To cut thin strips of wood by hand, use a sharp handsaw or a razor knife. When it comes to working with wood, cutting thin strips by hand is a common task.

Whether you need them for trim pieces or craft projects, having the ability to cut thin strips accurately is essential. While power tools can make the job easier, it is possible to achieve precise cuts by hand with the right techniques.

This article will guide you through the step-by-step process of cutting thin strips of wood by hand, using tools like a handsaw or a razor knife. With a bit of practice and attention to detail, you’ll be cutting thin strips like a pro in no time.

The Importance Of Accuracy And Precision

Accurate and precise cutting is paramount when it comes to hand cutting thin strips of wood. This ensures clean and seamless results, allowing for a smooth and professional finish. Maintaining accuracy and precision throughout the process is key to achieving the desired outcome.

Understanding The Need For Precise Measurements

Precision and accuracy are crucial when cutting thin strips of wood by hand. By understanding the importance of accurate measurements, you can ensure that your project turns out exactly as intended. Here are some points to consider:

- Length and Width: Properly measuring the length and width of the wood strips is essential. This will affect the overall dimensions and fit of your project.

- Consistency: Accurate measurements ensure consistency across all the wood strips. This is especially important when working on projects that require multiple strips to be cut to the same dimensions.

- Fit and Joinery: Precise measurements allow for a snug and seamless fit between the wood strips and other components of your project, such as joints or miters. This enhances the overall aesthetics and stability of the finished piece.

- Waste Reduction: By accurately measuring and cutting the wood, you can minimize waste and make the most out of the material you have. This is particularly beneficial if you are working with expensive or rare wood.

- Repeatability: Precision in measurement ensures that you can reproduce the same size and shape of wood strips in the future if needed. This is important for maintaining consistency in design elements or creating matching components.

How Accuracy Impacts The Final Project

The accuracy of your cuts directly affects the quality and functionality of the final project. Consider the following points:

- Visual Appeal: Precise and uniform cuts result in a visually appealing finished piece. Uneven or jagged cuts can detract from the overall aesthetic and professionalism of the project.

- Fit and Function: Accurate cuts enable the wood strips to fit tightly together, contributing to the structural integrity of the project. If the cuts are imprecise, gaps or misalignments may occur, compromising the functionality and stability of the finished piece.

- Time and Effort: Implementing precise measurements and cuts can save time and effort during assembly. When the pieces fit together perfectly, there is no need for excessive sanding, shaping, or adjusting.

- Professionalism: Attention to detail in the form of accurate measurements and cuts demonstrates a high level of craftsmanship and professionalism. It sets your project apart and showcases your skills as a woodworker.

- Overall Satisfaction: Ultimately, accuracy in cutting thin strips of wood by hand results in a project that meets your expectations. Precise measurements and cuts contribute to the overall satisfaction and pride in your finished piece.

By prioritizing accuracy and precision in your woodworking projects, you ensure that your thin wood strips are precisely cut to size, allowing for seamless assembly, visual appeal, and maximum functionality. Taking the time to measure accurately will pay off in the final result, creating a high-quality project that you can be proud of.

Essential Tools For Cutting Thin Strips By Hand

Discover the essential tools needed to cut thin strips of wood by hand effectively. Master the art of precision with these must-have tools for woodworking projects.

Hand Saws: The Key To A Clean Cut

When it comes to cutting thin strips of wood by hand, having the right tools is essential. Hand saws are your best bet for achieving a clean and precise cut. These versatile tools allow for greater control and accuracy, ensuring that your thin strips of wood come out just the way you want them.

Here are the key points to keep in mind about hand saws:

- Hand saws are designed specifically for cutting wood by hand, offering greater control and precision compared to power tools.

- These saws typically have a thin, sharp blade with crosscut or rip teeth, allowing for smooth and clean cuts in the grain of the wood.

- There are different types of hand saws available, each catering to specific cutting tasks. It’s important to choose the right saw for the job to ensure the best results.

- Hand saws come in various lengths and tooth configurations, so it’s crucial to select one that suits the thickness and type of wood you’re working with.

