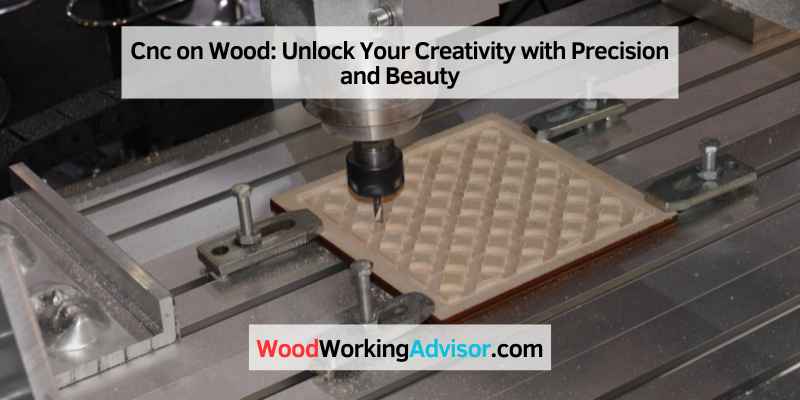

CNC on wood involves using a computer-controlled machine to create precise cuts and designs on wooden surfaces. This technology allows for intricate and detailed woodworking projects to be completed with high accuracy.

The process involves programming the machine with the desired design and then letting the CNC machine carve or engrave the pattern onto the wood. CNC on wood is revolutionizing the woodworking industry by offering efficiency and precision that traditional methods cannot match.

Whether it’s creating custom furniture pieces, intricate carvings, or personalized signage, CNC on wood opens up endless creative possibilities for woodworkers and craftsmen. This innovative technology has transformed how wooden items are manufactured, allowing for faster production times and higher levels of customization. With CNC on wood, the only limit is your imagination.

Getting Started With CNC On Wood

Choosing The Right CNC Machine

- Consider the size and power needed for your woodworking projects.

- Look for a machine with precise cutting capabilities and user-friendly software.

- Check reviews and compare features to find the best CNC machine for your needs.

Essential Tools And Materials

- Clamps: Secure the wood in place during the CNC cutting process.

- Router Bits: Choose the appropriate bits for different wood cutting tasks.

- Safety Gear: Wear goggles and ear protection to stay safe while working with CNC machines.

| Tool/Material | Description |

|---|---|

| Clamps | Secure wood during cutting |

| Router Bits | For precise cutting |

| Safety Gear | Protective goggles and ear protection |

Remember to always follow safety guidelines and experiment with different settings to achieve the desired results.

Credit: www.amazon.com

Designing For Cnc Woodworking

Designing for CNC woodworking requires careful consideration of the wood material, the capabilities of the CNC machine, and the overall design aesthetics. Whether you are a hobbyist or professional woodworker, creating designs specifically for CNC woodworking can greatly enhance the intricacy and precision of your projects. In this section, we’ll explore the software tools available for creating CNC designs and provide tips for designing intricate patterns that are well-suited for woodworking with a CNC machine.

Software For Creating Cnc Designs

When it comes to designing for CNC woodworking, software plays a crucial role in translating your creative ideas into precise instructions for the CNC machine. CAD/CAM software, such as AutoCAD, Fusion 360, or VCarve Pro, are popular choices for creating 2D and 3D designs that are compatible with CNC woodworking machines. These software tools allow you to generate toolpaths, specify cutting depths, and simulate machining processes to ensure accuracy before sending the design to the CNC machine.

Tips For Designing Intricate Patterns

- Consider the grain direction of the wood when designing intricate patterns to maximize the strength and aesthetics of the final piece.

- Use vector-based design software, such as Adobe Illustrator or Inkscape, to create scalable and easily editable designs for CNC woodworking.

- Utilize geometric shapes and symmetrical patterns to take advantage of the precision and repeatability of CNC woodworking machines.

- Experiment with different cutting tools and techniques to achieve varying levels of detail and texture in your CNC woodworking designs.

Precision And Accuracy In Woodworking

Achieve precision and accuracy in woodworking with CNC technology. Enhance your woodworking projects with CNC on wood, ensuring precise cuts and intricate designs, making your work stand out.

