Grinding cutting wheels are composed of abrasive grains held together by a bonding material and are used in angle grinders for cutting and grinding tasks. Grinding wheels consist of thousands of small abrasive grains, and as each grain becomes dull, it breaks away from the bonding material.

Grinding cutting wheels are an essential tool for metalworking and construction tasks. These wheels can cut through various metal surfaces, accurately and smoothly. They are ideal for grinding, cutting, and finishing metal surfaces. While Angle Grinders are an excellent tool for cutting both hard and soft metals, they perform various metal-related tasks with the right grinding or cutting disc.

There are various types of grinding wheels available, each designed to tackle specific tasks. Before choosing a cutting wheel, it is essential to consider factors such as the task at hand, the type of material to be cut, and the grinder’s power. Overall, cutting wheels are a crucial component for any metalworking job.

What Is A Grinding Cutting Wheel?

A grinding cutting wheel is a tool used for grinding and cutting through various surfaces such as metal, masonry, and concrete. It consists of thousands of small abrasive grains held together by a bonding material to create a cutting edge that smooths and shapes the surface.

Proper wheel selection is vital to prevent hazards and achieve optimal results.

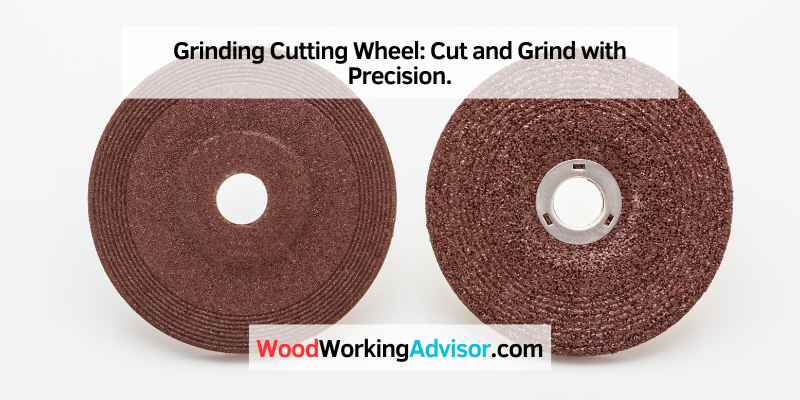

Composition Of A Cutting Wheel

A grinding cutting wheel is a highly versatile tool that is used for a wide array of metalworking applications like cutting, grinding, and polishing. It is composed of thousands of small abrasive grains held together by a bonding material. Each abrasive grain is a cutting edge, and as the grain passes over the workpiece, it cuts a small chip, leaving a smooth, accurate surface. The abrasive grains are usually made of aluminum oxide, silicon carbide, cubic boron nitride, or diamond.

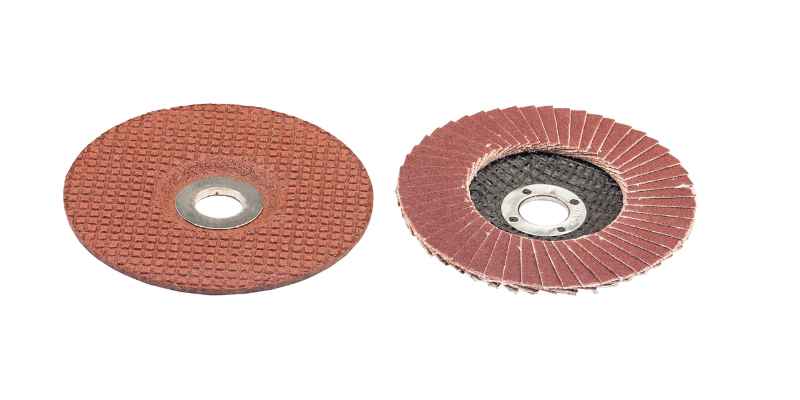

Different Types Of Cutting Wheels

There are several types of cutting wheels, each designed for specific applications. Below are some of the most common ones:

- Aluminum Oxide Wheels: These wheels are economical and versatile, making them ideal for general purpose cutting and grinding. They are commonly used to remove rust, paint, and other coatings, as well as shape and deburr metal surfaces.

