To sharpen bandsaw blades, use a file or a bandsaw blade sharpener. First, secure the blade in a vise and follow the teeth’s angle to file or sharpen them.

Sharpening Bandsaw Blades For Optimal Performance

Properly maintaining and sharpening your bandsaw blades is essential for achieving optimal performance and ensuring clean and precise cuts in your woodworking projects. A dull blade not only produces subpar results but can also be dangerous to operate. In this guide, we will discuss the importance of maintaining sharp bandsaw blades, how to recognize signs of a dull blade, and the necessary safety precautions to take before starting the sharpening process.

Importance Of Maintaining Sharp Bandsaw Blades

Sharp bandsaw blades play a crucial role in the overall performance of your bandsaw. They enable smooth and efficient cutting, drastically reducing the risk of accidents or damage to your workpiece. When blades are dull, they tend to wander off course, leaving behind rough, uneven cuts that may require additional sanding or reshaping. By regularly sharpening your bandsaw blades, you can optimize their cutting capabilities and prolong their lifespan.

Recognizing Signs Of A Dull Blade

Identifying the telltale signs of a dull bandsaw blade can help you address the issue promptly. One of the most noticeable indicators is a decrease in cutting speed. If you find that your bandsaw is laboring through the material or the cutting process takes longer than usual, it is likely that the blade needs sharpening. Additionally, rough and splintered cuts, excessive heat buildup, or an increase in feed pressure are clear signs of a dull blade. Regularly inspecting your blade for these signs will ensure you tackle any issues before they affect the quality of your work.

Safety Precautions Before Starting The Sharpening Process

Prior to sharpening your bandsaw blade, it is crucial to take certain safety precautions to protect yourself and your equipment. Remember to always wear safety goggles and gloves to shield your eyes and hands from any potential hazards. Secure the blade in a vise and ensure it is firmly held in place to prevent any accidental movement during the sharpening process. Furthermore, make sure to disconnect the power supply to your bandsaw to avoid any accidental startups while working on the blade.

Now that we understand the importance of maintaining sharp bandsaw blades, recognizing signs of a dull blade, and the necessary safety precautions, we can move on to the actual sharpening process. Stay tuned for our next blog post, where we will guide you through step-by-step instructions on how to sharpen your bandsaw blades effectively.

Preparing Your Bandsaw Blade

Properly preparing your bandsaw blade is crucial before you begin the sharpening process. By taking the time to clean the blade, selecting the right sharpening tools, and setting up your workspace, you’ll be well on your way to achieving optimal cutting performance. So, let’s dive into each of these steps in detail:

Cleaning The Blade Before Sharpening

Before you start sharpening your bandsaw blade, it’s important to clean off any built-up debris or residue. This not only ensures a more accurate sharpening process but also extends the life of your blade. To clean the blade:

- Unplug the bandsaw and remove the blade from the machine.

- Wipe down the blade with a clean cloth to remove any loose particles.

- For more stubborn residue, use a mild detergent diluted with water to gently scrub the blade.

- Rinse the blade thoroughly with clean water and dry it completely.

Selecting The Right Sharpening Tools

Choosing the appropriate sharpening tools is essential to achieve a sharp, precise cutting edge on your bandsaw blade. Here are the key tools you’ll need:

| Sharpening Tool | Description |

|---|---|

| Mill Bastard File | A coarse file used for reshaping and removing material from the blade. |

| Bandsaw Blade Sharpening Stone | A specialized stone designed for honing the blade’s cutting edge. |

| Felt Buffing Wheel | Used with a polishing compound to give the blade a final polish. |

Setting Up Your Workspace

Creating a well-organized and properly equipped workspace can significantly improve your sharpening process. Follow these steps to set up your workspace:

- Find a flat, stable surface to work on, such as a workbench or table.

- Ensure you have adequate lighting to clearly see the blade and the sharpening process.

- Place a non-slip mat or rubber pad on your work surface to prevent the blade from sliding or moving during sharpening.

- Organize your sharpening tools in a way that allows easy access and minimizes the risk of accidents.