Choosing The Right Saw For The Job

To achieve excellent results when cutting thin strips of wood, you need to choose the right saw for the job at hand. Here are some factors to consider:

- Tooth Configuration: Hand saws come with different tooth configurations, including crosscut and rip patterns. Crosscut saws have teeth that are designed to cut across the wood grain, while rip saws have teeth that follow the grain. Choose the appropriate tooth configuration based on the wood you’re working with.

- Blade Length: The length of the saw blade determines the depth of the cut you can make. For cutting thin strips of wood, a shorter blade is usually sufficient. Longer blades are better suited for thicker stock.

- Blade Thickness: Thinner blades create narrower kerfs, resulting in less wood waste and a cleaner cut. Thicker blades, on the other hand, may be more durable but can produce rougher cuts.

- Handle Comfort: Don’t forget to consider the handle comfort when selecting a hand saw. A comfortable handle will allow you to work for longer periods without feeling fatigued, improving both accuracy and efficiency.

Alternative Tools And Their Limitations

While hand saws are the go-to tools for cutting thin strips of wood, there are alternative options available. However, it’s important to note that these alternatives may come with certain limitations. Here are a few worth considering:

- Utility Knife: A utility knife can be useful for making shallow cuts or scoring the wood before using a hand saw. However, it may not provide the same level of precision and control as a hand saw.

- Table Saw: A table saw with a thin-kerf blade can be used to cut thin strips of wood quickly and accurately. However, this option requires access to a table saw and may not be feasible for everyone.

- Bandsaw: Another alternative is a bandsaw, which can be used to cut thin strips of wood with great precision. However, not everyone has access to a bandsaw, and it may not be suitable for small or intricate cuts.

- Router: A router fitted with a straight bit can be used to cut thin strips of wood, but it requires additional setup and may not be as straightforward as using a hand saw.

Keep in mind that while these alternative tools can work for cutting thin strips of wood, they may not offer the same level of control, precision, and ease as a hand saw. Therefore, it’s recommended to use a hand saw whenever possible for the best results.

Expert Techniques For Cutting Thin Strips

Learn the expert techniques for cutting thin strips of wood by hand to achieve precise results. These methods ensure an accurate and smooth cut, enhancing the overall quality of your woodworking projects. Gain insights into the best practices for a seamless cutting experience.

Cutting thin strips of wood by hand requires precision and careful execution. Expert techniques can make this task easier and ensure accurate results. In this section, we will explore the proper measuring and marking techniques, methods to secure the wood for precise cuts, and common mistakes to avoid when cutting thin strips.

Proper Measuring And Marking Techniques

Accurate measurements and markings are crucial for cutting thin strips of wood with precision. Follow these techniques to ensure you start off on the right foot:

- Use a reliable measuring tape or ruler to measure the desired width of the strip.

- Clearly mark the measurement on the wood using a pencil or marking knife.

- Double-check your measurements before proceeding with any cuts to avoid errors.

Securing The Wood For Precise Cuts

Securing the wood in place is essential to prevent it from moving during the cutting process. Consider the following methods to ensure stability:

- Use clamps or a vise to firmly hold the wood in place before making any cuts.

- Apply pressure evenly across the entire length of the wood strip to avoid warping or bending during cutting.

- If necessary, use scrap pieces of wood as backing boards to provide additional support and prevent tear-out.

Avoiding Common Mistakes In Cutting Thin Strips

To achieve clean and accurate cuts when working with thin strips of wood, it’s important to be aware of and avoid common mistakes. Take note of the following:

- Rushing through the process can lead to imprecise cuts. Take your time and maintain a steady hand throughout the cutting process.