- Silicon Carbide Wheels: These wheels are harder and more brittle than aluminum oxide wheels, making them suitable for cutting hard materials like cast iron, nonferrous metals, and masonry. They are also ideal for grinding concrete and stone surfaces.

- Diamond Wheels: These wheels are made with synthetic diamonds and are the hardest and most durable of all cutting wheels. They are used for cutting and grinding very hard materials like carbide, ceramics, and glass, as well as precision grinding applications like tool and cutter grinding.

- Cubic Boron Nitride (CBN) Wheels: These wheels are made with CBN grains and are ideal for grinding hardened steels and superalloys. They are also used for sharpening high-speed steel cutting tools.

When selecting a cutting wheel, it is crucial to identify the type of material you are cutting and choose a suitable wheel that can provide the best possible results. A wrong choice can lead to poor performance, excessive wear, and safety risks. Hence, it is always essential to use cutting wheels that have the correct specifications and are compatible with your work material.

Uses Of Grinding Cutting Wheel

Grinding cutting wheels are typically used for precision cuts on hard materials such as metal or concrete. These wheels are composed of abrasive particles, held in place by a bonding material, and they work by removing small chips of material from the workpiece, leaving a smooth surface behind.

Cutting Metal

Grinding cutting wheels are widely used for cutting metal as they are the quickest and most efficient way to cut through different types of metals such as steel, aluminum, iron, and copper. The cutting wheel’s high speed and cutting power can slice through even the thickest of metals, making it an essential tool for metalworkers and fabricators.

Sharpening Tools

Aside from cutting metal, grinding wheels can also be used for sharpening tools. With the right grit, a grinding wheel can sharpen tools such as knives, scissors, chisels, and even lawnmower blades. The coarse grit on a grinding wheel can quickly remove any dullness or chips, and the fine grit can provide a sharp edge for a precise cut.

Grinding Surfaces

Grinding cutting wheels can also be used for grinding surfaces, such as removing rust, paint, and other coatings from metal surfaces. Grinding wheels can also shape and smooth out rough edges on metal, wood, and plastic materials. Additionally, grinding wheels have different grit levels that can be used for polishing and finishing surfaces, such as honing knife blades, polishing jewelry, and cleaning and buffing metal surfaces.

Where To Find Grinding Cutting Wheel

Grinding cutting wheels are available in various shapes, sizes, and materials, making it easy to find a suitable one for your needs. They can be purchased online from retailers such as Amazon, Harbor Freight Tools, and Uline, or in-store from home improvement stores such as Lowe’s and NAPA Auto Parts. When using a grinding cutting wheel, it is essential to follow all safety precautions and use the correct wheel for your material and application to avoid accidents and ensure successful results.

How To Choose A Grinding Cutting Wheel

Choosing the right grinding cutting wheel is crucial for achieving the desired results. Look for the right size, material, and abrasiveness level to ensure effective and efficient grinding and cutting. Several options are available online and in physical stores, including diamond cutting wheels, ceramic wheels, and aluminum oxide wheels, among others.

Size And Thickness

When choosing a grinding cutting wheel, size and thickness should be the first factor to consider. The size of the wheel will determine the type and size of the workpiece it can cut. A smaller wheel is suitable for small tasks, while a larger wheel will handle larger tasks. The thickness of the wheel will affect the durability of the cutting tool. Thinner wheels make faster cuts, but thicker wheels last longer, making them ideal for heavy-duty use.

Material To Be Cut

The material to be cut should be the second factor to consider when choosing a grinding cutting wheel. Different wheels are designed to cut specific materials such as metal, stone, concrete, or tiles. Selecting the right wheel for the job ensures faster and efficient cutting, as well as longer wheel life.