Calibrating Your Cnc Machine

Calibrating your CNC machine is essential to achieving precision and accuracy in woodworking. Even the slightest misalignment can result in flawed cuts and inconsistent measurements. To ensure your machine is properly calibrated, follow these steps:

- Check the alignment of the cutting tools. Make sure they are parallel to the work surface to prevent any deviation in the cut.

- Verify the machine’s positioning accuracy. Run a few test cuts using a known reference point and measure the distance between the reference point and the actual cut. Adjust the machine if necessary.

- Ensure the spindle is perfectly perpendicular to the work surface. This is crucial for achieving precise cuts, especially when it comes to intricate designs and joinery.

- Regularly calibrate the machine’s axes. Use precision instruments to adjust the accuracy of each axis, ensuring they move smoothly and maintain their intended positions.

Maintaining Consistent Cut Quality

Maintaining consistent cut quality is vital for woodworkers who rely on CNC machines. Here are some key practices to keep in mind:

- Keep your cutting tools sharp. Dull tools can result in rough cuts and tear-outs. Regularly inspect and sharpen your blades or bits to ensure clean and crisp cuts.

- Properly clean and maintain your machine. Sawdust and debris can affect the machine’s performance and accuracy. Regularly clean the cutting area and lubricate moving parts to prevent friction and ensure smooth operation.

- Use suitable feed rates and cutting speeds. Adjusting these settings based on the type of wood and the desired cut can prevent burning or chipping, resulting in high-quality finishes.

- Perform test cuts on scrap pieces of wood. Before cutting into your final piece, it’s crucial to run a test cut to ensure the settings and measurements are accurate.

By calibrating your CNC machine and maintaining consistent cut quality, you can achieve unparalleled precision and accuracy in your woodworking projects. Take the time to regularly inspect and adjust your machine to ensure optimal performance and outstanding results.

Exploring Advanced Techniques

Discover the possibilities of CNC on wood with our advanced techniques. Unlock new horizons in woodworking with precision, creativity, and efficiency. Experience the perfect blend of technology and craftsmanship.

When it comes to CNC on wood, there’s so much more that can be achieved beyond the basics. Exploring advanced techniques takes your woodworking to a whole new level, allowing you to create intricate designs and achieve stunning results. In this article, we’ll delve into two advanced techniques that can be accomplished with CNC on wood: 3D carving and sculpting, and inlays and joinery methods.

3d Carving And Sculpting

3D carving and sculpting with CNC on wood opens up a world of possibilities for creating stunning, lifelike designs. This technique allows you to add depth and dimension to your woodwork, bringing your creations to life. By using specialized software and precise cutting tools, you can carve intricate patterns, textures, and complex shapes on the surface of your wood.

With 3D carving and sculpting, you can make highly detailed reliefs, replicate organic forms, and even recreate intricate sculptures. This advanced technique proves especially useful for creating decorative elements like floral motifs, architectural embellishments, and personalized engravings. Whether you’re crafting a unique piece of furniture or creating artwork, 3D carving and sculpting using CNC on wood will undoubtedly impress your viewers with its precision and intricacy.

Inlays And Joinery Methods

Inlays and joinery methods take CNC on wood to a whole new level by incorporating different materials and creating seamless connections in your designs. This technique involves cutting precise grooves or pockets into the wood surface to insert contrasting materials like metal, acrylic, or other types of wood. By combining different materials, you can enhance the visual appeal and add unique details to your woodworking projects.

Inlaying materials into wood not only enhances the overall aesthetics but also provides functional benefits. Inlays can be used to strengthen joints, add durability, and improve the structural integrity of your woodwork. By using CNC on wood to incorporate inlays, you can achieve precise and flawless results that may be difficult to attain using traditional woodworking techniques.

Joinery methods, such as dovetail joints or mortise and tenon joints, can also be accomplished with CNC on wood. These methods offer strong and aesthetically pleasing connections between different wood pieces. Whether you’re constructing furniture or assembling intricate wooden structures, using CNC to create joinery methods ensures a precise fit and long-lasting durability.