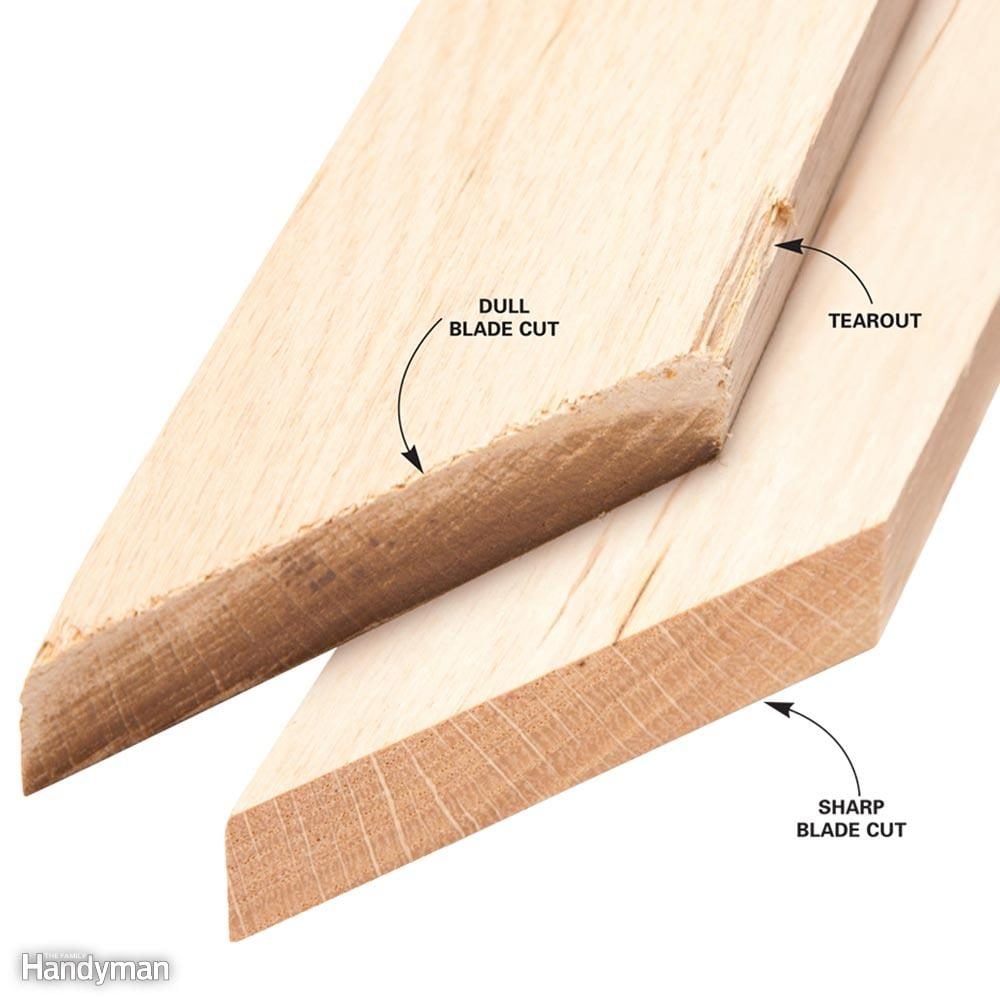

- Neglecting to use a sharp and appropriate saw blade can result in rough cuts or splintering. Ensure your blade is suitable for cutting thin strips of wood and sharpened as needed.

- Failing to follow the marked lines can lead to inaccuracies. Stay focused and make sure your saw cuts directly along the marked lines.

Mastering expert techniques for cutting thin strips of wood by hand can greatly improve the quality of your woodworking projects. By employing proper measuring and marking techniques, securely holding the wood, and avoiding common mistakes, you’ll be well on your way to achieving precise and flawless cuts.

Best Practices For Hand-Sawing Thin Strips

Learn the best practices for hand-sawing thin strips of wood to ensure accurate and clean cuts. Follow these guidelines to master the skill and achieve precise results by cutting thin wooden strips by hand.

When it comes to cutting thin strips of wood by hand, employing the right techniques and adhering to best practices can make all the difference. In this section, we will dive into the key considerations for achieving precise, straight, and smooth cuts while maintaining control and preventing binding.

