The LVL weight calculator allows you to accurately determine the weight of Laminated Veneer Lumber. LVL, or Laminated Veneer Lumber, is a popular engineered wood product known for its strength and versatility.

LVL (Laminated Veneer Lumber) Weight Calculator

It is commonly used in the construction industry for beams, headers, and other load-bearing applications. Determining the weight of LVL is essential for structural considerations and transportation planning. Thankfully, there are LVL weight calculators available that provide accurate measurements. By inputting specific dimensions and the type of LVL being used, these calculators can quickly estimate the weight of the lumber.

This information allows builders, architects, and engineers to make informed decisions and ensure the safety and efficiency of their projects. Understanding the weight of LVL is crucial for proper load calculations and structural integrity.

Composition Of Lvl

When it comes to understanding the composition of Laminated Veneer Lumber (LVL), it’s important to consider the key elements that make up this sturdy and versatile engineered wood product. LVL is engineered using layers of wood veneer and adhesive materials, resulting in a strong and durable material that is commonly used in construction and woodworking projects. Let’s delve deeper into the composition of LVL and explore the layers of veneer and the adhesive material used in its construction.

Layers Of Veneer

The layers of veneer in LVL play a crucial role in its structural integrity. Typically, an odd number of veneer layers are stacked and bonded together to form a strong and balanced composite material. These veneer layers are carefully selected to ensure uniformity in grain direction, minimizing any potential weak spots and enhancing the overall strength of the LVL product.

Adhesive Material

The adhesive material used in the manufacturing of LVL is a key component that holds the layers of veneer together. Often, phenol formaldehyde resins are used due to their exceptional bonding properties, which contribute to the high strength and stiffness of LVL. By effectively bonding the veneer layers, the adhesive material enhances the overall performance and load-bearing capacity of LVL.

Add your SEO-friendly content here

Credit: www.umass.edu

Factors Affecting Lvl Weight

The weight of laminated veneer lumber (LVL) is influenced by several factors, including the type and density of wood used, glue content, layer thickness, and resin application. These variables determine the weight and overall strength of the LVL product, impacting its suitability for specific construction applications.

Factors affecting LVL weight play a crucial role in determining the suitability of this versatile building material for different applications. Understanding these factors helps architects, engineers, and builders make informed decisions while using Laminated Veneer Lumber in their projects. In this section, we will explore the two key factors that significantly impact LVL weight: density of wood and thickness of layers.

Density Of Wood

The density of wood, measured in pounds per cubic foot, is a major factor influencing the weight of Laminated Veneer Lumber. Different species of wood have varying densities, which directly affect the weight of the final product. Woods with higher densities generally result in heavier LVL.

To put it in perspective, consider the density range of some common wood species typically used in LVL production:

| Wood Species | Density (lbs/ft3) |

|---|---|

| Southern Yellow Pine | 35 – 45 |

| Douglas Fir | 25 – 33 |

| Spruce-Pine-Fir | 25 – 30 |

The density of LVL can be estimated based on the wood species used and their respective densities. Higher density woods will result in heavier LVL, while lower density woods will yield lighter LVL.

Thickness Of Layers

Another important factor affecting LVL weight is the thickness of the layers used in its construction. LVL is made by bonding thin layers of wood veneers together, with each veneer contributing to the overall weight of the LVL beam or panel. As a general rule, the thicker the individual layers, the heavier the LVL product.

When it comes to LVL weight, the thickness of each layer can vary depending on the manufacturer’s specifications and the intended use of the LVL. While there is no definitive set thickness, as it depends on the requirements of the project, standard LVL thicknesses typically range from 1.125 inches to 3.5 inches.

In addition to the density of wood and the thickness of layers, other factors such as the adhesive used and moisture content can also influence the weight of LVL. However, the density of wood and the thickness of layers remain the primary considerations in determining the weight of Laminated Veneer Lumber.

By carefully considering these factors, architects, engineers, and builders can make informed decisions when utilizing LVL in their projects, ensuring optimal structural integrity and desired weight specifications. Whether it’s constructing beams for residential homes, manufacturing industrial flooring, or designing innovative furniture, understanding the factors that affect LVL weight is crucial for achieving successful outcomes.

