To rip a board with a circular saw, set the blade depth, align the saw with the cutting line, and push it steadily through the board. Ripping a board with a circular saw involves a few simple steps.

By following the right technique, you can achieve a clean and precise cut. We will guide you through the process of ripping a board with a circular saw, ensuring safety precautions and accuracy. So, whether you are a DIY enthusiast or a professional woodworker, read on to learn how to rip a board with a circular saw effectively.

Understanding The Circular Saw: Expert Tips And Tricks

Discover expert tips and tricks for effectively ripping a board with a circular saw. Acquire a deep understanding of this versatile tool with our comprehensive guide.

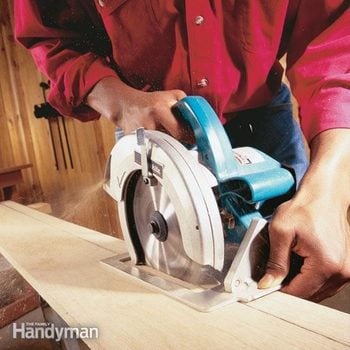

Having a circular saw is essential for any woodworking enthusiast or professional. This versatile power tool can make straight cuts on various materials, including ripping boards. However, before you start sawing away, it’s crucial to understand the circular saw and its components to ensure a safe and successful ripping process.

In this section, we will explore how to choose the right circular saw for ripping, proper maintenance and safety precautions, and familiarize ourselves with the saw’s components.

Choosing The Right Circular Saw For Ripping:

- Consider the power source: Circular saws can be corded or cordless, each with its advantages. Corded saws offer consistent power but require an electrical outlet, while cordless saws provide easier portability but may have limited battery life.

- Look for adequate power: The motor’s power rating determines the saw’s cutting ability. Higher horsepower (HP) or amperage (A) usually indicates stronger cutting performance.

- Check the blade diameter: Circular saw blades come in various sizes, typically measured in inches. A larger blade diameter allows for deeper cuts, but keep in mind that it may add weight and reduce maneuverability.

- Opt for adjustable depth and bevel settings: A circular saw with adjustable depth and bevel settings provides flexibility for different ripping needs. Ensure that these adjustments are easy to make and securely lock in place.

Proper Maintenance And Safety Precautions:

- Keep the saw clean and free from debris: Regularly remove sawdust, wood chips, and other debris from the saw’s body and blade area. This ensures smooth operation and prevents potential accidents.

- Sharpen or replace dull blades: Dull blades not only hinder cutting performance but also increase the risk of kickback. Sharpen the blades regularly or replace them when necessary to maintain optimal cutting efficiency.

- Use appropriate safety gear: Always wear safety goggles, ear protection, and gloves when operating a circular saw. Additionally, consider using a dust mask and a protective apron to minimize exposure to sawdust and wood particles.

- Secure the workpiece: Use clamps or a workbench to secure the board firmly before cutting. This prevents the wood from moving or binding during the ripping process.

- Practice proper cutting techniques: Position yourself to maintain balance and stability while cutting. Apply steady but gentle pressure to guide the saw smoothly along the cutting line, avoiding excessive force or erratic movements.

Familiarizing Yourself With The Circular Saw Components:

- Blade guard: The blade guard protects the user from accidental contact with the rotating blade. It automatically retracts when the saw is engaged but covers the blade when it’s not in use.

- Depth adjustment lever: This lever allows you to control the cutting depth of the blade. Adjust it according to the thickness of the board you intend to rip.

- Bevel adjustment: The bevel adjustment enables you to tilt the blade at an angle for beveled cuts. It’s useful when you need to rip boards with angled edges.

- Handle and trigger: The handle provides a comfortable grip, allowing you to control the saw’s movement. The trigger, located near the handle, activates the saw’s motor when pressed.

- Base plate: Also known as the shoe, the base plate rests on the material being cut and provides stability and support for accurate cuts. Ensure that the base plate is flat and without defects.

