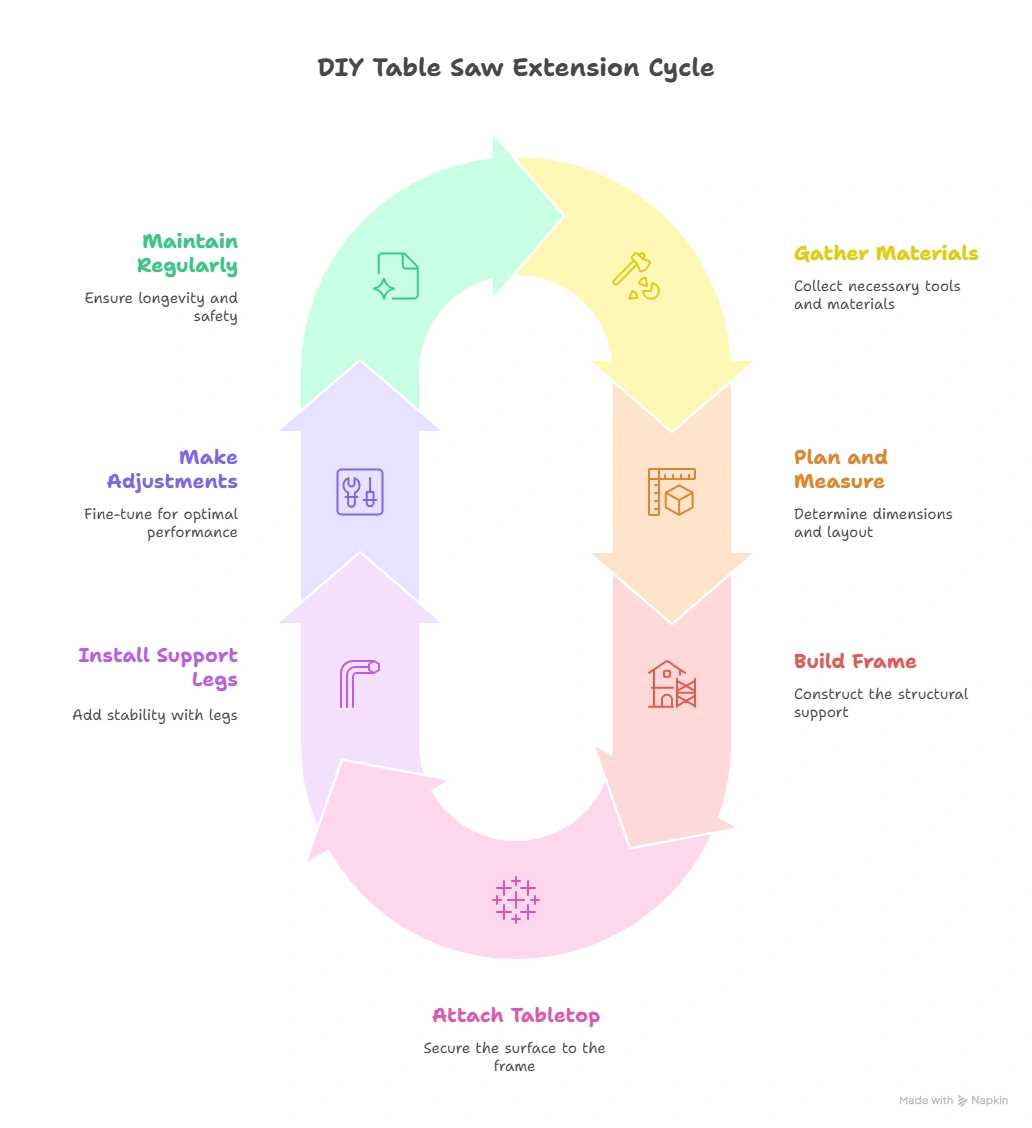

DIY Table Saw Extension: Boost Your Woodworking Efficiency

A DIY table saw extension can greatly enhance your woodworking projects. It’s an affordable and practical solution for more workspace.

Imagine having extra table space for your large woodworking pieces. A DIY table saw extension offers that flexibility. It helps you cut bigger wood pieces with ease and precision. You don’t need to spend a lot. With some basic tools and materials, you can build it yourself.