By following these steps, you’ll be well-prepared to sharpen your bandsaw blade effectively and efficiently. In the next section, we’ll delve into the actual sharpening process, so stay tuned!

How To Sharpen Bandsaw Blades: Expert Tips

Learn expert tips on how to sharpen bandsaw blades effectively. Improve the performance and longevity of your bandsaw with these easy-to-follow techniques.

Sharpening bandsaw blades is an essential maintenance task that every bandsaw owner should know how to do. Keeping your blades sharp not only ensures smooth and precise cuts, but it also extends their lifespan. In this guide, we’ll share expert tips on how to sharpen bandsaw blades effectively and efficiently. By following these step-by-step instructions and mastering the techniques for adjusting blade tension and ensuring consistency, you’ll be able to keep your bandsaw blades in optimal condition.

Step-by-step Guide On The Sharpening Procedure

The process of sharpening bandsaw blades may seem daunting at first, but with the right steps, it becomes a straightforward task. Follow this step-by-step guide to sharpen your bandsaw blades like a pro:

- Start by removing the bandsaw blade from the saw. This ensures your safety and allows for easier access to the blade for sharpening.

- Inspect the blade for any damages such as cracked or missing teeth. Replace the blade if necessary.

- Secure the blade in a vice or workbench to keep it stable during the sharpening process.

- Use a file designed specifically for bandsaw blades to sharpen each tooth individually. Ensure that you maintain a consistent angle and pressure while filing.

- Continue filing each tooth until the entire blade has been sharpened.

- After sharpening, clean the blade thoroughly to remove any metal filings or debris.

- Reattach the blade to the bandsaw, ensuring that it is properly tensioned.

- Test the blade by making some test cuts to verify its sharpness and performance.

Adjusting The Blade Tension For An Even Sharpening

Proper blade tension is crucial for achieving an even sharpening result. Follow these expert tips to adjust the blade tension before sharpening:

- Ensure the bandsaw is turned off and unplugged before adjusting the tension.

- Refer to your bandsaw’s manual to identify the proper tension specifications for different blade widths and types. Each bandsaw model may have specific tension requirements.

- Loosen the tension or blade tracking adjustment knob to release the tension on the blade.

- Safely adjust the tension by using a tension gauge or by applying moderate pressure to the blade with your finger. The blade should have a slight give but not be too loose.

- Check the tension again after sharpening to ensure it is still within the recommended range.

Techniques For Ensuring Consistency Across Teeth

Consistency across teeth is vital for achieving smooth and even cuts with your bandsaw. Here are some techniques to ensure that each tooth is sharpened consistently:

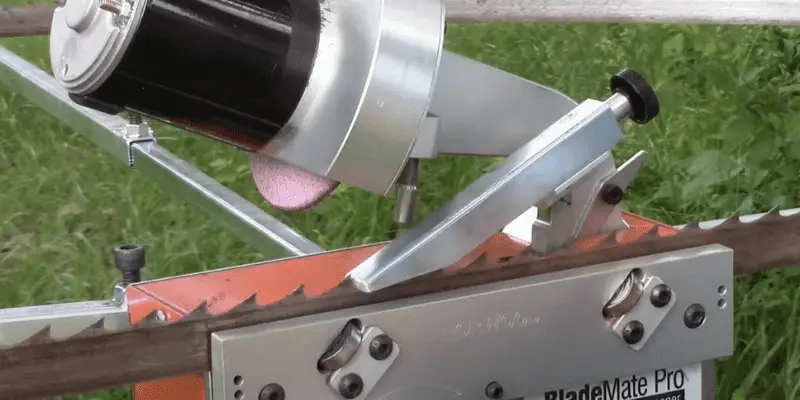

- Use a sharpening guide or jig to maintain a consistent angle while filing each tooth. This helps prevent uneven sharpening and prolongs the life of your blade.

- Avoid applying excessive pressure while filing. A light and steady stroke is more effective in maintaining consistent teeth height.

- Regularly inspect the teeth to verify consistent sharpening. Any irregularities should be corrected before continuing to sharpen.