By understanding how to choose the right circular saw, practicing proper maintenance and safety precautions, and familiarizing yourself with its components, you’ll be well-equipped to rip boards flawlessly with a circular saw. Remember, safety should always be the top priority when working with power tools.

Preparing For The Ripping Process

Learn how to prepare for the ripping process of board with a circular saw efficiently and safely. Gain valuable tips and techniques to ensure a smooth ripping experience.

Ripping a board with a circular saw may seem like a daunting task, but with proper preparation, it can be accomplished safely and effectively. Before you dive into the ripping process, it’s important to take a few steps to ensure accuracy, stability, and optimal performance in your workspace.

Here’s what you need to do:

Measuring And Marking The Board Accurately:

- Use a measuring tape or a ruler to determine the length and width required for your project.

- Mark the desired length and width with a pencil or a marking gauge.

- Double-check your measurements to avoid any mistakes that could result in an uneven rip.

Securing The Board For Stability And Control:

- Place the board on a stable work surface, such as a workbench or sawhorses.

- Clamp the board securely to prevent any movement during the ripping process.

- Check that the clamps are tight and in the proper position to ensure stability and control.

Setting Up Your Workspace For Optimal Performance:

- Clear your workspace of any debris or obstacles that could hinder your movement or cause accidents.

- Ensure there is enough space for the board to move freely and for you to operate the circular saw comfortably.

- Position yourself in a way that allows you to maintain balance and control throughout the ripping process.

Remember, preparing adequately for the ripping process is essential for a successful outcome. Taking the time to measure and mark the board accurately, securing it for stability, and setting up your workspace for optimal performance will help you achieve clean and precise cuts with your circular saw.

Now that you’re ready, let’s move on to the next step – selecting the right blade for your project.

Positioning And Handling The Circular Saw

Learn how to effectively position and handle a circular saw for ripping boards. Master the techniques and ensure accurate cuts for your woodworking projects.

Establishing the correct grip and posture:

- Hold the circular saw with both hands, ensuring a firm grip to maintain control and stability.

- Place your dominant hand on the main handle, while using your other hand to support the rear handle.

- Maintain a balanced stance, with your feet shoulder-width apart for enhanced stability.

- Keep your back straight and your body aligned with the saw to minimize strain and prevent accidents.

Adjusting the depth and angle of the saw blade:

- Before starting the cut, adjust the depth of the saw blade to slightly exceed the thickness of the board. This ensures efficient and safe cutting.

- Use the depth adjustment lever or knob provided on the saw to set the desired depth.

- For straight cuts, set the saw blade at 90 degrees to the surface of the board. However, if you require an angled cut, adjust the angle accordingly using the bevel adjustment feature.

Maintaining a steady and controlled cutting motion:

- Begin the cut by aligning the saw blade with the marked cutting line on the board.

- Start the circular saw and ease it into the board with a smooth and steady motion.

- Apply slight forward pressure on the saw while maintaining a controlled pace to prevent binding or kickback.

- Keep your focus on the cutting line, ensuring the saw blade remains along the desired path throughout the cut.

- Use both hands to guide the saw, but avoid exerting excessive force that could lead to loss of control or inaccurate cuts.

Remember, practicing proper positioning and handling techniques will not only ensure your safety but also result in clean and precise cuts while using a circular saw.

Executing The Ripping Cut

Learn how to execute the ripping cut with a circular saw and effortlessly rip a board. This step-by-step guide provides clear instructions to help you achieve accurate and smooth cuts for your woodworking projects.

**Starting The Cut With Precision And Confidence**

To execute a clean and accurate ripping cut with a circular saw, it is crucial to start the cut with precision and confidence. Here are some key steps to follow:

- Positioning the saw: Before starting the cut, ensure that the circular saw is properly positioned and aligned with the marked cutting line. Hold the saw firmly and maintain a comfortable stance to ensure stability and control throughout the cut.

- Safety first: Before powering on the saw, always prioritize safety. Put on safety goggles and ear protection to protect yourself from potential hazards. Make sure the work area is clear of any obstructions and that the board is securely positioned and clamped if necessary.

