Cost Of Redwood Vs Cedar: Proven Best

The biggest way to decide between Redwood and aromatic Cedar is to judge your budget against your desired lifespan. Generally, treated or western Red Cedar is the more budget-friendly choice for most outdoor projects, while high-grade, clear-heart Redwood commits you to a higher initial spend but offers superior, unmatched rot resistance if durability trumps initial low cost.

Choosing the right wood for an outdoor project—like a deck, fence, or raised garden bed—can toss even experienced woodworkers for a loop. That initial sticker shock at the lumberyard is real, and trying to figure out if you’re planting that money into something that lasts is tough with just a grade stamp.

The big two for natural outdoor finishes are Redwood and Cedar. Both look amazing and resist nature’s way of trying to break them down. Are you picking volume for coverage or premium aging ability? We won’t leave you second-guessing at the pro desk!

We are going to deep-dive into the actual prices—per board foot, the special tax on grades—and compare longevity. By the end of this guide, your budget calculator—and your woodworking confidence—is going to be much happier!

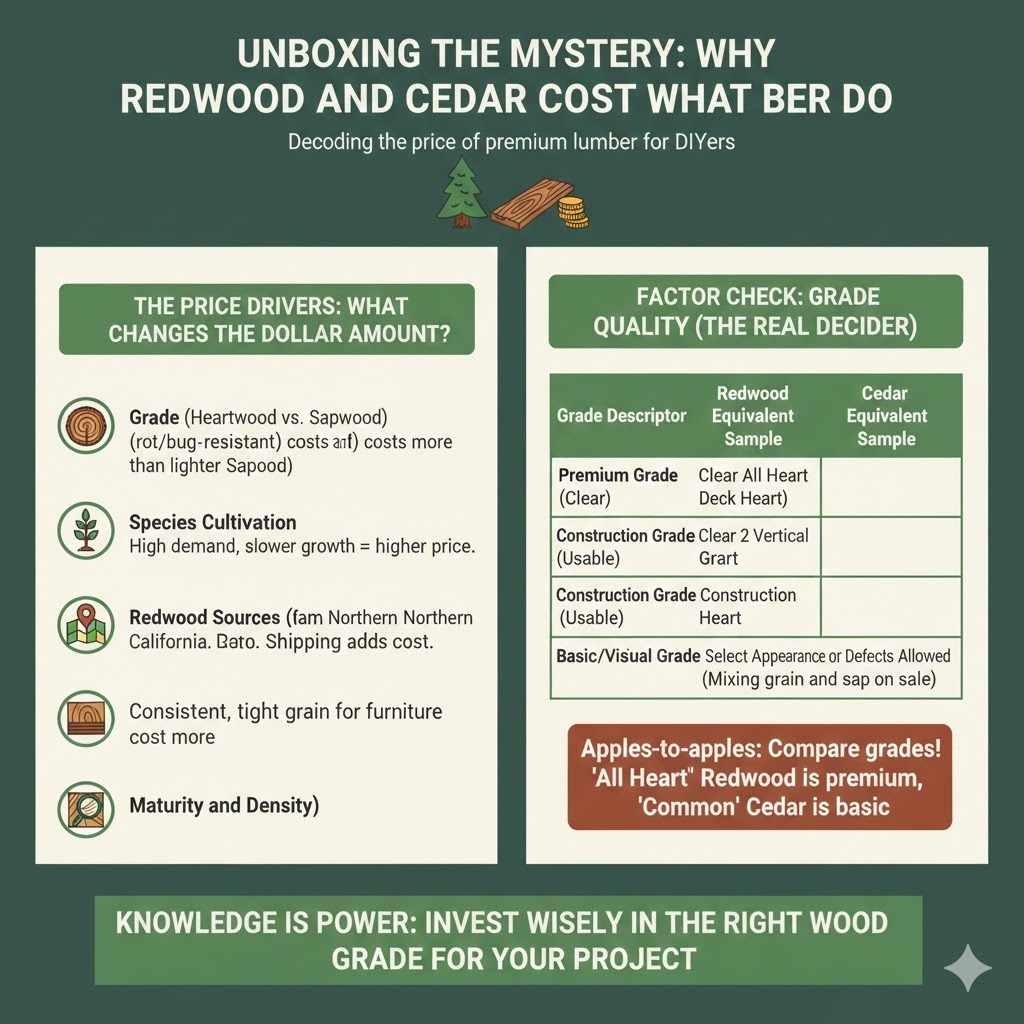

Unboxing the Mystery: Why Redwood and Cedar Cost What They Do

Works of art, including lumber, don’t just sprout beams tall and ready. The price tag reflects scarcity, harvest methods, decay resistance, density, and transit miles. Think of wood cost like buying a really good coffee; the flavor (durability) usually relates to the amount you fork over.</brFor beginners, the main factor differentiating these two woods is natural occurrence meets demand for perfection.

The Price Drivers: What Changes the Dollar Amount?

Neither Redwood nor Cedar costs five bucks a board foot consistently. Why the swing in tags at the home center versus the specialty lumberyard? Let Old Meraj walk you through the factors that impact the ‘cost of redwood vs cedar’ equation. If you don’t understand what you’re paying for, anyone can sell you junk disguised as premium stock.

- Grade (Heartwood vs. Sapwood): This is the single biggest thing. The reddish, darker sections in the center of the tree (Heartwood) naturally ooze tannins and oils that protect against bugs and rot. The lighter wood near the bark (Sapwood) rots much faster. Clear Vertical Grain (higher grade) demands way more cash than low-density construction grades.

