To figure out how much wood you need, measure the dimensions of the area and calculate the total square footage. Use this square footage to determine the amount of wood required for your project.

When planning a wood-based project, accurately estimating the amount of wood needed is essential to ensure you have enough materials and minimize waste. Whether you’re building a deck, installing flooring, or crafting furniture, understanding how to calculate the necessary amount of wood is crucial.

By following a few simple steps, you can determine exactly how much wood you need for your project. We will guide you through the process, helping you make accurate measurements and calculations to ensure a successful outcome. Read on to learn more about how to figure out how much wood you need for your next project.

Understanding Your Woodworking Project

Assessing Project Requirements

Before you embark on any woodworking project, it’s crucial to assess your project requirements. This will help you determine how much wood you need and guide you in making the right choices. Start by getting a clear vision of what you want to build. Consider the dimensions of your project, including its length, width, and height. Taking accurate measurements will prevent any wastage and ensure you have enough wood to complete your masterpiece. Remember to account for any additional features or components, such as shelves, drawers, or doors, which may require extra wood.

Considering Different Wood Types

Now that you have assessed your project requirements, it’s time to consider the different types of wood available. Each wood type has its unique characteristics, including color, grain pattern, hardness, and durability.

- Hardwood: Hardwood, such as oak, maple, or mahogany, is known for its strength and resistance to wear and tear. It’s an excellent choice for furniture and cabinets that require durability.

- Softwood: Softwood, such as pine, fir, or cedar, is less dense than hardwood and easier to work with. It’s typically used for projects that focus on aesthetics, like trim work or decorative pieces.

- Plywood: Plywood is a versatile option that consists of multiple layers of wood glued together. It’s durable, cost-effective, and suitable for various applications, including cabinets, flooring, and shelving.

Consider the specific needs of your project and the intended use of the finished product when choosing the right wood type. Keep in mind that different woods may have different costs and availability, so factor these variables into your decision-making process.

Measuring And Calculating Wood Dimensions

When it comes to woodworking projects, one of the most crucial steps is figuring out how much wood you need. Whether you’re building a small shelf or crafting a whole piece of furniture, accurate measurements and calculations are key to avoid wasting materials and time. In this article, we will guide you through the process of measuring and calculating wood dimensions, so you can ensure you have the right amount of wood for your project.