Follow these guidelines to master the art of hand-sawing thin strips:

Choosing The Right Blade For The Job

To ensure clean and accurate cuts, selecting the appropriate blade for your project is essential. Consider the following factors when choosing a hand-saw blade:

- Blade TPI (Teeth per Inch): Determine the appropriate TPI based on the thickness and hardness of the wood. Higher TPI is suitable for thin and delicate strips, while lower TPI is recommended for thicker materials.

- Tooth Geometry: Opt for a fine-toothed blade with crosscut or rip-cut teeth depending on your desired cut and the wood grain.

- Blade Length: Choose a blade that extends beyond the width of the wood strip to provide ample cutting space and prevent binding.

Achieving A Straight And Smooth Cut

Obtaining straight and smooth cuts requires skill and focus. Follow these tips to enhance your cutting technique:

- Marking and Measurement: Prior to cutting, mark a clear and accurate cutting line using a pencil or a combination square. This guideline will keep your cuts on track.

- Starting the Cut: Gently position the blade on the waste side of the marked line, applying light pressure. Begin the cut with a slow and controlled stroke, gradually increasing the pace.

- Maintaining Alignment: Focus on keeping the saw aligned with the marked line throughout the cutting process. Regularly check your progress to ensure accuracy.

- Supportive Hand Placement: Use one hand to grip the wood firmly and guide the saw, while the other hand controls the saw’s handle. This balanced grip improves control and stability.

- Steady Stroke: Maintain a steady rhythm and stroke length as you saw through the wood. Avoid rushing or applying excessive pressure, as it may cause the blade to wander or bind.

Tips For Maintaining Control And Avoiding Binding

Controlling the saw and preventing binding are crucial elements in cutting thin strips safely and effectively. Consider the following tips:

- Proper Body Position: Stand with your feet shoulder-width apart for stability and maintain a relaxed yet firm grip on the saw. Align your body with the direction of the cut.

- Gentle Pressure: Apply consistent and moderate pressure on the saw, allowing the teeth to do the cutting. Forcing the saw or using excessive pressure can lead to binding and inaccurate cuts.

- Clear Sawdust: Periodically clear away sawdust from the cut with a brush or quick blow. A clear cutting path ensures smooth progress and reduces the risk of the blade binding.

- Avoid Curved Cuts: Aim to maintain a straight cutting path without deviating from the marked line. Steering clear of curved cuts helps prevent binding and produces clean results.

By following these best practices for hand-sawing thin strips, you’ll improve your cutting precision, achieve smoother results, and effectively prevent binding. Remember to choose the appropriate saw blade, focus on maintaining a straight cut, and ensure proper control throughout the process.

Practice makes perfect, so keep honing your skills and enjoy the satisfaction of creating accurately cut thin wood strips by hand.

Techniques For Cutting Thin Strips On Various Types Of Wood

Learn the best techniques to cut thin strips of wood by hand effortlessly. Discover the step-by-step process and gain insights into achieving remarkable results on various types of wood.

Whether you’re a woodworking enthusiast or a professional carpenter, knowing how to cut thin strips of wood by hand is a valuable skill. However, different types of wood present varying challenges when it comes to cutting thin strips. In this section, we’ll explore the techniques and considerations for cutting thin strips on softwoods, hardwoods, veneer and plywood, as well as exotic woods.

Working With Softwoods Vs. Hardwoods

When it comes to working with different types of wood, it’s crucial to understand the characteristics of softwoods and hardwoods. Here are some methods you can employ when cutting thin strips on these types of wood:

Softwoods:

- Use a sharp handsaw to make precise cuts.

- Secure the wood firmly in place before cutting to avoid any slippage or accidents.

- Consider using a bench hook or miter box to ensure accurate and straight cuts.

- Take care not to apply excessive force while cutting, as softwoods may have a tendency to splinter.

Hardwoods:

- Invest in high-quality, ultrafine-toothed saws for smooth and clean cuts.

- Utilize a marking gauge or a pencil to clearly mark the desired width before cutting.

- If hand sawing becomes challenging, consider using a band saw or a table saw with a thin blade.

