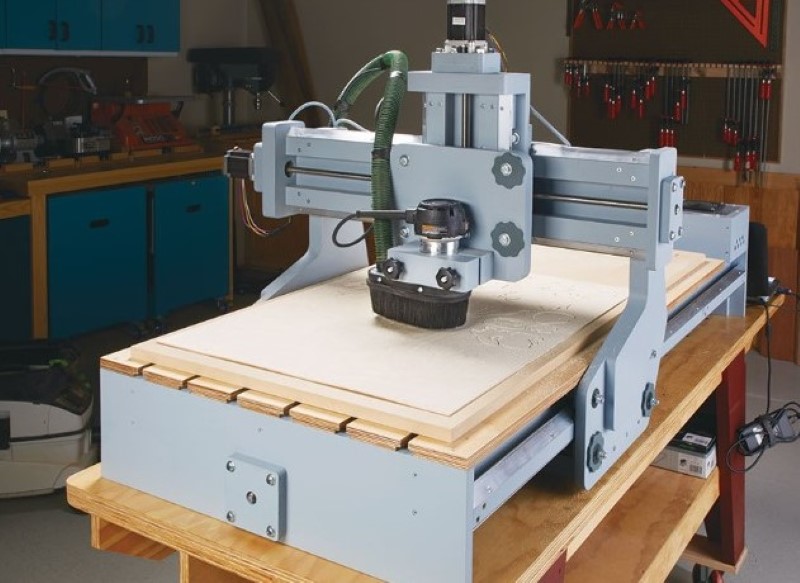

CNC wood carving machines are automated tools used for carving wood materials with precision and accuracy. These computer-controlled machines utilize various cutting and carving techniques to create intricate designs and patterns on wood surfaces.

Whether for hobbyists or professional woodworkers, CNC wood carving machines offer efficient and reliable performance in producing custom and detailed woodwork. With their versatile capabilities, these machines enable users to transform their artistic ideas into reality with ease and precision.

From intricate furniture design to decorative wood carvings, CNC wood carving machines are a valuable asset for any woodworking project.

Credit: buildyourcnc.com

Evolution Of Woodworking

Woodworking has evolved significantly with the introduction of CNC wood carving machines. These machines offer precise and efficient wood carving processes, revolutionizing the industry and allowing craftsmen to create intricate designs with ease.

The woodworking industry has undergone a remarkable evolution over the years, driven by innovative technologies that have revolutionized traditional woodcrafting techniques. From hand tools to power tools, the transition to computer numerical control (CNC) wood carving machines has fundamentally transformed the way woodworking is approached and executed.

Traditional Woodworking Techniques

Traditional woodworking encompassed manual processes, such as hand carving, chiseling, and sawing, requiring exceptional skill, precision, and time. Craftsmen meticulously shaped raw wood into intricate designs, a practice deeply rooted in the historical and cultural fabric of woodworking.

Introduction Of Cnc Wood Carving Machines

With the introduction of CNC wood carving machines, a new era of woodworking emerged. These computerized systems employ advanced design software and precision cutting tools to automate the carving and shaping of wood. They offer efficiency, accuracy, and the ability to create complex designs with remarkable detail, transforming the way woodworking projects are undertaken.

CNC wood carving machines have democratized woodworking, making the craft more accessible to enthusiasts and professionals alike. The digitization of designs and the automation of cutting processes have expanded the possibilities of what can be achieved with wood, allowing for intricate patterns, 3D reliefs, and custom designs that were previously painstaking and time-consuming to produce.

Understanding Cnc Wood Carving Machines

CNC wood carving machines revolutionize woodworking by automating intricate carving processes.

How Cnc Machines Work

CNC machines follow pre-programmed instructions to precisely carve designs on wood.

Types Of Cnc Wood Carving Machines

CNC wood carving machines come in various types such as 3-axis, 4-axis, and 5-axis machines.

