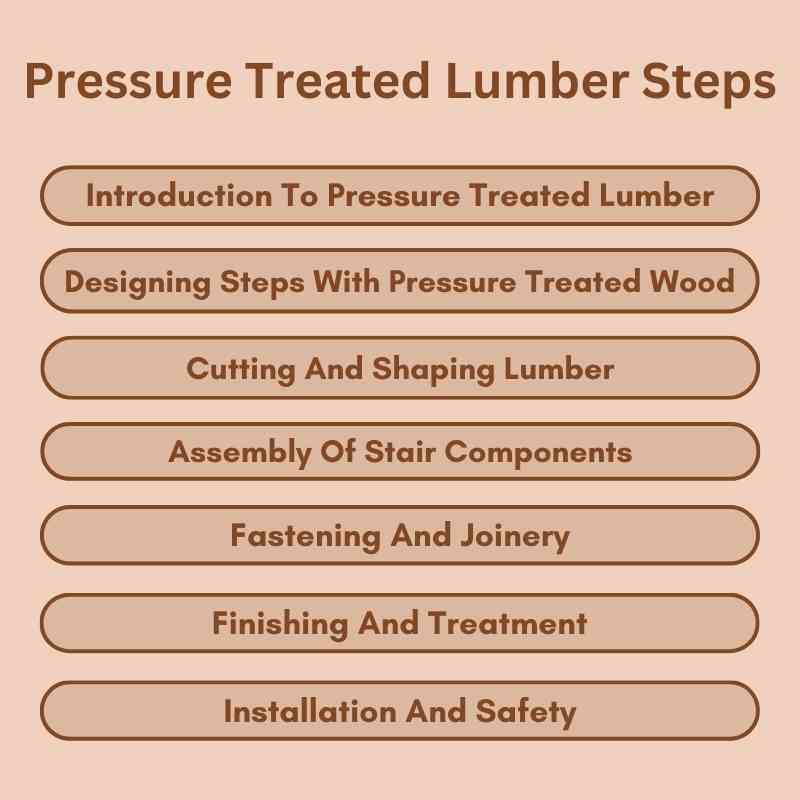

Pressure Treated Lumber Steps: Ensure Durable Stairs!

Pressure-treated lumber steps involve using wood that has been chemically treated to resist rot and insects. This process enhances durability, making them ideal for outdoor use.

Pressure-treated lumber is a popular choice for building steps due to its longevity and resilience. This type of wood undergoes a treatment process that infuses it with preservatives, protecting it from moisture, decay, and pests. Homeowners often prefer pressure-treated lumber for outdoor projects, including decks, fences, and steps, due to its ability to withstand harsh environmental conditions.

Proper installation and maintenance can further extend the life of these structures. Understanding the benefits and care involved in using pressure-treated lumber steps can help ensure safety and aesthetics for years to come. Embrace the functionality and appeal of pressure-treated wood in your next outdoor project.

Introduction To Pressure Treated Lumber

Pressure treated lumber offers many advantages for stair construction. It is durable and can resist rot. This type of wood is also affordable and widely available. Using pressure treated wood helps protect against insects and moisture.

Various types of pressure treated wood exist. Each type serves different needs. Here are some common options:

| Type | Uses | Benefits |

|---|---|---|

| Ground Contact | Decking, fence posts | High resistance to rot |

| Above Ground | Railings, stairs | Cost-effective and durable |

| Marine Grade | Piers, docks | Excellent moisture resistance |

Selecting The Right Lumber For Stairs

Choosing the right grade of lumber is crucial for stairs. Higher grades mean fewer knots and defects. Look for pressure-treated lumber to resist decay and insects. This helps ensure safety and durability.

Check the dimensions of the lumber for your specific project. Common sizes include 2×4, 2×6, and 2×12. Make sure the lumber is compatible with your design. This ensures a perfect fit and strong support.

Designing Steps With Pressure Treated Wood

Designing steps with pressure treated wood is both practical and durable. Accurate tread and riser calculations are essential for safety. Treads should be at least 10 inches deep. Risers need to be between 4 to 7 inches high. This creates a comfortable step height.

Landings add stability and safety. A landing should be at least 36 inches deep. This allows for safe transitions between steps. Proper design helps prevent accidents. Ensure that landings are level and clear of obstacles.

| Component | Measurement |

|---|---|

| Tread Depth | Minimum 10 inches |

| Riser Height | 4 to 7 inches |

| Landing Depth | Minimum 36 inches |

Cutting And Shaping Lumber

Safety is very important when cutting and shaping lumber. Always wear protective gear like gloves and goggles. Keep your workspace clean to avoid accidents.

Use the right tools for the job. A sharp saw makes cutting easier. Measure twice before making any cuts. This helps to ensure accuracy.