- Employ a slow and steady cutting motion to prevent any wood damage.

Tools And Techniques For Cutting Veneer And Plywood Strips

Cutting thin strips from veneer and plywood requires specific tools and techniques. Here’s what you need to know:

Tools:

- A veneer saw or a fine-toothed hand saw is ideal for cutting veneer sheets.

- For plywood, a circular saw or a table saw with a fine-toothed blade is recommended.

Techniques:

- When cutting veneer, sandwich it between two boards to prevent tearing and obtain precise cuts.

- Use masking tape along the cut line to reduce splintering when working with veneer.

- With plywood, ensure that the piece is adequately supported to prevent tear-out.

- Employ a zero-clearance insert on a table saw to minimize chip-out when cutting plywood.

Special Considerations For Exotic Woods

Exotic woods offer unique beauty and characteristics, but they require special considerations when cutting thin strips:

- Invest in high-quality, sharp cutting tools specifically designed for cutting exotic woods.

- The density and hardness of exotic woods may require more effort when sawing, so take breaks when needed to avoid fatigue.

- Avoid using excessive force, as some exotic woods may have a tendency to splinter or fray.

- Consider using a reduced feed rate or a slower cutting speed with power tools to minimize tear-out and achieve cleaner cuts.

- Take advantage of hand planes or a cabinet scraper to smooth and refine the edges of the thin strips.

By understanding the techniques for cutting thin strips on various types of wood, you’ll be able to create precise and clean cuts, whether you’re working with softwoods, hardwoods, veneer and plywood, or exotic woods. Remember to always prioritize safety and efficiency when handling hand tools or power tools to achieve optimal results in your woodworking projects.

Troubleshooting Common Challenges In Cutting Thin Strips

Learn effective ways to overcome common challenges when cutting thin strips of wood by hand. Discover practical troubleshooting tips to enhance your woodworking skills and achieve precise results.

Cutting thin strips of wood by hand can be a challenging task, even for experienced woodworkers. However, by understanding and implementing some troubleshooting techniques, you can minimize common issues like tear-out, splintering, and working with the grain. In this section, we will explore preventive measures for tear-out and splintering, ways to overcome wood grain challenges, and techniques to fix mistakes and salvage your work.

Preventing Tear-Out And Splintering:

To achieve clean and smooth cuts without tear-out or splintering, consider the following measures:

- Use a sharp saw blade: A dull blade can cause tear-out and result in rough edges. Make sure to use a sharp blade specifically designed for cutting wood.

- Mark and score the cut line: Before making the actual cut, use a marking gauge or a sharp utility knife to score the cut line lightly. This helps prevent splintering by creating a guide for the saw.

- Secure the wood: Securing the wood firmly in place can reduce vibrations and minimize tear-out. Use clamps or a vise to hold the wood steady during the cutting process.

- Cut with the grain: Cutting with the grain reduces the likelihood of tear-out and splintering. Pay attention to the direction of the wood grain and adjust your cutting technique accordingly.

- Use a backing board: Placing a sacrificial piece of wood behind the workpiece can provide support and prevent tear-out on the underside of the cut.

Overcoming Wood Grain Challenges:

Wood grain direction plays a crucial role in the ease and quality of cutting thin strips. Consider the following tips to overcome wood grain challenges:

- Understand the grain direction: Observe the grain pattern of the wood before cutting. It is essential to work with the grain rather than against it to minimize tear-out and maintain the integrity of the wood.

- Make multiple light passes: Instead of forcing the blade through the wood in one go, make multiple light passes. This approach reduces strain on the wood fibers and decreases the likelihood of tear-out.

- Use a scoring cut: In some cases, making a shallow scoring cut along the cut line can help prevent tear-out when the grain changes direction or features interlocking fibers.

Fixing Mistakes And Salvage Techniques:

Even with careful planning, mistakes can happen during the cutting process. Here are some techniques to fix and salvage your work:

- Glue and clamp technique: If you encounter tear-out or splintering, apply a minimal amount of wood glue to the damaged area. Press the wood fibers back into place and secure with clamps until the glue dries.

