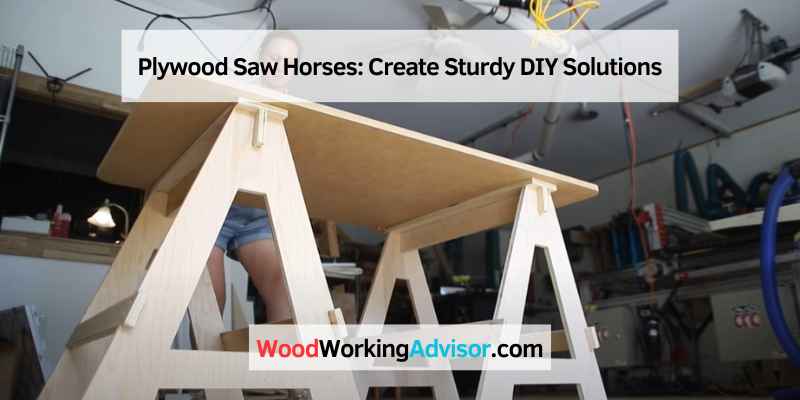

Plywood saw horses provide a stable and adjustable support for cutting plywood and other materials. They are versatile, durable, and easy to assemble.

Plywood saw horses are essential tools for any woodworking or construction project. Whether you’re a DIY enthusiast or a professional, having a reliable and sturdy support for cutting plywood and other materials is crucial. Plywood saw horses offer precisely that.

They are designed to provide a stable and adjustable platform, allowing you to make accurate and clean cuts. These saw horses are versatile, durable, and easy to assemble, making them a practical choice for any job site. We will delve into the features, benefits, and different types of plywood saw horses, helping you choose the right one for your needs. So, let’s explore the world of plywood saw horses and discover how they can enhance your woodworking experience.

Importance Of Plywood Saw Horses

Plywood saw horses are an essential tool for any woodworking enthusiast or professional. Not only do they provide a stable and secure surface for cutting and sawing, but they also offer several other important advantages that make them a must-have in any workshop. Let’s explore the versatility of plywood saw horses, as well as their cost-effectiveness.

Versatility Of Plywood Saw Horses

Plywood saw horses are incredibly versatile, offering a wide range of uses beyond their primary function. These sturdy stands can be used as makeshift workbenches, support platforms for heavy materials, or even as temporary tables for various projects. Their collapsible design allows for easy storage and transportation, making them ideal for on-site construction or outdoor jobs.

The adjustable height feature of plywood saw horses adds to their versatility. Whether you need a higher surface for precision cutting or a lower platform for assembling pieces, these saw horses can be easily adjusted to your desired height. This adaptability ensures maximum comfort and convenience, minimizing strain on your back and arms during extended work sessions.

Cost-effectiveness

When it comes to woodworking tools, cost is always a crucial factor. Plywood saw horses offer an affordable solution for a reliable and functional work surface. Constructed from durable plywood, these saw horses provide stability and support at a fraction of the cost of traditional workbenches or professional-grade stands.

Furthermore, plywood saw horses are incredibly long-lasting, meaning they will save you money in the long run. Unlike other options that may wear out quickly or require frequent repairs, these saw horses are built to withstand heavy use and demanding conditions, ensuring your investment goes a long way.

With the ability to make your own saw horses using basic tools and plywood, you can also save on purchasing pre-made ones. This do-it-yourself approach not only saves you money but also allows for customization, enabling you to adapt the dimensions and features of the saw horses to suit your specific needs.

| Benefits of Plywood Saw Horses: |

|---|

| 1. Versatile and multi-functional |

| 2. Adjustable height for added convenience |

| 3. Affordable and cost-effective |

| 4. Durable and long-lasting |

| 5. DIY option for customization |

In conclusion, plywood saw horses offer immense value to woodworkers of all levels. Their versatility, cost-effectiveness, and durability make them indispensable tools in any workshop or job site. Whether you are a DIY enthusiast or a professional carpenter, investing in quality plywood saw horses will undoubtedly enhance your woodworking experience.

Materials And Tools Needed

When building plywood sawhorses, the first step is gathering the necessary materials and tools. This section outlines the essential items required for constructing sturdy and reliable sawhorses for various woodworking projects.

Plywood Sheets

- 3/4 inch Plywood Sheets: Provide stability and durability. Use two sheets for each sawhorse.

- Saw: To cut plywood to the desired dimensions.

Saw, Screws, And Drill

- Circular Saw: For cutting the plywood sheets.

- Screws: Use 2 ½ inch wood screws for securing the joints.

- Drill: Necessary for driving the screws into the plywood.

Step-by-step Guide To Building Plywood Saw Horses

If you’re a DIY enthusiast or a professional woodworker, having a sturdy and reliable work surface is essential. Building your own plywood saw horses can provide the stability and support you need for various projects. To guide you through the process, here’s a step-by-step guide to building plywood saw horses.

Cutting The Plywood Sheets

Before you begin, gather your materials including a circular saw, measuring tape, and safety goggles. Start by measuring and marking the plywood sheets according to the desired saw horse dimensions. Using the circular saw, cut the plywood sheets into the appropriate pieces for the legs and top of the saw horses.

