A cut-off saw and a band saw is different tools used for different cutting purposes. A cut-off saw is commonly used for cutting through materials such as wood, metal, or plastic, while a band saw is primarily designed for making curved or intricate cuts in a variety of materials.

Both tools have their advantages and limitations, and the choice between them depends on the specific cutting needs and requirements. Whether you need straight cuts or more intricate shapes, understanding the capabilities of each tool will help you make an informed decision.

We will provide a detailed comparison and highlight the key differences between a cut-off saw and a band saw to help you choose the right tool for your cutting tasks.

Comparison Of Cut Off Saw And Band Saw

When it comes to cutting tools, both cut-off saws and band saws play crucial roles in various industries. Understanding the differences between these two tools can help you determine which one suits your needs best. In this article, we will dive into the functionalities and applications of both cut-off saws and band saws, allowing you to make an informed decision.

What Is A Cut-Off Saw?

A cut-off saw, also known as a chop saw or abrasive saw, is a power tool widely used for cutting through a variety of materials such as metal, plastic, and wood. It consists of a circular blade mounted on a pivot arm, which is then connected to an electric motor. The blade spins at a high speed, effortlessly slicing through the workpiece with precision and accuracy.

What Is A Band Saw?

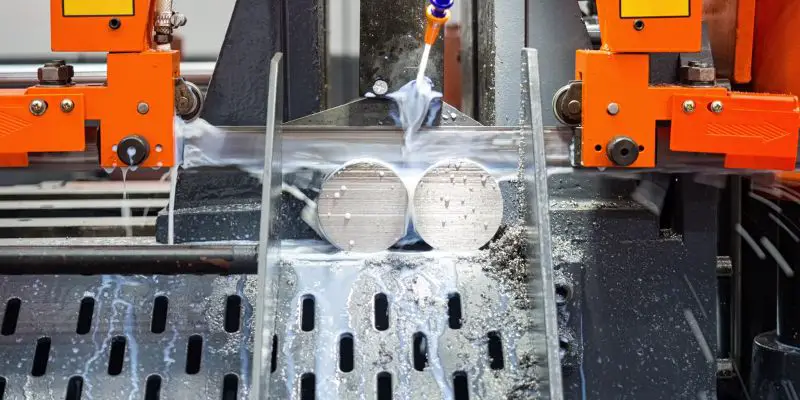

A band saw is another powerful cutting tool that operates using a continuous band of toothed metal, hence the name “band” saw. This tool is commonly used in woodworking, metalworking, and other industries that require intricate cuts. The blade of a band saw is stretched across two wheels, one of which is powered by an electric motor. As the workpiece is guided towards the blade, it smoothly cuts through the material, allowing for detailed and curved cuts.

Functionality And Applications of Off-Saw

A cut-off saw is renowned for its ability to make quick and precise cuts. Its functionality lies in its strong and durable blade, which is capable of slicing through tough materials with ease. The main applications of a cut-off saw include:

- Metal fabrication industries: Cut-off saws are extensively used in metal fabrication shops, as they can effortlessly cut through various metals, including steel, aluminum, and iron.

- Construction sites: Cut-off saws are essential tools in construction sites, allowing workers to quickly and accurately cut materials such as pipes, concrete, and bricks.

- Woodworking: Although primarily designed for metal cutting, some cut-off saws can also be used to cut wood, making them versatile tools in woodworking projects.

Functionality And Applications Of Band Saw

Band saws are known for their versatility and precision, making them indispensable in several industries. Some key functionalities and applications of a band saw include:

- Woodworking: Band saws are commonly used in woodworking, particularly for cutting curves, intricate designs, and rip cuts. They provide greater control and accuracy compared to other cutting tools.

- Metalworking: With appropriate blade adjustments and coolant, band saws can efficiently cut through various types of metals with high precision.

- Resawing: Band saws excel at resawing, which involves cutting a thick workpiece into thinner pieces. They are used in furniture making, veneer production, and lumber processing.

- Meat cutting: Band saws are widely employed in the meat processing industry to cut large pieces of meat, bones, and frozen food products.