Speed And Rpm

The speed and RPM of the grinding cutting wheel will impact the cutting performance. Faster speeds and higher RPMs generate more heat, resulting in faster cuts. However, if the speed and RPMs are too high, the wheel could wear out prematurely or even shatter. The recommended wheel speed should match the speed of the tool being used, which ensures both safety and effective cutting.

When choosing a grinding cutting wheel, it is essential to consider all the above factors together to ensure the right tool is selected for the job. Remember, a wrong choice can lead to inefficiency, safety hazards, and even damage to the tool or workpiece.

Safety Precautions While Using Grinding Cutting Wheel

When using a grinding cutting wheel, it is important to take safety precautions to prevent injury. Always wear proper eye and ear protection, maintain a safe distance from the work area, and avoid using a damaged or worn out wheel.

Grinding cutting wheel is a tool used in various metal-related tasks, including cutting, grinding, and finishing. It is essential to follow some safety precautions while using grinding cutting wheel to prevent any injuries or accidents. Here are some of the safety measures you need to keep in mind while using a grinding cutting wheel.

Wearing Personal Protective Equipment

Wearing personal protective equipment (PPE) is crucial while using a grinding cutting wheel. PPE includes safety goggles, face shields, gloves, and appropriate clothing. Goggles and face shields protect your eyes and face from flying debris while gloves protect your hands from sharp edges. You must also wear appropriate clothing that covers your body, such as a long-sleeved shirt, pants, and sturdy shoes with slip-resistant soles.

Secure the Workpiece

Before using the grinding cutting wheel, secure the workpiece using clamps or a vice. A loose workpiece may slip and cause a serious accident. It is also crucial to ensure that the workpiece is positioned correctly and is not in contact with the wheel’s sides.

Maintain Safe Distance

Maintaining a safe distance is essential while using the grinding cutting wheel. Ensure that there is enough space between you and the workpiece, and avoid standing directly in front of the wheel. Keep your body to the side of the cutting wheel and maintain distance such that you can work without leaning forward or reaching out.

Conclusion

In conclusion, following safety precautions while using the grinding cutting wheel is essential to prevent accidents and injuries. Wearing personal protective equipment, securing the workpiece, and maintaining a safe distance are some of the precautions you need to keep in mind while using the grinding cutting wheel. Ensure you follow the instructions on the package for operating the specific wheel you are using.

How To Cut Using Grinding Cutting Wheel

When using a grinding cutting wheel, it is important to keep safety in mind and follow the proper procedure. The grinding wheel is composed of abrasive grains which are held together by a bonding material. As the grain passes over the work piece, it cuts a small chip, leaving a smooth and accurate surface.

Secure The Workpiece

When working with a grinding cutting wheel, one of the essential things you must do is to secure the workpiece. If you fail to keep the workpiece secure, it can move, leading to inaccurate cuts or even accidents. Use a vise, clamp, or any other secure method to ensure that the workpiece doesn’t move.

Mark The Cut Line

To make an accurate cut, you need to mark the cut line before starting. Use a straight edge and a marker to create a visible and precise mark that you can follow. If the cut line is not visible, you may end up cutting off more than you intended, or worse, damaging the workpiece.

Cutting Technique

Once you have secured the workpiece and marked the cut line, it’s time to start cutting. First, make sure the grinding cutting wheel is suitable for the job. Next, hold the angle grinder firmly with both hands and turn it on. Begin cutting by placing the wheel’s edge against the marked cut line and gently applying pressure while moving the wheel back and forth. Keep your hands and body out of the way of the cutting wheel.

In conclusion, cutting with a grinding cutting wheel needs some preparation and attention to safety. You can always refer to the manual to know the correct wheel and technique to use for each job. Now that you know how to cut using a grinding cutting wheel, you can complete your projects easily and efficiently.