By following these expert tips on sharpening bandsaw blades, you can keep your blades in top condition and ensure precise, clean cuts every time. Remember to always prioritize safety, follow the manufacturer’s guidelines, and practice consistent maintenance to maximize the lifespan and performance of your bandsaw blades.

Maintaining Sharpness And Blade Health

When it comes to using your bandsaw effectively and getting the best results, maintaining the sharpness and overall health of the blade is crucial. A sharp blade not only ensures clean and accurate cuts but also prevents strain on your machine. In this section, we will explore some routine practices to prolong blade sharpness, when to sharpen versus when to replace, and storage tips for preserving blade edges.

Routine Practices To Prolong Blade Sharpness

To extend the life of your bandsaw blades and maintain optimal sharpness, it’s important to follow these routine practices:

- Clean the blade regularly: After each use, remove any debris, sawdust, or resin buildup from the blade. You can use a soft brush or a cleaning solution to clean the blade gently. This prevents the buildup from affecting the blade’s performance and adds longevity to its sharpness.

- Proper tensioning: Check the tension of the blade regularly using a tension gauge. A blade that is too loose or too tight can lead to premature dulling or even breakage. Keep the blade tension within the manufacturer’s recommended range for optimal performance.

- Cooling and lubrication: While cutting, make sure to use a suitable lubricant or coolant to prevent overheating and friction. This helps in reducing the stress on the blade and extends its sharpness.

- Feed rate management: Maintaining a consistent and appropriate feed rate while cutting ensures that the blade encounters minimal resistance and avoids excessive strain. Adjust the feed rate according to the material being cut to prevent premature dulling.

- Regular inspection: Inspect the blade for any signs of damage, such as missing or broken teeth, cracks, or excessive wear. Address any issues promptly to prevent further damage and maintain the blade’s sharpness.

When To Sharpen Vs. When To Replace

Knowing when to sharpen the bandsaw blade versus when to replace it is essential to ensure cutting efficiency and avoid potential hazards. Here’s a general guideline:

| Sharpen | Replace |

|---|---|

| The blade is dull but still in good condition | The blade has extensive damage, like missing or broken teeth |

| Blade performance is compromised, leading to reduced cut quality | Blade cannot be sharpened anymore due to excessive wear or damage |

| Sharpening does not restore optimal cutting efficiency | Repeated sharpening has significantly reduced the blade’s width or life |

Storage Tips For Preserving Blade Edges

Proper storage plays a vital role in preserving the edges of your bandsaw blades. Follow these tips to ensure your blades stay sharp and in excellent condition:

- Clean and dry the blade thoroughly before storage to prevent any corrosion or rust formation.

- Store the blade in a cool, dry place to avoid exposure to moisture or extreme temperatures.

- Use blade covers or blade sleeves to protect the sharp edges from accidental damages or contact with other tools or surfaces.

- Consider hanging the blades vertically, using specialized blade storage hooks or racks. This helps in maintaining the shape and prevents bending or warping.

- Regularly inspect stored blades for any signs of rust, corrosion, or damage, and take appropriate measures as needed.

Advanced Sharpening Techniques For Longevity

Your bandsaw blade is a vital tool in your woodworking arsenal, and daily wear and tear can take a toll on its performance. However, by employing advanced sharpening techniques, you can extend the longevity of your bandsaw blades and ensure they continue to deliver clean, precise cuts. In this section, we will explore three advanced sharpening techniques that will help you achieve finer edges, understand blade tooth patterns for specialty sharpening, and determine the sharpening frequency for various materials. Let’s dive in!

Using Diamond Sharpeners For Finer Edges

When it comes to achieving razor-sharp edges on your bandsaw blades, diamond sharpeners are an excellent tool to have in your workshop. Unlike traditional sharpening stones, diamond sharpeners offer superior hardness, allowing them to cut through the tough metal of the blade with ease. Their abrasive surface ensures precise sharpening, resulting in finer edges that deliver cleaner cuts.

Here’s a simple step-by-step guide on how to use diamond sharpeners:

- Secure the bandsaw blade using a vice or clamp, ensuring it remains stable during sharpening.