- Species Cultivation: Western Red Cedar (or Alaska Cedar) is incredibly popular. While many people source it sustainably, when there’s high milling demand mixed with slower growth rates, the retail price inches up.

- Redwood Sources (and Proximity): True Redwood is largely restricted to Northern California origins. If this wood has to travel halfway across the country to reach your non-coastal hardware barn, a surcharge the size of my favorite chisel kit adds on just for shipping and handling!

- Maturity and Density (Grain Consistency): Woods showing near-perfect structure with consistent tightness of the grain often rank higher for furniture build than boards for quick deck planks, bringing a higher cost.

Factor Check: Grade Quality (The Real Decider)

Forget if it’s the “cheapest” cedar. Compare grades on an even playing field.

| Grade Descriptor | Redwood Equivalent Sample | Cedar Equivalent Sample |

|---|---|---|

| Premium Grade (Clear) | Clear All Heart, Deck Heart | Clear Vertical Grain (CVG) |

| Construction Grade (Usable) | No. 2 or Better | Construction Heart |

| Basic/Visual Grade | Select Appearance or Defects Allowed | Common Grade (Mixing grain and sap on sale) |

See that? If the Redwood merchant is selling their highest, bug-slaying “All Heart” grade, and the cedar yard is selling mixed common grades, the Redwood price will absolutely dominate the comparison—and unfairly so, apples-to-apples!

Budget Breakdown: Average Costs Per Board Foot

When comparing the 15/16” x 5.5” size (a very common decking/capping board), real numbers always make your buying decisions concrete. Please take these values as rough estimations you might see in busy domestic markets well outside of heavy manufacturing zones. Always call your local specialty yard! These prices fluctuate heavily.

Cost Comparison Example Data Table (Visual Grades)

| Wood Type & Quality | Approx. Lower Range (Low Grade) $/BF | Approx. Higher/Mid Range (Usable Grade) $text{/BF}$ |

|---|---|---|

| Western Red Cedar $div$ Deck R/S | Per-line 4.50 ^ $4.50 | approx $8.00 |

| Redwood $div$ Deck Common Mix | While 6.50 ^ $6.50 | approx $10.50 |

| Premium/Garden-Grade Cedar Heartwood | $text{—}$ (Typically only Top Shop Bulk) | Around: approx $12.50 |

| Premium Clear Redwood Heart <strong $text{>(</stromng text{High $/BF}$ _}$ $ gt; $text{Costly (Harder to Stock__}$ | Note on sourcing: R/S is Rough Sawn. Always confirm treatme $text{}$’ or treatment. |