- Aligning the blade: Position the saw’s blade so that it is parallel to the marked cutting line on the board. Take a moment to double-check the alignment to ensure an accurate cut. Adjust the depth of the blade according to the thickness of the board, making sure it is set to slightly deeper than the actual thickness.

- Starting the cut: Once everything is in place, gently squeeze the saw’s trigger to start the blade slowly. Allow the blade to reach full speed before gradually guiding it into the board. Keep the saw’s base plate flat on the board to maintain stability and prevent any kickbacks. Maintain a steady and controlled movement throughout the cut.

- Maintaining control: As you guide the saw along the cutting line, it’s important to maintain control and focus. Avoid rushing the cut and take your time to ensure precision. Use both hands to securely grip the saw and keep your body positioned in a way that provides stability and balance.

- Confidence and practice: Building confidence in your cutting abilities comes with practice. The more comfortable you become with the circular saw, the better control and precision you will have. Don’t be discouraged if your first attempts are not perfect – embrace the learning process and keep practicing to refine your skills.

Executing the ripping cut with precision and confidence sets the foundation for a well-done woodworking project. By following these steps, you’ll be on your way to achieving clean and accurate cuts with a circular saw.

**Following The Marked Line Accurately**

To ensure precise and straight cuts while ripping a board with a circular saw, it is crucial to follow the marked cutting line accurately. Here are some tips to help you maintain accuracy:

- Marking the cutting line: Start by measuring and marking the desired cutting line on the board using a measuring tape, straight edge, and pencil. Take your time to ensure that the line is straight and aligned with your project’s specifications.

- Clear line of sight: Before starting the cut, make sure you have a clear line of sight to the marked cutting line. Remove any debris or sawdust that may obstruct your view, as it can interfere with accuracy. Clearing the line of sight allows you to maintain a proper guide while cutting.

- Cutting on the waste side: Always position the circular saw blade on the waste side of the marked line. This ensures that you achieve an accurate cut without veering off the desired line. By cutting on the waste side, you prevent damaging the piece you intend to keep.

- Using a guide: For added accuracy, consider using a straight edge or guide to serve as a reference for the circular saw. Secure the guide parallel to the cutting line, ensuring that the blade follows the exact path intended. This method helps maintain consistency and minimizes the chances of veering off-course.

- Patience and steady movement: While cutting, maintain a slow and steady movement along the marked line. Avoid rushing or forcing the saw through the board, as this may lead to inaccurate and jagged cuts. Allow the saw’s blade to do the work, following the guide or marked line carefully.

Following the marked cutting line accurately is essential for achieving precise and clean cuts with a circular saw. Take your time, be patient, and focus on maintaining alignment throughout the cut.

**Overcoming Potential Challenges And Obstacles**

While ripping a board with a circular saw, you may encounter various challenges and obstacles. Here are some common ones and how to overcome them:

- Splintering: To minimize splintering, place masking tape or painter’s tape along the marked cutting line. This tape helps prevent tear-out on the surface of the board, resulting in a cleaner cut. Additionally, using a sharp and fine-toothed blade can also reduce splintering.

- Kerf width: The width of the circular saw’s blade, known as the kerf, can cause the actual cut to be wider than the marked cutting line. To compensate for this, consider adjusting the marked line slightly to the waste side. This adjustment ensures that the final dimensions of the board remain accurate despite the kerf width.

- Saw blade drift: Sometimes, the circular saw blade may veer off-course during the cutting process, resulting in an inaccurate cut. To overcome this challenge, use a guide or straight edge to keep the saw on the correct path. Applying consistent and gentle pressure while cutting can also help maintain control and prevent drift.

- Workpiece support: Adequate support for the board is essential to prevent it from sagging or binding during the cut. Use sawhorses, workbenches, or other supporting structures to ensure stability and minimize the risk of mishaps. Proper support allows for smoother, safer, and more accurate cuts.