- Hold the diamond sharpener firmly and at a consistent angle, typically around 25 degrees. This angle allows for optimal contact between the sharpener and the blade’s teeth.

- Gently stroke the sharpener along the teeth’s cutting edges, moving in a consistent motion from the base to the tip of the blade.

- Repeat this process for each tooth, making sure to maintain a steady hand and applying equal pressure.

- After sharpening, clean any metal particles or debris from the blade, and inspect it for any remaining dull spots.

By incorporating diamond sharpeners into your sharpening routine, you can achieve finer edges and enhance the overall performance of your bandsaw blades.

Understanding Blade Tooth Patterns For Specialty Sharpening

Bandsaw blades come in various tooth patterns, each suited to specific cutting tasks and materials. Having a solid understanding of these patterns will allow you to sharpen your blades more effectively, ensuring optimal performance and longevity.

The following table provides an overview of common blade tooth patterns and their ideal applications:

| Tooth Pattern | Ideal Applications |

|---|---|

| Regular Tooth | General-purpose cutting in wood and softer materials |

| Hook Tooth | Aggressive cutting in thicker wood and plastics |

| Skip Tooth | Cuts thick materials with less risk of clogging |

| Vari-Tooth | Combines a mix of tooth patterns for versatility |

By identifying the tooth pattern of your bandsaw blade and understanding its ideal applications, you can hone your sharpening technique to maximize efficiency and longevity.

Sharpening Frequency For Various Materials

The frequency at which you should sharpen your bandsaw blades depends on the materials you frequently work with. Different materials will have varying levels of hardness, which affects the rate of blade dulling. It’s essential to adjust your sharpening schedule accordingly to maintain optimal performance and extend the blades’ lifespan.

Here’s a general guideline for sharpening frequencies based on material:

- Softwoods: Depending on usage, sharpen every 8-12 hours of cutting time.

- Hardwoods: Sharpen every 4-8 hours of cutting time for best results.

- Metals: Due to the high wear on blades, sharpen after every use to ensure consistent cutting quality.

- Plastics and composites: Similar to hardwoods, sharpen every 4-8 hours of cutting time.

By adhering to these sharpening frequencies, you can maintain the performance and longevity of your bandsaw blades across a range of materials.

Frequently Asked Questions For How To Sharpen Bandsaw Blades

Is It Worth Sharpening Bandsaw Blades?

Yes, it is worth sharpening bandsaw blades as it improves cutting performance and extends the blade’s lifespan, saving you money in the long run. Sharpening ensures cleaner cuts, reducing waste and enhancing accuracy, making it a worthwhile investment for woodworking and other industries.

How Many Times Can You Sharpen A Bandsaw Blade?

A bandsaw blade can typically be sharpened 3-5 times, depending on the severity of damage and quality of the blade. It’s important to monitor the blade for signs of wear and tear, and consult a professional to ensure proper sharpening.

How Do I Know If My Bandsaw Blade Is Dull?

To determine if your bandsaw blade is dull, look for signs such as difficulty cutting through material, rough or uneven cuts, and excessive heat or burning during cutting. Inspect the blade for wear, dull teeth, or damaged edges. Regular maintenance and sharpening can help maintain blade sharpness.

How Often Should I Sharpen My Bandsaw Blades?

Regular maintenance is essential to maintain the sharpness of your bandsaw blades. It is recommended to sharpen them every 10-15 hours of use or whenever you notice a decrease in cutting performance. Keeping the blades sharp ensures clean cuts and prolongs their lifespan.

Conclusion

Maintaining sharp bandsaw blades is crucial for achieving precise and clean cuts in woodworking projects. By following the step-by-step process outlined in this blog post, you can easily sharpen your bandsaw blades and extend their lifespan. Remember to prioritize safety by wearing appropriate protective gear and exercising caution.

With regular maintenance and proper sharpening techniques, you’ll be able to enjoy the benefits of sharp bandsaw blades for years to come. Happy woodworking!

One thought on “How to Sharpen Bandsaw Blades: Expert Tips for Razor-Sharp Results!”