Yes, you can cut plexiglass with a miter saw. Plexiglass is a versatile material commonly used in DIY projects, as it is lightweight and durable.

When cutting plexiglass with a miter saw, it is essential to use a fine-toothed blade specifically designed for plastics. This will help prevent chipping or cracking, ensuring clean and accurate cuts. Additionally, it is important to securely clamp the plexiglass before cutting to prevent it from shifting or vibrating during the process.

By following these precautions and using the appropriate tools, you can easily cut plexiglass with a miter saw for your various projects.

Understanding Plexiglass And Its Properties

Plexiglass, a popular material known for its durability and transparency, can be cut with a miter saw. Its properties, including resistance to shattering and flexibility, make it suitable for various applications, such as windows and signage.

Introduction To Plexiglass As A Popular Alternative To Glass

When it comes to creating stylish and functional designs, Plexiglass has become a popular alternative to traditional glass. This versatile material offers numerous advantages that make it an attractive option for a wide range of applications. Whether you’re a DIY enthusiast or a professional contractor, understanding the composition and properties of Plexiglass is essential to harnessing its full potential.

Explaining The Composition And Characteristics Of Plexiglass

Plexiglass, also known as acrylic glass or PMMA (polymethyl methacrylate), is a transparent thermoplastic that consists of long chains of monomers. These monomers are derived from a chemical process called polymerization, resulting in a durable material with excellent optical clarity. Plexiglass is available in various grades, including extruded and cast, which determine its specific properties and applications.

One of the standout characteristics of Plexiglass is its high impact resistance, making it less prone to shattering compared to traditional glass. This property is particularly crucial in environments where safety is a concern, such as schools, hospitals, and retail settings. Additionally, Plexiglass is lightweight and easy to handle, making it convenient for both structural and decorative purposes.

Highlighting The Advantages And Disadvantages Of Using Plexiglass In Different Applications

Using Plexiglass in various applications comes with its own set of advantages and disadvantages. Let’s explore some of the key factors to consider:

Advantages:

- UV resistance: Plexiglass has built-in UV resistance, protecting it from the harmful effects of sunlight, making it suitable for outdoor applications.

- Weather resistance: This material can withstand extreme weather conditions, including temperature fluctuations, making it ideal for both indoor and outdoor use.

- Customization options: Plexiglass is easily cut, drilled, and shaped, allowing for intricate designs and customization to fit specific requirements.

- Optical clarity: Plexiglass offers exceptional transparency, allowing for high visibility and optical clarity, making it suitable for windows, display cases, and protective barriers.

Disadvantages:

- Scratch susceptibility: Plexiglass is more susceptible to scratches compared to glass. It is essential to handle and clean it with proper care to maintain its appearance.

- Chemical sensitivity: Certain chemicals, such as acetone and ammonia-based cleaners, can cause damage to the surface of Plexiglass. It is crucial to choose compatible cleaning agents.

- Lower heat resistance: Plexiglass has a lower heat resistance compared to glass, and prolonged exposure to high temperatures can cause it to warp or melt. It is important to consider its limitations in applications involving heat sources.

Understanding the composition, characteristics, advantages, and disadvantages of Plexiglass empowers individuals and professionals to make informed decisions when working with this material. Whether you plan to cut Plexiglass using a miter saw or employ it in an architectural project, harnessing its unique properties will undoubtedly result in stunning and functional outcomes.

The Power Of A Miter Saw For Cutting Materials

The power of a miter saw lies in its ability to effortlessly cut through a variety of materials, making it a valuable tool in any DIY enthusiast or professional carpenter’s arsenal. With its precise and versatile cutting capabilities, a miter saw offers immense convenience and efficiency, allowing you to tackle a wide range of projects with ease.

Discussing The Capabilities And Features Of A Miter Saw

One of the key features of a miter saw is its ability to make miter cuts, whereby the blade can be angled to create precise angled cuts on materials. This allows you to create clean and accurate joints, making it an ideal tool for projects such as furniture-making or trim installation. Additionally, miter saws often come equipped with a laser guide that helps you achieve even greater precision, ensuring that each cut is made with absolute accuracy.