- Sanding and planing: Sanding or planing the damaged area can help smooth out rough edges or surface imperfections caused by tear-out. Start with a coarse grit sandpaper or a hand plane, gradually working your way to finer grits for a polished finish.

- Trimming and resizing: In cases where the damage is extensive, consider trimming the piece to remove the compromised section. Adjust your project plan accordingly to accommodate the resized piece.

Remember, cutting thin strips of wood requires patience, practice, and attention to detail. By implementing these troubleshooting techniques, you can enhance your cutting skills and achieve cleaner and more precise results.

Finishing And Sanding Thin Strips

Learn how to cut thin strips of wood by hand with precision using these simple steps. From choosing the right saw to sanding down the edges, this guide will help you achieve smooth and professional results.

Preparing The Cut Edges For A Clean Finish:

When it comes to cutting thin strips of wood by hand, ensuring clean and smooth edges is crucial for achieving a professional-looking finish. Here’s how you can prepare the cut edges for a clean outcome:

- Inspect the edges: After making the cuts, carefully examine the edges of the thin wood strips to identify any rough spots or imperfections.

- Trim any irregularities: Use a sharp chisel or a block plane to carefully trim away any uneven or protruding sections along the cut edges. This will help create straight and even surfaces.

- Smooth with sandpaper: Gently sand the cut edges using fine-grit sandpaper. Move the sandpaper in a back-and-forth motion, ensuring to sand evenly and consistently along the length of the strips.

- Round the corners: To further enhance the finished appearance of the thin wood strips, lightly sand the corners to create a smooth rounded shape. This will prevent rough or sharp edges.

Sanding Techniques For Smooth And Even Surfaces:

Once the cut edges are prepared, the next step is to achieve smooth and even surfaces on the thin wood strips. Follow these sanding techniques for optimal results:

- Start with coarse-grit sandpaper: Begin by sanding the surface of the thin wood strips with coarse-grit sandpaper. This will help in removing any roughness, unevenness, or surface imperfections effectively.

- Move to finer grits: Gradually transition to finer grit sandpapers, working your way up to medium and then fine grits. This progressive sanding process will help you achieve a smoother finish with each iteration.

- Check for uniformity: Regularly inspect the surface of the thin wood strips while sanding to ensure uniformity across the entire length. Focus on any areas that may require extra attention to achieve a consistent smoothness.

- Use a sanding block: To maintain a level surface and prevent uneven sanding, consider using a sanding block. This tool allows for even distribution of pressure and ensures a more uniform sanding result.

Applying The Appropriate Finish For Durability:

After achieving smooth and even surfaces on the thin wood strips, it’s essential to apply the appropriate finish to enhance durability and protect the wood. Consider the following steps:

- Choose the right finish: Select a finish that suits your project and the type of wood you are working with. Options include varnish, lacquer, shellac, or even natural oils like tung oil or linseed oil.

- Prepare the surface: Before applying the finish, ensure that the surfaces of the thin wood strips are clean, smooth, and free from any dust or debris. Wipe them down with a tack cloth for a pristine surface.

- Apply the finish: Using a brush, rag, or sprayer, apply a thin, even coat of your chosen finish to the wood strips. Follow the manufacturer’s instructions for applying subsequent coats, if necessary.

- Allow for drying and curing: After applying the finish, give it ample time to dry and cure according to the manufacturer’s guidelines. This is crucial for achieving a durable and long-lasting finish.

Remember that proper ventilation and following safety guidelines are essential when working with finishes, so make sure you are in a well-ventilated area and wear appropriate protective gear.

By following these steps, you can effectively prepare and sand thin wood strips to achieve clean edges and smooth surfaces. Applying the right finish will not only enhance the appearance of your project but also protect the wood for years to come.

Enhancing Safety While Cutting Thin Strips

Discover effective techniques for cutting thin strips of wood by hand while prioritizing safety. This comprehensive guide provides step-by-step instructions and valuable tips to enhance your woodworking skills.

