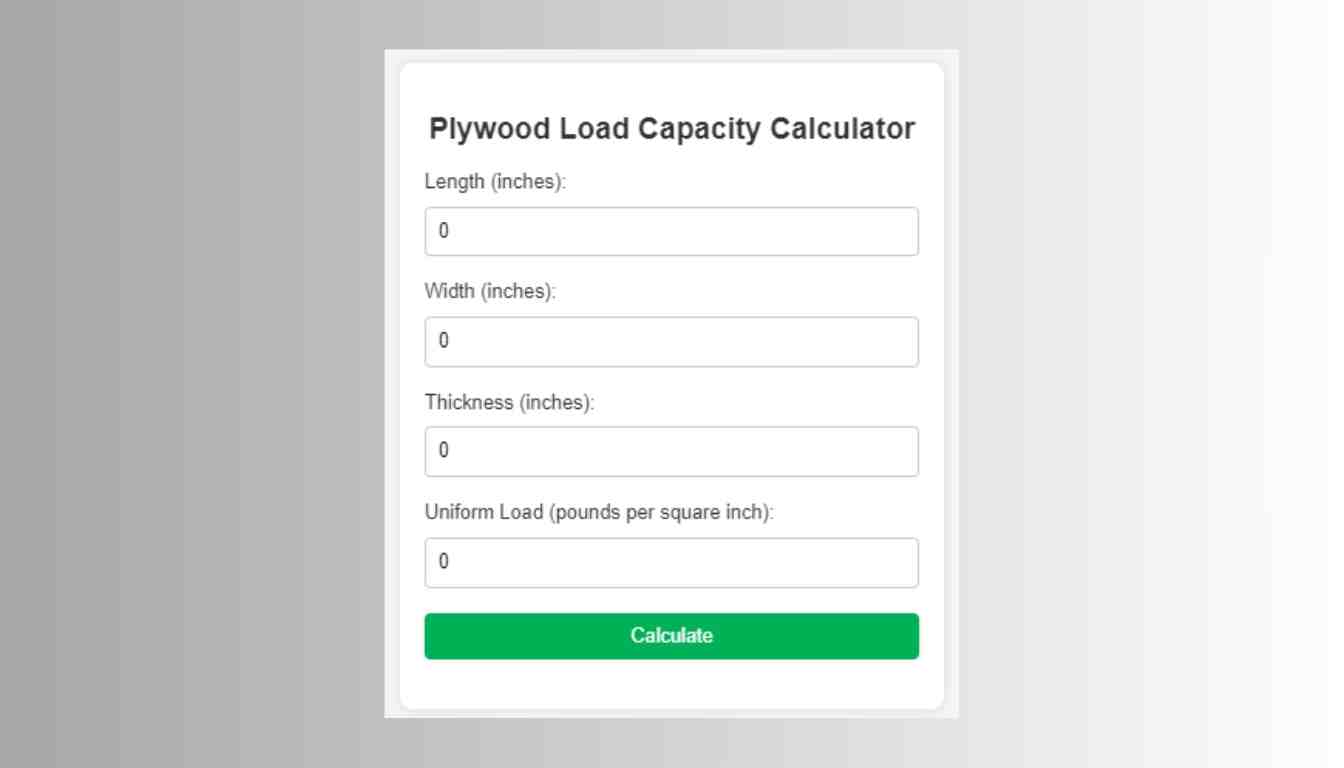

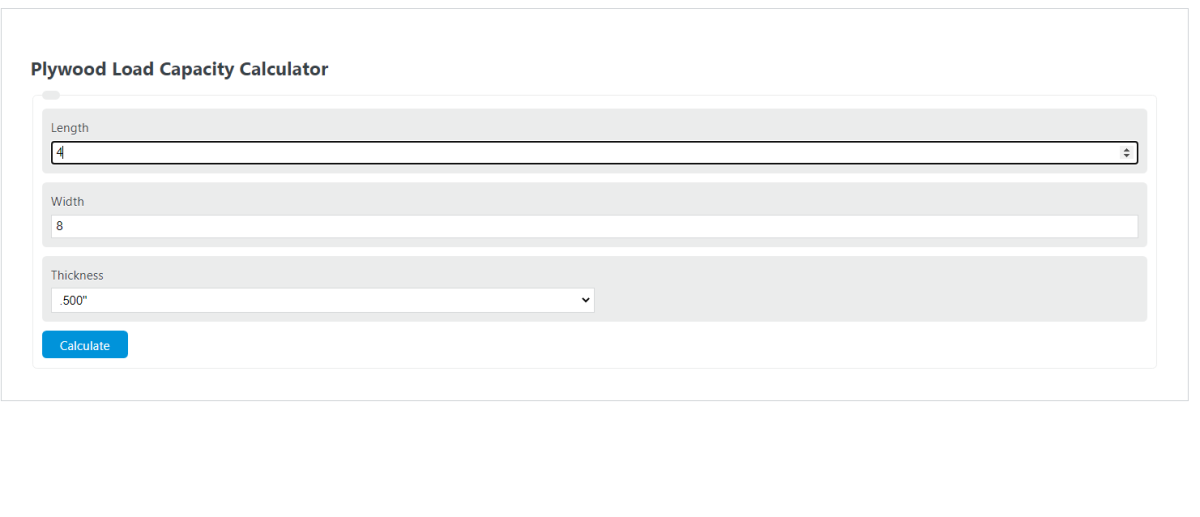

A Plywood Load Capacity Calculator estimates the weight a plywood sheet can support. This tool is essential for ensuring safe load management.

Plywood Load Capacity Calculator

Calculating the load capacity of plywood is crucial for architects, builders, and DIY enthusiasts to guarantee the structural integrity of construction and carpentry projects. Plywood, an engineered wood product, comprises several thin layers of wood veneer bonded together, making it a popular choice for various applications.

Its high strength-to-weight ratio, affordability, and versatility make plywood indispensable in the building industry. A Plywood Load Capacity Calculator helps to prevent overloading, which can lead to material failure and potentially hazardous situations. Proper use of this calculator aligns with building codes and safety standards, ensuring that every project involving plywood is secure and reliable.

Introduction To Plywood In Construction

Plywood has become a staple in building projects worldwide. Its versatility makes it a go-to choice for a plethora of construction needs. From houses to high-rises, plywood steps up as a reliable material. Now, builders have a robust tool – the Plywood Load Capacity Calculator. This tool ensures that construction plans are both safe and efficient.

The Role Of Plywood In Structural Projects

Plywood plays a crucial role in structural integrity. It offers uniform strength due to its cross-grain pattern. This unique composition distributes loads evenly. Plywood can act as a shear wall, resist bending, and add rigidity to frames. The right thickness can hold significant weight. It fits perfectly in floors, walls, and ceilings.

Benefits Of Using Plywood For Load-bearing Applications

- Lightweight: Easier to handle, reducing labor costs.

- Strength: Comparable to steel, making it ideal for heavy-duty use.

- Flexibility: Can bend without breaking under stress.

- Wide Sheets: Means fewer seams and a more cohesive structure.

- Cost-efficient: Less expensive than many alternative materials.

