How is Veneer Made: The Step-by-Step Process Explained

Veneer is a thin slice of wood. It is used in furniture and interiors.

But how is veneer made? The process is fascinating and detailed. Veneer production begins with selecting the right logs. These logs are then debarked and softened, usually by steaming or soaking in hot water. This makes the wood pliable for the next steps.

Afterward, the logs are sliced into thin sheets using specialized machines. These sheets are then dried to reduce moisture content. Finally, the veneer sheets are trimmed, sorted, and graded based on quality. The entire process ensures that each sheet of veneer is usable and aesthetically pleasing. Understanding how veneer is made can help you appreciate the craftsmanship behind your wooden furniture.

Introduction To Veneer

Veneer is a thin layer of wood. It is used to cover other materials. The veneer is often around 0.6 mm thick. It can be made from many types of wood. Common choices are oak, walnut, and maple. Each type has its own look and feel. Veneer gives furniture a smooth, finished look. It can also be used in flooring and walls. Veneer is popular because it is cost-effective. It allows the use of expensive wood in a budget-friendly way.

Veneer is used in many ways. It is common in furniture making. It adds a nice finish to tables and cabinets. Veneer is also used in flooring. It gives floors a rich, wooden look. Another use is in wall paneling. It can make a room look elegant. Veneer can even be used in musical instruments. It makes them look beautiful.

Credit: www.woodbois.com

Selecting The Timber

Only the best logs are picked for veneer. These logs need to be straight and strong. They should have few knots or defects. Experts look for logs with good color and grain. The right logs ensure a smooth veneer finish. Logs are checked for moisture content too. Dry logs are not good for veneer.

Many kinds of wood are used for veneer. Oak, maple, and walnut are popular choices. Each wood type offers a unique look. Some veneers are made from exotic woods. These include teak and mahogany. Using different woods adds variety to veneers. Softwoods and hardwoods both can be used. The choice depends on the desired finish.

Preparing The Logs

First, logs are placed on a machine. This machine removes the bark. Bark must be removed for the next steps. Bark can damage tools used later. The machine spins the log. Then, blades scrape off the bark. The log is then smooth and clean.

Logs are cut to a certain length. This length makes them easier to handle. Each log is measured first. The ends are cut off if they are damaged. Then, they are cut to the right size. This makes the logs ready for the next step.

Soaking And Steaming

The wood must be soft for veneer making. Soaking and steaming help in this process. Soaking involves placing the wood in water. This makes the wood fibers swell. Steaming heats the wood. This makes the fibers more flexible. Soft wood is easy to slice into thin sheets. Both methods are important. They make sure the wood does not crack.

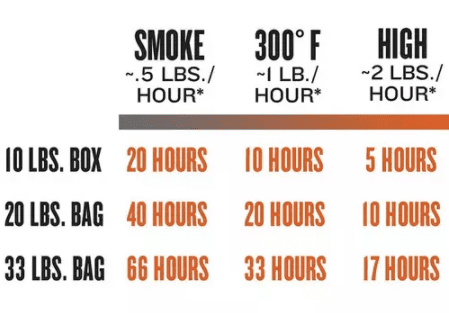

Time and temperature are key in soaking and steaming. Wood must soak for hours or even days. The longer it soaks, the softer it gets. Temperature control is also vital. Too hot and the wood may burn. Too cold and it won’t soften. Both factors need careful balance. This ensures the best quality veneer.

