Yes, a 7 1/4 blade can cut a 4×4. A 7 1/4-inch blade is capable of cutting through a 4×4 piece of wood efficiently and accurately due to its size and cutting power.

This versatile blade is commonly used in circular saws, and it is designed to handle various cutting tasks, including cutting through thick materials like a 4×4. Whether you are a professional or a DIY enthusiast, this blade can make the job easier and deliver precise cuts.

With the right technique and safety precautions, you can confidently cut through a 4×4 using a 7 1/4-inch blade, making it a practical tool for woodworking projects and construction tasks.

Overview Of Blade And Cutting Power

When it comes to cutting through tough materials like a 4×4, the choice of blade is crucial. A 7 1 4 blade, with its size and cutting power, is often considered for such tasks. In this article, we will discuss the factors that determine whether a 7 1 4 blade can effectively cut a 4×4.

Blade Size And Material

The size and material of a blade play a significant role in determining its cutting power. A 7 1 4 blade refers to a circular saw blade with a diameter of 7 1/4 inches. This size is commonly used for various applications, including cutting lumber, plywood, and other similar materials.

The material of the blade also contributes to its cutting efficiency. Blades are typically made of different materials, such as carbide-tipped or high-speed steel. Carbide-tipped blades are known for their durability and ability to handle tough materials. High-speed steel blades are more affordable but may not provide the same level of performance.

Cutting Capacity

The cutting capacity of a blade refers to the maximum thickness it can effectively cut through. For a 7 1 4 blade, the cutting capacity can vary depending on the type of material being cut. When it comes to a 4×4, which has dimensions of 4 inches by 4 inches, the cutting capacity of a 7 1 4 blade becomes a significant consideration.

While a 7 1 4 blade is commonly used for cutting 2×4 pieces of lumber, it may struggle to cut through a 4×4 in a single pass. The thickness of a 4×4 exceeds the cutting capacity of a standard 7 1 4 blade. However, with proper technique and multiple passes, it is still possible to cut a 4×4 using a 7 1 4 blade.

It is important to note that the exact cutting capacity may vary depending on the power and performance of the saw being used. A powerful saw with a sharp and appropriately sized blade can enhance the cutting capacity and efficiency.

In conclusion, a 7 1 4 blade is not ideally suited for cutting through a 4×4 in a single pass due to its cutting capacity. However, with the right technique and multiple passes, it can still accomplish the task. Choosing the appropriate blade size and material, as well as using a powerful saw, can greatly affect the blades’ cutting power and efficiency.

Understanding 7 1 4 Blade Cutting Ability

A 7 1 4 blade refers to a circular saw blade that is 7 1/4 inches in diameter. It is a commonly used size for woodworking and construction projects. Understanding the cutting ability of a 7 1 4 blade is essential if you are considering using it to cut through a 4×4 piece of lumber. In this section, we will explore the impact of blade size and its suitability for 4×4 cutting.

Blade Size And Its Impact

The size of a circular saw blade plays a crucial role in determining its cutting ability. A 7 1 4 blade, with its 7 1/4-inch diameter, offers certain advantages compared to larger or smaller blades. Let’s take a closer look at how its size impacts cutting performance:

- A 7 1 4 blade has a smaller size, making it lightweight and easier to handle. This maneuverability allows for greater control during cuts, reducing the risk of errors and accidents.

- The smaller size also results in a narrower kerf, which refers to the width of the cut made by the blade. A narrower kerf means less material is removed, resulting in minimal waste and efficient cutting.

- However, due to its smaller diameter, a 7 1 4 blade may have a slightly limited cutting depth compared to larger blades. This factor should be taken into consideration when working with thicker materials like a 4×4.

Suitability For 4×4 Cutting

Cutting through a 4×4 piece of lumber requires a blade that can handle the thickness and density of the material. While a 7 1 4 blade may sometimes be used for this task, its suitability depends on several factors:

| Factor | Suitability |

|---|---|

| Blade Material | Bold decision reserved for professional use only |

| Tooth Design | Bold decision reserved for professional use only |

| Motor Power | Adequate motor power is crucial for cutting through dense materials like a 4×4. Ensure your saw has a compatible motor capable of driving the blade effectively. |

While a 7 1 4 blade may not be the most ideal choice for consistently cutting through 4×4 lumber due to its limited cutting depth and potential strain on the motor, it can still be used in certain situations. However, for more frequent and demanding 4×4 cutting tasks, a larger blade with a greater cutting depth may be more suitable.