Coupled with the Plywood Load Capacity Calculator, these benefits ensure optimized material use and safety.

Plywood Load Basics

Welcome to the world of DIY and construction where understanding plywood is crucial. Plywood, versatile and sturdy, has become a staple in various projects. A Plywood Load Capacity Calculator becomes an essential tool in ensuring your structure’s safety and integrity. Knowing the basics helps in making informed decisions about the right kind of plywood for your project’s needs. Let’s dive into understanding the fundamentals of plywood load capacity.

Understanding Plywood Grades And Types

Plywood comes in various grades and types, each suited for different applications. Grades, ranging from A to D, denote the quality of the plywood’s finish. They point to the number of knots and imperfections in the wood. Types of plywood, like softwood and hardwood, suggest the kind of tree used to make the veneers.

- A-Grade: Smooth, paintable surface with minimal defects.

- B-Grade: Minor blemishes that can be easily repaired.

- C-Grade: More visible knots and defects.

- D-Grade: High number of blemishes, typically for utility purposes.

Types like Marine plywood or Pressure-Treated plywood are specially designed for moisture resistance and outdoor use. A clear understanding of grades and types ensures optimal choice for load capacity needs.

Factors Influencing Plywood Load Capacity

Several factors contribute to the load-bearing capacity of plywood. These critical aspects need consideration before using a Plywood Load Capacity Calculator. The thickness of the plywood is a major determinant. Thicker sheets typically bear more weight. The span between supports also plays a significant role. Shorter spans can support heavier loads. Here are other key factors:

| Factor | Impact on Load Capacity |

|---|---|

| Wood Species | Different species have varying strength properties. |

| Moisture Content | Wet plywood can compromise load bearing. |

| Panel Size | Larger panels might require additional support. |

| Direction of Load | Direction parallel to the grain bears more weight. |

Combining these factors with the correct plywood grade and type is essential for accurate load calculations.

