Glue Steel to Plastic: Ultimate Bonding Guide

To effectively glue steel to plastic, use a strong adhesive specifically designed for both materials, such as epoxy or cyanoacrylate. Ensure surfaces are clean and dry for optimal bonding.

Bonding steel to plastic presents unique challenges due to the differing properties of these materials. Steel is rigid and heavy, while plastic can be flexible and lightweight. Choosing the right adhesive is crucial for a strong, lasting bond. Various options are available, including epoxy, cyanoacrylate (super glue), and specialized plastic adhesives.

Each type has its advantages, depending on the specific application and environmental conditions. Proper surface preparation also plays a vital role in achieving a secure bond. By understanding the nuances of these materials and the adhesives, you can successfully create a strong connection that meets your needs.

Introduction To Adhesive Bonding

Adhesive bonding is a key part of joining materials. Glue is often used for this purpose. Understanding material compatibility is crucial. Not all materials bond well together.

Plastic and steel are different. Each has unique properties. Knowing how they interact helps create strong bonds.

Compatibility affects the strength of the bond. Some plastics may not stick to certain glues. Testing different combinations can yield better results.

Always check the glue’s instructions. This ensures the right type is used. Proper preparation of both surfaces is also important.

Types Of Adhesives For Steel To Plastic

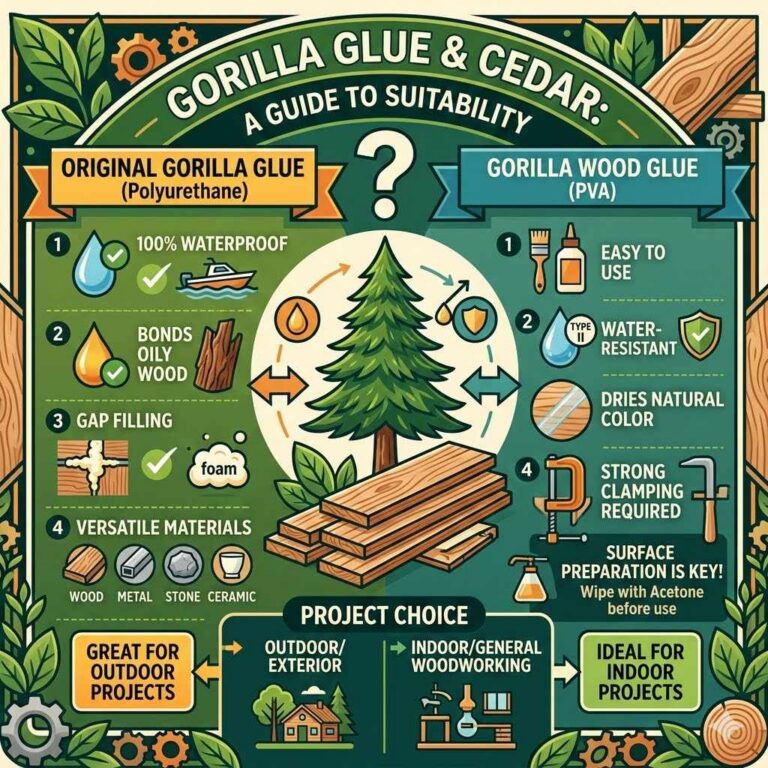

Epoxy adhesives are very strong. They work well on both steel and plastic. Mix two parts to create a bond. This type is great for heavy-duty projects.

Cyanoacrylate adhesives, often called super glue, bond quickly. They are perfect for small repairs. Just apply a drop and press the pieces together.

Polyurethane adhesives are flexible and waterproof. They can handle different temperatures. This makes them good for outdoor use.

Surface Preparation Techniques

Cleaning the surfaces is essential for a strong bond. Use soap and water to remove dirt. Rinse well and dry completely. For greasy surfaces, use a degreaser to ensure proper adhesion.

Abrading the surfaces helps improve the bond. Use sandpaper or a file to roughen the area. This creates more grip for the glue.

Applying a primer can enhance adhesion. Choose a primer suitable for both steel and plastic. Follow the manufacturer’s instructions for best results.

Applying The Adhesive

Choosing the right adhesive quantity is crucial for a strong bond. Use too much, and it can create a mess. Too little may not hold the materials together. Aim for a thin, even layer to ensure proper adhesion.

Precision in application matters for successful bonding. Use a small brush or a precision applicator for accuracy. Apply the adhesive directly to both surfaces. Press them together firmly for a few seconds.

Consider the curing time for the adhesive. Most adhesives require a specific time to set. Avoid moving the items during this period. Check the manufacturer’s instructions for best results.

Bonding Challenges And Solutions

Bonding steel to plastic can be tricky. One main problem is thermal expansion mismatch. Steel and plastic expand at different rates. This difference can cause stress and cracks.

To manage stress concentration, use the right adhesive. Flexible adhesives work better for this type of bonding. They can absorb the stress caused by temperature changes. Proper surface preparation also helps create a strong bond.

