compatibility. Reciprocating saw blades come with different shank designs, including universal and twist locks. Universal shank blades have a straight, flat profile that fits into the saw’s blade holder while twist lock shanks feature a unique twisting mechanism for secure attachment. Understanding the shank design of your reciprocating saw is essential for choosing blades that can be easily inserted and held securely in place.

Blade Length And Width

The length and width of the blade are other crucial factors to consider when evaluating compatibility. Reciprocating saw blades are available in various lengths, typically ranging from 4 to 12 inches. The width of the blade, also known as its thickness, varies from narrow to wide. It is important to check the specifications of your reciprocating saw to determine the maximum blade length and width it can accommodate. Using a blade that is too long or wide can lead to inefficient cutting and potential damage to the saw.

Tooth Configuration

The tooth configuration of a reciprocating saw blade plays a significant role in determining its compatibility with different materials and applications. Blades with different tooth configurations are designed to cut through specific materials more effectively. For instance, blades with fewer teeth per inch (TPI) are ideal for cutting wood, while those with higher TPI are better suited for cutting metal or plastic. Understanding the tooth configuration that best suits your cutting needs and matching it with the appropriate blade will ensure optimal performance and longevity.

Credit: www.homedepot.com

Understanding Blade Shank Designs

When it comes to reciprocating saw blades, understanding blade shank designs is crucial. Blade shanks determine the compatibility of a blade with a reciprocating saw, and having a clear understanding of the various shank designs can help you choose the right blade for your saw. In this section, we will discuss the three main types of blade shank designs: Universal Shank, Keyed Shank, and Tool-Less Blade Change Mechanisms.

Universal Shank

The Universal Shank is the most common type of reciprocating saw blade shank. As the name suggests, it is designed to fit most reciprocating saws available in the market. The Universal Shank has a straight blade with a small hole at the end, which allows it to be inserted into the saw’s clamp. This design ensures easy and quick blade changes without the need for any additional tools or mechanisms.

Keyed Shank

The Keyed Shank is less common but still found in some older reciprocating saw models. It features a blade with a rectangular cross-section and a corresponding clamp in the saw. The blade is inserted into the clamp and secured with a key or setscrew. While the Keyed Shank provides a secure connection between the blade and the saw, it requires the use of an additional tool (the key) for blade changes, which can be slightly inconvenient.

Tool-less Blade Change Mechanisms

Tool-Less Blade Change Mechanisms, also known as Quick-Change or Fast-Release mechanisms, are becoming increasingly popular in modern reciprocating saws. These mechanisms allow for effortless and efficient blade changes without the need for any additional tools. The blades typically have a notched design or a lever mechanism that locks them into place. With a simple press or twist of the mechanism, the old blade can be released, and a new one can be inserted. Tool-Less Blade Change Mechanisms add convenience and speed to the sawing process, making them a popular choice among users.

Diving Into Tooth Configurations

Understanding the different tooth configurations of reciprocating saw blades is crucial for achieving efficient and precise cuts. By delving into the nuances of tooth designs, DIY enthusiasts and professionals can optimize their cutting performance based on the specific requirements of their projects. Let’s explore the significance of variable-TPI blades and the distinctions between aggressive and fine tooth blades.

Variable-tpi Blades

Variable-TPI blades, or blades with variable tooth-per-inch designs, offer versatility in cutting a wide range of materials. These blades feature a changing tooth pattern, typically with a combination of large and small gullets, allowing for aggressive cuts on thicker sections while maintaining a finer finish on thinner materials. Their adaptability makes them suitable for tasks involving wood, metal, and plastics, providing users with the flexibility to tackle diverse cutting needs with a single blade.

Aggressive Vs. Fine Tooth Blades

Aggressive tooth blades are characterized by larger gullets and fewer teeth per inch, delivering rapid and efficient cuts through dense materials such as metal and lumber. Their design enables fast material removal, making them ideal for demolition or rough cutting applications. Conversely, fine tooth blades have a higher tooth count with smaller gullets, resulting in smoother and more precise cuts. These blades excel in finish work, intricate cuts, and cutting more delicate materials where a clean edge is paramount.

