A Clamping Force Calculator determines the required force to hold parts together during an assembly process. It simplifies complex calculations for better precision and efficiency.

Torque Calculator

Understanding the need for a reliable clamp force is crucial in manufacturing and engineering applications. It ensures that components are securely fastened during machining, bonding, or thermal processes. Utilizing a calculator for this purpose helps avoid under or over-clamping, which can lead to part deformities or assembly failures.

These tools are invaluable for engineers and technicians who strive for optimal outcomes. Accurate clamping ensures product quality and longevity, while also enhancing workplace safety by preventing accidental disassembly. The calculator serves as a guide for setting up equipment correctly and guarantees that all joining processes meet technical specifications and industry standards.

Credit: m.youtube.com

Introduction To Clamping Force Calculators

Clamping force calculators are key tools in manufacturing. They help ensure machine parts fit correctly. These calculators measure the force needed to hold components together. This force stops pieces during machining or assembly. With complex calculations, precision improves. Workers find these tools handy for quality and safety.

The Role Of Clamping Force In Manufacturing

Clamping force is vital. It’s the pressure applied to hold parts in place. This prevents movement during manufacturing. Without the right force, parts can slip causing defects or damage. Correct clamping force makes products safe and reliable.

Benefits Of Using A Calculator For Clamping Force

- Accurate calculations boost product quality.

- Saves time compared to manual calculations.

- Reduces waste by decreasing errors.

- It promotes consistent manufacturing results.

- Enhances safety by preventing part slip-offs.

Fundamentals Of Clamping Force

The ‘Fundamentals of Clamping Force’ are crucial in the world of manufacturing and engineering. This force keeps tools and workpieces secure. Without proper force, the quality and safety of a project can suffer. Let’s explore the basics and peel back the layers of clamping force’s importance.

Understanding Clamping Pressure

At its core, clamping pressure is the force applied to hold two or more objects together. It prevents movement during a process like drilling or milling. Think of it as a firm handshake between machine and material.

A Clamping Force Calculator can help ensure this handshake is just right. It’s a tool that figures out the right amount of pressure. Knowing this prevents damage to parts or tools. It also keeps everything safe and steady.

Proper clamping leads to better accuracy and finishes. A job done right comes down to the right level of clamp pressure.

Key Factors Affecting Clamping Force

Several factors can change the amount of force needed. Here’s a list that highlights the main ones:

- Material Type: Hard metal or soft wood, the material matters.

- Surface Area: More surface means more pressure spread.

- Operation Type: Cutting, drilling, or welding, all need different forces.

- Tool Condition: Worn tools need more force to hold firmly.

Each factor requires careful consideration. Failing to account for these may lead to project failure.

A table may help visualize how these factors interact:

| Factor | Effect on Clamping Force |

|---|---|

| Material | Harder materials often need more force. |

| Surface Area | Larger areas spread the force and need adjustment. |

| Operation | Varies with the intensity and type of work. |

| Tool Health | New tools work better with less force. |

Proper force keeps a project on track. Knowing these factors helps predict the force needed.

With this knowledge, you’re better equipped to calculate clamping force accurately. Remember, ensure safety and quality with the right amount of pressure.

Types Of Clamps And Their Force Requirements

Clamps are essential in various industries for holding objects in place. Different tasks require specific clamps with the right force. The Clamping Force Calculator helps to determine the necessary force. Here’s a look at toggle clamps and hydraulic clamps.

Toggle Clamps And Force Dynamics

Toggle clamps are popular for their quick action and reliable hold. Ideal for woodworking and assembly, they apply force through a pivoting mechanism. Toggle clamps come in different types :

- Horizontal handle: For lateral clamping with minimal clearance.

- Vertical handle: Delivers downward pressure, good for workbenches.

- Push-pull: Versatile, for both pulling and clamping applications.