Exploring The Various Materials That Can Be Cut Using A Miter Saw

One of the greatest advantages of a miter saw is its versatility in cutting different materials. Whether you’re working with wood, metal, plastic, or even some types of masonry, a miter saw can handle them all. Its powerful motor and sharp blades are designed to effortlessly cut through these materials, providing you with a smooth and clean cut every time.

When it comes to wood, a miter saw excels in cutting various types and sizes of lumber, from thin and delicate moldings to thick and sturdy timber. It can also handle hardwoods like oak or softwoods like pine, making it a go-to tool for any woodworking project.

Furthermore, a miter saw is capable of cutting through other materials such as plastic and metal with the right blade. While plexiglass, being a type of plastic, requires a specific type of blade and technique to achieve optimal results, a miter saw can indeed be used to cut it effectively.

Highlighting The Precision And Versatility Of A Miter Saw In Cutting Different Angles And Shapes

One of the standout capabilities of a miter saw is its ability to cut at different angles and shapes, providing you with endless possibilities for your projects. Whether you need to make a bevel cut, where the blade is angled to create an edge with a specific angle, or a compound cut, where both miter and bevel cuts are combined, a miter saw can accomplish it with ease.

Moreover, a miter saw offers the flexibility to adjust the cutting angles and the depth of the cuts, allowing you to create intricate designs and custom shapes. This versatility is especially beneficial when working on projects that require precise and complex joinery, such as picture frames or crown moldings.

Overall, the power of a miter saw cannot be overstated when it comes to cutting a wide range of materials and achieving precise angles and shapes. With its capabilities and features, it proves to be an indispensable tool that enhances the efficiency and accuracy of any woodworking or DIY project.

Addressing The Common Concerns And Misconceptions About Cutting Plexiglass With A Miter Saw

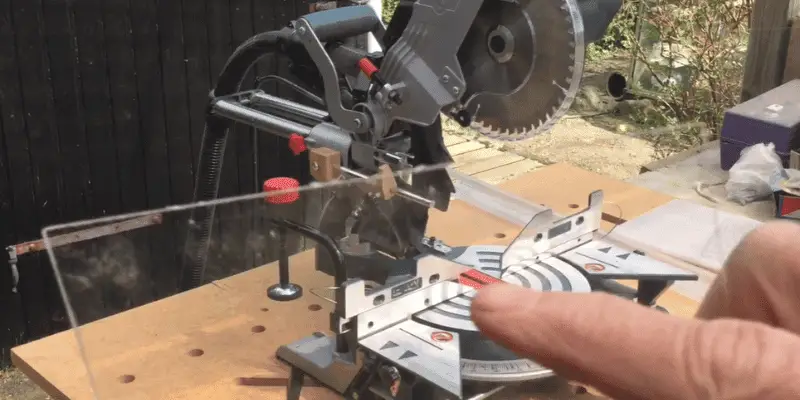

When it comes to cutting Plexiglass with a miter saw, there are several common concerns and misconceptions that need to be addressed. Many people worry that using a miter saw will cause the Plexiglass to crack, splinter, or melt. However, with the right technique and safety precautions, it is possible to achieve clean, precise cuts without any damage to the material.

One misconception that needs to be clarified is that using a regular wood-cutting blade on a miter saw is not suitable for cutting Plexiglass. Plexiglass requires a specialized blade that has a high tooth count and is specifically designed for cutting plastics. These blades have smaller teeth and produce finer cuts, reducing the risk of cracking or splintering the Plexiglass.

Another concern is the possibility of the Plexiglass overheating and melting during the cutting process. This can happen if the blade is spinning too fast or if excessive pressure is applied. By using the right blade and following the appropriate cutting speed and technique, the risk of melting can be minimized.

Providing Step-by-step Instructions On How To Safely And Effectively Cut Plexiglass Using A Miter Saw

Now that we have addressed the concerns and misconceptions, let’s dive into the step-by-step instructions for cutting Plexiglass with a miter saw. Please note that safety should always be a top priority when working with power tools. Be sure to wear appropriate safety gear, such as safety goggles, gloves, and hearing protection, before proceeding with the cutting process.

- Start by measuring and marking the desired cut line on the Plexiglass. Use a pencil or a marker to make a clear and visible mark.