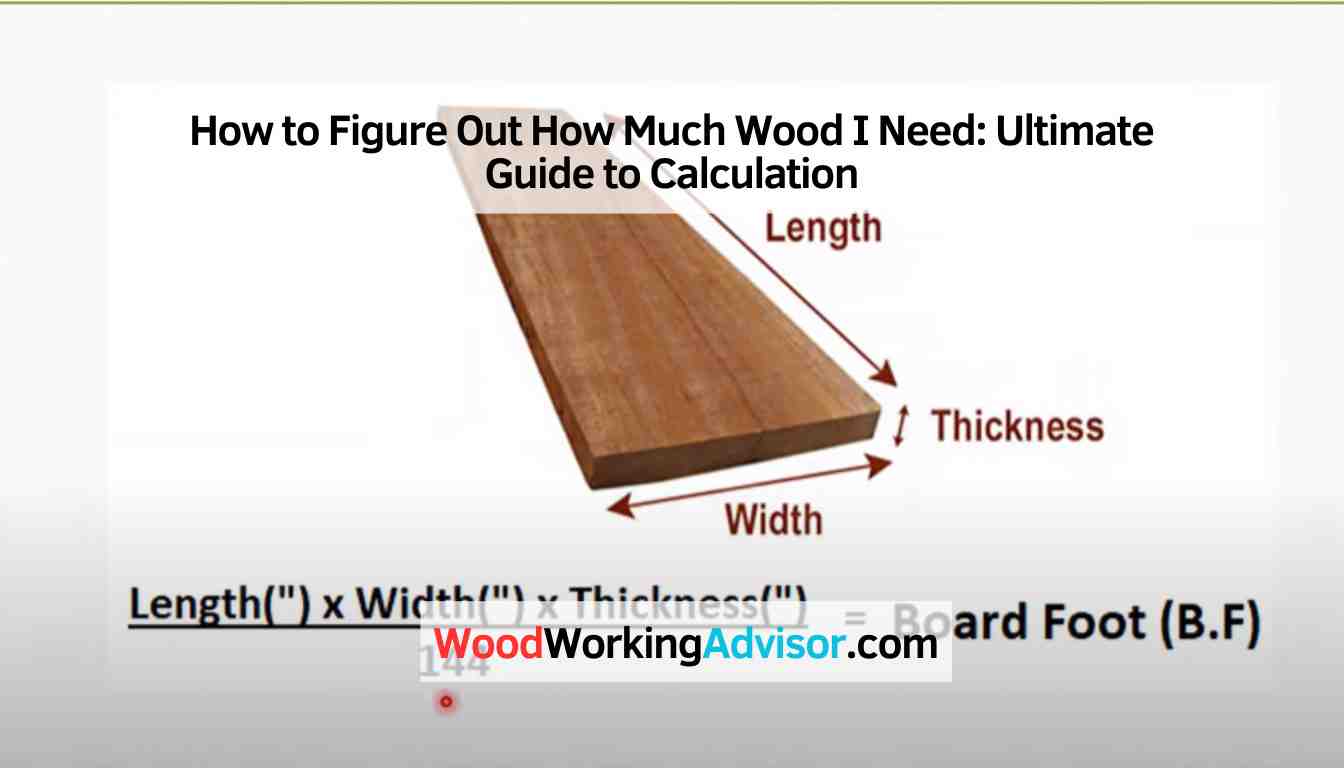

Understanding Board Feet Measurement

Before diving into the calculations, it’s important to understand how wood is measured and sold. The standard unit for measuring wood is board feet (bd. ft.), which represents a volume measurement. A board foot is equivalent to a piece of wood that is one foot long, one foot wide, and one inch thick. This standard allows for easy comparison and purchasing of lumber.

Calculating Wood Volume Needed

Now that you have a clear understanding of board feet, it’s time to calculate the amount of wood you’ll need for your project. To do this, you’ll need to follow a simple formula:

- Measure the length, width, and thickness of each wood piece required for your project.

- Convert these measurements into inches.

- Multiply the length, width, and thickness in inches to get the total volume in cubic inches.

- Divide the total volume by 144 to convert it into board feet.

For example, let’s say you need three boards that are 6 feet long, 4 inches wide, and 1 inch thick. You can calculate the total wood volume needed as follows:

| Board | Length (ft) | Width (in) | Thickness (in) | Total Volume (in3) | Total Volume (bd. ft.) |

|---|---|---|---|---|---|

| Board 1 | 6 | 4 | 1 | 24 | 0.17 |

| Board 2 | 6 | 4 | 1 | 24 | 0.17 |

| Board 3 | 6 | 4 | 1 | 24 | 0.17 |

| Total Wood Volume (bd. ft.) | 0.51 | ||||

Based on this calculation, you will need approximately 0.51 board feet of wood to complete your project.

By following these simple steps and calculations, you can accurately measure and calculate the wood dimensions needed for your woodworking projects. This will not only help you save money by avoiding unnecessary waste but also ensure a smoother and more efficient woodworking process.

Factoring In Wastage And Additional Cuts

When estimating the amount of wood needed for your project, it is essential to account for wastage and the potential for additional cuts. Accounting for wastage and adjusting for multiple cuts and errors can help ensure that you have enough wood for your project.

Accounting For Wastage

Wastage is an inevitable part of any woodworking project, as it accounts for cuts that may go wrong or pieces that become unusable due to defects. It is recommended to include a wastage factor of 10-20% when calculating the amount of wood needed. This additional allowance will help compensate for any unexpected errors or defects in the wood.

Adjusting For Multiple Cuts And Errors

When making multiple cuts from the same piece of wood, it’s important to have extra material to account for errors or adjustments. The best approach is to add an extra 20-30% to the total amount of wood needed when planning for multiple cuts. This additional allowance will ensure that you have enough wood to accommodate any mistakes or alterations that may arise during the cutting process.

