A plywood calculator estimates the number of plywood sheets needed for a project. It ensures efficient material usage and cost planning.

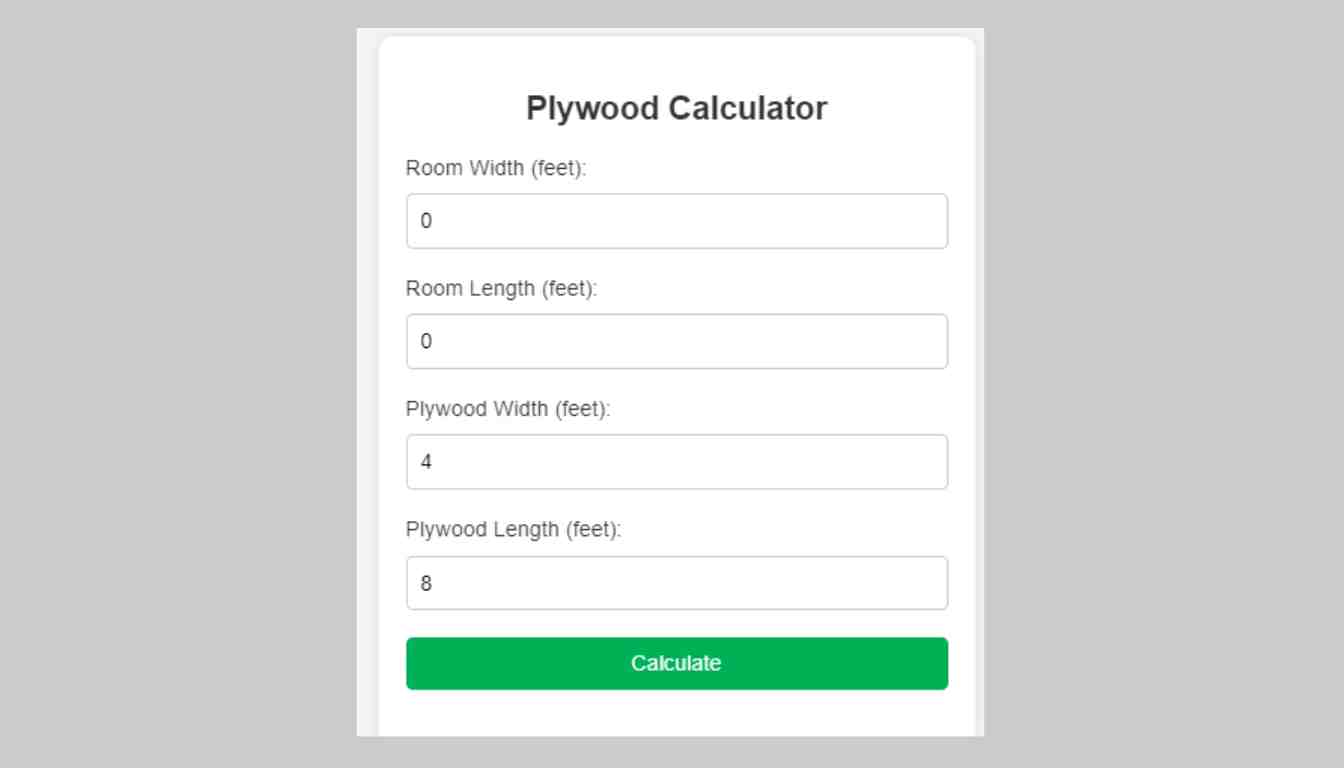

Plywood Calculator

Constructing a new piece of furniture, remodeling your home, or engaging in any woodworking project involves accurate calculations to avoid waste and ensure project success. Using a plywood calculator is vital for both DIY enthusiasts and professional contractors. It helps in determining the exact amount of plywood required, thereby preventing unnecessary costs and material surplus.

By inputting the dimensions of the area to be covered with plywood, this tool provides an immediate estimation of the number of sheets needed, taking into account the size of the plywood sheets available. It simplifies budgeting, material ordering, and can significantly reduce the time spent on manual calculations, allowing for a more streamlined and efficient building process.

Credit: hoopsoup.com

Introduction To Plywood Usage

Plywood stands as a steadfast ally in the construction and carpentry worlds. Its layers, known as veneers, are glued together to create a durable sheet. Not only does plywood boast impressive strength, but it also maintains a uniform thickness and comes in various sizes. This makes it a versatile choice for various projects, necessitating the use of a plywood calculator to estimate the right quantity for your needs.

Common Applications

- Furniture Making: Plywood offers the perfect canvas for desks, chairs, and bookcases.

- Interior Decorating: Its smooth surface is ideal for wall paneling and cabinetry.

- Construction Projects: From subfloors to roofing, plywood proves essential.

