To measure length for a 45-degree cut, use a measuring device and mark the necessary length on the material. Then, measure and mark the desired angle of 45 degrees from the marked point, ensuring accuracy and precision.

It’s important to measure with caution to achieve the correct length for a 45-degree cut. This ensures straight and precise cuts that fit perfectly in your project. Before beginning any cutting process, always double-check your measurements to avoid any errors and ensure a successful outcome.

By following these steps, you can achieve accurate measurements for a 45-degree cut.

Choosing The Right Tools

When it comes to measuring length for a 45 degree cut, having the right tools is essential. With precise measurements, you can achieve accurate cuts that fit seamlessly together. In this section, we will explore two tools that are crucial for measuring length accurately: selecting the correct measuring tape and utilizing a speed square.

Selecting The Correct Measuring Tape

When selecting a measuring tape, you want to ensure it is reliable and easy to use. Look for a tape with clear and visible markings, preferably in both inches and centimeters. A tape with a locking mechanism is also handy to keep your measurement in place.

Consider the length of the measuring tape as well. For most woodworking projects, a tape that extends up to 25 feet or 7.5 meters should be sufficient. However, if you frequently work on larger projects, investing in a longer tape may be beneficial.

Utilizing A Speed Square

A speed square, also known as a tri-square or rafter square, is a versatile tool that can assist in measuring and marking 45-degree angles accurately. It consists of a 90-degree angle and a 45-degree angle, making it perfect for various woodworking tasks.

When using a speed square to measure length for a 45-degree cut, place the long side of the square along the edge of the material. Ensure it is straight and firmly held in place. Then, align the 45-degree angle of the square with the line you want to cut at. The long side of the square will now guide your saw along the correct angle, resulting in the desired cut.

Make sure to double-check all measurements and angles before making any cuts. Accuracy is key in achieving precise and well-fitted joints.

Accurate Measurement Techniques

Accurate measurements are crucial when it comes to achieving precise 45-degree cuts. The ability to measure length correctly ensures that your cuts are clean and aligned, resulting in professional-looking finished pieces. In this article, we will explore two essential techniques for measuring accurately: mastering the use of measuring tape and understanding the speed square measurements.

Mastering The Use Of Measuring Tape

Measuring tape is an indispensable tool in any woodworker’s arsenal. By following these steps, you can enhance your measurement skills:

- Start by extending the tape measure along the length of the material you want to cut. Ensure the tape lies flat against the surface, without any kinks or bends.

- Hold the tape measure securely and align the zero mark with the edge of the material. Make sure the tape is taut for accurate measurements.

- Read the measurement at the point where the material ends. Take note of the exact length. If the measurement falls between two markings, note the fraction or measurement down to the nearest smaller increment.

- Double-check your measurement to avoid any errors before making your cut. Remember, even the smallest mistake in measurement can lead to significant inaccuracies in the final cut.

Following these steps will ensure accurate measurements with your measuring tape, giving you the confidence to make precise 45-degree cuts.

Understanding The Speed Square Measurements

The speed square is another valuable tool that can help you achieve accurate 45-degree cuts. Here’s how you can make the most of its measurements:

- Begin by placing the speed square’s shorter edge along the edge of the material you want to cut, ensuring it is flush and aligned.

- Locate the angle marking on the speed square that corresponds to a 45-degree angle. This marking is typically labeled “45.”

- Align your pencil or marking tool with the edge of the speed square that intersects with the angle marking.

- Draw a line along the edge of the speed square using your marking tool, extending it across the material. This line will guide your 45-degree cut.

- Ensure the line is straight and aligned with your intended cut. Double-check the alignment before proceeding to make the cut.

By understanding and utilizing the measurements on your speed square effectively, you can achieve accurate 45-degree cuts time and time again.

Marking And Cutting The Material

Achieving an accurate 45-degree cut requires precise marking and using the correct cutting tools. Below, we’ll discuss the essential steps for marking and cutting materials at a 45-degree angle.

Precise Marking For 45 Degree Cuts

Precision is crucial when marking materials for a 45-degree cut. Use a quality carpenter’s square to ensure accurate angles. Measure and mark exact points on the material to guide the cutting process.

