Easily calculate the amount of premix concrete needed for your project with a premix concrete calculator. By entering the dimensions and depth, you can get an accurate estimation.

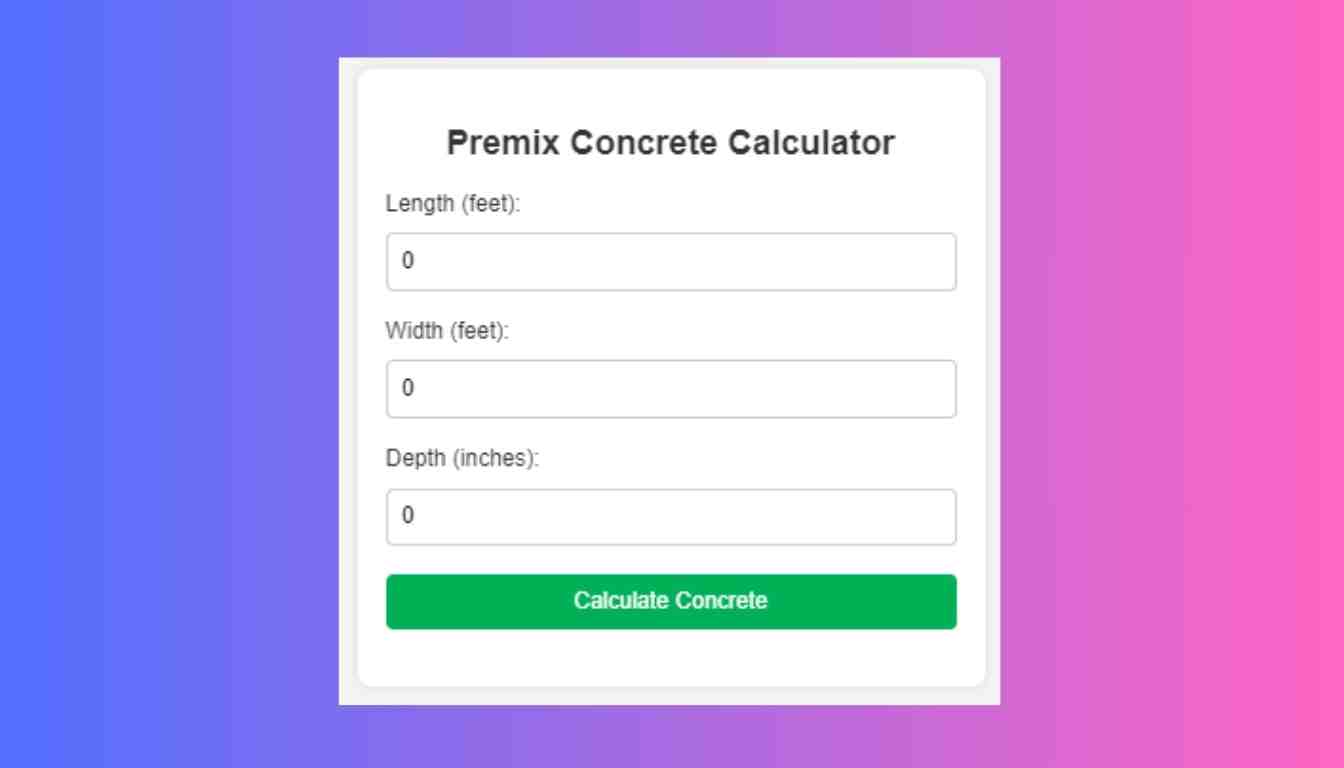

Premix Concrete Calculator

Planning a construction project and unsure about how much premix concrete to order? Utilizing a premix concrete calculator can simplify the process by providing you with the precise quantity required. Whether you’re working on a small DIY project or a large-scale construction endeavor, having a reliable tool like a premix concrete calculator at your fingertips can help you budget effectively and avoid wastage.

Let’s delve deeper into how these calculators work and why they are a valuable asset for anyone working with concrete.

