A wood milling machine is a powerful tool used to shape and cut wood. It is essential for woodworking projects.

Wood milling machines are versatile tools that can be used to create a variety of shapes and designs from raw wood material. These machines are equipped with various cutting tools and can be operated manually or with computer numerical control (CNC) technology.

With their precision and capability to produce intricate designs, wood milling machines are indispensable for furniture making, cabinetry, and other woodworking applications. They are commonly used in manufacturing facilities, woodworking shops, and hobbyist workshops. Whether it’s crafting custom furniture or shaping raw lumber, a wood milling machine is an invaluable asset for woodworkers of all skill levels.

The Evolution Of Milling Machines

The evolution of milling machines has greatly impacted the woodworking industry, revolutionizing the way wood is processed and shaped. From early developments to significant technological advancements, milling machines have continued to play a vital role in enhancing woodworking precision and efficiency.

Early Developments

The inception of milling machines traces back to ancient civilizations, where manual hand tools were used to shape and mill wood. As time progressed, basic milling machines emerged, enabling crude wood-cutting processes.

Technological Advancements

With technological advancements, milling machines have evolved significantly, incorporating automation, computerized controls, and precision engineering. Modern milling machines now boast enhanced capabilities, offering complex shaping, carving, and cutting functionalities.

Credit: www.amazon.com

Types Of Milling Machines

There are various types of milling machines used in woodwork, each with unique capabilities and applications.

Vertical Milling Machines

Vertical milling machines have a vertical spindle axis that creates vertical cutting movements.

Horizontal Milling Machines

Horizontal milling machines have horizontally oriented spindles for cutting along the length of the workpiece.

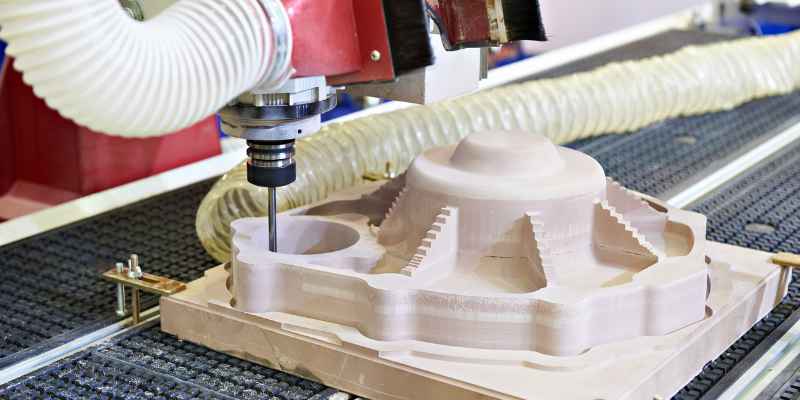

Cnc Milling Machines

CNC milling machines are computer-controlled devices that offer precise and automated milling operations.

Key Components Of A Milling Machine

Milling machines are widely used in manufacturing processes to shape and cut various materials, including wood. These machines consist of several crucial components that work together to achieve precise and efficient machining results. Understanding the key components of a milling machine is essential for anyone operating or considering the use of this versatile tool. In this article, we will explore the three main components of a milling machine: the spindle, cutting tool, and table with workholding. We will also touch upon the importance of a control panel in ensuring optimal machine performance.

Spindle

The spindle is the heart of a milling machine. It is responsible for rotating the cutting tool at high speeds, allowing it to remove material from the workpiece. The spindle is typically driven by a motor and consists of a spindle shaft, bearings, and a tool-holding device. The tool-holding device, known as a collet or a chuck, securely holds the cutting tool in place. The spindle’s rotational speed, also known as the spindle speed, can be adjusted to suit different materials and cutting requirements.

Cutting Tool

The cutting tool is another critical component of a milling machine. It is attached to the spindle and is responsible for performing the actual cutting or shaping of the workpiece. Milling machines can accommodate various types of cutting tools, including end mills, face mills, and fly cutters. These tools come in different sizes, shapes, and materials, allowing operators to select the most suitable tool for their specific machining needs. The choice of cutting tool depends on factors such as the material being machined, the desired surface finish, and the type of cut required.

Table And Workholding

The table and workholding system form the foundation of a milling machine. The table provides a stable platform for securing the workpiece during machining. It can be moved in different directions, allowing for precise positioning of the workpiece relative to the cutting tool. The table is equipped with various types of workholding devices, such as vises, clamps, and fixtures, which securely hold the workpiece in place. The workholding system must be robust and rigid to ensure the workpiece remains steady during the machining process, preventing any undesired movement or vibrations that could affect the machining accuracy.

Control Panel

The control panel plays a vital role in operating a milling machine effectively. It houses the necessary controls and interfaces to adjust the machine’s settings, such as spindle speed, feed rate, and depth of cut. The control panel also allows the operator to program and execute precise machining operations, including toolpath selection, tool change, and coolant activation. A well-designed control panel provides an intuitive user interface, allowing operators to fine-tune machine parameters and monitor the machining process efficiently. Additionally, a control panel often includes safety features and emergency stop buttons to ensure operator safety.

Understanding the key components of a milling machine, such as the spindle, cutting tool, table with workholding, and control panel, is essential for achieving optimal machining results. Each component plays a crucial role in the overall performance and capabilities of the machine. By familiarizing oneself with these components and their functions, operators can harness the full potential of milling machines to tackle a wide range of wood machining tasks.