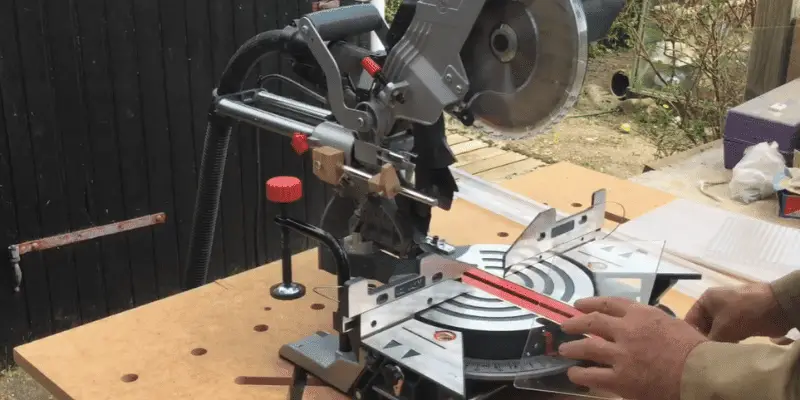

- Set up your miter saw workstation by securing the Plexiglass firmly in place. Use clamps or a vise to hold the material steady and prevent any movement during the cutting process.

- Install a specialized plastic-cutting blade with a high tooth count onto your miter saw. Make sure the blade is securely attached and in good condition.

- Adjust the cutting speed of your miter saw to a lower setting to minimize heat buildup. This will help prevent the Plexiglass from overheating and melting.

- Before making the cut, take a moment to double-check your setup and ensure everything is aligned correctly. This will help you achieve accurate and clean cuts.

- Gently lower the blade onto the marked cut line, applying light and consistent pressure. Let the blade do the work and avoid forcing or rushing the cut.

- Continue cutting along the marked line until you have achieved the desired length or shape.

- Once the cut is complete, turn off the miter saw and allow the blade to come to a full stop before lifting it away from the Plexiglass.

- Inspect the cut for any rough edges or burrs. If needed, use sandpaper or a fine grit file to smooth out the edges and achieve a clean finish.

Discussing The Recommended Safety Precautions And Tools For Cutting Plexiglass With A Miter Saw

When cutting Plexiglass with a miter saw, it is crucial to take the necessary safety precautions to avoid any accidents or injuries. Here are some recommended safety measures:

- Always wear safety goggles, gloves, and hearing protection to protect yourself from flying debris and noise.

- Ensure that the miter saw is placed on a stable and level surface to prevent any movement during the cutting process.

- Use clamps or a vise to secure the Plexiglass firmly in place and prevent it from shifting or vibrating.

- Choose a specialized plastic-cutting blade with a high tooth count to achieve clean and precise cuts.

- Adjust the cutting speed of the miter saw to a lower setting to reduce heat buildup and minimize the risk of melting the Plexiglass.

- Take breaks if needed to let the blade and the Plexiglass cool down to avoid overheating.

Following these safety precautions and using the appropriate tools will help you cut Plexiglass with a miter saw safely and effectively, allowing you to achieve the desired results for your project.

Tips And Techniques For Cutting Plexiglass With A Miter Saw

When it comes to cutting plexiglass with a miter saw, there are specific techniques and tips that can help you achieve clean and accurate cuts. In this article, we will explore different cutting techniques, discuss the importance of selecting the right blade and setting the correct cutting speed, and provide troubleshooting tips for common issues encountered when cutting plexiglass with a miter saw.

Exploring Different Cutting Techniques And Tips For Achieving Clean And Accurate Cuts On Plexiglass

To achieve clean and accurate cuts on plexiglass, it is important to use the appropriate cutting techniques. Here are some tips to ensure successful cutting:

- Measure and mark your cutting line clearly with a permanent marker or masking tape for precise cuts.

- Support the plexiglass firmly during cutting to minimize vibrations and prevent chipping. Using clamps or a miter saw workstation can help provide stability.

- When making the cut, apply steady and even pressure to the plexiglass to maintain control and avoid cracking.

- Consider using a lubricant, such as a silicone spray or soapy water, to reduce friction and prevent the blade from overheating.

