How Much Are Table Saws: Essential Guide

The cost of table saws varies widely, from around $100 for basic portable models to $1500+ for professional cabinet saws. For beginners, expect to spend between $200 and $500 for a reliable contractor or hybrid saw that balances features and affordability. Consider your project needs and space when choosing.

How Much Are Table Saws

Thinking about adding a table saw to your workshop? It’s a fantastic tool for woodworking, making precise cuts easier than ever. But when you start looking, you might feel a little overwhelmed by the price tags. “How much are table saws?” is a common question for anyone starting out in DIY or home improvement projects. Don’t worry, it’s totally normal to wonder about the investment! This guide is here to break down the costs, explain what you get for your money, and help you find the perfect saw without breaking the bank. Let’s get you cutting with confidence!

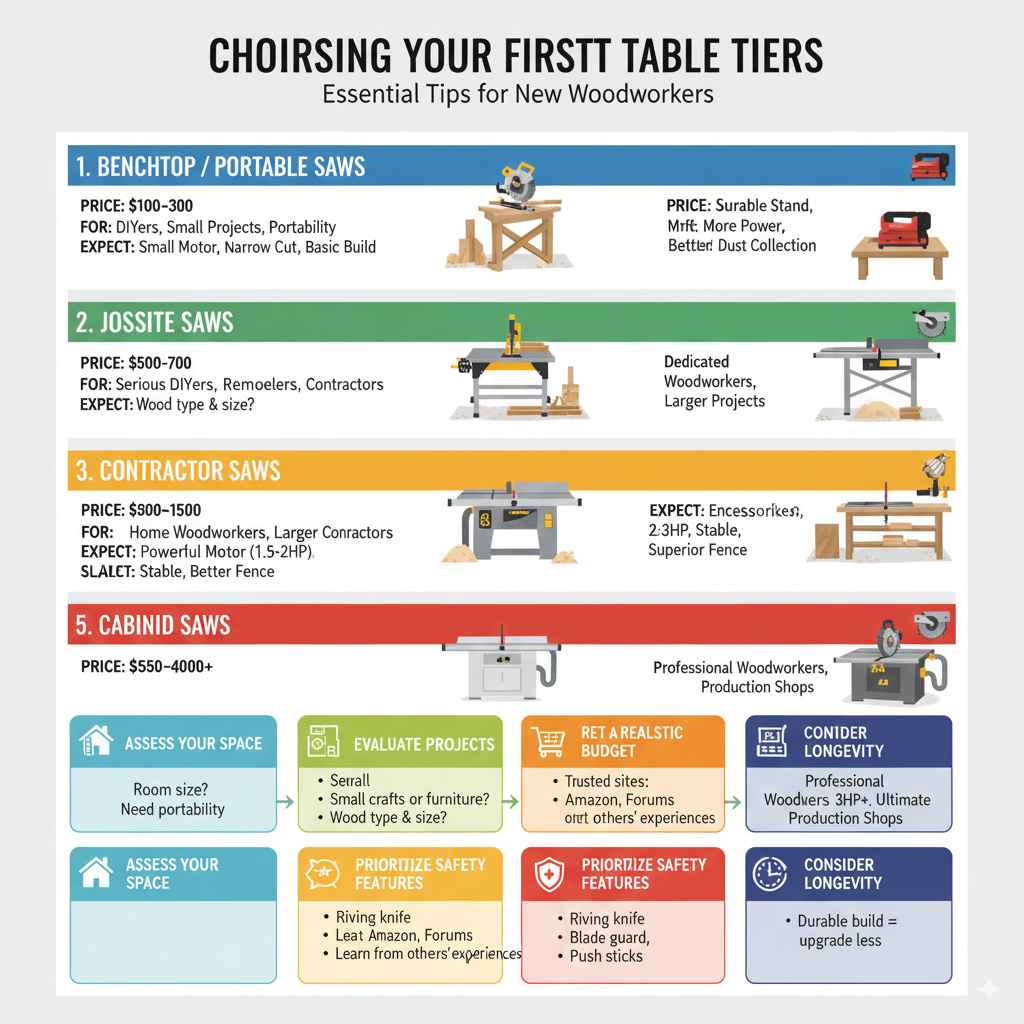

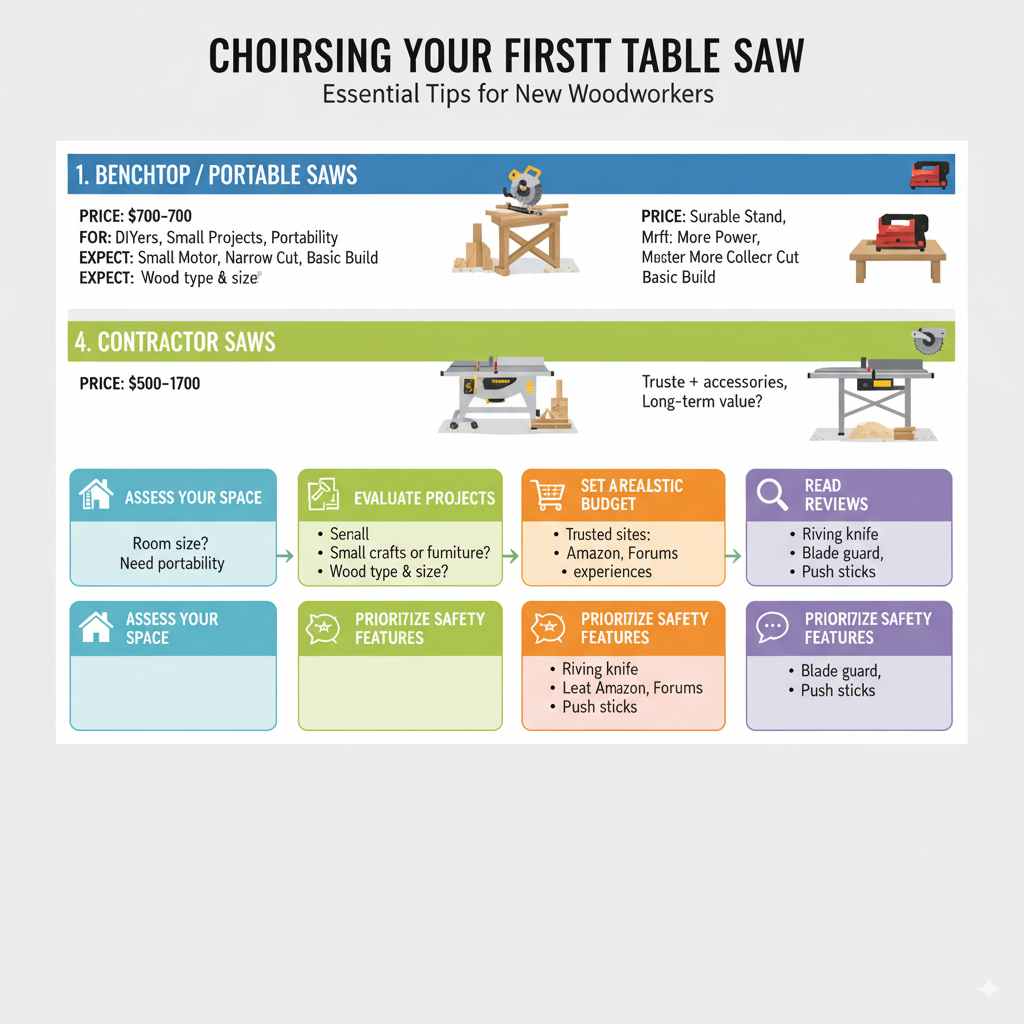

Understanding Table Saw Price Tiers

Table saws aren’t a one-size-fits-all purchase. Their prices are a reflection of their size, power, features, and intended use. Generally, you can categorize them into a few main types, each with its own typical price range.

1. Benchtop/Portable Table Saws

These are the most entry-level saws. They’re lightweight, compact, and designed to be easily moved around a garage or job site. They often sit on a workbench or come with a small, foldable stand.

- Price Range: $100 – $300

- Who are they for? DIYers with limited space, hobbyists doing small projects, or those who need portability.