- Peripheral vision: When following the cutting line, avoid focusing solely on the saw’s blade. Instead, maintain a wider field of vision that includes the entire length of the marked line. This peripheral vision helps you stay on track and maintain accuracy throughout the cut.

By understanding and proactively addressing these potential challenges, you can overcome obstacles that may arise while ripping a board with a circular saw. Adjustments, precautions, and a steady hand will help you achieve precise and professional-looking cuts.

Fine-Tuning The Rip Cut

Want to learn how to rip a board with a circular saw? Fine-tuning the rip cut is essential. Master the technique with these simple steps.

Removing any excess materials or splinters:

- Before proceeding with the next steps, it is crucial to inspect the board for any loose splinters or excess materials that may hinder the smoothness of the rip cut.

- Use a sandpaper or a file to carefully sand down any rough edges or splintered parts, ensuring a clean and smooth surface for the circular saw to glide through effortlessly.

- Remove any loose debris or sawdust from the board to maintain clarity and precision throughout the rip cut process.

- Regularly check for any irregularities or imperfections on the board’s surface and address them accordingly before proceeding.

Smoothing the edges for a clean finish:

- After removing excess materials or splinters, it is important to focus on achieving a clean finish by smoothing the edges of the board.

- Utilize a router or a trim router to round off the edges, ensuring a neat and professional look to the ripped board.

- If you don’t have access to a router, a block plane or a sanding block can also be used to smooth the edges manually.

- Always remember to work in a controlled and steady manner, keeping the board stable and using consistent pressure to achieve a uniform smoothness.

Ensuring the straightness and accuracy of the rip cut:

- To guarantee a straight and accurate rip cut, it is recommended to use a straight edge guide or a rip fence as a guide for the circular saw.

- Attach the straight edge guide or rip fence firmly to the board, aligning it parallel to the desired rip cut line.

- Maintain a steady grip on the circular saw, keeping it firmly pressed against the guide or fence while making the cut.

- Be mindful of any deviations or inconsistencies during the rip cut process and make minor adjustments as needed for a precise result.

- Double-check the straightness of the rip cut by measuring the distance between the newly cut edge and the opposite edge of the board, ensuring parallelism.

Remember, fine-tuning the rip cut involves removing any excess materials or splinters, smoothing the edges for a clean finish, and ensuring the straightness and accuracy of the cut. By following these steps, you’ll be on your way to achieving a flawless and professional rip cut using a circular saw.

Enhancing Safety And Precision

Enhance the safety and precision of your woodworking projects by learning how to rip a board with a circular saw. With these step-by-step instructions, you can ensure accurate cuts and minimize the risk of accidents.

When it comes to ripping a board with a circular saw, safety and precision are paramount. By following a few essential tips and techniques, you can ensure that your woodworking projects are not only accurate but also carried out with utmost caution.

In this section, we will explore using guides and clamps for added stability, employing safety accessories and protective gear, and implementing advanced techniques for increased accuracy.

Using Guides And Clamps For Added Stability:

- Position guides: Align your circular saw with a straight-edge guide to maintain a straight cutting path. This can be a dedicated guide rail or a simple straight board.

- Secure with clamps: Use clamps to secure the board and guide in place, preventing any movement during the cutting process.

- Measure twice, cut once: Before making any cuts, double-check your measurements to ensure accurate results.

- Maintain a firm grip: Hold the circular saw with both hands, ensuring a stable grip while guiding it along the straight-edge guide.

Employing Safety Accessories And Protective Gear:

- Safety goggles: Protect your eyes from flying debris by wearing safety goggles throughout the cutting process.

- Ear protection: Circular saws can be loud, so it is advisable to wear ear protection to prevent potential hearing damage.

- Dust mask: Wear a dust mask to avoid inhaling fine sawdust particles that may be released during the cutting process.

- Protective gloves: By wearing suitable gloves, you can safeguard your hands from accidental cuts or abrasions.

Implementing Advanced Techniques For Increased Accuracy:

- Score the cut: Create a shallow scoring cut along the intended cutting path before making a full-depth cut. This helps prevent splintering or tear-out.

