Looking for replacement blades for Stanley planes? Check online retailers or specialty woodworking stores for a wide selection.

These blades are essential for maintaining the sharpness and effectiveness of your Stanley planes, ensuring precise and efficient woodwork. Whether you’re a professional woodworker or a DIY enthusiast, having quality replacement blades on hand is crucial for achieving excellent results in your woodworking projects.

From standard blades to specialty options, there are various choices available to suit your specific needs and preferences. Read on to discover the best sources for acquiring replacement blades for your Stanley planes.

Choosing The Right Replacement Blade

Understanding The Different Types

When selecting replacement blades for Stanley planes, it’s essential to grasp the various types available.

- Standard Blades: Suitable for general-purpose woodworking tasks.

- High-Carbon Steel Blades: Provides sharpness and durability.

- Laminated Blades: Offers premium quality and enhanced cutting performance.

Key Factors To Consider

There are crucial factors to keep in mind when choosing a replacement blade for your Stanley plane.

- Compatibility: Ensure the replacement blade fits your specific Stanley plane model.

- Material: Opt for high-quality steel blades for longevity and precision cutting.

- Blade Width: Select the appropriate width for the woodworking task at hand.

- Grind Angle: Consider the grind angle that suits your cutting needs.

Installing Your Replacement Blade

Preparing Your Plane

Before starting the installation, gather your tools: screwdriver, replacement blade, and a secure work surface.

Step-by-step Installation Guide

- Start by loosening the screws on the old blade, then carefully remove it from the plane.

- Carefully insert the new replacement blade into the plane, ensuring it is secure and aligned correctly.

- Tighten the screws firmly but not overly tight to avoid damaging the blade.

- Check the alignment and make any necessary adjustments before testing the plane on a scrap piece of wood.

- Once satisfied with the blade’s installation, your plane is ready for use.

Maintaining And Sharpening Blades

When it comes to maintaining and sharpening your replacement blades for Stanley planes, proper care and sharpening techniques are essential for ensuring optimal performance and longevity. Whether you’re a seasoned woodworker or a DIY enthusiast, knowing how to care for and sharpen your plane blades is crucial for achieving precise and smooth cuts in your woodworking projects.

Proper Blade Care

Proper maintenance of your Stanley plane blades is key to their performance. Here are some essential tips for ensuring your replacement blades remain in top condition:

- Regularly inspect the blade for any signs of wear, chipping, or dullness.

- Clean the blade after each use to remove any wood residue, preventing corrosion and damage.

- Store the blades in a protective case or sheath to prevent accidental damage or dulling.

- Keep your blades oiled to prevent rust and corrosion.

Sharpening Techniques

Keeping your Stanley plane blades sharp is crucial for achieving precise and clean cuts. Here are some effective sharpening techniques to maintain the sharpness of your replacement blades:

- Use a honing guide to maintain the correct bevel angle while sharpening the blade.

- Start with a coarse grit stone to remove any nicks or damage, then progress to finer grits for a razor-sharp edge.

- Ensure consistent pressure and strokes along the entire length of the blade for even sharpening.

- Finish with a leather strop or honing compound to refine the blade’s edge for a polished finish.