Assembling The Saw Horses

Once the plywood pieces are cut, it’s time to start assembling the saw horses. Begin by laying out the pieces and aligning them to ensure precise construction. Using a drill and screws, attach the legs to the top, creating a sturdy frame. Make sure to check for stability and adjust as needed before fastening the components securely.

Enhancing Stability And Durability

When it comes to plywood saw horses, enhancing stability and durability is crucial for efficient and safe use. By incorporating the right features, such as bracing, reinforcement, and non-slip elements, you can ensure that your saw horses are strong, sturdy, and capable of withstanding heavy loads. In this article, we will explore some key ways to enhance stability and durability for plywood saw horses.

Bracing And Reinforcement

One of the most effective ways to enhance stability is by incorporating bracing and reinforcement into the design of your plywood saw horses. This involves adding additional horizontal and vertical supports to the legs and the top of the saw horses to prevent wobbling and improve structural integrity.

Here are some ways you can enhance stability through bracing and reinforcement:

- Utilize diagonal braces to connect the legs of the saw horses, creating a stronger and more rigid structure.

- Add cross braces between the legs on the side and end panels to distribute the weight evenly and reduce the risk of tipping.

- Reinforce the top of the saw horses with plywood panels or metal brackets to provide additional support and prevent sagging under heavy loads.

Adding Non-slip Features

Another important aspect of enhancing stability is adding non-slip features to your plywood saw horses. These features not only prevent the material you are working on from sliding but also provide a secure footing for the saw horses themselves.

Consider the following non-slip features to improve stability:

- Attach rubber pads or non-slip materials on the top of the saw horses to provide traction and prevent your workpieces from slipping.

- Incorporate anti-slip feet or leveling devices at the bottom of the legs to ensure stability on uneven surfaces.

By taking these measures to enhance stability and durability, you can elevate the performance and reliability of your plywood saw horses. Bracing and reinforcement, along with non-slip features, will provide you with a solid foundation for various woodworking and construction projects.

Customization And Adjustability

Add functionality to your projects with customizable and adjustable plywood saw horses. The ability to modify heights, lengths, and configurations makes these sawhorses versatile for any task. Explore the options for tailoring these sawhorses to your specific needs.

Changing Heights And Lengths

- Adjust the height of the sawhorses to suit different working environments.

- Modify the length of the sawhorses to accommodate various project sizes.

Modifying For Specific Projects

- Customize the sawhorses for woodworking, construction, painting, or other tasks.

- Adapt the sawhorses with accessories like clamps, shelves, or tool holders.

Benefits Of Using Diy Plywood Saw Horses

DIY Plywood Saw Horses can be personalized to specific height and width requirements.

Customization allows for comfortable working positions and increased stability.

DIY Plywood Saw Horses offer significant cost savings compared to ready-made alternatives.

Choosing this option also promotes sustainability through reuse of materials.

Safety Measures And Tips

Discover essential safety measures and tips for working with plywood sawhorses. Ensure stability and prevent accidents by choosing sturdy pieces, setting a flat surface, and securing the wood properly. Stay safe during your projects with these helpful guidelines.

Secure Working Environment

When using plywood saw horses, ensure the work area is clear of clutter and debris to prevent tripping hazards and provide a stable foundation for the saw horses.

Always work in a well-lit area to enhance visibility and reduce the risk of accidents.

Proper Handling Of Tools

Handle all tools with care and follow the manufacturer’s instructions to avoid accidents and injuries.

- Keep saw blades sharp and in good condition for efficient cutting.

- Securely clamp the workpiece to the saw horses to prevent slipping during cutting.

Align and secure the plywood saw horses properly to ensure stability while cutting materials.

Frequently Asked Questions On Plywood Saw Horses

What Are The Advantages Of Using Plywood Saw Horses?

Plywood saw horses offer stability and durability, making them ideal for supporting heavy materials during woodworking projects. They are lightweight, portable, and easy to store, making them a convenient choice for DIY enthusiasts and professional carpenters alike.

How To Properly Maintain Plywood Saw Horses For Longevity?

To ensure the longevity of your plywood saw horses, regularly inspect them for any signs of wear or damage. Keep them clean and dry, and store them in a dry, well-ventilated area when not in use. Avoid exposing them to extreme temperatures or prolonged moisture to prevent warping or deterioration.

Can Plywood Saw Horses Be Customized For Specific Project Requirements?

Yes, plywood saw horses can be customized to meet specific project needs. You can adjust their height, width, and stability to accommodate different types of workpieces and tasks. This flexibility makes them a versatile tool for various woodworking and construction projects.

Conclusion

Plywood saw horses are versatile, affordable, and durable tools that every DIY enthusiast should consider adding to their workshop. Whether you are a professional carpenter or a hobbyist, these saw horses provide a stable and secure platform for cutting and sawing tasks.

With their adjustable height and portable design, they offer convenience and ease of use, making them an essential tool in any woodworking project. So, don’t overlook the benefits of plywood saw horses and elevate your woodworking game today.