Designing With Plywood Load In Mind

Understanding the load capacity of plywood is critical in fields such as construction and furniture design. Woodworkers, architects, and engineers must consider several factors that interact to define the robustness and durability of plywood structures. Accurate load calculations ensure safety and longevity. The right tools, including a Plywood Load Capacity Calculator, simplify this task.

Key Considerations For Plywood In Engineering

- Material Quality: Choose higher-grade plywood for greater strength.

- Thickness: Opt for appropriate thickness to support expected loads.

- Panel Dimensions: Balance the panel size with structural requirements.

- Support Span: Shorter spans increase the load-bearing capacity.

- Load Type: Differentiate between static and dynamic loads.

- Environmental Factors: Protect from moisture and extreme temperatures.

The Importance Of Load Distribution On Plywood

Evenly spread loads prevent stress concentration on the plywood. This uniform distribution is essential for maintaining the structural integrity over time. Proper load distribution avoids bending, breaking, or warping of the plywood panels. Incorporating a Plywood Load Capacity Calculator guides in mapping out where and how loads should be applied for optimal performance.

Use the calculator’s inputs to model various scenarios:

| Input Parameter | Description | Impact |

|---|---|---|

| Dimensions | Length and Width | Affect stress distribution |

| Thickness | Plywood sheet thickness | Directly relates to capacity |

| Support Conditions | Edge or point supports | Influences deflection limits |

Remember, a well-distributed load on plywood ensures stability, safety, and functionality for any structure or piece of furniture.

Calculating Plywood Load Capacity

Calculating the load capacity of plywood is pivotal in ensuring safety and integrity in construction and woodworking projects. This calculation determines if the plywood can support the expected load without bending or breaking. Understanding how to accurately calculate the load capacity of plywood is essential for architects, builders, and DIY enthusiasts alike.

The Mathematics Behind Plywood Load Calculations

Plywood load capacity relies on factors such as thickness, grade, and support span. The mathematics involved includes principles of physics and material science. The key formula used is:

F = (E I) / (L D)- F stands for the maximum load (in pounds).

- E represents the modulus of elasticity.

- I is the moment of inertia.

- L is the length between supports.

- D signifies deflection limits.

By manipulating these variables, one can determine the safe load capacity for a given plywood panel.

Software Tools Vs. Manual Calculations

Calculating plywood load capacity can be daunting. Advancements in technology have resulted in software tools that automate these calculations. These tools are often more accurate and vastly quicker than manual calculations.

| Software Tools | Manual Calculations |

|---|---|

| Quick and accurate | Time-consuming and prone to error |

| User-friendly interfaces | Requires strong mathematical understanding |

| Can handle complex variables | Limited to simpler scenarios |

Despite the convenience of software, understanding the fundamental mathematics behind load calculations is beneficial for a deeper insight into the mechanics of plywood.

Plywood load capacity calculators help ensure that plywood used in any project can withstand the load without fail.

Impact Of Environmental Conditions On Plywood

The world of construction relies heavily on plywood for its versatility and strength. Yet, not all plywood is alike, and its load capacity can shift under different environmental factors. Understanding how moisture and temperature impact plywood is crucial for ensuring safety and durability in your projects.

How Moisture And Temperature Affect Plywood Strength

Plywood behaves differently when exposed to various levels of moisture and temperature. These two factors can greatly alter its structural integrity.

- Moisture: High humidity can make plywood swell and weaken.

- Dry conditions: Conversely, plywood can shrink and become brittle.

This performance shift is essential to keep in mind during both planning and execution phases. A proper Plywood Load Capacity Calculator takes these conditions into account to provide accurate guidance.

Long-term Vs. Short-term Load Capacity

Plywood distinguishes between temporary and ongoing weight. This distinction is critical for matching the right plywood to your project needs.

| Load Type | Impact on Plywood |

|---|---|

| Short-term Load | Temporary weight, less impact |

| Long-term Load | Persistent weight, greater impact |

Selecting the right plywood for long-term loads without factoring in the environmental effects could lead to premature material failure. The Plywood Load Capacity Calculator allows for accurate estimations to mitigate this risk.

Credit: seblog.strongtie.com

Safety Margins And Testing

Imagine building a bookshelf. You choose plywood for shelves. But how much weight can it hold? Safe structures need proper load capacity info. Plywood Load Capacity Calculator helps designers and DIY enthusiasts ensure their projects stand strong. Safety is key. Testing plywood helps define how much weight it can carry without failing. This part of the post explores the importance of using safety margins and the process of testing plywood to ensure durability and stability in your projects.

Incorporating Safety Factors In Load Calculations

Safety factors prevent accidents. They add extra strength to calculations. It’s like carrying a backup rope during a climb. Here is how to do it:

- Determine the maximum load.