- What to expect: Smaller motor, narrower rip capacity (the distance from the blade to the fence), and often less robust build quality. They are great for basic crosscuts and rip cuts on thinner materials.

2. Jobsite Table Saws

A step up from benchtop models, jobsite saws are built for durability and portability. They often have a sturdier stand, larger cutting capacity, and more powerful motors. They’re popular with contractors who need to make precise cuts on site.

- Price Range: $300 – $700

- Who are they for? Serious DIYers, remodelers, and contractors who prioritize portability but need more power and capacity.

- What to expect: Better dust collection, stronger fences, and larger table surfaces. Some models have features like soft-start motors for smoother operation.

3. Contractor Table Saws

These are a classic choice and often considered the sweet spot for serious hobbyists and home workshops. They offer a good balance of power, capacity, and features at a reasonable price. They are typically heavier and less portable than jobsite saws, often designed to stay put in a dedicated space.

- Price Range: $500 – $1000

- Who are they for? Enthusiastic home woodworkers and those tackling larger or more frequent projects.

- What to expect: More powerful motors (often 1.5-2 HP), larger cast-iron trunnions (the part that holds the blade assembly), better fences, and a more stable cutting experience.

4. Hybrid Table Saws

Hybrid saws offer a blend of contractor and cabinet saw features. They typically have the enclosed base of a cabinet saw but use a belt-drive system like a contractor saw, making them more affordable than full cabinet models. They are heavier and more stable than contractor saws.