| Adhesive Type | Benefits |

|---|---|

| Epoxy | Strong and durable |

| Polyurethane | Flexible and impact-resistant |

| Silicone | Good for temperature changes |

Testing And Performance

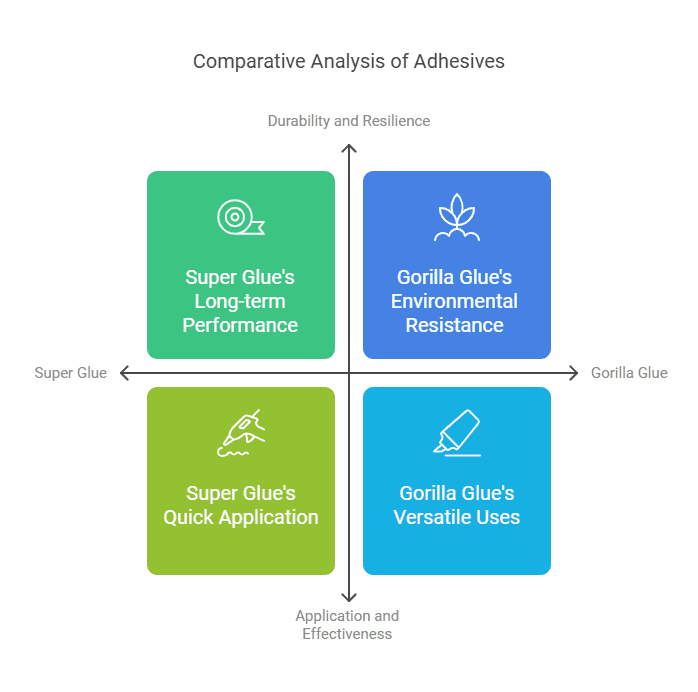

Tensile strength testing measures how much force a bond can handle. This test shows the strength of the glue used on steel and plastic. Strong glue should withstand heavy pulling without breaking. The results help choose the best glue for projects.

Environmental resistance testing checks how glue performs in different conditions. This includes temperature changes, moisture, and chemicals. Good glue should resist these factors over time. Testing helps ensure the bond lasts in various environments.

Safety And Environmental Considerations

Always use protective gear like gloves and goggles when handling chemicals. Ensure proper ventilation in your workspace. This helps to avoid inhaling harmful fumes. Store chemicals in labeled containers to prevent confusion.

For disposal, follow local regulations for hazardous waste. Never pour chemicals down the drain. Instead, take them to a designated disposal site. Clean spills immediately with appropriate materials to ensure safety.

| Item | Action |

|---|---|

| Gloves | Wear during use |

| Goggles | Protect eyes |

| Fumes | Avoid inhalation |

| Spills | Clean immediately |

Case Studies And Real-world Applications

The automotive industry uses glue to bond steel and plastic parts. This method helps save weight and improve fuel efficiency. Cars often have plastic panels glued to steel frames. Such designs enhance aerodynamics and reduce manufacturing costs.

For example, many car manufacturers use a special epoxy adhesive. This strong glue can withstand high temperatures and vibrations. It creates a durable bond that lasts a long time.

Home DIY projects also benefit from gluing steel to plastic. This technique can repair broken parts or create new items. Using the right adhesive ensures a strong and lasting bond.

| Application | Material Used | Benefits |

|---|---|---|

| Car Panels | Steel & Plastic | Lightweight & Fuel Efficient |

| Interior Parts | Plastic & Metal | Durable & Cost-effective |

| DIY Repairs | Various | Simple & Quick Fixes |

Maintenance And Repair Tips

Regular inspection of the bond between steel and plastic is vital. Check for any signs of wear or damage. Look for cracks, separation, or changes in color. These can indicate weak spots in the bond.

Establish a maintenance routine to ensure durability. Clean the surfaces regularly to remove dust and grease. Use a soft cloth and mild soap for cleaning. Avoid using harsh chemicals that can damage the materials.

For effective repairs, use a high-quality adhesive designed for both steel and plastic. Follow the manufacturer’s instructions carefully. Allow the adhesive to cure fully before applying stress to the bond.

| Inspection Tips | Maintenance Tips | Repair Tips |

|---|---|---|

| Look for cracks | Clean with mild soap | Use quality adhesive |

| Check for separation | Regular cleaning schedule | Follow instructions |

| Watch for color changes | Avoid harsh chemicals | Let it cure fully |

Future Trends In Adhesive Technology

The future of adhesive technology focuses on innovations that benefit the environment. Eco-friendly adhesives use natural materials. These options reduce harmful chemicals in products. Many companies are now developing these sustainable solutions.

Bonding durability is another key trend. Stronger adhesives can hold materials together longer. This leads to fewer repairs and waste. Improved technology allows for stronger bonds between different surfaces.

Research continues to create adhesives that work on various materials, including steel and plastic. These advancements help in many industries, from construction to automotive. The goal is to provide reliable solutions that meet modern needs.

Frequently Asked Questions

Can You Glue Steel To Plastic?

Yes, you can glue steel to plastic using specific adhesives. Epoxy and cyanoacrylate glues are popular choices. Ensure both surfaces are clean and dry before applying the adhesive. Allow adequate curing time for a strong bond. Always check the manufacturer’s instructions for the best results.

What Type Of Glue Is Best For Steel And Plastic?

The best glue for bonding steel and plastic is epoxy. Epoxy provides a strong, durable bond suitable for various applications. Cyanoacrylate glue, also known as super glue, can work for lighter tasks. Choose an adhesive that matches your project’s requirements for optimal performance.

How Long Does Glue Take To Dry On Steel And Plastic?

Drying time for glue on steel and plastic varies by adhesive. Most epoxies take about 24 hours to fully cure. Super glue typically sets within minutes but may require additional time for maximum strength. Always refer to the product label for specific drying times.

Is It Necessary To Prepare Surfaces Before Gluing?

Yes, surface preparation is crucial for a strong bond. Clean both steel and plastic surfaces to remove dirt, grease, or dust. Sanding the surfaces lightly can also enhance adhesion. Proper preparation ensures that the glue adheres effectively, resulting in a durable connection.

Conclusion

Successfully gluing steel to plastic can enhance your projects’ durability and functionality. Choosing the right adhesive is crucial for a strong bond. Always follow manufacturer instructions for the best results. With the right techniques, you can achieve a seamless and lasting connection.

Embrace these tips for your next DIY endeavor.