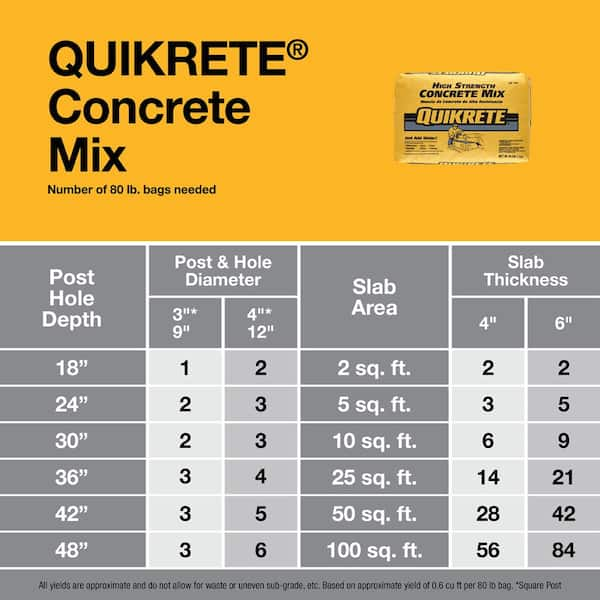

Credit: www.homedepot.com

What Is A Premix Concrete Calculator?

A premix concrete calculator is a tool that helps individuals and construction professionals determine the amount of concrete needed for a specific project.

By inputting the dimensions of the area to be filled with concrete, the calculator generates the exact quantity of premix concrete required.

It takes into account factors such as depth, width, and length of the area to provide accurate results.

How Does It Work?

The premix concrete calculator operates by calculating the volume of the concrete needed based on the dimensions provided by the user.

It then computes the quantity of premix bags required to fulfill the specified requirements.

Why Is It Useful?

Utilizing a premix concrete calculator saves time and money by ensuring the precise amount of concrete is ordered for a project.

It helps in preventing wastage and minimizes the risk of running out of materials during construction.

Key Components Of A Premix Concrete Calculator

A premix concrete calculator simplifies the process of estimating concrete needs for construction projects. The calculator is composed of essential elements that contribute to its functionality and accuracy. Let’s delve into the key components that make up a premix concrete calculator.

Digital Interface

- The digital interface of a premix concrete calculator is user-friendly and intuitive.

- It allows users to input specific measurements and obtain precise calculations swiftly.

Measurement Inputs

- Users enter measurements such as length, width, and depth of the concrete project.

- Accurate measurement inputs are crucial in determining the amount of concrete required.

Calculation Algorithm

| Calculation Algorithm: | The calculator employs a sophisticated algorithm to compute the exact amount of concrete needed. |

|---|---|

| Algorithm Accuracy: | The algorithm takes into account variables like project type and concrete mix ratio for precise results. |

Benefits Of Using A Premix Concrete Calculator

Utilizing a premix concrete calculator can offer a multitude of advantages, making it an invaluable tool for construction projects of any scale.

Accuracy

Precise measurements are vital in any construction project. A premix concrete calculator provides exact quantities, ensuring that you only order the required amount of concrete.

Time-saving

By swiftly computing the needed concrete quantities, a premix concrete calculator eliminates the time spent on manual calculations. This allows construction teams to optimize their schedule and focus on essential tasks.

Cost-effective

Efficiently managing concrete quantities translates to cost savings. With accurate measurements, there’s no wastage, ultimately leading to a more budget-friendly construction process.

Credit: www.quikrete.com

How To Use A Premix Concrete Calculator

Using a premix concrete calculator can greatly simplify your construction project by accurately determining the quantity of concrete required. This handy tool saves you time and money, ensuring you order the correct amount of concrete mix. By following these simple steps, you can easily utilize a premix concrete calculator to streamline your project planning and execution.

Step 1: Input The Project Details

Begin by inputting the necessary project details into the premix concrete calculator. These details typically include the dimensions of the area to be concreted, such as length, width, and depth. By precisely entering these measurements, the calculator can generate an accurate estimate of the concrete quantity required for your project.

Step 2: Select The Concrete Mix Type

Once you’ve entered the project details, it’s time to select the appropriate concrete mix type. Concrete mixes vary in strength and composition, depending on the nature of your project. The calculator will provide you with a range of options to choose from, typically categorized by their intended use, such as residential, commercial, or industrial. Select the mix type that best aligns with your specific project requirements.

Step 3: Calculate The Quantity Required

After choosing the concrete mix type, the calculator will process the information you’ve provided and calculate the precise quantity of concrete required for your project. The result will be displayed in a clear and concise format, allowing you to quickly and efficiently determine the quantity of premix concrete needed to complete your construction endeavor.

By following these three simple steps, you can utilize a premix concrete calculator to accurately determine the quantity of concrete required for your construction project. This ensures that you order the right amount of premix concrete, avoiding wastage and unnecessary expenses. Make use of this valuable tool to streamline your project planning and execution, saving time, money, and effort in the process.