Slicing The Veneer

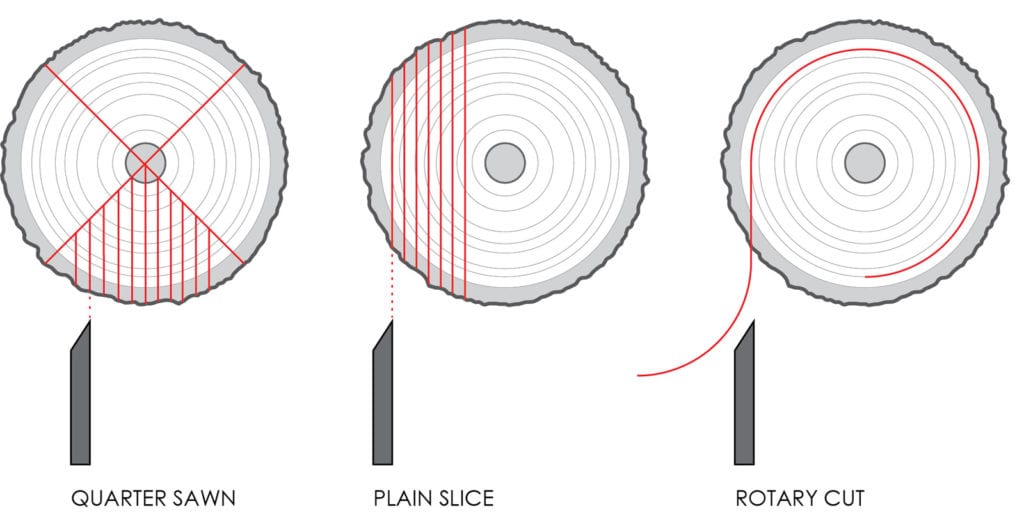

Rotary cutting involves a log being rotated on a lathe. A sharp blade peels off a thin layer. This method creates wide sheets of veneer. The grain pattern is circular and broad. Rotary cutting is fast and efficient. It minimizes waste and is cost-effective. The process is used for making plywood.

Plain slicing cuts logs in parallel lines. The blade moves up and down. This creates a straight grain pattern. Plain slicing shows the natural beauty of wood. Quarter slicing cuts logs at a right angle. It reveals the growth rings. The grain pattern is tight and uniform. This method is more precise and detailed. It is often used for fine furniture.

Credit: www.keywaydesigns.com

Drying The Veneer

Drying veneer is a key step. Two main methods are used. One is air drying. The other is kiln drying. Air drying takes longer. Kiln drying is faster. Both methods remove water from the veneer. Proper drying is essential.

Controlling moisture is very important. Too much water can ruin veneer. Too little water can cause cracks. Checking moisture levels is a must. Keeping the right balance ensures quality. This makes the veneer strong and durable.

Grading And Sorting

Veneer quality grading is essential. Each piece is checked. Flaws like knots or discoloration are noted. High-quality veneers have few flaws. Lower grades might have more defects. This grading helps in pricing.

Sorting ensures uniformity. Veneers are grouped by color and pattern. This makes sure the final look is consistent. Uniform veneers are used in high-end furniture. Non-uniform ones might go to less visible areas. Sorting is a key step in quality control.

Credit: www.finewoodworking.com

Final Processing

Final processing of veneer involves drying, trimming, and sanding. This ensures the veneer is smooth and ready for use.

Trimming And Sanding

Veneer sheets are trimmed to the desired size. This step ensures they fit the required dimensions. Sanding makes the surface smooth. Smooth surfaces are important for a good finish. Sanding removes rough spots and small imperfections. Both trimming and sanding are crucial for quality veneer.

Packaging And Storage

Finished veneer sheets are carefully packed. Packing prevents damage during transport. Sheets are stacked and wrapped. They are stored in a dry place. Proper storage keeps the veneer in good condition. Moisture can damage the veneer. So, keeping it dry is key. This ensures the veneer stays in top shape until use.

Frequently Asked Questions

What Is Veneer Made From?

Veneer is made from thin slices of natural wood. These thin slices are typically glued onto core panels like plywood, particleboard, or MDF.

How Is Veneer Manufactured?

Veneer is manufactured by slicing logs into thin sheets. These sheets are then dried, glued, and pressed onto core materials for various applications.

What Types Of Wood Are Used For Veneer?

Various types of wood are used for veneer, including oak, maple, cherry, and walnut. The choice of wood depends on the desired appearance and application.

Is Veneer Eco-friendly?

Yes, veneer is considered eco-friendly. It uses less wood compared to solid wood products, reducing the demand for timber and preserving forests.

Conclusion

Veneer making is a fascinating process. It starts with selecting quality logs. Then, skilled workers slice or peel them into thin sheets. These sheets get dried, pressed, and trimmed. Finally, they become the beautiful veneer seen in furniture and interiors.

Understanding this process helps appreciate the craftsmanship. Next time you see veneer, remember the work behind it. Now, you can share this knowledge with others!