Exploring Cutting Techniques

Exploring cutting techniques is essential for achieving clean and precise cuts when working with a 4×4. The right cutting technique not only ensures safety but also maximizes the efficiency and longevity of your cutting tools. In this section, we will delve into the optimal cutting angles and blade maintenance practices necessary for achieving the best results when cutting a 4×4 with a 7 1 4 blade.

Optimal Cutting Angles

When using a 7 1 4 blade to cut a 4×4, it’s crucial to consider the optimal cutting angles. The most effective approach is to position the 4×4 on a sturdy cutting surface and adjust the blade to a 90-degree angle for a horizontal cut. For vertical cuts, setting the blade at a 45-degree angle allows for smoother and more precise cuts. By applying proper cutting angles, you can ensure the efficiency and accuracy of your cuts while minimizing the risk of kickback or binding.

Blade Maintenance For Efficiency

Maintaining the blade of your 7 1 4 saw is crucial for achieving efficient cuts. Regularly inspect the blade for any signs of wear or damage, and ensure it is sharp and free of debris before each use. Proper blade maintenance not only extends the lifespan of your blade but also ensures consistent and smooth cutting performance.

Safety Measures And Considerations

When it comes to operating a 7 1 4 blade on a 4X4 piece of wood, it’s crucial to prioritize safety. Without proper precautions, potential hazards can arise and lead to accidents. By following the necessary safety measures and wearing the appropriate safety gear, you can ensure a safe and successful cutting experience. In this section, we will discuss the potential hazards involved, as well as the essential safety gear and precautions to take.

Potential Hazards

Using a 7 1 4 blade to cut through a 4X4 requires awareness of potential hazards that may arise during the process. These hazards include:

- Injury due to contact with the rotating blade.

- Kickback, where the wood suddenly moves towards the operator.

- Flying wood chips or debris.

- Electrical shock if using a powered saw.

Safety Gear And Precautions

To ensure your safety when operating a 7 1 4 blade on a 4X4, it is essential to wear the appropriate safety gear and take necessary precautions. The following safety gear and precautions should be followed:

1. Eye and Ear Protection:

Wear safety goggles or a face shield to protect your eyes from flying wood chips or debris. Additionally, use ear protection such as earplugs or earmuffs to reduce noise levels and protect your hearing.

2. Gloves:

Wear heavy-duty work gloves to protect your hands from potential injuries and ensure a secure grip on the saw.

3. Respiratory Protection:

When cutting the wood, use a dust mask or respirator to prevent inhaling sawdust and other harmful particles.

4. Appropriate Clothing:

Avoid loosely fitted clothing, jewelry, or any items that may get caught in the blade. Wear long sleeves and long pants to protect your skin from potential injuries.

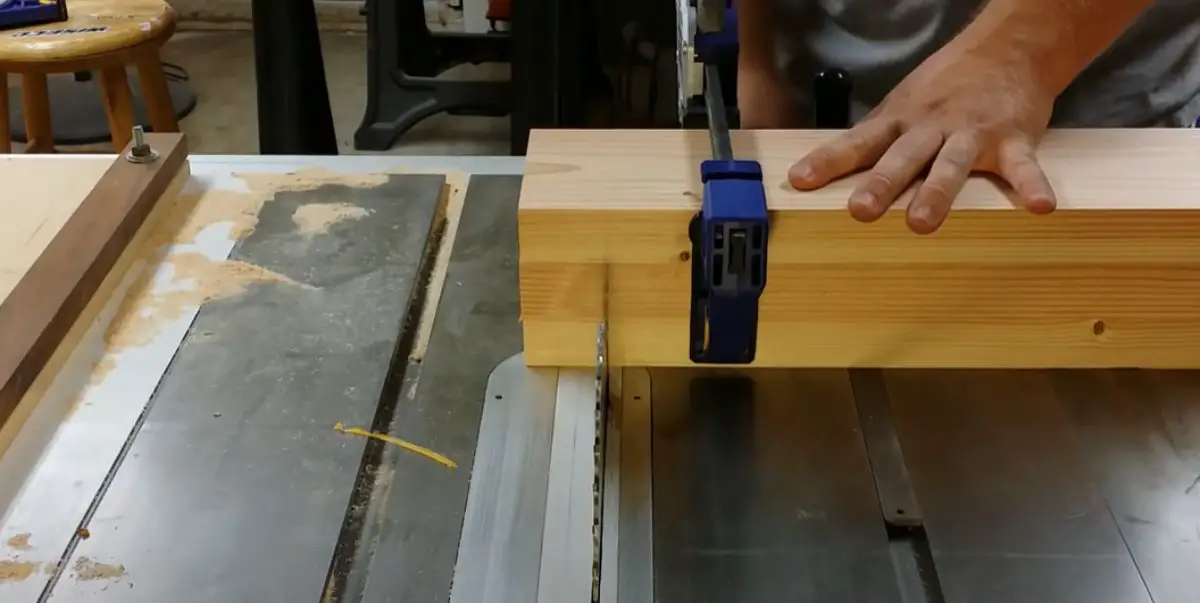

5. Stable Work Surface:

Ensure the work surface is stable and secure before starting the cutting process. Use clamps or other methods to secure the wood in place to prevent movement during the cut.