Calculating Lvl Weight

Calculating the weight of Laminated Veneer Lumber (LVL) is an essential step in any construction or engineering project. By accurately determining the weight of LVL beams and panels, builders and architects can ensure the structural integrity and safety of their designs. In this section, we will explore the methods and tools available for calculating LVL weight, including the formula for weight calculation and online LVL weight calculators.

Formula For Weight Calculation

Calculating the weight of LVL can be done using a simple formula that takes into account the density of the material:

| Formula: |

|---|

| Weight (lbs) = Volume (ft3) x Density (lbs/ft3) |

In this formula, the volume of the LVL is multiplied by the density of the material to obtain the weight in pounds (lbs). The volume can be calculated by multiplying the cross-sectional area of the LVL by its length.

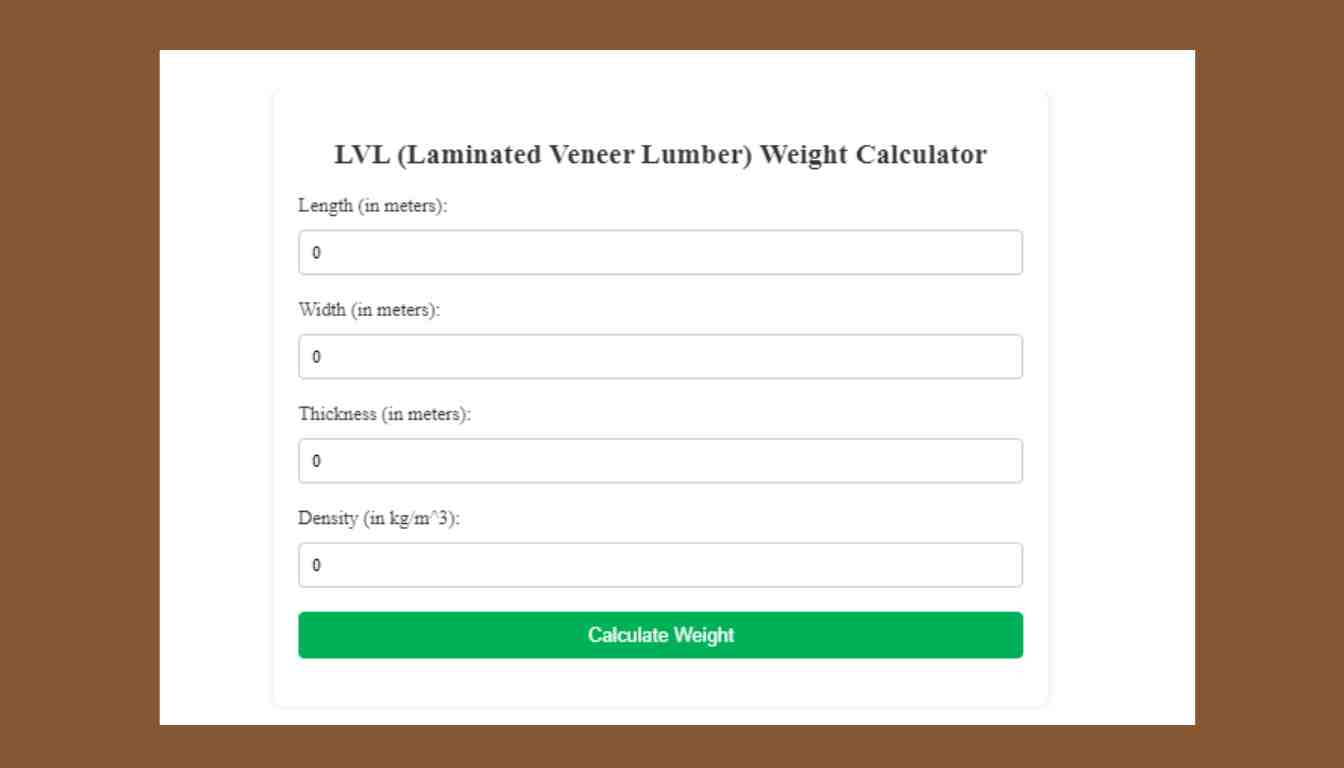

Online Lvl Weight Calculators

If you prefer a simpler and more convenient method to calculate the weight of LVL, you can utilize online LVL weight calculators. These tools are readily available on various websites and provide instant calculations without the need for manual formulas.