- Apply a safety factor, usually between 1.5 to 2.5.

- Calculate the safe load using the formula:

Safe Load = Maximum Load / Safety Factor.

This simple step can save lives and money. It confirms that the plywood can handle more than expected. Always err on the side of caution and adopt a robust safety factor.

Industry Standards For Plywood Load Testing

Industry standards guide plywood load testing. These standards ensure that every piece can support a certain amount of weight. The most common standards include:

| Standard | Description |

|---|---|

| ASTM D5456 | Guideline for evaluating the load-bearing capabilities of wooden panels. |

| ISO 12466-1 | Criteria for plywood in dry conditions. |

| EN 636 | European norms for plywood in varying environments. |

Certified labs test plywood using these standards. They apply controlled loads to the plywood until it bends or breaks. This testing provides essential data. The data contributes to the load capacity calculations in calculators. Understanding these standards helps you trust the plywood chosen for your projects.

Case Studies: Plywood Load In Action

Understanding plywood load capacity is crucial for any construction or DIY project. Real-world applications and failures provide valuable insights. Let’s explore some case studies.

Real-world Examples Of Plywood Load Applications

Diverse projects rely on plywood for its strength and versatility. Here are some examples:

- Flooring support: Plywood is widely used to provide a stable base in residential flooring.

- Wall sheathing: It adds rigidity and load-bearing capacity to walls in commercial buildings.

- Furniture design: Plywood offers durability for bookshelves and cabinets under heavy weight.

Lessons Learned From Plywood Load Failures

Mistakes can lead to failures, but these are learning opportunities. Here’s what we can learn:

- Choosing the right plywood grade is imperative for the intended load.

- Proper support spacing prevents sagging or snapping under weight.

- Understanding environmental factors like moisture can impact plywood strength.

Tables can be helpful to present data easily. Here’s an instance:

| Project | Plywood Type | Load Capacity | Result |

|---|---|---|---|

| Home Shelving | CDX Plywood | 50 lbs/sq ft | Success |

| Outdoor Decking | Marine Plywood | 100 lbs/sq ft | Failure |

Credit: calculator.academy

Future Of Plywood In Load-bearing Construction

The world of construction constantly evolves. Plywood, a mainstay in building, is no exception. With advancements in technology, the use of plywood in load-bearing scenarios is seeing innovative changes. Now, we’re not just relying on its traditional merits but also witnessing its transformation. A Plywood Load Capacity Calculator is a handy tool in this new age, ensuring safe and efficient use of plywood in construction.

Innovations In Plywood Manufacturing

New techniques in plywood manufacturing are enhancing its load-bearing capabilities. Here’s a glimpse at groundbreaking changes:

- Adhesives with higher tolerance: They now withstand extreme weather, making plywood more reliable.

- Cross-laminated plywood: This new structure boosts strength and stability for heavier loads.

- Automated inspections: Machines check for flaws, ensuring each sheet meets high standards.

Emerging Trends In Construction And Material Science

In the realm of construction and materials science, the future looks bright:

- Eco-friendly options gain traction. Builders want materials that are both strong and sustainable.

- Smart plywoods are emerging, with sensors embedded to monitor health and stress.

- 3D printing with plywood is on the horizon, potentially revolutionizing how we think about construction.

Frequently Asked Questions For Plywood Load Capacity Calculator

How Does Plywood Thickness Influence Load Capacity?

Plywood thickness directly affects its load capacity. Thicker plywood can support more weight, as it offers greater stability and resistance to bending or breaking. It’s crucial to choose the right thickness for your project’s load requirements.

What Is The Maximum Load 3/4″ Plywood Can Hold?

A sheet of 3/4″ plywood can typically support up to 50 pounds per square foot. However, this can vary based on the grade of plywood and the span between supports. Always refer to manufacturer specifications for precise information.

Can I Calculate Load Capacity For Different Plywood Sizes?

Yes, with a plywood load capacity calculator, you can input various sizes and thicknesses to determine the specific load capacity for different types of plywood sheets. This ensures appropriate material selection for your project needs.

Does Plywood Type Affect Its Load-bearing Strength?

Absolutely, the type of plywood impacts its load-bearing strength. For instance, hardwood plywood usually has a higher load capacity compared to softwood plywood due to its denser composition and improved structural properties.

Conclusion

Having a reliable plywood load capacity calculator is indispensable for construction and DIY projects alike. By employing such tools, safety and efficiency get a considerable boost, ensuring materials hold up under stress. Embrace this digital assistance to make informed decisions for your structural needs.

Remember, accurate calculations lead to sturdy outcomes.