Table showing typical plywood sizes and their common applications

| Size | Application |

|---|---|

| 4′ x 8′ | Building construction |

| 5′ x 5′ | Furniture creation |

| 2′ x 4′ | DIY projects |

Benefits Of Plywood Construction

Choosing plywood for construction tasks brings a host of advantages:

- Plywood’s cross-grained nature increases its strength and stability.

- Its resistance to cracking, shrinkage, and warping surpasses that of traditional wood.

- With its ability to disperse stress uniformly, it enhances the longevity of structures.

Plywood Sizes And Thicknesses

Choosing the right size and thickness for your plywood can be puzzling.

But fear not! Understanding standard dimensions and the appropriate thickness for your project ensures a perfect fit.

Standard Dimensions

Plywood comes in various sizes to complement different projects.

The most common size is 4 feet by 8 feet.

| Dimension (feet) | Dimension (mm) |

|---|---|

| 4 x 8 | 1220 x 2440 |

| 5 x 10 | 1525 x 3050 |

| 6 x 12 | 1830 x 3660 |

These dimensions fit walls, floors, and roofs perfectly.

Other sizes are also available to match specific needs.

Choosing The Right Thickness

Thickness determines plywood’s strength and application.

- 1/4 inch (6 mm): Ideal for light tasks and furniture backing.

- 1/2 inch (12 mm): A go-to for cabinet and wardrobe doors.

- 3/4 inch (19 mm): Perfect for building robust shelves and subfloors.

Use a plywood calculator to estimate how many sheets and thickness you need.

It saves time and reduces waste.

Calculating Plywood Needs

The right amount of plywood ensures your project runs smoothly. Too little, and you hit a wall. Too much, and you’ve got waste. Calculating plywood needs correctly is a must. Here’s a step-by-step guide to help you measure accurately.

Understanding Area Coverage

Measuring your project area is first on the list.

- Find length and width.

- Multiply for the area.

- Note down in square feet.

For irregular shapes, divide them into smaller squares or rectangles. Add their areas together. This way, you cover all bases.

Accounting For Waste

Projects rarely use every inch of plywood.

Accept that some plywood will go unused. Planning for waste is smart. It keeps you ready for mistakes or last-minute changes.

| Project Type | Waste Percentage |

|---|---|

| Simple | 5% |

| Complex | 10-15% |

Simple jobs need less extra plywood. Complex ones demand more. Calculate waste percentage based on your project type. Then add it to your total area. Now you have a realistic quantity for your task.

Types Of Plywood

Understanding the “Types of Plywood” is key in selecting the right material for your project.

It all starts with knowing the plywood’s use. The right type can ensure durability and finish.

Softwood Vs Hardwood Plywood

Softwood plywood often comes from trees like pine or cedar. Think frames or sheds. It’s fit for general construction. Low cost yet effective.

Hardwood plywood uses trees such as oak or maple. Ideal for furniture and cabinets due to its robust nature. It’s costlier but lasts longer.

Here’s a quick glance at their differences:

| Plywood Type | Primary Use | Cost |

|---|---|---|

| Softwood Plywood | Construction, Frames | Less Expensive |

| Hardwood Plywood | Furniture, Cabinetry | More Expensive |

Specialty Plywood Grades

- Marine plywood: Resistant to moisture and rot.

- Fire-retardant plywood: Treated to resist burning.

- Flexible plywood: Bends easily for curved structures.

Each specialty grade suits specific needs.

Marine plywood works well for boat parts. Its water-resistant capability is key.

Buildings with high safety standards may require fire-retardant plywood. This type helps to slow down fire spreading.

For artistic projects, flexible plywood is a top choice. It allows easy creation of curved edges.

Tools For Plywood Calculation

Project success often hinges on accurate measurements,

especially when working with materials like plywood. Misjudging dimensions

can lead to wasted resources and time. The right tools can make the process

simpler and more precise. Whether you prefer manual calculation

methods or the convenience of digital calculators,

we’ve got you covered with a comprehensive guide to both approaches.

Manual Calculation Methods

Traditionalists and hands-on crafters often favor manual methods for

calculating the amount of plywood needed for a project. This approach

involves using simple tools but requires attention to detail

to ensure accuracy.

- Measuring Tape: Measure the length and width of the space you plan to cover.

- Pencil and Paper: Sketch a layout and jot down the measurements.

- Calculator: Use basic math to determine the total square footage.

Tip: Always include extra material in your calculations to account for cuts and errors.

Digital Plywood Calculators

For those who prefer modern solutions, digital plywood calculators streamline the calculation process. These tools offer quick and convenient measurements with minimal room for error.

- Input the dimensions of your plywood sheets and the area you wish to cover.

- The calculator will compute the quantity needed, including waste.

Popular digital calculators are available online, with many providing additional features such as cost estimation and material lists.