Utilizing The Correct Cutting Tools

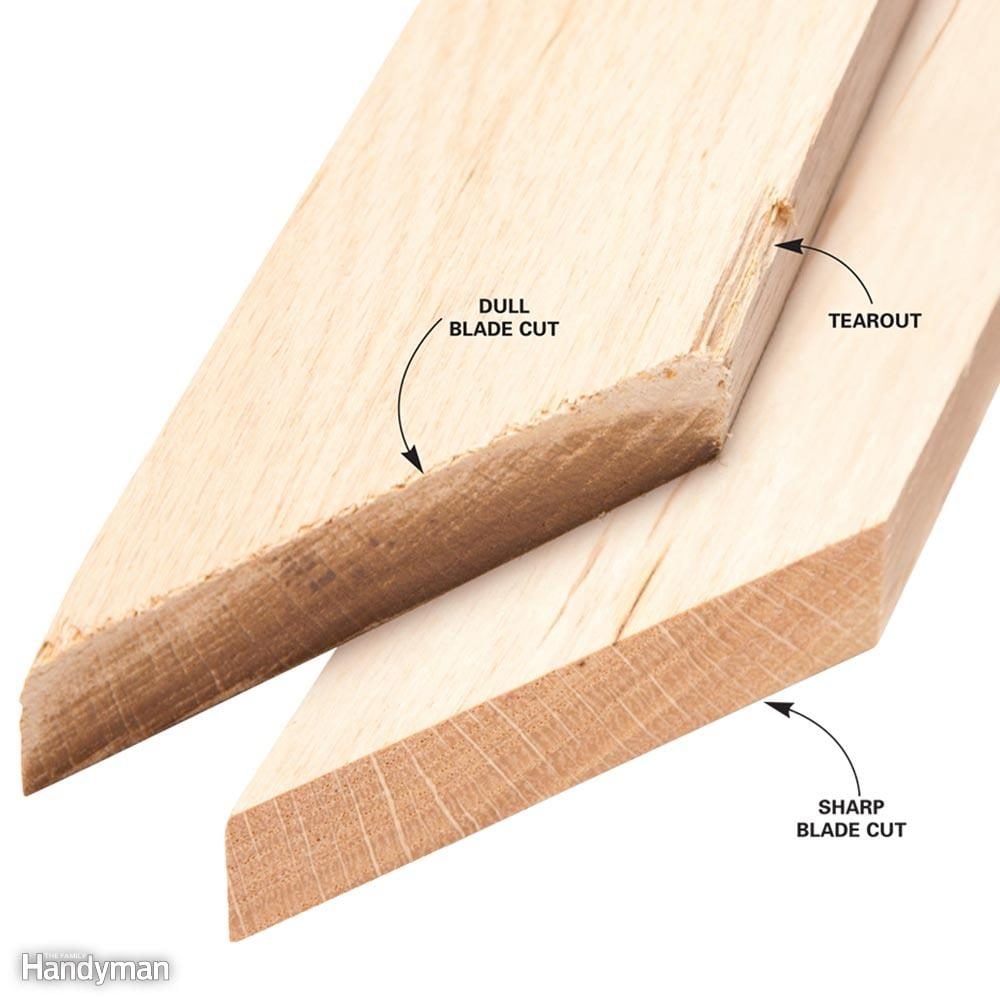

When cutting materials at a 45-degree angle, it’s vital to use the right tools. A miter saw is highly recommended for accurate and efficient cuts. Ensure the saw blade is sharp and in good condition to achieve clean and precise cuts.

Credit: www.youtube.com

Double-checking And Adjusting

When it comes to carpentry and woodworking, accuracy is paramount. You want to ensure that every cut you make is precise and exactly to the specifications you require. This is especially true when measuring lengths for a 45-degree cut. Even the smallest misalignment can throw off the entire project. That’s why double-checking and adjusting your measurements is a vital step in the process.

Verifying The Accuracy Of The Measurements

Before making any cuts, it’s essential to verify the accuracy of your measurements. This ensures that you start with a solid foundation and reduces the risk of errors. To do this, follow these steps:

- Using a tape measure, measure the length of the material you will be cutting. Make sure to hold the tape measure firmly against the surface to avoid any gaps.

- Double-check the measurement by measuring from the opposite end. This helps to eliminate any human error or inconsistencies.

- If the two measurements match, you can proceed with confidence. However, if there is any discrepancy, take additional measurements until you are confident in the accuracy of your measurement.