Discussing The Importance Of Selecting The Right Blade And Setting The Correct Cutting Speed

The blade and cutting speed are crucial factors when cutting plexiglass with a miter saw. Here’s what you need to consider:

| Blade Selection | Cutting Speed |

|---|---|

| Choose a blade specifically designed for cutting plexiglass, such as a carbide-tipped blade or a triple-chip tooth blade. | Set the saw’s speed to the lowest possible setting to prevent melting or chipping of the plexiglass. A slower speed helps in achieving cleaner cuts. |

Providing Troubleshooting Tips For Common Issues Encountered When Cutting Plexiglass With A Miter Saw

While cutting plexiglass, you may encounter some common issues. Here are a few troubleshooting tips to overcome them:

- If the plexiglass starts melting or chipping, reduce the cutting speed or try using a lubricant to cool down the blade.

- If the cut edges are rough or jagged, consider using a fine-toothed blade or sanding the edges lightly after cutting.

- In case the plexiglass cracks or shatters, check if the blade is dull or worn out. Replacing the blade may solve the problem.

By following these tips and techniques, you can ensure precise and clean cuts when cutting plexiglass with a miter saw. Remember to always prioritize safety by wearing appropriate protective gear and following the manufacturer’s instructions.

Conclusion: Discover The Power And Precision Of Cutting Plexiglass With A Miter Saw

Summarizing the key points discussed in the article:

Throughout this article, we have explored the exciting possibilities of cutting Plexiglass with a miter saw. From understanding the properties of Plexiglass and the challenges it presents to discovering the features and benefits of using a miter saw, we have covered it all. Let’s summarize the key points to refresh your memory:

- Plexiglass, a versatile and durable material, requires specific cutting methods to ensure a clean and precise finish.

- Traditional cutting tools like knives or saws may cause chipping or cracking, compromising the integrity of the material.

- A miter saw, designed with sharp and fine-toothed blades, provides the power and precision needed to cut Plexiglass effectively.

- The miter saw’s ability to control the cutting speed, combined with the support of an adjustable fence, ensures accurate and clean cuts every time.

- Using the right blade type, such as a carbide-tipped or fine-toothed blade, further enhances the miter saw’s effectiveness for cutting Plexiglass.

Emphasizing the benefits of using a miter saw for cutting Plexiglass:

Now that we’ve discussed the key points, it’s important to understand the numerous benefits of using a miter saw for your Plexiglass cutting needs:

- Precision: With its adjustable fence and controlled cutting speed, a miter saw guarantees precise cuts, reducing the need for additional finishing work.

- Efficiency: The power and smooth operation of a miter saw allow for faster cutting, saving time and effort compared to other manual cutting methods.

- Clean Cuts: The sharp and fine-toothed blade of a miter saw ensures clean edges without chipping or cracking, resulting in professional-looking finishes.

- Versatility: A miter saw is not only suitable for cutting Plexiglass but can also be utilized for various other woodworking projects, making it a versatile tool to have in your workshop.

Encouraging readers to explore the possibilities of using a miter saw for their Plexiglass cutting needs:

As you can see, a miter saw offers unparalleled power and precision for cutting Plexiglass. If you work with Plexiglass regularly or are planning a project that requires accurate cuts in this material, it’s time to consider investing in a miter saw. Unlock the true potential of your woodworking projects and enjoy the benefits that come with using this exceptional tool. Explore the possibilities and elevate your craftsmanship with the unmatched performance of a miter saw.

Frequently Asked Questions Of Can You Cut Plexiglass With A Miter Saw

Can Plexiglass Be Cut With A Miter Saw?

Yes, a miter saw can be used to cut plexiglass. However, it is important to use the correct blade and take proper precautions. Use a fine-tooth blade specifically designed for cutting plastic, and reduce the blade speed to prevent melting or chipping.

Always wear protective goggles and gloves when cutting plexiglass to ensure safety.

Conclusion

To conclude, cutting Plexiglass with a miter saw is indeed possible, but precautions must be taken to avoid cracking or splintering the material. By using the right blade and following the correct technique, one can achieve clean and precise cuts.

However, it is important to wear protective gear and work in a well-ventilated area to minimize the risk of injury. Remember to measure twice and cut once for successful results. Happy cutting!