Blade Material And Cutting Applications

When it comes to reciprocating saw blades, the blade material plays a crucial role in determining its performance and cutting applications. Different materials offer varying levels of durability, cutting speed, and versatility. Let’s take a closer look at some popular blade materials and their specific cutting applications:

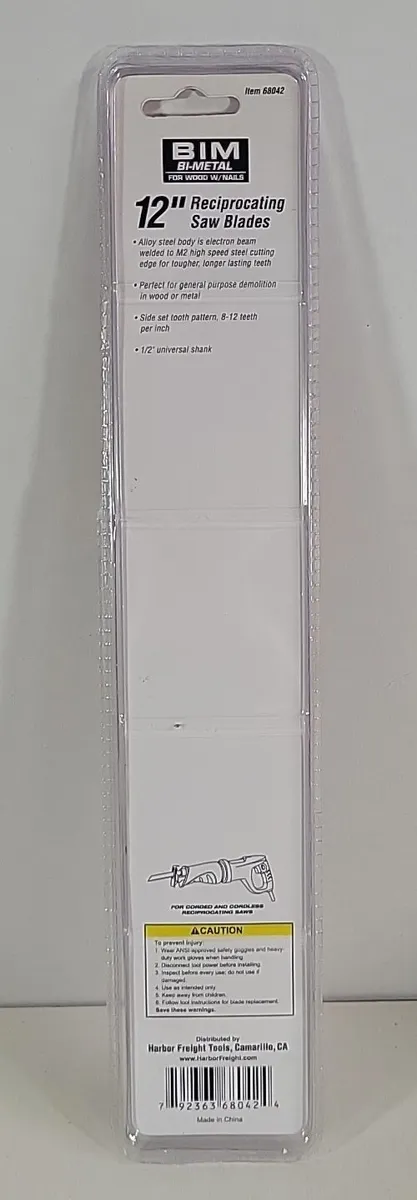

Bi-metal Blades

Bi-metal blades are the most common and versatile type of reciprocating saw blades. These blades are made from two different metals – high-speed steel teeth are welded onto a flexible carbon steel body. This combination allows the blade to withstand high cutting forces, making it suitable for a wide range of materials, including wood, metal, plastic, and even nail-embedded wood. The high-speed steel teeth provide excellent cutting performance, while the carbon steel body adds flexibility to prevent breakage during tough applications.

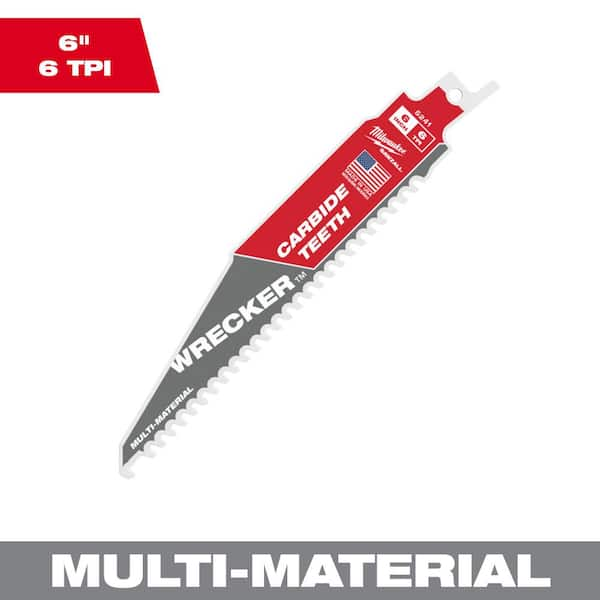

Carbide-tipped Blades

Carbide-tipped blades are known for their exceptional strength and durability. These blades have carbide teeth that are brazed onto a steel body, providing unmatched cutting power and longevity. Carbide-tipped blades are primarily used for cutting hard materials, such as ceramics, porcelain, masonry, and cast iron. The carbide teeth can endure high temperatures and are less prone to wear, ensuring long-lasting cutting performance even under the toughest conditions.

Specialty Blades For Specific Materials

In addition to bi-metal and carbide-tipped blades, there are specialized reciprocating saw blades available for specific cutting applications. These blades are designed with unique tooth configurations and materials to optimize cutting performance in specific materials. For example:

- Abrasive blades with diamond or tungsten carbide grit are perfect for cutting through tough materials like rebar, fiberglass, and non-ferrous metals.