Follow these precision techniques for better results:

- Mark your cuts clearly.

- Support the lumber properly while cutting.

- Cut slowly and steadily.

- Check your angles for accuracy.

By following these steps, you can work safely and effectively with pressure-treated lumber.

Assembly Of Stair Components

To secure treads and risers, use strong screws or nails. Make sure they are flush with the surface. This prevents tripping hazards. Choose weather-resistant fasteners for outdoor projects.

For stabilizing stringers, ensure they are properly aligned. Use a level to check each stringer. Attach them firmly to the deck and the ground. This helps support the entire stair structure.

Regularly inspect the stairs. Look for signs of wear or damage. Early repairs can extend the life of your stairs.

Fastening And Joinery

Choosing the right fasteners for pressure treated lumber is crucial. Galvanized or stainless steel fasteners work best. These materials resist rust and corrosion. Avoid using regular steel fasteners, as they can degrade quickly.

Consider the size and length of the fasteners. They should penetrate the wood deeply for strong connections. Always follow the manufacturer’s guidelines for proper usage.

Reinforcement strategies enhance the durability of your projects. Use brackets and angles for added strength. Glue can also improve the bond between joints.

Regularly check your fasteners and reinforcements for wear. Maintaining these components ensures the longevity of your structure.

Finishing And Treatment

Sealing and staining pressure treated lumber is essential for its longevity. Choose a high-quality sealant that protects against moisture and UV rays. Apply the sealant after the wood has dried completely. This helps maintain its natural beauty and prevents warping.

Regular maintenance is key. Inspect the wood every year for signs of wear. Reapply sealant as needed, especially in high-traffic areas. A good rule is to restain every two to three years. This keeps the wood looking fresh and prevents damage.

Use a cleaning solution to remove dirt and grime. A gentle scrub will help maintain its appearance. Avoid harsh chemicals, as they can harm the wood.

Installation And Safety

Ensure code compliance by following local building regulations. Check for required permits before starting.

Use pressure treated lumber for steps, railings, and balusters. This lumber resists rot and insects. Choose the right sizes for your project to ensure safety.

| Component | Recommended Size |

|---|---|

| Steps | 2″ x 10″ |

| Railings | 2″ x 4″ |

| Balusters | 2″ x 2″ |

Properly install railings and balusters for safety. Follow the spacing guidelines for balusters. This prevents accidents and ensures a sturdy structure.

Common Mistakes To Avoid

Improper spacing can lead to serious issues with pressure treated lumber. Always allow space between boards for expansion and contraction. This helps prevent warping and cracking over time.

Ignoring environmental factors is another common mistake. Rain, humidity, and sunlight can affect the wood. Always consider these factors before installation. Use products that offer protection against weather elements.

Case Studies

Many homes have benefited from using pressure treated lumber. It resists rot and insects, making it ideal for outdoor projects. One family built a beautiful deck that lasts for years. They enjoyed summer barbecues and family gatherings on it.

In commercial projects, pressure treated lumber shines as well. A local park used it for benches and fencing. These features withstand weather changes, providing a safe place for visitors. Businesses often choose it for exteriors that need to last.

| Project Type | Benefits |

|---|---|

| Residential Decks | Durable and great for family fun |

| Commercial Parks | Weather-resistant and safe for all |

Frequently Asked Questions

What Is Pressure Treated Lumber?

Pressure treated lumber is wood that has been infused with preservatives. These chemicals help resist rot, insects, and weather damage. It’s commonly used for outdoor projects like decks and steps. The treatment process extends the lifespan of the wood significantly compared to untreated lumber.

How Long Does Pressure Treated Lumber Last?

Pressure treated lumber can last 15 to 25 years. Its lifespan largely depends on environmental conditions and maintenance. Proper sealing and regular inspections can enhance durability. Always choose quality products and follow manufacturer guidelines for the best results.

Is Pressure Treated Lumber Safe For Outdoor Use?

Yes, pressure treated lumber is safe for outdoor use. It’s designed to withstand harsh weather and resist pests. However, ensure proper handling and use gloves during installation. Following safety precautions minimizes any potential health risks associated with the chemicals used.

Can I Paint Or Stain Pressure Treated Lumber?

Yes, you can paint or stain pressure treated lumber. However, it’s essential to wait until the wood is fully dry. This can take several months after installation. Using quality exterior paint or stain improves aesthetics and adds an extra layer of protection.

Conclusion

Choosing pressure-treated lumber for your steps ensures durability and longevity. This material withstands the elements, making it ideal for outdoor use. Proper installation and maintenance will enhance its lifespan. By opting for pressure-treated lumber, you invest in a safe and sturdy solution for your outdoor spaces.

Enjoy your beautiful, functional steps for years to come!