Importance Of Precision In Milling Wood

Milling wood is a crucial process in woodworking that requires the utmost precision and attention to detail. Achieving fine wood detailing, minimizing material wastage, and ensuring the perfect fit of components are all dependent on precision in milling wood. Let’s explore these aspects in more detail below:

Achieving Fine Wood Detailing

Precision in milling wood is essential for achieving fine wood detailing. Whether you are crafting intricate furniture pieces or creating custom woodworking projects, the accuracy of your milling process directly impacts the final outcome. Only with precise milling can you create clean cuts, sharp edges, smooth surfaces, and intricate designs that give your piece a refined and professional look.

Minimizing Material Wastage

One of the primary benefits of precision milling wood is the ability to minimize material wastage. When working with expensive or limited wood resources, every inch counts. By ensuring precise measurements and cuts, you can maximize the use of your materials, reducing unnecessary waste and saving both time and money. Additionally, optimizing material usage also contributes to environmental sustainability, making precision milling an eco-friendly choice.

Ensuring Perfect Component Fit

Achieving tight and accurate component fit is crucial in woodworking projects. Whether it’s assembling furniture or constructing cabinetry, precise milling ensures that each piece fits together seamlessly without any gaps or misalignments. This level of craftsmanship not only enhances the overall aesthetic appeal but also guarantees structural integrity and longevity of the finished product. Precision milling allows for consistent dimensions, allowing for effortless assembly and ensuring a sturdy, reliable end result.

Precision in milling wood is paramount for woodworking enthusiasts and professionals who strive to create exceptional craftsmanship. By achieving fine wood detailing, minimizing material wastage, and ensuring perfect component fit, precision milling guarantees high-quality results that stand the test of time. Incorporating precision into your woodworking processes elevates your craftsmanship, making your creations truly outstanding.

Enhancing Efficiency With Advanced Techniques

Enhance your woodworking efficiency with advanced milling techniques using the innovative wood milling machine. Achieve precise results and streamline your production process for optimal output.

High-speed Machining

Milling wood machines are optimized for high-speed machining, increasing production efficiency.

Multi-axis Machining

Utilizing multi-axis machining in wood milling enhances precision and cuts down production time.

Modern milling wood machines incorporate advanced techniques to optimize efficiency and productivity.

The Impact Of Milling On Woodworking Productivity

Woodworking productivity is greatly impacted by the milling process, which plays a crucial role in shaping the final quality and efficiency of the end products. The use of milling machines in the woodworking industry has revolutionized the way wood is processed, resulting in significant improvements in production time and output quality. In this blog post, we will delve into the key ways milling impacts woodworking productivity, including the significant reduction in production time and the consistent quality output achieved through this advanced technology.

Reduction In Production Time

Milling wood machines have drastically reduced production time, allowing woodworking businesses to meet demands more efficiently. The precision and speed of milling machines contribute to faster wood shaping and cutting processes, ultimately streamlining production timelines and enhancing overall project turnaround.

Consistent Quality Output

Milling technology ensures consistent and high-quality output in woodworking. The precise cutting and shaping capabilities of milling machines result in uniform and flawless wood components, leading to exceptional product quality. This consistency contributes to the reputation and reliability of woodworking businesses, as customers can expect top-notch products time and time again.

Challenges And Solutions In Milling Wood

Milling wood involves various challenges that can impact the efficiency and quality of the process. Addressing these challenges requires effective solutions to ensure smooth operations and optimal outcomes. In this article, we’ll explore the key hurdles encountered in milling wood and how they can be overcome.

Tool Wear And Maintenance

Tool wear is a common issue during wood milling, leading to reduced precision and productivity. Regular maintenance and sharpening of tools are essential to mitigate wear and prolong their lifespan. Implementing proper cutting speeds and feeds, as well as investing in high-quality tool coatings, can significantly minimize wear and enhance overall cutting performance.

Dust And Chip Management

Dust and chip accumulation pose challenges in wood milling, affecting the workspace environment and operator health. Utilizing efficient dust collection systems and chip extraction methods is crucial to maintain a clean and safe working environment. Implementing proper ventilation and employing HEPA filters can effectively reduce airborne particles, contributing to a healthier and more comfortable milling environment.

Future Trends In Milling Wood Machines

The future trends in milling wood machines are poised to revolutionize the woodworking industry through cutting-edge advancements.

Smart Automation

Smart automation in milling wood machines brings efficiency by streamlining processes.

Automated systems perform tasks with precision, reducing human error significantly.

Integration Of Ai For Predictive Maintenance

Integrating AI for predictive maintenance enhances machine performance and minimizes downtime.

AI algorithms analyze data to predict maintenance needs, ensuring optimal operation.

Frequently Asked Questions On Milling Wood Machine

What Is The Main Function Of A Milling Wood Machine?

A milling wood machine is used to shape and smooth wood surfaces with precision and accuracy, making it easier to create custom wood products and furniture.

How Does A Milling Wood Machine Work?

The machine uses rotating cutters to remove excess wood material, allowing users to achieve the desired shape and smoothness on the wood surface efficiently and effectively.

What Are The Benefits Of Using A Milling Wood Machine?

Using a milling wood machine results in increased productivity, precise woodworking outcomes, smoother wood surfaces, and the ability to create intricate designs with ease.

Conclusion

Explore the endless possibilities of using a milling wood machine for your woodworking projects. With precision and efficiency, this machine can elevate your craftsmanship to new heights. Embrace the innovation and creativity that this tool offers in shaping your woodwork with finesse.

Elevate your projects today!