Online LVL weight calculators typically require you to input the dimensions and grade of the LVL, and they will instantly provide you with the weight in pounds (lbs) or kilogram (kg).

Some websites even offer advanced calculators that consider additional factors such as moisture content and specific gravity to provide more accurate weight calculations. These calculators can be especially useful in scenarios that require precise weight estimations.

When using online LVL weight calculators, it’s important to double-check the input values to ensure accuracy. Additionally, it’s recommended to use calculators from reputable sources or consult with professionals familiar with LVL weight calculations to ensure reliability.

Applications Of Lvl

Laminated Veneer Lumber (LVL) is a versatile and practical material that finds numerous applications in various industries. Understanding the applications of LVL is essential in maximizing its benefits. Let’s delve into the specific uses of LVL and explore how this innovative material plays a vital role in different sectors.

In Construction Industry

LVL is widely utilized in the construction industry for its exceptional strength and durability. It is commonly employed in structural applications as beams, headers, and joists. The consistent and reliable properties of LVL make it an ideal choice for supporting heavy loads in building projects.

In Furniture Making

LVL is also favored in the furniture-making industry for its versatility and stability. It provides a strong and stable foundation for furniture pieces such as tables, chairs, and cabinets, ensuring long-lasting performance and quality craftsmanship. Additionally, LVL’s uniform composition makes it suitable for creating intricate designs and shapes, enhancing the aesthetic appeal of the furniture.

Comparing Lvl Weight With Other Building Materials

Laminated Veneer Lumber (LVL) is a popular choice in construction projects due to its strength and versatility. Let’s compare LVL weight with other common building materials to understand its advantages further.

Comparison With Solid Timber

LVL weight is comparable to solid timber, but it offers more consistent performance and can often support heavier loads.

- LVL is lighter in weight than solid timber, making it easier to handle during construction.

- LVL’s uniform strength properties make it a reliable choice for structural applications.

Comparison With Steel Beams

When comparing LVL weight with steel beams, LVL is significantly lighter while still providing excellent structural support.

- LVL is less dense compared to steel, making it a preferred choice for projects where weight is a concern.

- The ease of installation of LVL compared to steel beams can save time and labor costs.

Benefits Of Using Lvl

LVL (Laminated Veneer Lumber) is a versatile construction material with numerous benefits that make it a popular choice for various building projects. Let’s explore the advantages of using LVL, including its Strength and Durability and Cost-effectiveness.

Strength And Durability

- LVL exhibits incredible strength, making it suitable for heavy load-bearing applications.

- Its superior durability ensures long-term structural integrity even in challenging environments.

- Resistant to warping, twisting, and splitting, LVL provides consistent performance over time.

Cost-effectiveness

- LVL offers cost savings compared to traditional lumber due to its efficient use of resources.

- Reduced installation time contributes to lower labor costs, making it a budget-friendly option.

- Longevity and minimal maintenance requirements further enhance the overall cost-effectiveness of LVL.

Credit: www.yalongwood.com

Frequently Asked Questions Of Lvl (laminated Veneer Lumber) Weight Calculator

What Is Laminated Veneer Lumber (lvl)?

LVL is a strong engineered wood product made from thin layers of wood veneers bonded together for structural support in construction projects.

How To Use The Lvl Weight Calculator?

Enter the dimensions and quantity of LVL pieces to determine the total weight accurately, aiding in logistics and project planning.

What Are The Benefits Of Using Lvl In Construction?

LVL offers high strength, stability, and consistency, making it ideal for beams, headers, and other load-bearing structural elements.

Is Lvl Environmentally Friendly?

LVL is considered eco-friendly as it utilizes fast-growing and sustainable wood species, minimizing environmental impact while providing durable structural solutions.

Conclusion

Using a Laminated Veneer Lumber weight calculator simplifies construction planning. Understanding the weight of LVL beams aids in logistics and structural design, ensuring safety. By incorporating this tool, builders and engineers can optimize material usage, cost, and efficiency across various projects.

Explore the benefits of leveraging this dynamic calculator.