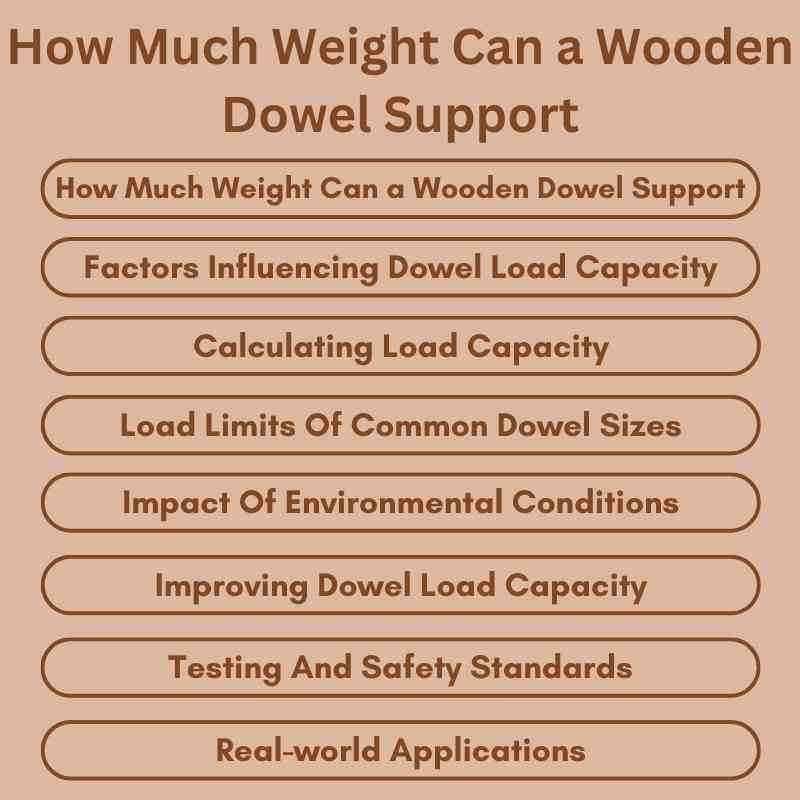

How Much Weight Can a Wooden Dowel Support? Load Limits Revealed

A wooden dowel can typically support between 20 to 50 pounds, depending on its diameter and type of wood. Factors like the length of the dowel and how it’s used also affect its weight capacity.

Wooden dowels are versatile tools found in various applications, from crafts to furniture making. Understanding their weight-bearing capacity is crucial for safe and effective use. Different wood types, such as oak or pine, contribute to the dowel’s strength. The diameter plays a significant role; thicker dowels generally support more weight.

Proper installation techniques can enhance their load-bearing abilities. Whether for DIY projects or professional craftsmanship, knowing how much weight a wooden dowel can support ensures durability and safety. This knowledge helps avoid mishaps in projects involving shelving, supports, or decorative elements.

Introduction To Wooden Dowels

Wooden dowels are important tools in construction. They provide strength and stability to various projects. Dowels help join materials together securely. They are often used in furniture making and cabinetry.

Different types of wood can be used for dowels. Common woods include oak, pine, and maple. Each type has its own strength and flexibility. Oak dowels are strong and great for heavy loads. Pine dowels are lightweight and easy to work with. Maple dowels offer a smooth finish and are often used for visible joints.

Factors Influencing Dowel Load Capacity

Wood species play a big role in the strength of a dowel. Hardwoods, like oak and maple, usually hold more weight. Softwoods, such as pine, are generally less sturdy.

The diameter and length of the dowel also matter. A thicker dowel can support more weight. Shorter dowels are often stronger than longer ones. Always choose the right size for your project.

| Wood Species | Strength Rating |

|---|---|

| Oak | High |

| Maple | High |

| Pine | Moderate |

Calculating Load Capacity

To find the load capacity of a wooden dowel, use basic formulas. Start by knowing the dowel diameter and wood type. Different woods have different strengths. Common woods include pine, oak, and maple.

The basic formula for load capacity is:

- Load Capacity = Diameter x Length x Wood Strength Factor

For example, a 1-inch dowel made of oak might support a load of 50 pounds. A 1-inch dowel made of pine might hold only 30 pounds. Always check the wood’s strength rating for accurate results.

Performing these calculations helps ensure safety and effectiveness in your projects.

Load Limits Of Common Dowel Sizes

Small dowels</strong are usually 1/8″ to 1/4″ in diameter. They work well for light projects. These dowels typically support about 10 to 30 pounds. Common uses include crafts and small furniture.