Credit: www.theperfectloaf.com

Accounting For Joinery And Design Elements

When estimating the amount of wood needed for joinery and design elements, it’s essential to measure accurately and account for potential wastage. Start by creating a detailed plan and calculating the required dimensions for each component to determine the necessary wood quantity.

Remember to factor in allowances for potential errors or unusable sections during the cutting process.

Incorporating Joinery Allowance

Always account for extra wood needed for connections.

Anticipate the varying sizes of wood needed.

Include a buffer for any mistakes or adjustments.

Considering Design Features Impact

Think about intricate designs that may require extra wood.

Look at any ornate patterns that might increase wood requirements.

Factor in any unique shapes or angles in the design.

Consider the overall aesthetic impact on wood needs.

Special Considerations For Complex Shapes And Angles

When determining the wood needed for complex shapes and angles, precise measurements are essential to avoid material waste. Calculating accurately based on dimensions ensures efficient use of resources and cost-effective project completion. Attention to detail is key in estimating the necessary wood quantity for intricate designs.

Determining the amount of wood needed for a project becomes trickier when dealing with complex shapes and angles. Here are some tips to help you calculate wood needs accurately.

Calculating Wood Needs For Curved Shapes

Curved shapes require extra wood to accommodate the bending and shaping process. Measure the length of the curve and consider the width of the wood to calculate the additional material needed.

Determining Wood Quantity For Angled Cuts

For angled cuts, account for the waste generated due to the non-linear nature of the cuts. Make precise measurements to minimize excess wood and avoid running short on material during your project.

Keep these considerations in mind when planning your project to ensure efficient use of wood and a successful outcome.

Using Online Calculators And Apps For Efficiency

When it comes to estimating the amount of wood required for a project, using online calculators and woodworking apps can significantly enhance efficiency and accuracy. These digital tools eliminate the guesswork and provide precise measurements for materials needed, ensuring that you purchase the right amount of wood without excess waste.

Exploring Digital Wood Calculators

Digital wood calculators are invaluable resources for those embarking on woodworking projects, enabling users to input the specific dimensions and requirements of their projects to yield a precise quantity of wood needed. These calculators take into account factors such as the type of wood, project dimensions, and even allow for adjustments based on wood grain or defects, providing detailed and accurate estimations.

Benefits Of Woodworking Apps

Woodworking apps offer a range of features that go beyond simple calculations. They can help streamline the entire woodworking process, from planning and design to tracking inventory and managing project timelines. In addition to accurate wood quantity estimations, these apps can provide access to tutorials, project galleries, and even facilitate the purchase of materials, making them an indispensable tool for woodworking enthusiasts.

Consulting With Professionals And Experienced Woodworkers

When it comes to figuring out how much wood you need for your project, seeking advice from professionals and experienced woodworkers can be extremely valuable. These experts have years of experience and a wealth of knowledge that can help guide you in making the right decisions. There are two main ways you can engage with these individuals: seeking advice from woodworking experts and engaging with experienced professionals.

Seeking Advice From Woodworking Experts

Woodworking experts are individuals who have dedicated their lives to mastering the craft of working with wood. They have an intricate understanding of not only the various types of wood available but also the specific requirements of different projects. By seeking their advice, you can gain insights on the type and quantity of wood that would be needed for your specific project.

When seeking advice from woodworking experts, it is important to provide them with detailed information about your project. Be prepared to discuss the size, design, and purpose of the item you are building, as well as any specific requirements you may have. These details will help the experts provide you with more accurate guidance on the amount of wood you will need.

Engaging With Experienced Professionals

In addition to woodworking experts, engaging with experienced professionals in the industry can also be helpful. These professionals may include contractors, carpenters, or individuals who have worked on similar projects in the past. Their real-world experience can provide you with practical insights and tips on estimating the quantity of wood you will need.