Factors To Consider When Choosing A Power Tool

When it comes to purchasing a power tool, there are several factors that you need to take into consideration. Whether you are a DIY enthusiast or a professional contractor, choosing the right power tool can greatly impact the quality and efficiency of your work. In this blog post, we will discuss the factors you should consider when deciding between a cut-off saw and a band saw. These factors include the type of material you will be working with, the level of accuracy and precision required, the size and portability of the tool, your budget and cost constraints, as well as the safety features offered.

Type Of Material

The type of material you will be cutting is an essential factor to consider when choosing between a cut-off saw and a band saw. Both types of saws have their strengths and weaknesses in handling different materials. For example, a cut-off saw, also known as a chop saw, is ideal for cutting through hard materials such as metals and masonry. On the other hand, a band saw is better suited for cutting through softer materials like wood and plastic. Therefore, it is crucial to assess the nature of your project and select the power tool that is most suitable for the materials you will be working with.

Accuracy And Precision

Accuracy and precision are vital aspects to consider when selecting a power tool. If your project requires intricate and detailed cuts, you should opt for a tool that offers high precision. A band saw, with its continuous cutting motion and adjustable blade width, provides more accurate cuts compared to a cut off saw that relies on a single, downward cutting motion. Additionally, band saws are equipped with features like miter gauges and rip fences that enhance their cutting precision. Therefore, if precision is of utmost importance in your project, a band saw would be the better choice.

Size And Portability

Size and portability are also significant factors to consider when choosing a power tool. Cut-off saws tend to be heavier and bulkier compared to band saws. If your work requires you to move around frequently or work in tight spaces, a smaller and portable tool like a band saw would be more suitable. Band saws are often compact and lightweight, allowing for easy maneuverability and transportation. However, if you have a dedicated workspace and need a tool for heavy-duty applications, a larger cut-off saw might be the better option.

Budget And Cost

It is crucial to consider your budget and cost limitations when purchasing a power tool. Cut-off saws are generally more affordable compared to band saws. If you are on a tight budget, a cut-off saw could be a cost-effective choice. However, it is important to note that band saws offer more versatility and capabilities for different types of cuts and materials. Therefore, if your project demands a wider range of cutting options, it might be worth investing in a band saw despite the higher price tag.

Safety Features

The safety features provided by a power tool should never be overlooked. Both cut-off saws and band saws come with safety features to protect the user during operation. Cut-off saws often include features such as blade guards, spark deflectors, and emergency stop mechanisms to ensure safe use. Band saws typically have safety features like blade tensioning devices, blade guards, and anti-kickback pawls. It is essential to thoroughly review the safety features of each tool and choose the one that provides the highest level of protection to minimize the risk of accidents or injuries.

Frequently Asked Questions For Cut-Off Saw Vs Band Saw

What Is A Cut-Off Saw?

A cut-off saw, also known as a chop saw or abrasive saw, is a power tool used to make precise cuts in metal, masonry, and other materials. It features a high-speed rotating blade that cuts through the material cleanly and efficiently.

What Is A Band Saw?

A band saw is a power tool consisting of a continuous band of toothed metal that is stretched between two or more wheels. It is primarily used for cutting curves in wood, metal, and other materials. The blade’s teeth make rapid downward and forward motions, creating precise cuts.

How Does A Cut-Off Saw Work?

A cut-off saw works by spinning a cutting disc at a high speed. When the material is pressed against the disc, it cuts through it quickly. The blade’s teeth make rapid downward and forward motions, creating precise cuts.

How Does A Band Saw Work?

A band saw operates by driving a continuous loop of toothed metal, known as a blade, around two or more wheels. When the material is fed into the blade, the teeth grip it and draw it into the blade, creating a clean and accurate cut.

Conclusion

To sum it up, both the cut-off saw and the band saw have their own set of advantages and uses. While the cut-off saw is perfect for fast and precise straight cuts on tough materials, the band saw offers versatility and the ability to make curved cuts.

Ultimately, the choice between the two depends on your specific project needs and budget. So, make your decision wisely and enjoy a seamless cutting experience.