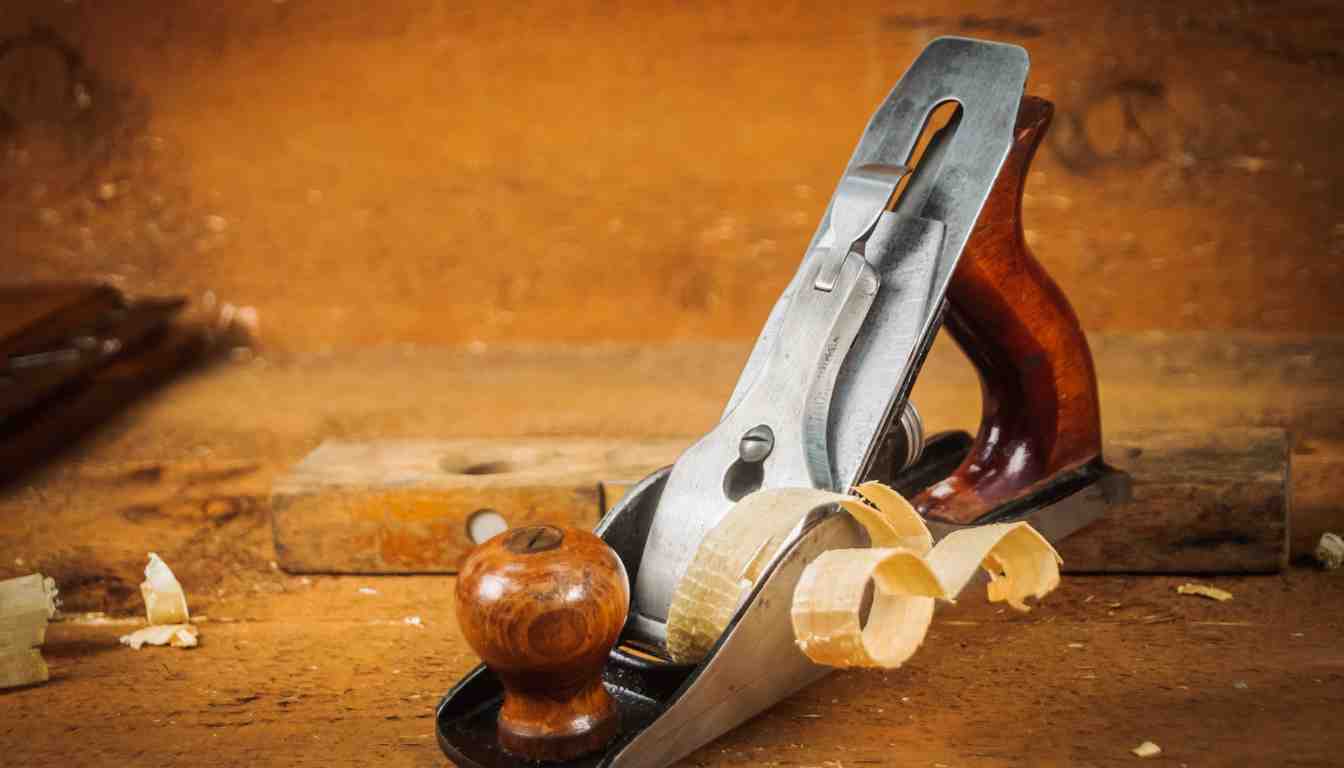

Achieving Superior Results

When it comes to achieving superior results with your Stanley planes, using the right replacement blades is essential. Upgrading your plane’s blade can make a significant difference in the precision and efficiency of your woodworking tasks.

Enhanced Precision

One of the key advantages of using replacement blades for Stanley planes is the enhanced precision they offer. These blades are manufactured to meet the highest standards, ensuring accurate and clean cuts every time. With their sharp edges and finely honed bevels, these blades enable you to achieve precise shaping and finishing, even on the most intricate woodwork projects.

Improved Efficiency

Another benefit of investing in replacement blades is the improved efficiency they provide. These blades are designed to enable smooth and effortless planing, reducing resistance and minimizing the effort needed to achieve optimal results. With their exceptional durability, they maintain their sharpness for longer, reducing the frequency of blade changes and increasing productivity.

Moreover, replacement blades for Stanley planes are available in various sizes and configurations for different types of cutting tasks. Whether you are working on rough stock removal or fine smoothing, you can easily find a blade that suits your specific needs.

Exploring Specialty Blades

When it comes to replacing blades for Stanley planes, it is important to understand that not all blades are created equal. While the standard blades that come with most planes are designed for general woodworking tasks, there are specialized blades available that cater to unique applications. These specialty blades are crafted with precision and are optimized to deliver exceptional performance for specific tasks.

Understanding Unique Applications

Specialty blades are specially designed to tackle specific woodworking tasks that may require more precision and control. Understanding the unique applications for these blades can help you make an informed decision when it comes to replacing the blade on your Stanley plane. Here are a few examples of specialty blades and their respective applications:

| Specialty Blade | Application |

|---|---|

| Chipbreaker Blades | Ideal for reducing tear-out and producing smoother finishes on challenging wood grains. |

| Bevel-Up Blades | Perfect for precision work and creating fine, delicate cuts. |

| Rabbet Blades | Designed specifically for creating rabbet joints and grooves with ease. |

Benefits Of Specialized Blades

Investing in specialized blades for your Stanley plane can bring several benefits to your woodworking projects. Here are a few benefits that make these blades worth considering:

- Enhanced Performance: Specialty blades are designed with specific tasks in mind, allowing them to excel in their respective applications. This ensures optimal performance and better results.

- Precise Control: These blades offer superior control and maneuverability, making it easier to achieve the desired outcome, especially when working on intricate designs or delicate materials.

- Improved Efficiency: By using a blade that is tailor-made for a particular task, you can streamline your workflow and complete projects more efficiently. This saves both time and effort.

- High-Quality Finishes: Specialty blades are engineered to deliver exceptional finishes, minimizing tear-out and leaving the wood with a smooth, professional look.

Frequently Asked Questions On Replacement Blades For Stanley Planes

How Thick Are Stanley Plane Blades?

Stanley plane blades are typically 2-3 inches in width and 1/8 inch in thickness. These blades are designed to fit various Stanley plane models for woodworking tasks.

How Do You Sharpen A Stanley Plane Blade?

To sharpen a Stanley plane blade, use a sharpening stone to hone the cutting edge, ensuring it is flat and polished.

What Are The Sizes Of Stanley Hand Planers?

Stanley hand planers come in varying sizes to accommodate different needs, typically ranging from 6 inches to 10 inches.

What Is The Blade Width Of A Stanley No 4 Plane?

The blade width of a Stanley No 4 plane is usually around 2 inches. It is a versatile tool for woodworking tasks.

Conclusion

Finding the right replacement blades for Stanley planes is crucial to maintaining the efficiency of your tools. With a wide range of options available, you can easily find the perfect blade for your specific needs. Whether you are a professional woodworker or a DIY enthusiast, having the right blades is essential for achieving accurate, smooth results in your woodworking projects.