This guide will show you how to create a table saw extension that fits your needs. You’ll learn the steps and gather tips to make the process smooth. Ready to expand your woodworking capabilities? Let’s dive into the world of DIY table saw extensions.

Materials Needed

You need a saw for cutting. A drill is essential for making holes. Sandpaper smooths the edges. A measuring tape ensures accuracy. Clamps hold pieces in place. A pencil marks measurements. Safety goggles protect your eyes.

Plywood is strong and durable. Use screws to join pieces firmly. Wood glue adds extra strength. Paint or varnish finishes the surface. Nails can be useful for quick fixes. Hinges allow for easy folding or adjustments.

Planning And Measurements

First, measure the width and length of your table saw. Note down these measurements. These will help design the extension. Ensure the measurements are accurate. Use a tape measure for precision. Check the height too. The extension must be level with the saw.

Plan the size of the extension. It should match your saw’s dimensions. Draw a rough sketch. This will guide you during the build. Choose the right materials. Plywood is a good option. It is strong and easy to work with. Think about adding legs for support. This will make the extension stable. Consider the tools you will need. A saw, drill, and screws are essential. Gather everything before you start.

Building The Frame

First, measure the wood pieces. Use a measuring tape. Mark the lengths with a pencil. Next, use a saw to cut the wood. Try to keep the cuts straight. This makes assembly easier. Sand the edges smooth. This helps in fitting the pieces better. Always wear safety gear.

Lay the wood pieces on a flat surface. Align them properly. Use screws and a drill to join them. Check if the frame is square. Adjust if needed. Tighten all screws. Your frame should be sturdy now. Test the frame by pressing on it. Make sure it does not wobble.

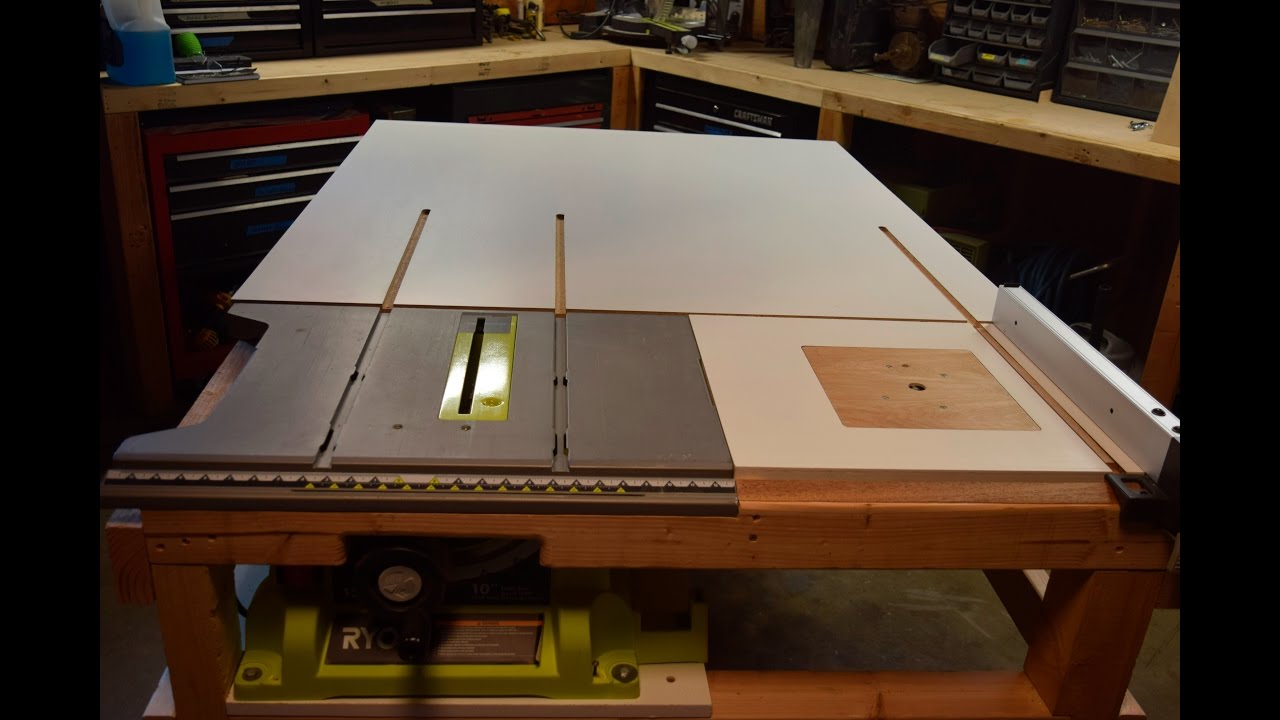

Credit: www.youtube.com

Attaching The Tabletop

Wood and metal are common choices. Wood is easy to work with. Metal is strong and durable. Plywood is affordable. Solid wood looks nice. Choose a material that fits your needs.