Factors To Consider When Using A Premix Concrete Calculator

Using a premix concrete calculator can be a game-changer when it comes to determining the amount of concrete required for your project. However, it is important to understand the key factors that influence the accuracy of the calculator results. By taking these factors into account, you can ensure that your concrete mix is designed for optimal performance and that your project environment is well-suited for the pouring and curing process.

Project Environment

The project environment plays a crucial role in determining the type and quantity of concrete required. Before using a premix concrete calculator, it is important to evaluate the following aspects:

- Climate conditions: Different climate conditions can impact the rate of concrete curing. For example, hot and dry weather can lead to rapid drying of the concrete, which may require additional measures like misting or the use of curing compounds. On the other hand, cold temperatures can slow down the curing process, necessitating the use of insulating blankets or heating systems.

- Access to the site: Consider the logistics of delivering concrete to your project site. Factors such as the distance from the supplier, obstacles like narrow driveways or low overhead clearances, and site accessibility can affect the efficiency of concrete delivery. Taking these factors into account will help you plan the necessary resources for a smooth and timely pour.

- Site preparation: Proper site preparation is essential to ensure a solid foundation for your concrete. Factors like soil conditions, slope, and existing structures or utilities underground can impact the stability and longevity of your concrete. Conducting a thorough site analysis will help you identify any potential pitfalls and plan accordingly.

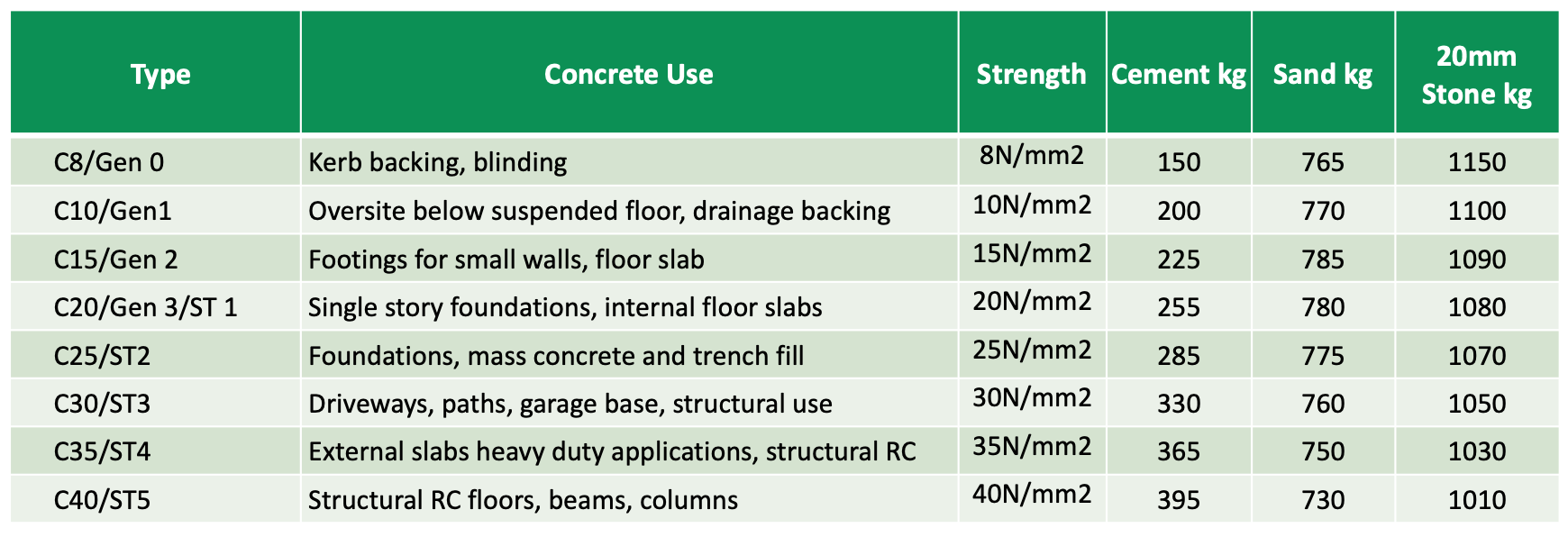

Concrete Mix Design

The concrete mix design determines the proportions of various components in the concrete, including cement, aggregates, water, and additives. Consider the following factors when using a premix concrete calculator:

- Strength requirements: The intended use of the concrete will dictate the strength requirements. Whether you need a standard-grade mix for general use or a high-strength mix for heavy-duty applications, selecting the right strength class is crucial.