Making Minor Adjustments If Needed

If the measurements do not align perfectly, it may be necessary to make some minor adjustments to ensure a precise 45-degree cut. Here are some tips to help you make those adjustments:

- If the measurement is slightly too short, you can add a small amount of material to compensate. This can be achieved by using shims or layered tape to build up the length.

- Conversely, if the measurement is slightly too long, you can remove a small amount of material. This can be done by sanding or planing the material until it reaches the desired length.

- Remember to make these adjustments incrementally, checking the measurement after each modification. This allows you to achieve maximum precision without overcompensating.

By double-checking your measurements and making minor adjustments as needed, you can ensure that your 45-degree cuts are accurate and precise. This attention to detail will result in high-quality work and a finished project that meets your standards. Now that you know how to verify and adjust your measurements, you can approach your next carpentry or woodworking project with confidence.

Credit: www.familyhandyman.com

Pro Tips For Perfect 45 Degree Cuts

When it comes to precision woodworking, achieving perfect 45-degree cuts is essential. Whether you’re working on a DIY project or a professional undertaking, having the right techniques and tools can make all the difference. In this section, we’ll explore some pro tips that will help you measure length for a 45-degree cut with accuracy and precision.

Maintaining A Clean Workspace

One of the first pro tips for ensuring perfect 45-degree cuts is to maintain a clean and clutter-free workspace. A cluttered workspace not only hampers your focus but also increases the chances of measurement errors. By keeping your work area tidy, you can easily access your tools and materials, minimizing the chances of accidents or mistakes.

A clean and organized workspace also means having a dedicated surface to work on. Investing in a sturdy workbench or table with a smooth surface can provide stability and ensure accurate cuts. Additionally, make sure you have adequate lighting to clearly see your measurements and markings.

Practicing Patience And Precision

When it comes to measuring length for a 45-degree cut, practicing patience and precision is key. Rushing through the process can lead to inaccurate measurements and uneven cuts. Take your time and follow these tips:

- Use a reliable measuring tool: Start by using a durable and accurate measuring tool, such as a tape measure or a combination square. Ensure that your measuring tool is properly calibrated to avoid any discrepancies in your measurements.

- Measure twice, cut once: This age-old carpenter’s adage holds true for 45-degree cuts as well. Double-check your measurements before making any cuts to prevent errors.

- Mark the cut area: Use a pencil or a marking knife to clearly mark the area where you intend to make the 45-degree cut. This will act as a visual guide and reduce the chances of making incorrect cuts.

- Secure your workpiece: Before making the cut, secure the workpiece firmly in place using clamps or a vice. This will prevent any unnecessary movement or slipping, ensuring a precise and accurate cut.

- Use a miter saw or miter gauge: To achieve a perfect 45-degree cut, using a miter saw or a miter gauge can be immensely helpful. These tools allow you to set the desired angle and make precise cuts with ease.

By following these pro tips and practicing patience and precision, you can achieve flawless 45-degree cuts that will enhance the quality and aesthetics of your woodworking projects. Remember, the key is to take your time, focus on accuracy, and maintain a clean workspace for optimal results.

Credit: www.homedepot.com

Frequently Asked Questions On How To Measure Length For A 45 Degree Cut

How Do You Work Out The Length Of A 45 Degree Angle?

To work out the length of a 45-degree angle, use the formula: length = base/sin (45°).

How Do You Measure Miter Cut Length?

To measure the miter cut length, use a tape measure or ruler and place it along the length of the mitered cut. Measure from the starting point to the desired endpoint and record the measurement. This will give you the accurate length of the miter cut.

How Do You Measure An Angle Cut?

To measure an angle cut, use a protractor or angle finder tool. Place the tool on the angle’s vertex and align its base with one side of the angle. Read the measurement from the tool’s scale to determine the angle’s size accurately.

How Do You Measure And Cut A 45 Degree Angle For A Frame?

To measure and cut a 45-degree angle for a frame, use a miter saw for accuracy. Measure and mark the exact halfway point of the frame board, then set the miter saw to a 45-degree angle. Cut the board along the marked line for a precise angle.

Conclusion

Measuring length for a 45-degree cut requires precision and attention to detail. Following the correct techniques and using the right tools will ensure accurate results. Practice makes perfect, so don’t be discouraged if you don’t get it right the first time.

With these tips, you’ll soon be cutting with confidence.

One thought on “How to Easily Measure Length for a Perfect 45-Degree Cut”