First, place the tabletop on the frame. Make sure it is centered. Use screws to attach the tabletop to the frame. Drill pilot holes to avoid splitting the wood. Tighten the screws until they are snug. Check that the tabletop is level.

Installing Support Legs

Measure the height of the table saw. Add the thickness of the extension. Use a tape measure for accuracy. Mark the measurement on the wood. Ensure the wood is sturdy. Use a saw to cut the wood to the marked length. Sand the edges for smoothness.

Position the legs at each corner of the frame. Use clamps to hold them in place. Drill pilot holes for screws. Ensure the legs are straight. Insert screws into the pilot holes. Tighten screws securely. Check stability of legs. Repeat for all corners.

Final Adjustments

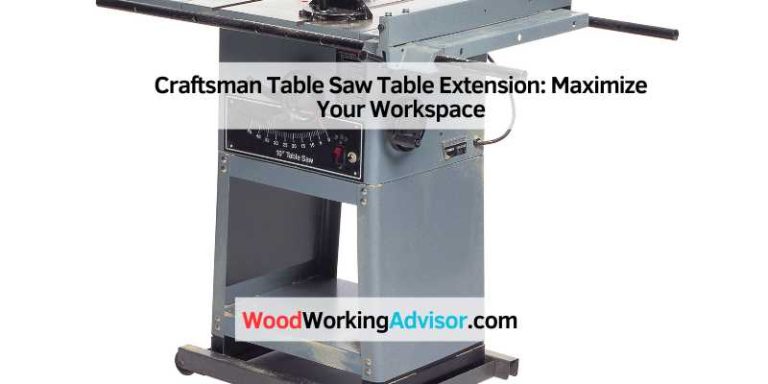

Use a level to check the table saw extension. It must be flat. Adjust the legs if needed. This ensures smooth cuts. The surface should match the saw’s height.

Place a board across the saw and extension. It should lay flat. No gaps. If there are gaps, adjust again. Precision is key. A flat surface prevents accidents.

Check the extension’s stability. Press down on each corner. It should not wobble. Tighten screws if it moves. A stable extension is safe. It keeps cuts straight.

Place a heavy object on the extension. It should hold the weight. No tilting. Stability means reliable performance. Always double-check stability before use.

Maintenance Tips

Check your table saw regularly for any damage or wear. Look at the blades, bolts, and screws. Make sure everything is tight and secure. If you see any problems, fix them right away. This can prevent accidents.

Keep your table saw clean. Dust can cause problems. Use a brush or vacuum to remove dust. Wipe the surface with a damp cloth. Do not let water stay on the surface. Dry it completely.

Lubricate the moving parts. This helps the saw run smoothly. Use a good machine oil. Apply it lightly. Too much oil can attract dust. Keep the blades sharp. This will make your cuts cleaner and safer.

Credit: www.reddit.com

Credit: www.youtube.com

Frequently Asked Questions

What Is The #1 Danger When Using A Table Saw?

The #1 danger when using a table saw is kickback. Kickback occurs when wood is thrown back at the operator, causing severe injuries.

What Extension Cord Do I Need For A Table Saw?

Choose a 12-gauge extension cord for your table saw. Ensure it’s rated for outdoor use and handles at least 15 amps.

How To Extend A Folding Table?

To extend a folding table, unlock the table’s hinges or latches. Pull the table sides apart gently. Insert the extension leaf into the gap. Secure the latches or hinges again to stabilize the table.

Can You Add A Saw Stop To A Table Saw?

No, you can’t add a SawStop to an existing table saw. SawStop technology is built into specific models by the manufacturer.

Conclusion

Building your own table saw extension is achievable and rewarding. It saves money and enhances your workspace. Simple tools and clear instructions make this project manageable. Enjoy the satisfaction of crafting something useful. Get started today and see the difference in your workshop.

Happy building!