Grinding Vs Cutting

Grinding and cutting are two different methods of removing materials from a workpiece. A Grinding Cutting Wheel is a tool that is used for both grinding and cutting. The grinding wheel is composed of small abrasive grains held together by a bonding material, while the cutting wheel is composed of a disc-shaped blade with sharp teeth on the edge.

Both wheels are used in angle grinders, and their usage depends on the task at hand.

Grinding and cutting are two different processes, each requiring a different type of wheel. It is important to understand the differences before deciding which wheel to use for a project.

Difference Between Grinding and Cutting

Grinding involves removing small amounts of material from a surface, typically with a smooth grinding wheel. The process smoothes out rough edges, removes burrs, and shapes materials to a specified tolerance. Cutting, on the other hand, removes larger sections of material through a slicing motion with a sharper cutting wheel. This process is typically used to cut through thick metal or for tasks like trimming tiles or cutting pipes.

When to Use Grinding or Cutting Wheel

Choosing the right wheel for a job is crucial to ensure both efficiency and safety. Materials that require a fine finish or precise tolerances, such as metal parts, should be ground with a grinding wheel. Cutting wheels, which are generally designed with a more abrasive and sharp edge, are better suited for tasks such as cutting through thicker metals or concrete. It is essential always to use a wheel that matches the specific task to ensure efficiency, safety, and optimum results.

In conclusion, knowing the difference between grinding and cutting and when to use each type of wheel is essential for successful and safe completion of a project. Matching the right wheel with the task at hand can make all the difference, leading to polished finishes, smooth edges, and accurate cuts.

Common Mistakes To Avoid When Using A Grinding Cutting Wheel

When using a grinding cutting wheel, it is important to avoid common mistakes that could lead to injury or damage to the machine. Some examples of mistakes to avoid include failing to wear protective gear, using a damaged wheel, and applying too much pressure.

Proper safety precautions and maintenance are essential for optimal performance.

A grinding cutting wheel is an essential tool in any metalworking shop. It is a versatile tool that can help you cut, grind, and polish metals. However, improper use of the wheel can lead to accidents, damage to the equipment, and reduced efficiency. In this article, we will look at the common mistakes to avoid when using a grinding cutting wheel, and how to use it in a safe and efficient manner.

Using Wrong Wheel for the Job

One of the most common mistakes people make when using a grinding cutting wheel is using the wrong wheel for the job. Different types of discs are designed for specific purposes, such as cutting, grinding, or polishing different types of metal. Therefore, it is essential to choose the right wheel for the job. The wrong wheel can cause damage to the equipment or lead to accidents, so it is critical to check the manufacturer’s guidelines before using any grinding cutting wheel.

Overusing the Wheel

Another common mistake people make when using the grinding cutting wheel is overusing it. It’s easy to keep using the same wheel time and time again, especially if it’s still cutting or grinding. Unfortunately, overusing the same disc can result in a reduction of efficiency, a less smooth finish, and can lead to accidents. It is essential to monitor the wheel frequently and replace it when it becomes worn or damaged.

Ignoring Safety Precautions

Arguably, the most critical mistake to avoid when using a grinding cutting wheel is ignoring safety precautions. Safety should always be a priority when using any tool, particularly in metalworking. When using a grinding cutting wheel, it is essential to wear safety gear like gloves and goggles to protect your eyes, ears, and hands from debris or sparks. Additionally, avoid wearing loose clothing and keep the work area clean and free from trip hazards. Finally, ensure the machine is off before changing wheels and use the appropriate guard to protect yourself while working.

In Conclusion

A grinding cutting wheel is a versatile tool that can help you achieve excellent results if used correctly. However, it is critical to avoid common mistakes, such as using the wrong wheel, overusing the wheel, and ignoring safety precautions. By following the manufacturer’s guidelines, replacing the wheel when needed, and taking safety precautions, you can use the grinding cutting wheel safely and efficiently.