- Aggregate size and type: The choice of aggregate significantly impacts the workability, strength, and durability of the concrete. The size and type of aggregate should be selected based on the project requirements and local availability.

- Admixtures: Admixtures are additives that can enhance certain properties of the concrete, such as workability, durability, or setting time. The selection and dosage of admixtures should be based on the specific needs of your project.

Reinforcement Requirements

For projects that require additional strength and structural stability, reinforcement is essential. When using a premix concrete calculator, you should take into consideration:

- Rebar or wire mesh: The type and spacing of reinforcement, such as rebar or wire mesh, should be determined based on the load-bearing capacity required for your project. Consulting with a structural engineer will ensure that the reinforcement meets the necessary design standards.

- Embedment and curing: Proper embedment of the reinforcement and sufficient concrete cover are crucial for optimal structural performance. The concrete calculator should account for the additional volume occupied by reinforcement, ensuring that the calculated quantity of concrete accounts for both the formwork and reinforcement requirements.

Comparison With Traditional Concrete Calculation Methods

When it comes to calculating concrete requirements, the traditional methods often involve manual calculations or relying on estimations provided by suppliers. However, with the advent of modern technology, the use of premix concrete calculators has revolutionized the way concrete quantities are determined.

Manual Calculation

Manual calculation involves the use of mathematical formulas and measurements to estimate the concrete needed for a project. This method often requires precise calculations and may be prone to errors due to human factors.

Estimation Through Suppliers

Estimation through suppliers involves relying on the expertise of concrete suppliers to provide an estimate of the required concrete quantity based on the project specifications. While this method can save time, it may lack accuracy and can result in over or underestimation of concrete needs, leading to potential delays and additional costs.

Examples Of Premix Concrete Calculator Tools

Exploring the world of premix concrete calculators unveils a diverse range of tools designed to streamline and simplify construction projects. Let’s delve into some examples of premix concrete calculator tools, categorized by their unique functionalities.

Company-specific Calculators

Several companies in the construction industry offer tailored premix concrete calculators on their websites. These calculators typically factor in variables such as mix type, slab thickness, and project dimensions to provide accurate quantity estimations. Users can input their specific requirements and receive instant results.

Mobile Applications

For on-the-go access and convenience, mobile applications dedicated to premix concrete calculation have gained popularity. These apps offer a user-friendly interface, real-time calculations, and customization options to meet the needs of various projects. Users can easily download these apps on their smartphones or tablets for quick and reliable concrete estimations.

Credit: fibointercon.com

Challenges And Limitations

Premix concrete calculation can present various challenges and limitations, especially when dealing with the variability in mix designs and complex project requirements.

Variability In Mix Designs

Each project may require different mix designs, leading to challenges in accurately estimating the amount of premix concrete needed.

Complex Project Requirements

Ensuring that the specific project requirements are met can be demanding and may involve intricate calculations to avoid compromising the quality of the concrete.

Frequently Asked Questions For Premix Concrete Calculator

What Is A Premix Concrete Calculator And How Does It Work?

A premix concrete calculator is a tool that helps calculate the quantity of concrete needed for a project. It works by taking inputs like the dimensions of the area to be concreted and the desired thickness, and then calculates the amount of materials needed, including cement, sand, and aggregate.

Why Should I Use A Premix Concrete Calculator?

Using a premix concrete calculator ensures accuracy and helps prevent wastage of materials. It also saves time and effort by providing an instant estimate of the required quantity of concrete, enabling you to plan accordingly and avoid any delays or extra costs.

How Do I Use A Premix Concrete Calculator?

To use a premix concrete calculator, simply input the dimensions of the area to be concreted, such as length, width, and thickness, and select the desired units. The calculator will then determine the amount of concrete, cement, sand, and aggregate needed for the project.

Can A Premix Concrete Calculator Account For Variations In The Project?

Yes, a good premix concrete calculator allows for variations in the project. It typically allows you to adjust the parameters like wastage factor or add additional layers, ensuring that the calculation takes into account any variations or changes in the project requirements.

Conclusion

Incorporating a premix concrete calculator can streamline your construction projects. The convenience and accuracy it offers can save time and resources. With the proper calculations at your fingertips, you can ensure efficient and cost-effective planning. By using this tool, you can enhance the quality and precision of your concrete applications.