- Demolition blades with extra thick bodies and aggressive tooth designs are ideal for heavy-duty cutting tasks, such as demolishing walls, cutting through thick pipes, or removing tree roots.

- Wood-pruning blades with large, offset teeth are specifically designed for fast and efficient cutting through branches and tree limbs.

By selecting the right blade material and type, you can maximize the efficiency and effectiveness of your reciprocating saw for various cutting applications. Whether you’re tackling a DIY project or working on a professional job, understanding the different blade materials and their specific cutting applications will help you achieve precise and efficient cuts every time.

Compatibility With Different Reciprocating Saws

Reciprocating saw blades are not universal and vary in compatibility with different saws. It’s essential to match the blade with the saw’s brand and model to ensure a safe and efficient cutting experience. Always check the manufacturer’s guidelines for the correct blade fitting.

When it comes to using a reciprocating saw, one common concern often raised is whether the blades are universal and compatible with various saw brands and models. This is an important consideration as it directly impacts the functionality and efficiency of your cutting tasks. To help you better understand the compatibility aspect, let’s explore two key factors: brands and models, and choosing the right blade for your saw.

Brands And Models

Reciprocating saw blades are designed to fit specific brands and models. Each manufacturer typically produces blades that are compatible with their own saws. For example, Bosch reciprocating saw blades are specifically designed for use with Bosch reciprocating saws. Similarly, Dewalt produces blades that are meant to be used with Dewalt reciprocating saws. While there may be some interchangeability between compatible brands, it is always advisable to use the blades recommended by the manufacturer for optimal performance.

To ensure that the blades you choose are compatible with your particular reciprocating saw, it is crucial to identify the brand and model of your saw. This information can usually be found on the saw itself or within the product documentation. Once you have this information, you can easily select the appropriate blades designed for your specific saw.

Choosing The Right Blade For Your Saw

Now that you know the importance of using blades compatible with your reciprocating saw, it is essential to choose the right blade for your cutting needs. There is a wide variety of reciprocating saw blades available, with each blade offering different features and suitability for specific applications.

When selecting a blade, consider the material you will be cutting. Reciprocating saw blades are designed to cut through various materials, such as wood, metal, plastic, or even masonry. Therefore, it is crucial to choose a blade that is specifically designed for the material you will be working with.

Beyond the material, other factors to consider include the length and number of teeth on the blade. Longer blades are ideal for cutting through thicker materials, while shorter blades offer more maneuverability in tight spaces. Additionally, the number of teeth on the blade affects the cutting speed and smoothness of the cut. Blades with fewer teeth are best for quickly cutting through material, whereas blades with more teeth provide smoother cuts.

By carefully considering the material, length, and tooth count of the blade, you can select the right blade that will optimize the performance of your reciprocating saw and ensure efficient and precise cutting.

Credit: www.cascadefarmandoutdoor.com

Frequently Asked Questions For Are Reciprocating Saw Blades Universal

Do All Reciprocating Blades Fit All Saws?

Not all reciprocating blades fit all saws. Suitability depends on factors such as blade design, size, and mounting style. It is important to choose the correct blade that matches the specifications of your particular saw model for safe and effective usage.

Will Milwaukee Sawzall Blades Fit Ryobi?

Yes, Milwaukee Sawzall blades will fit Ryobi.

How Do I Know Which Sawzall Blade To Use?

Choose a Sawzall blade by considering material, thickness, and teeth per inch. Use a bi-metal blade for metal and a carbide-tipped one for concrete or masonry. For wood, a high-carbon steel blade is suitable. To cut nail-embedded wood, use a demolition blade.

Always refer to the manufacturer’s guidelines for specific cutting tasks.

Do Diablo Blades Fit Dewalt Reciprocating Saw?

Yes, Diablo blades are compatible with Dewalt reciprocating saws.

Conclusion

In the end, it’s clear that reciprocating saw blades are not universal. You need to consider various factors, such as blade size, shank design, and tooth configuration. It’s essential to check the compatibility with your saw before purchasing. By understanding these differences, you can make the right choice for your cutting needs.