Force dynamics in toggle clamps vary:

| Clamp Type | Force Range (lbs) |

|---|---|

| Horizontal | 150-700 |

| Vertical | 200-1,200 |

| Push-Pull | 100-2,500 |

Hydraulic Clamps And Precision Force Application

Hydraulic clamps exert precise force using fluids. They fit perfectly in metalworking and assembly lines for their control and strength. Here’s why they are chosen:

- Consistent force delivery

- Adjustable pressure settings

- Long-lasting with minimal wear

Force requirements for hydraulic clamps can be intricate. The calculator assesses factors such as:

- Piston diameter: Affects force output

- Pressure setting: Determines the clamping force

- Material to be clamped: Guides the required force

Credit: www.carrlane.com

How Do Clamping Force Calculators Work?

Clamping force calculators are essential tools in engineering and manufacturing. They ensure a secure fit between components. These calculators help in applying the right amount of force. Too much force can cause damage; too little can lead to disassembly. Understanding the operation of these calculators is crucial.

Input Parameters For Accurate Calculations

For precise clamping force estimations, the following inputs are necessary:

- Material Properties: Different materials react to force differently.

- Surface Area: Larger surfaces distribute force more evenly.

- Clamping Distance: Distance influences force requirements.

- Friction Coefficient: It helps predict slippage risks under force.

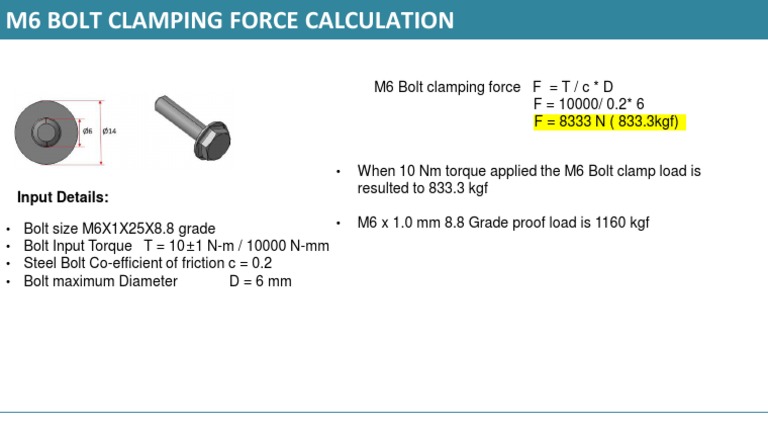

The Underlying Mathematical Formulas

Clamping force calculators use physics and mathematics to compute the force needed. They involve key formulas.

Here are the primary equations:

| Formula | Description |

|---|---|

| F = μN | The basic friction formula, where F is the clamping force, μ is the friction coefficient, and N is the normal force. |

| σ = F/A | Stress is force per unit area, where σ is stress, F is force, and A is area. |

These calculators convert input parameters into precise clamping force values using these formulas.

Selecting The Right Clamping Force Calculator

Finding the perfect clamping force calculator is crucial for any machining project. It ensures your workpiece remains secure without causing damage. Let’s explore what features to look for and the compatibility with different clamping systems.

Features To Look For

Performance and accuracy hold the key to selecting the right calculator. Here are essential features:

- Ease of use: A user-friendly interface tops the list.

- Precision: High accuracy rates help in calculating correct forces.

- Versatility: It should offer various pressure units.

Additional features can include a history log for previous calculations and real-time calculations for dynamic projects.

Compatibility With Different Clamping Systems

The right tool works with a plethora of clamping systems. Ensure it supports:

| Clamping System | Compatibility |

|---|---|

| Hydraulic Clamps | Yes |

| Mechanical Clamps | Yes |

| Vacuum Clamps | Yes |

| Magnetic Clamps | Yes |

Multipurpose calculators are handy, saving time and resources. They should accommodate various materials and shapes.

Credit: www.scribd.com

Optimizing Your Manufacturing Process With Clamping Force Analysis

Understanding the clamping force is vital in any manufacturing setup. By optimizing the exact force needed, you ensure product stability and precision during the machining process. Clamping Force Calculators play a crucial role in achieving this balance. They help prevent product deformation and maintain the integrity of the machining operation.