Benefits Of Cnc Wood Carving Machines

Elevate Your Wood Carving Game with CNC Wood Carving Machines

CNC wood carving machines have revolutionized the woodworking industry, bringing a host of benefits that have made traditional methods seem archaic. These machines offer precise and accurate carving, high efficiency, and time savings, as well as the ability to create complex designs and intricate details effortlessly. Let’s explore these advantages in more detail:

Precision And Accuracy

One of the remarkable benefits of CNC wood carving machines is their exceptional precision and accuracy. These machines are equipped with advanced technology that allows them to carve with incredible detail and accuracy, down to the tiniest measurements. With CNC machines, you can consistently produce flawless carvings, ensuring that your finished pieces are of the highest quality.

Efficiency And Time Savings

When it comes to efficiency and time savings, CNC wood carving machines are unparalleled. These machines are designed to automate the carving process, eliminating the need for manual labor and reducing production time significantly. With CNC machines, you can produce multiple pieces simultaneously, increasing your productivity and saving valuable time.

Complex Designs And Intricate Details

The ability to create complex designs and intricate details is a game-changer for woodworkers. CNC wood carving machines can effortlessly carve intricate patterns, curves, and shapes that would otherwise be extremely time-consuming and challenging to achieve manually. Whether it’s intricate filigree or elaborate engravings, CNC machines make it possible to bring your creative vision to life with ease.

With CNC wood carving machines, you can take your woodworking skills to new heights. The precision and accuracy, efficiency and time savings, as well as the ability to create complex designs and intricate details, offer endless possibilities for woodworking enthusiasts and professionals alike.

Credit: www.woodsmith.com

Choosing The Right Cnc Wood Carving Machine

When it comes to CNC wood carving machines, selecting the right one can make a significant difference in the efficiency and quality of your woodworking projects. With numerous options available in the market, it can be overwhelming to decide which machine suits your specific needs. To help you make an informed decision, here are some considerations for selection and best practices for integration.

Considerations For Selection

Before choosing a CNC wood carving machine, it’s crucial to assess specific factors that align with your requirements. Considering these aspects can help you find a machine that optimizes your woodworking capabilities:

- Project Size: Determine the size of projects you intend to work on. Select a machine that can accommodate your projects while offering precise carving abilities.

- Accuracy: Look for a machine that delivers high accuracy and precision in carving. This ensures your final products meet your design specifications.

- Speed: Consider the speed at which the machine operates. A faster machine can enhance your productivity without compromising on quality.

- Software Compatibility: Check if the machine’s software is compatible with your existing design software or if it provides user-friendly design software for easy integration and workflow.

- Construction Quality: Assess the construction quality of the machine to ensure durability and stability during operation. A sturdy machine is less likely to experience vibrations that can impact carving precision.

- Budget: Finally, determine your budget and explore machines that offer the best value for your investment. While cost is an important factor, prioritizing features and performance is crucial.

Best Practices For Integration

After selecting the right CNC wood carving machine, integrating it effectively into your woodworking setup is key to achieving optimal results. Here are some best practices for seamless integration:

- Training: Invest time in acquiring training or attending workshops to understand the capabilities and nuances of operating the machine. This enables you to make the most of its functionalities.

- Design Preparation: Before carving, ensure your design files are compatible and properly prepared for the machine. This includes setting appropriate dimensions and tooling paths.

- Material Selection: Choose the right wood material that suits the requirements of your project. Different types of wood may have varying hardness, grain patterns, and carving characteristics.

- Tool Maintenance: Regularly maintain and sharpen the carving tools to ensure optimal performance, longevity, and consistent carving quality.

- Regular Calibration: Periodically calibrate the machine to maintain accurate carving results. This applies to both the machine itself and the software used.

- Safety Measures: Implement appropriate safety measures, such as wearing safety goggles and securing the workpiece correctly, to prevent accidents and injuries during carving.