When it comes to cutting thin strips of wood by hand, safety should always be a top priority. By following the right precautions and using proper protective gear, you can significantly reduce the risk of accidents. Here are some essential guidelines to keep in mind:

Protective Gear: Gloves, Goggles, And More

To ensure your safety while cutting thin strips of wood by hand, make sure to wear the appropriate protective gear. Here are some essential items you should consider using:

- Gloves: Wear a durable pair of gloves to protect your hands from sharp edges, splinters, and potential cuts.

- Goggles: Protect your eyes from flying wood particles and any debris that may be produced during the cutting process.

- Ear protection: Consider using earplugs or earmuffs to shield your ears from excessive noise levels if you are using power tools.

- Dust mask: Using a dust mask can help prevent the inhalation of wood dust and particles.

Safety Precautions To Prevent Accidents

In addition to wearing protective gear, it’s crucial to take specific safety precautions to minimize the risk of accidents while cutting thin strips of wood. Here are some guidelines to follow:

- Clear workspace: Ensure that your work area is free from any clutter or obstacles that could cause you to trip or lose control while cutting.

- Secure the wood: Before starting, make sure the wood you’re cutting is properly secured in place, either with clamps or a vise, to prevent it from moving unexpectedly.

- Use the right tools: Ensure you are using the appropriate tools for the job and that they are in good working condition. Dull or damaged tools can lead to accidents.

- Maintain focus: Always pay close attention to your cutting process, avoiding distractions that could compromise your safety. The slightest lapse in concentration can result in an injury.

- Take breaks: Cutting thin strips of wood requires precision and focus, so it’s important to take regular breaks to prevent fatigue, which can increase the chances of accidents.

Proper Handling And Storage Of Cutting Tools

Handling and storing your cutting tools correctly is essential for both safety and longevity. Here are some tips to ensure you are handling and storing your tools properly:

- Store tools in a designated area: Keep your cutting tools organized and stored in a secure location, away from children or anyone who is not trained to use them.

- Handling with care: When using cutting tools, always maintain a firm grip and use them within their intended purpose. Avoid using excessive force or applying pressure in an unsafe manner.

- Clean after use: After each use, make sure to clean your tools thoroughly, removing any debris or sawdust that may have accumulated. This helps prevent rust and keeps the tools in optimal condition.

- Properly store sharp objects: When not in use, ensure that sharp objects, such as saws or chisels, are safely stored in their original sheaths or protective covers to avoid accidental cuts or injuries.

Remember, by following these safety measures and applying proper techniques, you can enjoy cutting thin strips of wood by hand while minimizing the risk of accidents. Stay safe and make woodworking a fulfilling and enjoyable experience!

Final Thoughts: Mastering The Art Of Cutting Thin Strips By Hand

Discover the secrets to cutting thin strips of wood by hand in ‘Final Thoughts: Mastering the Art of Cutting Thin Strips by Hand. ‘ This informative guide provides step-by-step instructions and helpful tips for achieving precise results without the need for power tools.

Developing Skill And Precision Through Practice:

Practicing the art of cutting thin strips of wood by hand requires dedication and patience. Here are some steps to help you develop your skills and achieve precision:

- Start by selecting the appropriate wood for your project. Choose a type of wood that is suitable for cutting thin strips, such as maple or birch.

- Use a sharp and well-maintained handsaw. A dull blade can cause the wood to splinter and ruin your cut. Make sure to maintain your saw regularly by sharpening it and checking for any damage.

- Mark your cutting line clearly on the wood using a straight edge and a pencil. This will help guide your saw and ensure a straight cut.

- Practice your grip and technique. Hold the saw handle firmly but not too tightly, allowing for flexibility and control. Start the cut with a gentle hand and gradually increase your speed and pressure as you become more comfortable.

- Keep your saw blade aligned with the marked cutting line. Follow the line closely to achieve an accurate cut.

- Use short and precise strokes. Avoid forcing the saw or applying too much pressure, as this can result in a jagged or uneven cut. Let the saw do the work, and focus on maintaining a steady and controlled motion.

