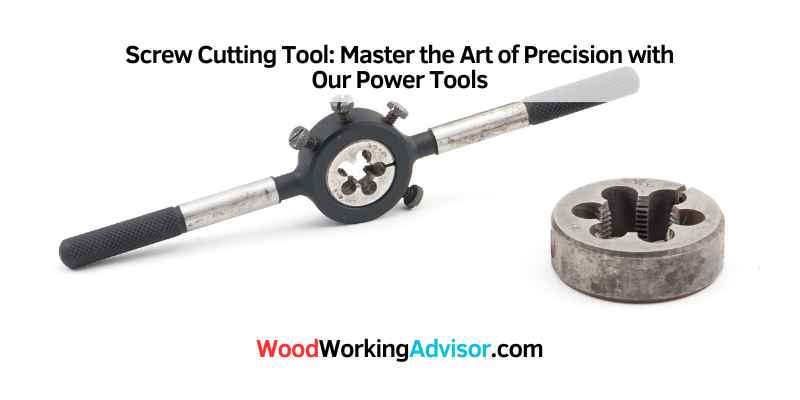

A screw cutting tool is used to create threads on a workpiece for fastening components. It is essential in metalworking projects to ensure secure connections.

Screw cutting tools are indispensable in various industries, such as automotive, manufacturing, and construction. These tools come in different types, including taps, dies, and thread mills, and can be operated manually or with machine assistance. By using a screw cutting tool, workers can effortlessly cut precise threads on materials like metal and plastic, facilitating the assembly of machinery and equipment.

Understanding the importance of screw cutting tools and how to use them correctly is crucial for achieving high-quality results in industrial applications. Whether for creating custom parts or repairing existing threads, these tools play a vital role in efficient and accurate manufacturing processes.

Credit: www.walmart.com

The Art Of Screw Cutting Tool

Screw cutting is a delicate craft that demands precision and expertise in tool use. Understanding the Art of Screw Cutting Tool is essential for creating high-quality and accurate threads. Let’s delve into the key aspects of Screw Cutting Tool.

Introduction To Screw Cutting

Screw cutting involves the process of cutting threads on a cylindrical workpiece using specialized cutting tools. It is a fundamental technique in machining and metalworking.

Mastering Precision In Screw Cutting

Attaining precision in screw cutting requires skillful manipulation of cutting tools to achieve accurate thread profiles and pitch consistency.

Understanding Power Tools

Power tools are essential for various DIY projects, offering efficiency and precision in tasks. Understanding different types of power tools is crucial for selecting the right one for specific applications. When it comes to screw cutting, having the appropriate power tool can make the process smooth and accurate.

Types Of Power Tools

1. Drill Machines: Portable and versatile tools commonly used for drilling holes in various materials including wood and metal.

2. Electric Screwdrivers: Ideal for fastening screws quickly and efficiently with adjustable torque settings.

3. Rotary Tools: Compact and multifunctional tools suitable for intricate tasks like engraving, polishing, and cutting.

4. Impact Drivers: Powerful tools designed for driving large screws and bolts effortlessly.

Choosing The Right Power Tool For Screw Cutting

Consider the following factors when selecting a power tool for screw cutting:

- Power Requirements: Ensure the tool has sufficient power to handle screw cutting tasks effortlessly.

- Adjustable Speed: Look for tools with variable speed settings for precise control during cutting.

- Comfort and Ergonomics: Choose a tool that is comfortable to hold and operate for extended periods.

- Compatibility: Verify that the power tool is compatible with the type and size of screws you will be using.

Essential Techniques For Screw Cutting

Learn essential techniques for screw cutting with our innovative screw cutting tool. Master the art of precision cutting, proper tool alignment, and speed control. Elevate your craftsmanship to new levels with our comprehensive screw cutting tool.

Tool Selection And Maintenance

Screw cutting is a precision process that demands an understanding of the essential techniques for optimal results. As vital as the cutting process may be, the tool selection and maintenance play an equally crucial role. Let’s explore these critical aspects in detail.

Precision Tips For Optimal Results

When engaging in screw cutting, precision is paramount. Utilize high-quality tools, maintain strict accuracy, and adhere to recommended techniques for precise results.

Choosing the right tools is fundamental for successful screw cutting. Consider factors such as material, size, and cutting thread type. Proper maintenance of these tools is equally important, as a well-maintained tool ensures accuracy and prolongs its lifespan.

For optimal results, practicing precision is essential. This includes measuring and marking accurately, ensuring proper tool alignment, and utilizing the appropriate cutting speed and feed. By adhering to these precision tips, you ensure the highest quality in screw cutting, ultimately enhancing the overall performance of the screw threads.

Safety Measures In Screw Cutting

Screw cutting is a common process in industries that relies heavily on the use of screws. While using a screw cutting tool, it is important to prioritize safety measures to prevent accidents and ensure the well-being of workers. Here are some essential safety measures to consider when engaging in screw cutting:

Protective Gear And Equipment

Wearing the right protective gear and equipment is crucial when working with a screw cutting tool. This helps to minimize the risk of injuries and keeps the operator safe. Some essential safety gear and equipment include:

- Safety goggles/face shield: Protects the eyes from any flying debris or metal fragments during the cutting process.