Engaging with experienced professionals is a great way to expand your understanding of the wood requirements for your project. You can ask them about the challenges they have faced in the past, any specific considerations you should keep in mind, and any shortcuts or tricks that can help you make the most of your materials.

When consulting with professionals and experienced woodworkers, remember to be open-minded and receptive to their suggestions. Their expertise can help you avoid common pitfalls and ensure that you purchase the right amount of wood for your project, saving you both time and money in the long run.

Reviewing And Adjusting Calculations For Precision

To ensure accuracy in determining wood quantity, perform a meticulous review and adjustment of calculations. This process guarantees precise measurements, aiding in the accurate estimation of the required wood amount. Consistently reviewing and refining calculations is essential for achieving precision in determining the necessary wood supplies.

When it comes to any woodworking project, accuracy is key. A small miscalculation can result in wasted materials and unnecessary expenses. Therefore, reviewing and adjusting your measurements and calculations is crucial to ensure precision in your project. In this section, we will discuss two essential steps to help you achieve this: Double-Checking Measurements and Calculations, and Making Adjustments for Accuracy. By following these steps, you can minimize errors and confidently move forward in your woodworking endeavor.

Double-checking Measurements And Calculations

Before making any cuts or purchasing materials, it’s essential to double-check your measurements and calculations. Here are some practical tips to help you ensure accuracy:

- Verify your initial measurements: Take a moment to re-measure all dimensions and angles to confirm their accuracy.

- Check your calculations: Calculate the total length, width, and volume by adding up all the individual measurements. Use a calculator or a trusted online tool to avoid any possible mathematical errors.

- Consider practicality: While the calculations provide the theoretical measurements, take into account any adjustments needed to accommodate joints, saw kerfs, or other practical considerations. This step will help you determine more precise quantities needed.

- Consult woodworking references: Reference books or online sources can provide guidelines for typical allowances and dimensions. These resources can help you cross-reference your calculations to ensure accuracy.

Making Adjustments For Accuracy

Even the most careful calculations may require some adjustments to achieve optimal precision. Here are some practical strategies to help you make necessary adjustments:

- Minimize waste: After calculating your initial measurements, evaluate the amount of wood you need. If the quantity appears excessive, look for opportunities to optimize your design to reduce waste. Consider rearranging or rethinking your layout to minimize scrap.

- Account for margin of error: It’s important to be realistic about the margin of error in any measurement or calculation. Adjusting measurements slightly can help compensate for any small discrepancies that may occur during the woodworking process.

- Order extra material: It’s always advisable to order slightly more wood than you calculated to account for errors, unforeseen challenges, and cutting mistakes. This extra material can serve as a backup and prevent unnecessary delays in your project.

Remember, reviewing and adjusting your measurements and calculations is a vital part of achieving precision in your woodworking projects. By double-checking your measurements and making necessary adjustments, you can ensure accurate results and avoid costly mistakes. Take the time to review your work, consult references, and account for practical considerations to maximize your woodworking success.

Frequently Asked Questions On How To Figure Out How Much Wood I Need

How Do I Calculate The Amount Of Wood Needed For A Project?

To determine the quantity of wood required, measure the dimensions of the project area. Calculate the area to be covered and consider extra for wastage or unexpected needs. Take into account the type and thickness of the wood for accurate estimation.

What Factors Should I Consider When Deciding How Much Wood To Buy?

Consider the project’s size, design intricacies, and any potential additional needs. Factor in the type of wood, as different woods have varying densities and widths. Plan for any potential errors or changes during the project to avoid running out of materials.

Are There Any Online Tools Available To Help Me Calculate The Wood Quantity?

Yes, various online wood calculators can assist in determining the precise amount of wood needed based on your project’s specifications. These tools often consider the type of project, dimensions, and any additional factors to provide an accurate estimation of required material quantities.

Conclusion

So, there you have it – figuring out how much wood you need is not as daunting as it may seem. By following these simple steps and using a reliable wood amount calculator, you can confidently plan your wood projects with ease.

Now, go ahead and tackle that project with your newfound knowledge!