Case Studies: Improved Production Quality

Several manufacturers have transformed their production with apt clamping force analysis. Here’s a glimpse into the impact of accurate calculations:

- Aerospace parts manufacturer: Reduced rejections by 30%

- Automotive assembly line: Improved joint stability, boosting overall vehicle quality

- Electronic components factory: Achieved finer precision in circuit board assembly

Reducing Waste And Enhancing Efficiency

Incorrect clamping force not only affects quality but also leads to waste. Over-clamping can cause damage to materials, while under-clamping results in product inaccuracies. By deploying a Clamping Force Calculator, manufacturers have seen a significant reduction in waste. Efficiency gains are evident through:

| Parameter | Before | After |

|---|---|---|

| Material Use | High wastage | Optimized material |

| Production Time | Longer cycles | Streamlined operations |

| Energy Consumption | Excessive | Reduced usage |

Common Mistakes To Avoid In Clamping Force Calculation

Strong joints depend on accurate clamping force calculation. But mistakes can happen. Recognizing these errors helps ensure reliable and safe assembly in any project. Here are common pitfalls to steer clear of.

Overestimating Clamping Force Needs

It’s easy to think “more is better,” but that’s not always true for clamping force. Overestimating what you need can harm your materials and tools. Keep these points in mind:

- Measure the minimal force needed.

- Check material tolerances.

- Avoid excessive pressure that damages surfaces.

Misinterpreting Calculator Outputs

Calculators are helpful but can be misunderstood. Interpret the results with care. Here’s how:

- Verify all input data is correct.

- Understand the units of measurement.

- Use the output as a guide, not an absolute.

Future Developments In Clamping Technology

The evolution of clamping technology is a key factor in enhancing manufacturing precision and safety. Recent advancements have led to the development of innovative Clamping Force Calculators; these tools are crucial for ensuring optimal pressure in various applications, from woodworking to automotive assembly. With an eye on the future, let’s explore the potential shifts expected to revolutionize the clamping landscape.

Innovations In Calculator Software

The next generation of Clamping Force Calculators is set to integrate with artificial intelligence and machine learning algorithms. These features will enable not just precise calculations but also predictive analysis based on historical data. Improved usability with user-friendly interfaces will significantly reduce the learning curve, making these tools accessible to a wider audience.

- Real-time analysis for immediate adjustments.

- Integration with cloud-based systems for data sharing.

- Enhanced customization options suited for specific clamping needs.

Advances In Clamping Mechanisms And Materials

Material innovation in clamping technology promises lighter, stronger, and more durable clamps. Expect to see eco-friendly materials that offer comparable strength to traditional metals but at a fraction of the weight. These advancements will also extend to the mechanisms themselves, with improved ergonomic designs that foster both efficiency and user comfort.

| Material Type | Benefits |

|---|---|

| Composite Materials | Lightweight, resistant to corrosion |

| Advanced Alloys | High strength-to-weight ratio, durability |

As these advancements become more widespread, expect a significant uptick in productivity and a decrease in work-related strain injuries. The automation of clamping processes will further redefine efficiency in manufacturing sectors.

- Smart sensors for pressure monitoring in real-time.

- Self-adjusting clamps that respond to material variances.

- Hybrid systems combining manual and automated operations.

Frequently Asked Questions On Clamping Force Calculator

What Is A Clamping Force Calculator?

A clamping force calculator is a tool used to estimate the force required to hold workpieces together during manufacturing processes. Its precision ensures optimal pressure application, preventing material slip or deformation.

How Do Clamping Force Calculators Work?

Clamping force calculators operate by inputting parameters such as material properties, clamping area, and coefficient of friction. They then apply formulas to provide the necessary clamping force for a specific application.

Why Is Clamping Force Calculation Important?

Accurate clamping force calculation is crucial for workpiece stability and machinery protection. It prevents damage from excessive force while ensuring a reliable hold for precision during machining or assembly.

Can I Use A Clamping Force Calculator For Any Material?

Most clamping force calculators are versatile, designed to handle various materials. Input the specific material characteristics to get a correct clamping force value for your project.

Conclusion

Utilizing a clamping force calculator simplifies complex engineering tasks. It ensures optimal pressure for secure joins without material damage. For precision in manufacturing, embrace this ingenious tool. Streamline processes and enhance product integrity starting now. Embrace the innovation that a clamping force calculator offers your projects.