- Ear protection: Reduces the risk of hearing damage from the noise generated by the screw cutting machine.

- Respiratory mask: Prevents the inhalation of metal dust and particles that may be produced during the cutting process.

- Protective gloves: Shield the hands from cuts, abrasions, and potential exposure to harmful chemicals or substances.

- Steel-toed safety boots: Provide protection against heavy objects, accidental drops, and sharp materials on the floor.

Safe Operation Practices

Implementing safe operation practices is essential to ensure the smooth and accident-free process of screw cutting. Some key practices to follow include:

- Inspect the screw cutting tool: Before each use, carefully examine the tool for any signs of damage or malfunctions. Do not operate the tool if it appears defective.

- Secure the workpiece: Make sure that the workpiece is securely held in place to prevent it from moving or rotating during the cutting process.

- Use the appropriate cutting speed: Adjust the speed of the screw cutting tool according to the material being cut and the specifications recommended by the manufacturer.

- Avoid loose-fitting clothing: Wear proper attire that fits well to avoid entanglement with the tool or any moving parts.

- Never leave the tool unattended: Always turn off the screw cutting machine and unplug it when not in use or during maintenance tasks.

Advanced Applications Of Screw Cutting

Discover the practical applications of screw cutting tools for precise threading in advanced manufacturing processes. These cutting tools offer exceptional accuracy and efficiency in creating custom screw threads for various industrial applications. Upgrade your machining operations with the latest screw cutting tools for enhanced productivity and quality output.

Innovative Approaches In Screw Cutting

When it comes to the world of engineering and manufacturing, screw cutting plays a vital role. It is a process that involves creating different types of threads on the surface of a screw for specific applications. Apart from the standard threads, there are many advanced applications that take screw cutting to a whole new level. These innovative approaches not only enhance the functionality of screws but also offer countless possibilities to industries across various sectors.

One of the key innovative approaches in screw cutting is customization. With advancements in technology, manufacturers are now able to customize screws according to specific requirements. This level of customization allows for tailoring screws to fit unique applications, ensuring optimal functionality and performance. Whether it’s about adjusting the thread angle, length, or diameter, customization empowers industries to create screws that perfectly align with their needs.

Exploring Customization And Specialized Cuts

Another aspect of advanced screw cutting revolves around specialized cuts. These cuts are designed to cater to specialized applications that demand precision and efficiency. Some common examples of specialized cuts include multiple-start threads, acme threads, buttress threads, and trapezoidal threads. Each of these cuts serves a specific purpose in industries such as automotive, aerospace, and medical.

Moreover, specialized cutting techniques like thread milling and thread whirling have gained popularity due to their ability to create complex thread profiles. These techniques enable manufacturers to produce threads with intricate designs, including flutes, twists, and custom shapes. Such advanced screw cutting approaches are particularly useful in industries where a high level of precision is required, such as the defense and energy sectors.

In conclusion, the advanced applications of screw cutting have revolutionized the way industries operate. With innovative approaches like customization and specialized cuts, screw cutting has become more versatile and efficient than ever before. These advancements not only enhance the functionality of screws but also open up endless possibilities for industries across various sectors. By embracing these advanced techniques, manufacturers can achieve superior thread quality, precision, and performance, thereby driving overall success in their respective industries.

Credit: tikweld.com

Frequently Asked Questions On Screw Cutting Tool

What Is A Screw Cutting Tool Used For?

A screw cutting tool is used to create screw threads on a workpiece. It is a crucial tool in metalworking and woodworking, allowing for the creation of precise threads that securely fasten objects together.

How Does A Screw Cutting Tool Work?

A screw cutting tool works by removing material from the workpiece to form the desired screw thread. It has a cutting edge that engages with the workpiece and gradually creates the threaded profile. The tool is guided by a lead screw or a template to ensure accuracy and uniformity of the threads.

What Types Of Materials Can Be Used With A Screw Cutting Tool?

A screw cutting tool can be used with various materials, including metals like steel, aluminum, brass, and cast iron. Additionally, it can work with softer materials like wood and plastic. The choice of tool material and cutting speed may vary depending on the workpiece material to achieve optimal results.

How To Choose The Right Screw Cutting Tool?

When choosing a screw cutting tool, consider factors such as the desired thread size, pitch, and material. Select a tool with the appropriate design, such as a single-point or multi-point tool, to match the workpiece requirements. It is also essential to ensure compatibility between the tool and the cutting machine or lathe being used.

Conclusion

Screw cutting tools are essential for precision and efficiency in machining processes. With the right tool, you can create accurate and clean screw threads quickly. Choosing the best tool for your specific application is key to achieving consistent results and improving productivity.

Invest in high-quality screw cutting tools for optimal performance and professional results.