Remember to double-check all digital results to ensure they match your project’s specifications.

Estimating Costs

Crafting a project with plywood means planning ahead for expenses.

Estimates can swing widely based on several factors.

A Plywood Calculator becomes essential for transparency and budgeting.

With precise numbers in hand, project expenses no longer hold any surprises.

Factors Affecting Price

You must consider several variables when calculating the cost of plywood:

- Quality and Type: Plywood varies from basic sheets to high-grade veneers.

- Size: Standard sizes cost less than custom cuts.

- Thickness: Thicker plywood commands a higher price tag.

- Quantity: Bulk purchases could lead to discounts.

- Geographical Location: Prices differ from place to place.

How To Get The Best Value

Do your homework to get the most from your investment.

- Compare prices from different suppliers.

- Opt for standard sizes to avoid additional fees.

- Check for discounts on bulk orders.

- Consider thinner options that meet project requirements.

- Calculate the total cost of materials using a reliable Plywood Calculator.

Remember, getting the best value doesn’t always mean the lowest cost.

Aim for a balance between quality and price.

Working With Plywood Sheets

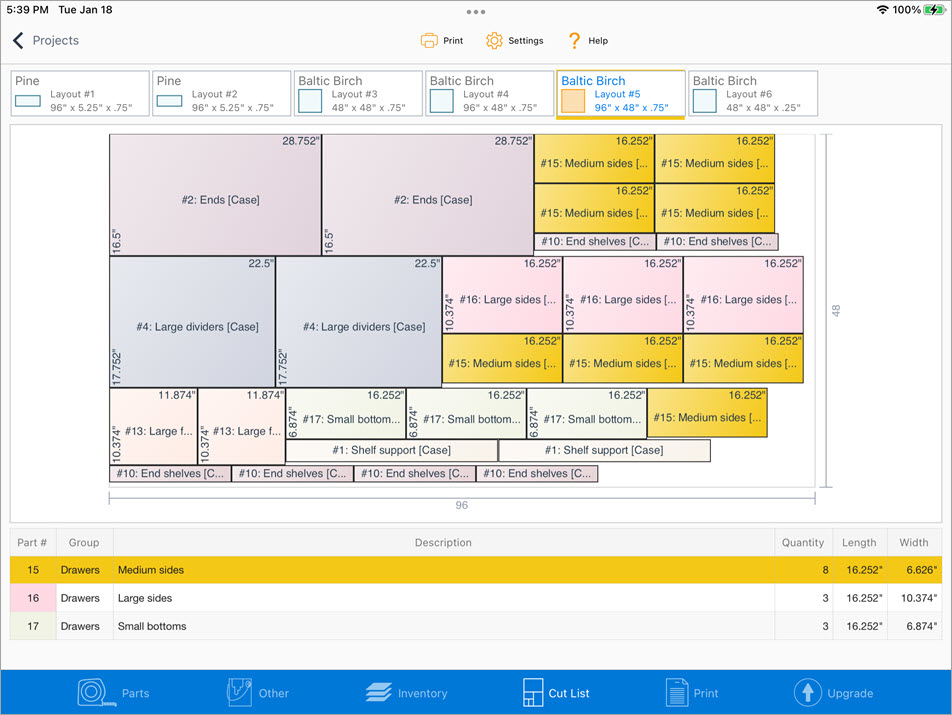

Building with plywood means cutting and joining pieces to fit your project. This section dives into techniques for working with plywood sheets. A Plywood Calculator can help plan your cuts and minimize waste.

Cutting Techniques

Proper cutting is crucial to any plywood project. It ensures pieces fit together neatly.

- Measure twice, cut once: Double-check your measurements before cutting.

- Use the right tools: Circular saws or table saws give you straight cuts.

- Support the sheet: Avoid splintering by supporting the plywood while you cut.

Mark your cut lines directly on the plywood sheet. Use a straight edge or chalk line to guide your saw. Remember, a Plywood Calculator optimizes your cut layout.

Joining And Fastening

Strong joints are key to a sturdy build. Find the best ways to connect your plywood pieces.

- Gluing: Wood glue creates a solid bond between plywood edges.

- Screwing: Use wood screws for a strong mechanical join.

- Clamping: Clamp pieces together while the glue dries for a tight bond.

When joining edges, consider using rabbet or dado joints for extra strength. Always predrill holes to prevent the wood from splitting. A Plywood Calculator helps plan for joins, reducing extra cuts and conserving materials.

Safety Considerations

While using a plywood calculator can simplify the process of estimating materials for your projects, safety remains paramount. Correct handling and the use of appropriate protective gear can prevent injuries, ensuring your woodworking remains a pleasant experience. Let’s explore essential safety measures.

Handling And Storage

Proper handling and storage of plywood sheets are crucial to avoid accidents. Follow these steps for safe handling:

- Always lift with your legs, not your back, to prevent strain.