- Practice, practice, practice! Cutting thin strips of wood by hand takes time and practice to perfect. Keep challenging yourself with different projects and gradually increase the difficulty level to improve your skills and precision.

The Satisfaction Of Creating Precise Woodwork By Hand:

Cutting thin strips of wood by hand not only requires skill but also offers a rewarding sense of accomplishment. Here are some reasons why:

- Handcrafted woodwork brings a unique touch to your projects. Each cut and carve is a reflection of your craftsmanship and personal touch.

- Achieving precision through hand cutting allows you to create intricate designs and patterns that may not be possible with power tools.

- Working with your hands cultivates a deep connection with the wood and the process. You can feel the texture, smell the aroma, and appreciate the natural beauty of the material you’re working with.

- The time and effort invested in hand-cutting thin wood strips result in a one-of-a-kind piece that stands out from mass-produced items.

- The satisfaction of seeing your vision come to life, knowing that you accomplished it solely by your skill and dedication, is truly fulfilling.

Recommended Resources For Further Learning:

If you want to delve deeper into the art of cutting thin strips of wood by hand, here are some valuable resources to explore:

- Books: “The Complete Manual of Woodworking” by Albert Jackson and David Day, “The Handplane Book” by Garrett Hack, and “Understanding Wood: A Craftsman’s Guide to Wood Technology” by R. Bruce Hoadley are excellent references for woodworking techniques and knowledge.

- Online tutorials and videos: Websites like YouTube offer a wide range of free tutorials and instructional videos on hand-cutting thin wood strips. Renowned channels such as Woodworking for Mere Mortals and The Wood Whisperer provide step-by-step guidance and tips from experienced woodworkers.

- Woodworking forums and communities: Participating in online forums and communities such as WoodNet or Woodworking Talk can connect you with fellow woodworkers who can offer advice, share experiences, and answer any specific questions you have.

- Local woodworking classes or workshops: Look for woodworking schools, community centers, or craft clubs that offer hands-on classes or workshops. Learning alongside others and receiving guidance from experienced instructors can accelerate your progress and provide valuable feedback.

Remember, mastering the art of cutting thin strips of wood by hand is a journey that requires continuous learning, practice, and experimentation. Embrace the process, enjoy the satisfaction of creating beautiful woodwork, and let your creativity flourish!

Credit: www.familyhandyman.com

Frequently Asked Questions Of How To Cut Thin Strips Of Wood By Hand

How Do You Cut Narrow Strips Of Wood?

To cut narrow strips of wood, follow these steps:

1. Measure and mark the desired width on the wood.

2. Use a table saw or a circular saw with a guide to make a straight cut along the marked line.

3. Keep your hands at a safe distance from the blade and use a push stick for safety.

4. Repeat the process, adjusting the fence or guide as needed, to cut multiple narrow strips.

How Do You Cut Thin Strips Without A Table Saw?

To cut thin strips without a table saw, use a circular saw with a guide attachment.

What Is The Easiest Way To Cut Thin Wood?

The easiest way to cut thin wood is by using a sharp handsaw or a small electric saw.

How Do You Cut Thin Wood Without A Saw?

To cut thin wood without a saw, you can use a utility knife or a sharp blade.

Conclusion

Cutting thin strips of wood by hand can seem like a daunting task, but with the right technique and tools, it can be made much easier. By following the steps outlined in this blog post, you can achieve clean, precise cuts that are essential for various woodworking projects.

Start by choosing the appropriate saw for the job, whether it’s a rip saw or crosscut saw. Then, ensure you have a solid work surface and secure the wood securely before making your cuts. Remember to use proper hand placement and a steady rhythm throughout the process.

Lastly, take your time and be patient as you work through each strip. With practice, you will become proficient at cutting thin strips of wood by hand, allowing you to tackle a wide range of woodworking projects with confidence. Happy woodworking!

3 thoughts on “How to Easily Cut Thin Strips of Wood by Hand: Expert Techniques”