- Price Range: $800 – $1500

- Who are they for? Dedicated woodworkers who need more power, precision, and stability for a wide range of projects, but don’t have the budget or space for a full cabinet saw.

- What to expect: Robust construction, powerful motors (often 2-3 HP), excellent dust collection, and superior fence systems.

5. Cabinet Table Saws

These are the workhorses of professional woodworking shops. They are heavy, powerful, and designed for precision and durability. They have powerful 3-phase motors (though some residential models use single-phase), superior trunnions, and the best dust collection systems.

- Price Range: $1500 – $4000+

- Who are they for? Professional woodworkers, cabinet makers, and serious hobbyists who demand the highest level of precision, power, and longevity.

- What to expect: Incredible stability, powerful motors for even the hardest woods, highly accurate fences, and the best overall cutting performance.

Factors Influencing Table Saw Prices

So, why such a big price difference? Several key factors contribute to the cost of a table saw:

- Motor Power (Horsepower – HP): More powerful motors allow you to cut through thicker, harder woods more easily and with less bogging down. Higher HP generally means a higher price.

- Table Size and Material: Larger cast-iron tables provide more stability and a larger surface area for guiding material. Aluminum or stamped steel tables are lighter and cheaper.

- Fence System: A high-quality fence is crucial for accurate ripping. More expensive saws feature robust, easy-to-adjust fences that lock securely and remain parallel to the blade.

- Trunnions: These are the heavy-duty brackets that hold the motor and blade assembly and allow for tilting. Cast-iron trunnions are more stable and precise than lighter aluminum ones.

- Portability Features: Saws designed for portability (like jobsite saws) will have stands, wheels, and lighter construction, which can influence the price.

- Dust Collection: Better dust collection systems, especially integrated ones found on higher-end saws, add to the cost but are essential for a cleaner and safer workshop.

- Brand Reputation and Features: Well-known brands often command higher prices due to their perceived quality, durability, and customer support. Additional features like soft-start, blade guard designs, and onboard storage also add to value and cost.

Table Saw Price Breakdown by Type (Summary)

To give you a quick overview, here’s a table summarizing the typical price ranges for different table saw types:

| Table Saw Type | Typical Price Range (USD) | Best For |

|---|---|---|

| Benchtop/Portable | $100 – $300 | Light DIY, small projects, limited space |

| Jobsite | $300 – $700 | Serious DIY, contractors, portability needs |

| Contractor | $500 – $1000 | Home workshops, enthusiast hobbyists |

| Hybrid | $800 – $1500 | Dedicated woodworkers, diverse projects |

| Cabinet | $1500 – $4000+ | Professional shops, maximum precision |

What Can You Expect for Your Money?

Let’s dive deeper into what specific price points offer:

Under $300: The Entry Level

At this price, you’re looking at basic benchtop or very lightweight portable saws. These are usually powered by universal motors that are louder and can overheat with heavy use.

- Pros: Very affordable, easy to move, good for occasional light tasks.

- Cons: Limited power and cutting capacity, less precise fence, can be noisy and dusty.

- Ideal Projects: Small shelves, basic repairs, cutting thin plywood or pine.

$300 – $700: The Jobsite Workhorse

This range offers jobsite saws that are more robust. They usually have a sturdier, foldable stand, a better fence system, and a motor that can handle more demanding work. They are still portable but feel more substantial.

- Pros: Good balance of power and portability, better dust collection than benchtop, more durable build.

- Cons: Can still be noisy, rip capacity might be limited for very wide boards.

- Ideal Projects: Framing, decks, larger DIY projects, where you need to cut lumber on-site.

$500 – $1000: The Contractor’s Choice

This is where you start seeing proper contractor saws. They feature cast-iron tops and often cast-iron trunnions, leading to more stability and less vibration. The motors are typically induction motors, which are quieter and more durable. The fence systems are a significant upgrade.

- Pros: Excellent value for home workshops, stable cutting, powerful enough for most hardwoods, quieter operation.

- Cons: Heavier, less portable, may require a 240V circuit for some models.

- Ideal Projects: Furniture making, cabinetry, larger home renovation projects.

$800 – $1500: The Hybrid Performer

Hybrid saws bridge the gap. They boast a more enclosed cabinet base, improved dust collection, and often more powerful motors than contractor saws. They offer a smoother, more professional feel without the full cabinet saw price tag.

- Pros: Very stable, powerful, good dust collection, smooth operation, excellent precision.

- Cons: Significant investment, requires dedicated space, usually needs a 240V circuit.

- Ideal Projects: Advanced woodworking, detailed cabinetry, projects requiring high precision and repeatability.

$1500+: The Professional Cabinet Saw

These are the top-tier saws. They are incredibly heavy, powerful, and built for years of intense use. They feature heavy-duty cast-iron trunnions, powerful (often 3-phase) induction motors, high-capacity rip fences, and superior dust management.