- Carry plywood sheets on their edge to enhance visibility and balance.

- Use an assistant when moving large sheets to distribute weight.

Safe storage is equally important:

- Store plywood flat to prevent warping.

- Keep sheets dry and away from direct sunlight.

- Secure sheets in a stable position to prevent sliding or falling.

Personal Protective Equipment

Using the right personal protective equipment (PPE) is a must. Essential PPE items include:

| PPE Item | Usage |

|---|---|

| Gloves | Protect hands from splinters and cuts. |

| Safety Glasses | Shield eyes from sawdust and debris. |

| Ear Protection | Reduce risk of hearing damage from machinery. |

| Dust Mask | Prevent inhalation of harmful dust particles. |

Always check your PPE before starting your project. Ensuring there are no tears or defects can be the difference between a safe work environment and a dangerous one.

Troubleshooting Common Issues

Working with plywood means facing a few common hurdles. Knowing how to handle them is key. This guide digs deep into the challenges you might face while calculating your plywood needs. Let’s fix those pesky plywood problems together!

Dealing With Warping

Warping can drive any woodworker nuts. It messes up calculations and ruins projects. But don’t fret! Here’s the lowdown on how to keep your plywood flat:

- Store plywood properly: Lay it flat and support it evenly to avoid bends.

- Balance the moisture: Keep your workspace humidity-controlled to minimize warping.

- Choose the right thickness: Thicker sheets are generally more stable against warping.

- Fix warp before use: Attach warped sheets to a flat surface to straighten them over time, if possible.

Managing Imperfections

Imperfections can be a real headache. Fear not! You can conquer those blemishes:

| Type of Imperfection | Management Technique |

|---|---|

| Knots | Use wood filler or opt for higher-grade plywood. |

| Splits | Apply glue and clamp it or cut away the affected area. |

| Surface Roughness | Sand the surface until it’s smooth. |

Remember these tips and you’ll master the plywood game. Say goodbye to warping woes and imperfection issues!

Sustainability In Plywood Use

Plywood is a staple in construction and woodworking. Its strength, versatility, and cost-effectiveness have made it a popular choice. Yet, its environmental impact cannot be ignored. Sustainable practices in plywood use are vital for a healthier planet. This includes choosing eco-friendly options and ensuring proper disposal and recycling. Let’s explore these areas further.

Eco-friendly Plywood Options

Choosing the right plywood means considering its environmental footprint. Eco-friendly plywood options are crafted from sustainable forests. These forests are managed for regeneration and biodiversity. Here are some choices:

- FSC Certified Plywood: Ensures wood comes from responsibly managed forests.

- Bamboo Plywood: Grows faster than traditional trees, absorbing more carbon dioxide.

- Agricultural Waste Plywood: Made from plant fibers left after harvests. Reduces waste.

Selecting these products supports forest conservation. It also promotes responsible resource use.

Proper Disposal And Recycling

Once a plywood product reaches the end of its life, proper disposal becomes key. Disposing of plywood correctly prevents environmental harm. Follow these steps:

- Check Local Guidelines: Research recycling rules in your area.

- Reuse: Consider reusing plywood for smaller projects.

- Recycle: Locate nearby facilities that accept plywood for recycling.

These steps ensure materials find new life. They also minimize landfill waste.

| Plywood Sustainability Quick Tips | |

|---|---|

| Use Eco-Friendly Options | Choose plywood with sustainability certifications. |

| Reduce Waste | Optimize cuts using a Plywood Calculator to minimize scrap. |

| Recycle | Turn scraps into new projects or recycle them properly. |

Credit: www.inchcalculator.com

Frequently Asked Questions On Plywood Calculator

How Does A Plywood Calculator Work?

A plywood calculator estimates the number of plywood sheets needed for a project. It uses dimensions of the area to cover and sheet size. You input length and width, and it outputs total sheets required.

What Factors Affect Plywood Sheet Calculation?

Several factors impact the calculation, including the size of plywood sheets, waste factor, and area to be covered. Unique project features, such as cutouts, can also affect the total number of sheets needed.

Can I Save Materials Using A Plywood Calculator?

Yes, using a plywood calculator can reduce waste by providing an accurate estimate of materials needed. This ensures you purchase only the necessary amount of plywood, avoiding excess.

Is There A Standard Plywood Sheet Size For Calculations?

Standard plywood sheets typically measure 4 feet by 8 feet. However, calculators can adjust for different sizes, ensuring they fit any project’s specific requirements.

Conclusion

Wrapping up, our Plywood Calculator is a must-have tool for your project planning. It simplifies calculations, ensuring you purchase the right amount without waste. Streamline your DIY or professional endeavor today—let our calculator help you make informed, efficient material choices.