$textsuperscripttext{Cost is significantly higher due to scarcity

“

What does that table mainly tell a beginner? Straight out of the gate for a standard visual-grade deck building (where some defects are okay), you will almost invariably expect Cedar board ft pricing to undercut standard Redwood board ft pricing. Typically look for a minimum spread of $2 to $5 per board foot favoring Western Red Cedar.

Pro Tip: Checking the Grades in Real Life (Safety First)

Always trust your eyes more than the tag sometimes. When checking cedar, smell it a bit! Authentic western cedarwood gives off that amazing, distinctive aromatic scent due to its natural preservative oils. Redwood should have deep orange-to-slightly-brown tones to confirm it’s true decay-resistant heart material, not pale redwood sap.

For critical structure like retaining walls or decks anchoring to concrete—always opt for grades marked ground-contact tolerant via appropriate treatment if available, or stick strictly to heartwood from each species. Knowing durability ratings is key. For verified performance standards in the U.S., look at guides provided by organizations, like those detailing accepted lumber standards from associations reviewed by The National Institute of Standards and Technology (NIST) on wood material specification compliance.

Rot Resistance: Where the Lasting Peace of Mind Lives

This is arguably the most important comparison after cost. Price gets you standing material today; rot resistance makes sure that purchase stays outdoors for the next two decades!

Western Red Cedar: A Worthy Competitor

Cedar gains extreme respect because of its natural oils, called Thujaplicins. Think of these oils as the wood’s personal internal pest control and anti-mold SWAT team. As long as that wood lasts against the damp soil or coastal spray condition, the chemicals protect it.

Pros of Cedar Lumber

- Superior, wonderful aroma greatly utilized in closets and hot tubs to repel moths and mildew.

- Very lightweight and easy to carry, cut, and move around the job site.

- Excellent resistance to fading; taking a beautiful silver-gray patina over years even with UV sun exposure—requiring minimal upkeep if you like that look.

- Consistent, year-over-year availability keeps pricing mildly predictable against severe weather supply halts.

- Generally boasts a lower barrier to entry price point when comparing standard purchase grade vs standard redwood boards in most DIY shops.

Typical Cedar Lifespan:

If not subjected to constant stream or submersion into wet soil (best above-ground/on joists unless rated “Ground Contact”): Lifespan of 15–25 Years. Properly sealed and stained, cedar can indeed push past the 25-mark considerably depending on local climate and drying conditions.

Coast Redwood: Hard to Beat for Tough Jobs

Redwood’s secret sauce comes again from tannins locked deep within the dense Heartwood structure. The sheer density makes it hold up longer to wear and tear, even before we discuss fungal resistance. It’s inherently more bug-resistant than most common softwoods!

For sheer outdoor supremacy, the highest-grade Claro or Coast Redwood timber sometimes feels unfair; it feels denser and handles the worst ground contact scenarios slightly better than commodity cedar strains. It is often viewed structurally and aesthetically higher in premium architectural decking markets.

Pros of Heart Redwood Timber

- Unparalleled ability to take harsh finishes or stains without peeling or cracking issues seen in lower-yield density woods; stability is high.

- Denser build resists abrasion and denting better than similarly aged cedar woods (big help for busy patios or playgrounds).

- Coloration is striking—a rich dark red that often darkens impressively well under exterior varnish processes.

- Holds its shape extremely well once installed, which combats racking and warping common in wood substructures over many intense summer/winter cycles.

Typical Redwood Lifespan:

With high heartwood percentage, above-ground installs routinely last anywhere from (very optimistic) 25 to 50+ long years. Cedar often gains ground if Redwood is allowed to extensively sit in humid or near-water contact conditions where the sap areas degrade quickly.