Large dowels range from 1/2″ to 1″ in diameter. They can hold much heavier loads. Large dowels can support up to 100 pounds or more. Use them for structural support in furniture and larger projects.

| Dowel Size | Weight Limit | Common Uses |

|---|---|---|

| Small (1/8″ – 1/4″) | 10 – 30 pounds | Crafts, small furniture |

| Large (1/2″ – 1″) | 100+ pounds | Structural support, larger projects |

Impact Of Environmental Conditions

Wooden dowels can be affected by moisture and temperature. High moisture can cause swelling. This reduces the dowel’s strength. Low humidity may lead to shrinkage. Shrinkage can create gaps in joints.

Temperature changes can also affect dowels. Extreme heat may weaken the wood. Cold can make it brittle. Long-term exposure to these conditions can lead to failure. Proper storage is essential for maintaining the dowel’s strength.

Consider using sealants to protect the wood. Sealants can help prevent moisture damage. Storing dowels in a stable environment is also important. This ensures durability and strength over time.

Improving Dowel Load Capacity

Wooden dowels can support different weights based on their treatment and coatings. Special treatments can enhance their strength. For example, heat treating makes dowels stronger and more durable.

Coatings like epoxy or polyurethane add protection from moisture. This prevents warping and extends the dowel’s life. Choosing the right coating is crucial for heavy loads.

| Type of Dowel | Weight Capacity (approx.) |

|---|---|

| Untreated Wooden Dowel | 10-20 LBS |

| Heat-Treated Dowel | 20-40 LBS |

| Composite Dowel | 30-50 LBS |

Composite dowels offer high strength and low weight. They resist splitting and bending. Using these dowels can improve overall project durability.

Testing And Safety Standards

Wooden dowels must meet strict safety standards. Different methods test their strength. Common tests include compression, tension, and shear tests. Each method checks how much weight a dowel can hold.

Industry testing often follows specific protocols. These ensure that dowels are safe for use. Dowels must also adhere to local building codes. These codes protect users and ensure structural integrity.

| Testing Method | Purpose |

|---|---|

| Compression Test | Measures how much weight the dowel can withstand when pressed. |

| Tension Test | Checks how much pulling force the dowel can handle. |

| Shear Test | Determines the dowel’s ability to resist sliding forces. |

Real-world Applications

Wooden dowels are often used in many real-world applications. They are common in furniture making and crafts. In these cases, the weight capacity is crucial.

One study showed that a 1-inch dowel can support about 50 pounds. Another case involved a 3/4-inch dowel supporting 30 pounds in a shelving unit. Both cases highlight the importance of proper sizing.

| Case Study | Dowel Size | Weight Supported |

|---|---|---|

| Furniture Making | 1 inch | 50 pounds |

| Shelving Unit | 3/4 inch | 30 pounds |

Experts recommend testing dowels with weights before final use. This ensures they meet the required strength. Safety is always a top priority.

Frequently Asked Questions

How Much Weight Can A Wooden Dowel Hold?

The weight a wooden dowel can support varies by diameter and wood type. Generally, a standard 1-inch diameter dowel can hold around 20 to 30 pounds. However, this can change depending on the dowel’s length and the method of load distribution.

Always consider these factors for optimal performance.

What Factors Affect Dowel Weight Capacity?

Several factors influence a dowel’s weight capacity. The dowel’s diameter, length, and material type play significant roles. Additionally, how the load is applied—whether it’s evenly distributed or concentrated—affects strength. Understanding these variables will help you choose the right dowel for your project.

Can I Use Dowels For Heavy-duty Projects?

Yes, dowels can be used for heavy-duty projects if chosen wisely. Opt for larger diameter dowels made from sturdy materials like hardwood. Reinforcing joints with adhesive or using multiple dowels can also enhance strength. Always test your setup to ensure it meets your weight requirements.

Are All Wooden Dowels The Same Strength?

No, not all wooden dowels are the same strength. Different wood types have varying densities and structural integrity. For instance, oak is stronger than pine. Always check the specifications of the dowel to ensure it meets your specific needs for strength and durability.

Conclusion

Understanding the weight capacity of wooden dowels is crucial for various projects. Factors like material, diameter, and length all play significant roles. By carefully considering these elements, you can ensure your projects are safe and effective. Always test your dowels before use to avoid any mishaps and achieve the best results.