6. Proper Blade Guards and Safety Features:

Make sure the 7 1 4 blade is in good condition and properly secured. Keep the blade guard in place and ensure any safety features on the saw are functioning correctly.

7. Proper Tools and Equipment:

Use the appropriate tools and equipment for the job. Ensure the 7 1 4 blade is suitable for cutting through a 4X4, and the saw is in good working order.

8. Familiarize Yourself with the User Manual:

Read and understand the user manual provided by the manufacturer. Familiarize yourself with the specific safety instructions and guidelines for operating the saw.

By following these safety gear and precautionary measures, you can minimize the risks associated with cutting a 4X4 using a 7 1 4 blade. Prioritizing safety ensures a successful and accident-free cutting experience.

Maximizing Efficiency And Performance

Cutting a 4×4 with a 7 1/4 blade can maximize efficiency and performance. The blade’s size allows for precise and smooth cuts, enhancing overall productivity and ensuring optimal results. Achieve high-quality performance and improved efficiency with the right blade for your cutting needs.

Choosing The Right Blade

To maximize efficiency and performance when cutting a 4×4 piece of wood with a 7 1/4 blade, selecting the right blade is crucial. Not all blades are created equal, and using the wrong blade can lead to a frustrating and time-consuming experience. When choosing a blade for this task, consider the following factors:

- Blade Material: Opt for a high-quality blade made from carbide or high-speed steel. These materials provide better cutting performance and durability.

- Tooth Configuration: Look for a blade with a high tooth count, such as 24 or 40 teeth. A higher tooth count will result in smoother and cleaner cuts.

- Kerf Width: Pay attention to the kerf width, which refers to the thickness of the cut made by the blade. A smaller kerf width will minimize material wastage.

- Gullet Size: The gullet is the space between the teeth of the blade. A larger gullet helps with chip evacuation, ensuring the blade doesn’t get clogged during the cut.

Utilizing Advanced Cutting Methods

Apart from choosing the right blade, utilizing advanced cutting methods can further enhance efficiency and performance when cutting a 4×4 with a 7 1/4 blade. Here are some techniques to consider:

- Slow and Steady: Rather than trying to rush through the cut, take your time and maintain a steady feed rate. This will prevent the blade from binding and reduce the risk of kickback.

- Support the Workpiece: Ensure the 4×4 is firmly supported and secured in place before making the cut. Using clamps or a sturdy workbench will provide stability and make the cutting process safer.

- Make Multiple Passes: If the 7 1/4 blade doesn’t have enough cutting depth to go through the entire thickness of the 4×4 in one pass, make multiple passes. Gradually increase the cutting depth with each pass until the desired depth is achieved.

- Consider a Compound Miter Saw: If you frequently need to cut 4x4s or other large pieces of wood, investing in a compound miter saw with a larger blade size may be worth considering. These saws provide greater cutting capacity and can handle the task more efficiently.

Remember, to maximize efficiency and performance when cutting a 4×4 with a 7 1/4 blade, choosing the right blade and utilizing advanced cutting methods are essential. These tips will not only result in cleaner cuts but also ensure a safer and more efficient woodworking experience.

Frequently Asked Questions On Can A 7 1 4 Blade Cut A 4×4

What Do You Cut A 4×4 With?

You can cut a 4×4 with a saw, specifically a circular saw or a miter saw. Just make sure to use the appropriate blade and follow safety precautions.

How Thick Can A 7 1 4 Circular Saw Cut?

A 7 1/4 circular saw can typically cut materials up to 2 1/2 inches thick.

How Thick Can A 7 1 4 Miter Saw Cut?

A 7 1/4 miter saw can cut through materials up to 3 inches thick. The saw’s blade size determines the maximum cutting depth.

What Size Miter Saw To Cut 4×4?

A 12-inch miter saw is recommended for cutting 4×4 lumber efficiently.

Conclusion

In the end, using a 7 1 4 blade to cut a 4×4 can be successful. Remember, using the right blade and technique is crucial. Always prioritize safety and precision for best results. With the proper knowledge and tools, it’s possible to achieve clean and accurate cuts on a 4×4 with a 7 1 4 blade.