Choosing Dimensions and Thickness: The Size Price Spike

When you ask for a price quote, remember, dimensionality matters way more than wood type sometimes, especially when moving from standard 2x lumber (actual 1.5” $times 7.25”$ size) up to heavy timbers like reclaimed beams (which might require specialty milling or handling).

This is a truth across all wood purchases for beginners:

- Using standard dimensional lumber size (like 2×6, 4×6) is always the thriftiest route because this sizing matches factory production machines exactly.

- Moving to larger “bulk” sizes (8x8s or salvaged timbers) jumps your cost per hour of milling/handling much more.

If you build a large pergola structure out of chunky 8×10 beams:Expensive Option: 8×10’s in Clear Grade Redwood ($$$$).

Cheaper Parallel Option: Large framing in dense, naturally treated Pressure-Treated Lumber or Douglas Fir may serve the bulk structure at a fraction of Redwood’s entry point, saving money for you to use the higher caliber Cedar around the seating contact points.

A Crucial Word on Treatment and “Rating”

For backyard durability that truly contends directly with quality Redwood Heartwood life span but might cost a little more than basic Cedar?

You can’t forget treated (pressure-treated, or ‘PT’) pine or fir solutions intended for contact applications. While these woods often need hiding by paint or other veneers, scientifically, they often meet or exceed durability standards needed near ground contact. Review established building codes regarding MCA ($Alkaline Copper Quat (ACQ) related approvals$) treated lumber suitability relative to your geographic humidity concerns, which influences any wood lifespan outdoors.

Visual Project Suitability: Where Looks Matter Most

If your project is purely ornamental – a fancy trellis wall, decorative screen, or outdoor cladding where water saturation is low—the decision shifts purely to aesthetic preference and which one fits your palette best.

Why Choose All Redwood Structure Pieces?

You like bold, dramatic red tones now and see that lumber naturally aging slowly toward a deeper patina over a very long time frame. You prioritize ultimate density contact support.</तुम might be looking online for outdoor vertical slatted patio partitions; high-grade Redwood fencing components are historically prized here for holding crisp painted white trims against strong heat. Choose Redwood here if the upcharge is affordable for this specific aesthetic goal.

Why Choose Cedar for Project Elements?

You want softer, silvery-blond natural colors, the scent benefit, and quicker availability.

Cedar typically stains lighter naturally, giving a pale wood finish that contrasts beautifully with darker patio flooring.

- Best for Saunas or Screened-in Porches (incredible scent experience).

- Fantastic visual match outdoors when capped or complemented with cedar shakes on the main roof structure nearby.

- Easiest to purchase in rough-sawn texture finishes if you are using a rustic look builder material.

Remember dear friend, if you stain both woods with dense UV-blocking opaque deck stain (a great moisture layer applied correctly following guidelines from material finishing suppliers), you somewhat obscure some of the woods’ long-term advantages anyway—so pick the inherently cheaper/best option for bulk!