Finishing Touches For A Professional Look

When it comes to CNC on wood projects, the finishing touches play a crucial role in achieving a professional look. By paying attention to the details in sanding, smoothing, staining, and sealing, you can elevate the overall appearance of your woodwork. Let’s dive into some effective techniques for achieving a polished, professional finish.

Sanding And Smoothing Techniques

Effective sanding and smoothing are essential for creating a professional look on CNC wood projects. Begin with an 80-grit sandpaper to remove any rough edges or imperfections, then progress to finer grits such as 120 and 220 to achieve a smooth surface. Take care to sand evenly and in the direction of the wood grain, ensuring a uniform finish. Lightly round edges for a professional touch and use a tack cloth to remove any sanding residues before proceeding to the staining phase.

Staining And Sealing Methods

Once the wood is meticulously sanded and smoothed, it’s time to apply a suitable stain to enhance the natural beauty of the wood. Choose a stain that complements the wood’s grain and apply it evenly with a brush or cloth, following the direction of the grain. After allowing the stain to penetrate the wood for the recommended time, seal the surface with a clear topcoat or varnish to protect the finish and add a professional luster. For a flawless result, apply the sealant in thin, even coats, allowing each layer to dry completely before adding the next.

Inspiring Projects To Try

Ready to get inspired and take your CNC wood projects to the next level? Check out these inspiring projects to try, from custom sign making to home decor and furniture projects. Get your creative juices flowing and start creating stunning pieces with CNC on wood!

Custom Sign Making

Custom signs are a fantastic way to add a personal touch to any space. Whether it’s for your business, a special event, or home decor, CNC technology opens up a world of possibilities for creating unique, eye-catching signs. From intricate designs to bold lettering, custom sign making offers endless opportunities to express creativity and make a visual impact.

Furniture And Home Decor Projects

Elevate your space with furniture and home decor projects crafted with CNC on wood. Create custom shelving, unique wall art, or one-of-a-kind furniture pieces that reflect your personal style. The precision of CNC allows for intricate detailing and seamless assembly, resulting in professional-quality pieces that will impress and enhance any interior.

Safety Measures And Maintenance

- Wear safety goggles to protect eyes from wood chips.

- Use earplugs to prevent hearing damage from machine noise.

- Wear a dust mask to avoid inhaling wood particles.

- Wear sturdy gloves to protect hands and improve grip.

- Regularly clean CNC machine to prevent dust buildup.

- Check and tighten all bolts and screws for secure operation.

- Lubricate moving parts according to manufacturer’s guidelines.

- Inspect cutting tools for wear and tear, replace if necessary.

Frequently Asked Questions On Cnc On Wood

What Are The Benefits Of Using Cnc On Wood?

CNC machining on wood offers precise carving, intricate designs, and customized patterns. It ensures consistent quality, reduces manual errors, and enhances productivity, making it ideal for woodworking projects.

How Does Cnc On Wood Differ From Traditional Woodworking Methods?

Unlike traditional woodworking, CNC carving on wood utilizes computer-controlled machines to achieve precise and intricate designs, ensuring consistent quality. It reduces human error, saves time, and allows for complex patterns that may be challenging using traditional methods.

What Types Of Wood Are Suitable For Cnc Machining?

A variety of woods, including oak, maple, cherry, and walnut, are suitable for CNC machining. Each wood type offers unique characteristics, such as hardness, texture, and grain patterns, allowing for diverse design possibilities and customization.

Are There Any Limitations To Using Cnc On Wood?

While CNC machining offers precision and accuracy, certain limitations include the size restrictions of the wood pieces that can be carved and the need for proper machine programming to ensure desired results. However, these limitations can be minimized with careful planning and expertise.

Conclusion

To sum up, CNC on wood offers a versatile way to unleash creativity and precision in woodworking. With the right tools and techniques, you can create intricate designs and exceptional finishes. Embracing CNC technology opens up a world of potential for woodworkers to elevate their craft and push boundaries.

Explore the possibilities and make your mark with CNC on wood.