- Pros: Unmatched power, precision, stability, and durability. The best for serious production.

- Cons: Very expensive, require a lot of space and often 240V (or even 3-phase power), not portable at all.

- Ideal Projects: Professional furniture making, large-scale woodworking operations, high-volume production.

Should You Buy New or Used?

The decision to buy new or used can significantly impact your budget. Here’s a look at both:

Buying New

- Pros: Comes with a warranty, you know its history (or lack thereof), access to the latest features and safety standards, often easier to find financing.

- Cons: Higher upfront cost, depreciation is immediate.

Buying Used

- Pros: Can get a higher-quality saw for your budget, potentially find discontinued models with great features, less depreciation.

- Cons: No warranty, potential for hidden issues (bent parts, worn motor, damage), safety can be a concern if not inspected thoroughly, requires more knowledge to assess condition.

If you opt for used, always try to see the saw in action. Check for wobble in the blade, easy movement of the fence and trunnions, and listen for unusual motor noises. Reputable sites like Rockler and Woodcraft often have used sections or forums where you might find good deals, and local classifieds or auction sites can also be sources. For safety standards, the Consumer Product Safety Commission (CPSC) offers important safety information to consider, especially when buying older models.

Essential Features to Look For on a Budget

Even if you’re on a tighter budget, some features are non-negotiable for safety and good results. Here’s what to prioritize:

- Solid Fence: A fence that glides smoothly and locks securely without shifting is vital for accurate rip cuts. Look for a “beveled” or “T-square” style fence system.

- Blade Guard and riving Knife/Splitter: A good blade guard assembly that allows for kickback protection and a riving knife or splitter are crucial safety features. A riving knife moves with the blade and is generally considered superior to a fixed splitter for preventing wood from binding.

- Reasonable Power: Aim for at least a 1.5 HP motor if possible. This will handle most common tasks without struggling.

- Cast Iron Table (if possible): While not always feasible on the lowest end, a cast-iron table offers more stability and dampens vibration, leading to cleaner cuts.

- Standard Blade Size: Most home workshop saws use 10-inch blades, which are readily available in various types and prices.

Cost of Accessories and Ongoing Expenses

Don’t forget that the cost of the table saw itself is just the beginning! You’ll also need accessories and will have ongoing expenses:

- Blades: A basic blade comes with the saw, but you’ll want specialized blades for different tasks (e.g., a fine-tooth blade for plywood, a ripping blade for hardwoods). Budget $30-$100+ per blade.

- Push Sticks and Safety Gear: Essential for safety. Safety glasses, hearing protection, and dust masks are a must. Push sticks help keep your hands away from the blade. Budget $20-$50.

- Dado Stack (Optional): For cutting wide grooves (like for shelves), a dado stack is needed. This can cost $100-$200.

- Measuring Tools: A good tape measure and combination square are crucial for precision.

- Dust Collection: While some saws have built-in ports, a shop vac or dedicated dust collector improves air quality and keeps your workspace clean. Hose and fittings can add $50-$200+.

- Mobile Base (Optional): If you need to move your saw around a lot, a mobile base adds convenience and cost ($100-$200).

- Power: Ensure you have adequate electrical outlets for your saw. Some larger saws require a 240V outlet, which might necessitate an electrician (cost varies widely).

Tips for Choosing Your First Table Saw

Choosing your first table saw should be exciting, not stressful! Here are a few tips to guide your decision:

- Assess Your Space: How much room do you have for a saw, and do you need to move it often? This will help narrow down types.

- Evaluate Your Projects: Are you building small crafts, furniture, or large home structures? The size and type of wood you’ll be cutting are key factors.

- Set a Realistic Budget: Factor in the cost of essential accessories. It’s better to get a slightly less expensive saw and good accessories than the other way around.

- Read Reviews: Look for reviews from other DIYers and woodworkers on trusted sites like Amazon, Home Depot, Lowe’s, and dedicated woodworking forums.

- Prioritize Safety Features: Never compromise on safety. Always look for features like a riving knife and a good blade guard. For more on safety, check out resources from organizations like the Woodworking Network.

- Consider Longevity: A slightly more expensive saw now might save you money in the long run if it’s more durable and capable, preventing you from needing an upgrade too soon.

Frequently Asked Questions (FAQ)

Q1: What is the cheapest type of table saw I can buy?

A: The cheapest table saws are typically benchtop or portable models, which can often be found for under $300. These are great for very light-duty tasks but lack the power and precision of larger saws.

Q2: Is a contractor saw a good starting point for a home workshop?

A: Absolutely! A contractor saw often hits the sweet spot for home workshops. They offer a good balance of power, stability, and features for their price, usually ranging from $500 to $1000.