How To Maintain Grinding Cutting Wheel

To maintain your grinding cutting wheel, you need to clean it after every use and remove any debris from the wheel surface. Keep the wheel dry and protected from moisture to prevent rust. Always store the wheel in a clean and dry place to avoid contamination and damage.

Grinding cutting wheels are an essential part of many industries. They are used for cutting, grinding, and polishing various materials, including metal, concrete, and masonry. To ensure the grinding cutting wheel remains effective, it’s vital to regularly maintain it. In this section, we’ll outline some of the best practices for maintaining a grinding cutting wheel.

Inspecting the Wheel for Damage

Inspecting the wheel for damage is an important step in maintaining it. You should check the wheel for cracks, chips, or any other signs of damage before and after each use. Using a damaged wheel can be dangerous and even cause injury to the user. Replace the wheel immediately if you notice any damage, as it might not function accurately, leading to bad results.

Cleaning and Lubrication

Cleaning and lubrication also play a vital role in maintaining a grinding cutting wheel. After use, you should clean the wheel to remove any debris, dirt or oil that may cause the wheel to wear out quickly. To clean the wheel, use a stiff brush to remove any dirt or debris. Next, use a cloth soaked with water and mild soap to clean the wheel thoroughly. Dry the wheel carefully before storing it.

Storing the Wheel

Storing the wheel correctly is a key factor in extending its lifespan. Store the wheel in a dry, cool, and clean place to prevent rusting and other forms of damage. Avoid storing the wheel in a place where it’s exposed to moisture and extreme temperatures, as it can reduce its effectiveness and durability.

In conclusion, maintaining a grinding cutting wheel is crucial to ensuring its longevity and effectiveness. Inspect the wheel for damage, clean and lubricate it after each use, and store it properly to extend its lifespan. With proper maintenance, your grinding cutting wheel can last for a long time and deliver excellent results every time.

Frequently Asked Questions On Grinding Cutting Wheel

Can You Use A Cutting Wheel On A Grinder?

Yes, you can use a cutting wheel on a grinder. Angle grinders are excellent tools for cutting both hard and soft metals. With the right grinding or cutting disk, they can perform various metal-related tasks, including cutting. However, make sure to use a cutting wheel specifically designed for your grinder and follow safety precautions.

What Is The Grinding Wheel Cutting Method?

The grinding wheel cutting method is a process in which thousands of small abrasive grains held together by a bonding material cut small chips from the work piece, leaving a smooth surface. The abrasive grain acts as a cutting edge and breaks away from the bonding material when it becomes dull.

Grinding and cutting wheels, including ceramic wheels, can be used for tool and cutter grinding with an angle grinder.

What Type Of Grinding Wheel Is Best For Tool And Cutter Grinding?

The best type of grinding wheel for tool and cutter grinding is the ceramic wheel. It has a mix of ceramic alumina that makes it perfect for grinding various tool steels. The ceramic wheel has the highest productivity, fastest stock removal rate, and longest life.

Can You Use A Grinding Disk For Cutting?

Yes, you can use a grinding disk for cutting with an angle grinder. However, it is important to use the right grinding or cutting disk for the job. Angle grinders are versatile tools that can perform various metal-related tasks, including cutting both hard and soft metals.

Suggestions on the best type of wheel for each task can be found through various resources including product manufacturers and online retailers.

Conclusion

To sum up, a grinding cutting wheel is a must-have tool for any professional metal worker or DIY enthusiast. It provides a convenient and efficient way to cut, grind, and shape various metals. By choosing the right type of wheel, you can achieve precise results, increase productivity, and save time and money.

Whether you need to cut a sheet of steel or grind down a weld, a cutting wheel and angle grinder combo is versatile and easy to use. So invest in a high-quality wheel, keep it well-maintained, and enjoy the benefits of this powerful tool for years to come.