- Clean blade and proper depth: Ensure your circular saw blade is clean and in suitable condition. Set the blade depth, so it extends no more than 1/4 inch below the material you are cutting.

- Steady feed rate: Maintain a consistent and steady feed rate while guiding the circular saw along the cutting path for smoother and more accurate cuts.

- Proper support: Use sawhorses or a workbench to support longer boards, preventing them from sagging and resulting in uneven cuts.

By employing these safety measures and advanced techniques, you can enhance both the precision and safety of ripping boards with a circular saw. Remember, safety should always be prioritized, and taking your time to ensure accuracy will ultimately lead to more successful woodworking projects.

Stay safe and enjoy the process of creating something remarkable with your circular saw!

Troubleshooting Common Issues

Learn how to troubleshoot common issues when ripping a board with a circular saw. Discover effective techniques to ensure precise cuts and avoid potential problems.

Addressing Kickback And Blade Binding

When working with a circular saw, it is crucial to be aware of and address any potential kickback or blade binding issues. Kickback occurs when the saw blade gets caught or pinched in the material, causing the saw to jerk backward towards the user.

Blade binding happens when the saw blade gets stuck in the wood, preventing smooth cutting. To troubleshoot these common issues, consider the following:

- Ensure that the blade is properly aligned and tightened in the saw.

- Use a blade suitable for the material you are cutting, ensuring it is sharp and in good condition.

- Adjust the cutting depth according to the material thickness, ensuring the saw does not cut too deep or shallow.

- Maintain a firm grip on the saw with both hands and position yourself in a stable stance.

- Allow the saw to reach full speed before starting the cut and avoid forcing the saw through the material.

- Use a saw with safety features such as an anti-kickback pawl and riving knife.

- Keep the work area clear of debris and ensure there is enough space for the material to move freely.

Fixing Mistakes Or Inaccuracies During The Cut

It’s not uncommon to encounter mistakes or inaccuracies while ripping boards with a circular saw. However, these issues can be easily fixed to ensure a clean and precise cut. Here are some troubleshooting tips:

- If the cut veers off the desired path, stop the saw and realign it with the intended cutting line. Take your time to make precise adjustments.

- In case the saw drifts away from the straight line, use a straightedge or guide clamp to ensure a more accurate cut.

- If the saw blade binds or gets stuck in the wood, avoid forcing it. Release the trigger, allow the blade to stop spinning, and carefully remove the saw from the material. Assess the cause of the binding, such as a misaligned blade or improper cutting speed.

- For minor inaccuracies or rough edges, you can use sandpaper or a file to smooth them out and achieve a better finish.

- Remember to measure and mark your cutting line accurately before starting the cut to minimize mistakes.

Troubleshooting Issues With Cut Quality And Finish

The quality of the cut and the overall finish are crucial aspects when ripping boards with a circular saw. To troubleshoot any issues related to cut quality and finish, consider the following:

- Ensure the saw blade is sharp and suitable for the type of material you are cutting. Dull blades can result in tear-out or uneven cuts.

- Use a higher tooth count blade for finer cuts and a lower tooth count for rougher cuts.

- Check the speed and feed rate of the saw. Cutting too fast or too slow can affect the quality of the cut.

- If there are splintering or tear-out on the surface of the board, try placing a sacrificial backing board beneath the workpiece to support the wood fibers and reduce tear-out.

- Always cut with the good side of the material facing down to minimize tear-out on the visible side.

- Make sure the workpiece is held securely in place, either with clamps or a workbench, to prevent movement during the cut.

- If the cut is not straight or square, adjust your cutting technique and practice using a guide or straightedge until you achieve the desired result.

Remember, troubleshooting common issues when ripping boards with a circular saw is part of the learning process. With practice and attention to detail, you can improve your cutting skills and achieve clean, accurate cuts for your DIY projects.

Credit: www.familyhandyman.com

Mastering Specialized Ripping Techniques

Learn how to efficiently rip a board using a circular saw with our step-by-step guide. Master specialized ripping techniques for precise and accurate cuts every time.