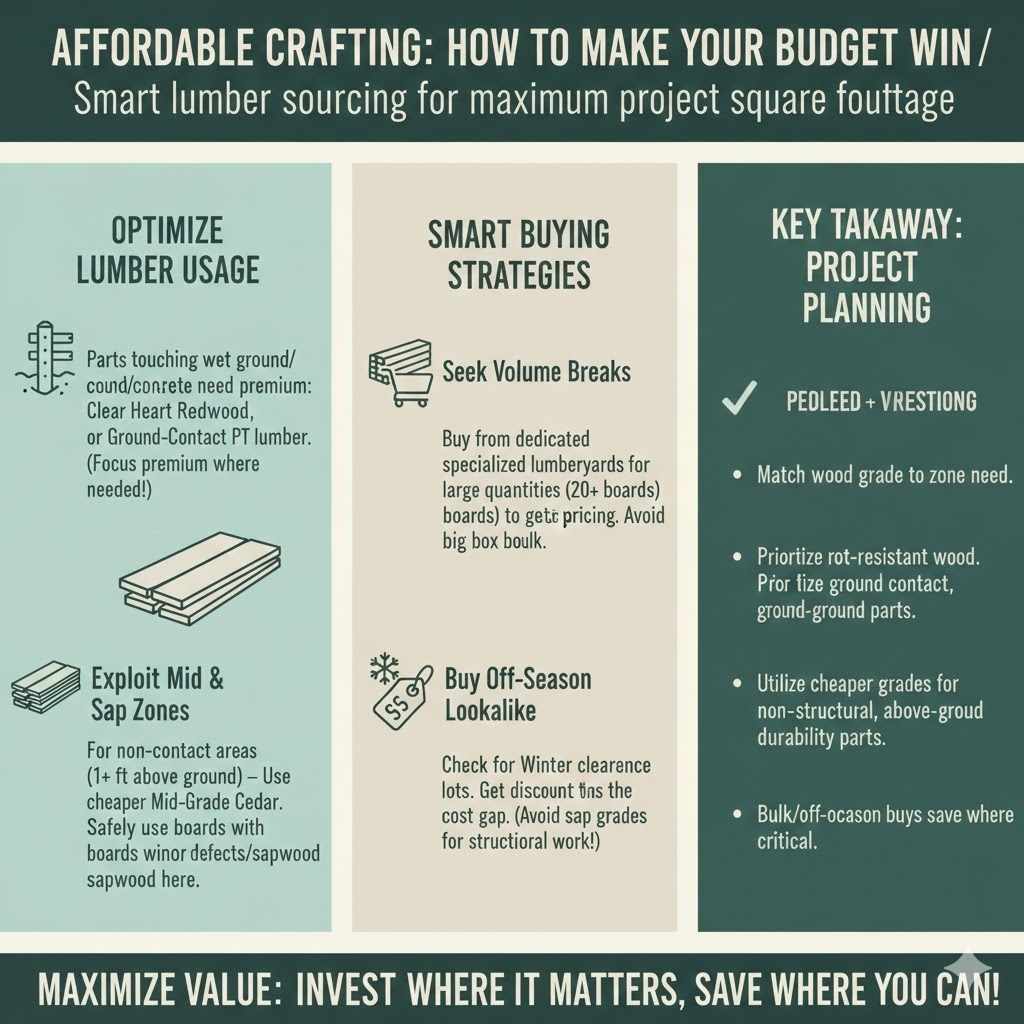

Affordable Crafting: How to Make Your Budget Win

Here’s your mentorship mission: Use the wrong wood too much of either species, and you lose money. Follow these key steps to maximize project square footage when dealing with fluctuating costs of redwood vs cedar.

- Identify the Necessary Depth Zone Area: Which parts touch wet dirt, concrete seams, or ground lines you cannot easily protect? Those areas must get the premium product: Clear Heart Redwood, or at least Ground-Contact PT lumber regardless of cost penalty. (This might be only 10’ of a 50’ lineal fence foundation).

- Exploit Mid and Sap Zones for Clearance Areas: For non-contact sections one foot above ground—Use the cheaper Mid-Grade Cedar. Here, the minor defectiveness or sapwood sections that are usually overpriced in clearer grades can be safely relegated in your materials management planning.

- Seek Volume Breaks: Buy material off-grid—not from online-shippers or big box stores with massive inventory costs. Head to a true, dedicated specialized lumberyard. They earn repeat business specifically by providing large quantities needed for decks or large runs that get slightly better pricing if you are purchasing 20+ boards.

- Buy Off-Season Lookalike: Keep a weathered eye on inventory clearance lots in Winter during the off-season here. Often, specialty mills clear inventory that you can now purchase at a decent discount that might close the normal cost of redwood vs cedar price gap considerably for your specific project use. (But avoid sap grades for structural work, regardless of depth).