Applications In Woodworking

Furniture Making

With CNC wood carving machines, furniture making is precise and efficient.

Art And Decorative Woodwork

Art and decorative woodwork benefit from the intricate detailing capabilities of CNC machines.

Architectural Elements

Architectural elements like moldings and trim are easily produced with CNC wood carving machines.

Mastering CNC wood Carving Techniques

Welcome to our blog post on mastering CNC wood carving techniques. Whether you are a hobbyist or a professional woodworker, mastering CNC wood carving techniques is essential for achieving precise and intricate designs. In this article, we will explore key elements that will help you enhance your CNC wood carving skills, including digital design and modeling, and toolpath optimization.

Digital Design And Modeling

Effective use of digital design and modeling software is crucial for creating intricate and detailed designs for CNC wood carving. Utilizing software such as AutoCAD or Fusion 360 allows you to design complex patterns and shapes with precision. Additionally, 3D modeling software enables you to visualize your designs before they are carved, ensuring that every detail meets your expectations.

Toolpath Optimization

Optimizing toolpaths is a critical part of mastering CNC wood carving techniques. By optimizing the toolpaths, you can minimize carving time and reduce waste material. This can be achieved by carefully planning the order in which the CNC machine will carve the design, as well as selecting the appropriate cutting tools and speeds for each operation. Efficient toolpath optimization not only enhances the overall quality of the carving but also improves productivity and material utilization.

Challenges And Solutions

CNC wood carving machines offer immense precision and efficiency in creating intricate designs, but they are not without their challenges. From maintenance to software, woodworkers encounter various hurdles in maximizing the potential of these machines.

Maintenance And Calibration

Maintaining CNC wood carving machines is crucial to ensure optimal performance. Regular cleaning, lubrication, and inspection of components such as spindles and tool holders are essential. Calibration of the machine’s axes, ensuring they are perpendicular and parallel, is vital for accurate carving.

Software And Programming Challenges

The complexity of software and programming can be daunting for users. Understanding CAD/CAM software and G-code programming requires training and expertise. Additionally, troubleshooting errors in the programming can be time-consuming and challenging.

Future Innovations In CNC Wood Carving

CNC wood carving machines have revolutionized the woodworking industry, offering precision and efficiency like never before. The future of CNC wood carving holds exciting possibilities, with advancements that are set to enhance automation and integration as well as material compatibility.

Automation And Integration

Automation in CNC wood carving machines is poised to streamline the entire woodworking process, from design to final product. Integration with design software will allow for seamless communication and precise execution, increasing production efficiency significantly.

Enhanced Material Compatibility

Future innovations in CNC wood carving will focus on enhancing material compatibility, allowing for a broader range of wood types and densities to be efficiently carved. This will open up new creative possibilities for woodworkers and expand the capabilities of CNC machines in the woodworking industry.

Frequently Asked Questions For Cnc Wood Carving Machines

What Are The Benefits Of Using Cnc Wood Carving Machines?

Using CNC wood carving machines enhances precision, efficiency, customization, and productivity in wood carving projects. It allows for intricate designs, reduces manual labor, and ensures consistency in finished products.

How To Maintain A Cnc Wood Carving Machine?

Regularly clean the machine, lubricate moving parts, calibrate the spindle, check for wear on cutting tools, and monitor software updates. Follow manufacturer guidelines for maintenance schedules and procedures to ensure optimal performance.

Can Beginners Use Cnc Wood Carving Machines?

Yes, beginners can use CNC wood carving machines with proper training and guidance. Many manufacturers offer tutorials, online resources, and training programs to help individuals of all skill levels learn how to operate and create with these machines.

Conclusion

To sum up, Cnc wood carving machines are revolutionizing the woodworking industry. Their precision and efficiency offer endless creative possibilities. Whether you are a hobbyist or a professional, investing in the right CNC machine can take your projects to the next level.

Explore the world of CNC carving today!