Ripping wider boards or panels:

When faced with a wider board or panel that needs to be ripped, follow these steps to ensure a smooth and accurate cut:

- Measure and mark the desired width of the board using a tape measure and pencil.

- Set the circular saw blade depth slightly deeper than the thickness of the board, ensuring the blade still extends below the surface of the board.

- Align the saw blade with the marked line, positioning the blade slightly to the waste side of the cut.

- Slowly start the saw and guide it along the marked line, applying even pressure and keeping a steady pace.

- Use a push stick or a push block to keep your hands safely away from the blade while ripping.

Ripping with bevel or angle cuts:

For projects that require bevel or angle cuts, follow these guidelines to achieve precise and professional results:

- Adjust the bevel angle on your circular saw to the desired degree, typically ranging from 0 to 45 degrees.

- Measure and mark the desired angle or bevel on the board using a protractor or angle finder.

- Secure the board firmly before making the cut to ensure stability and safety.

- Align the saw blade with the marked line, positioning the blade according to the desired angle or bevel.

- Initiate the cut by starting the saw and guiding it along the marked line, maintaining a controlled motion throughout the cut.

Advanced applications for curved or irregular boards:

Sometimes, you may need to rip boards that have irregular or curved profiles. Here are some techniques to handle such situations:

- Create a template or pattern that matches the desired shape or curve you want to replicate.

- Attach the template securely to the board to be ripped, ensuring it won’t shift during the cutting process.

- Use a jigsaw or coping saw to roughly cut close to the template, removing excess material.

- Once the excess material is removed, secure the board firmly and follow up with a circular saw to make the final precise rip cut along the template.

- Take your time and make light passes with the circular saw, allowing the blade to smoothly follow the curve or irregular shape.

By mastering specialized ripping techniques, you can confidently handle a variety of cutting challenges, whether it’s working with wider boards, incorporating bevel or angle cuts, or handling curved or irregular boards. These skills will enhance your woodworking abilities and allow you to create custom projects with precision and professionalism.

So, grab your circular saw and get ready to tackle any rip cut with ease!

Frequently Asked Questions For How To Rip A Board With A Circular Saw

How Do You Rip Straight With A Circular Saw?

To rip straight with a circular saw, follow these steps:

1. Measure and mark the desired cut line on the material.

2. Set the blade depth of your circular saw slightly deeper than the material’s thickness.

3. Align the saw’s base plate with the marked cut line.

4. Hold the saw steady and slowly guide it along the marked line, keeping the blade straight and parallel.

What Is The Best Tool To Rip A Board?

The best tool to rip a board is a table saw with a rip fence.

How Do You Rip A 2X4 With A Circular Saw?

To rip a 2×4 with a circular saw, first, measure and mark the desired cutting line. Then, adjust the saw blade depth to slightly deeper than the wood thickness. Next, firmly grip the board and align the marked line with the saw blade.

Finally, switch on the saw and make a slow, steady cut along the marked line, using a guide for straightness if needed.

How Do You Rip A 2 Inch Board?

To rip a 2 inch board, use a table saw with a rip fence for precise and straight cuts.

Conclusion

Ripping a board with a circular saw may seem daunting at first, but with the right technique, it can be a efficient and precise process. By following the steps outlined in this guide, you can ensure that your cuts are straight and accurate every time.

Start by setting up the proper workspace and securing the board in place. Next, adjust the depth and angle of the circular saw to fit your desired cut. Remember to always prioritize safety by wearing protective gear and using a guide rail for added stability.

As you become more comfortable with this skill, you’ll be able to tackle a variety of woodworking projects with ease. Whether you’re building furniture or making home improvements, mastering the art of ripping boards with a circular saw is a valuable skill that every DIY enthusiast should possess.

So grab your circular saw, put these tips into practice, and let your creativity soar!

3 thoughts on “How to Master the Art of Ripping a Board With a Circular Saw: Expert Tips and Tricks”