Frequently Asked Questions (Beginner Toolbox Entry)

| Q (> Beginner Challenge $text{< $textbackslash}$ >) | A (> Mentor Takeaway) |

|---|---|

| Which dries faster after raining, promoting stability? | Redwood generally sheds surface moisture quicker than cedar’s tendency to soak up a bit like a darker sponge due to slight absorption differences across certain densities. |

| Can I blend Cedar caps and Redwood framing without aesthetic issues? | Yes, provided you use non-opaque stain/sealant combos. Look for them aging into that cool, two-tone aesthetic that designers love. The key is ensuring the wood shares a primary finish type (Clear Cedar vs. Clear Redwood) regardless of specie difference. |

| Is Cedar cheaper than Pressure Treated Lumber (PT)? | Currently, often NO. High-quality, naturally resistant cedar generally costs more upfront than the standard, ground-contact-rated chemically-treated Fir/Pine, even if Cedar requires less fuss regarding potential preservative treatments needing specialized handling later. |

| What is the best size thickness to ensure I choose the correct starting stock? | For standard residential decks surfaces, stick to “one inch actual” deck boards (which will usually measure right between 3/4” to 1”) or 2x pressure-rated stock for joists beneath. Smaller doesn’t save much if structural fails after year five! |

| Do I need to seal Cedar fencing the day I install it? | No, but sealing it quickly, especially in high-UV load areas, maximizes those protective oils you paid for. Wait 2 to 4 sunny dry days after install to let superficial excess dampness breathe out before applying the first oil finish. |

| If I want reddish brown only, do I skip cedar completely? | For vibrant redness that lasts years untreated outside, stick robustly to Heart Redwood. Any application asking sheer reddish pigment that must survive intense weather will lean strongly away from naturally softer-toned cedars—even rich aroma Cedar fades faster naturally outdoors than Redwood deep colors. |

The Final Financial Stance: When is the Cost Difference “Proven Best”?

Cedars Path to Savings (Best Budget Option)

You are doing an above-ground project for an extended family retreat. You calculate a great need for 300 sq. ft when bought today via midpoint pricing (Cedar in the $7.00 -$8.50 per BF window). The structure is sound, over joists, and you’ll routinely wipe debris and water away because cleanup supports the material health.

–> The Cost of Redwood vs Cedar’s best answer leans heavily toward Cedar here because the premium cost of Redwood protection isn’t functionally needed for the extra structure lifespan; you save thousands right now without immediate compromise.

Redwoods Path to Value (Best Long-Shot Performer)

You are building your forever deck or custom backyard primary seating zone that gets heavy use. Or, perhaps a retaining wall that can never fail its inspection, relying strictly on woods that decay resistance naturally without reliance on any sealant or chemical absorption being perfect. You aren’t coming back next year for touch-ups!

–> The cost of redwood vs cedar is justified as an Investment, not just an Expense. Though you pay 65 – 100% more upfront per board foot for similar non-heart material grades, the time value of maintaining your deck replacement cycle shifts far longer, rendering the 40-year-old Redwood structure cheaper than rebuilding the Cedar structure (assuming fair environmental placement) for a second time at today’s dollars.

Your Next Steps to Confidence in Lumber Buying

Fellow builder, never let the confusing price matrix freeze your actual progress!

You now understand three simple takeaways for navigating the cost of redwood vs cedar debate:

- The cheaper one rarely handles the ground contact like the clearer, pricier version of either wood.

- Cedar starts cheaper for equivalent aesthetic finishes across general market buying patterns.

- Premium long-life goals ultimately mean seeking out the Clear Heart version of both**, confirming that the Redwood premium just starts measurably bit higher across grades. Always know what grade you aren’t allowing past your saw table.

Grab your pencil this weekend. Visit a specialty yard instead of that big blue box depot you usually stop at. Compare quoted bulk costs for the exact number of equivalent grades necessary* across 20+ feet. Don’t just buy on the perceived average price tag from this post. Buy intelligently!

You’ve got the knowledge now to select the perfect long-lasting material. Now go craft something awesome, safely and confidently!