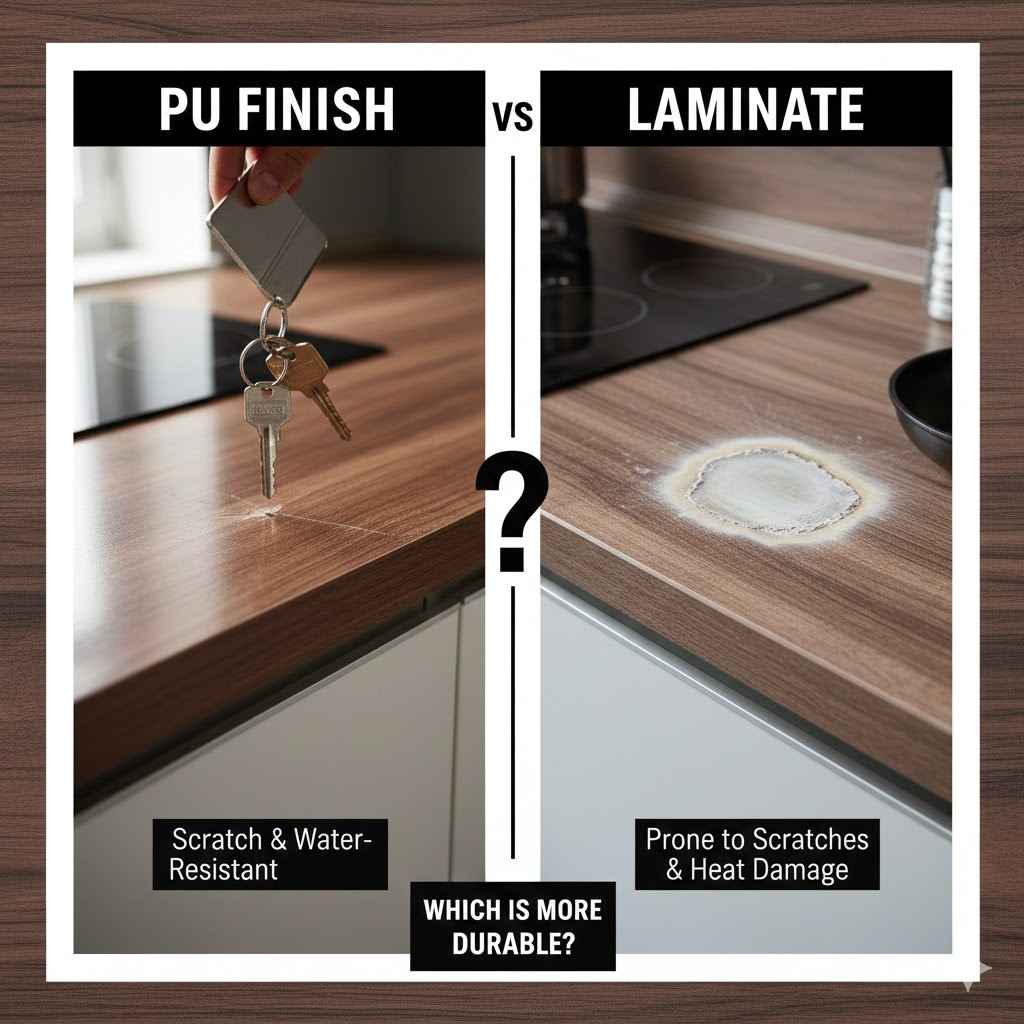

PU Finish vs Laminate Which Is More Durable

Deciding between a PU finish and laminate for your furniture or surfaces can feel a bit tricky when you’re just starting out. Both look great, but knowing which one will stand up to daily life is key. You might wonder, PU Finish vs Laminate: Which Is More Durable? This guide breaks it all down simply.

We’ll walk through what each one is, how they compare, and help you pick the best option for your needs. Get ready for a clear, easy way to understand your choices.

Understanding PU Finish

A PU finish, short for polyurethane, is a type of coating applied to surfaces like wood, metal, or plastic. It’s known for its protective qualities and can give a surface a smooth, often glossy, appearance. This coating hardens into a tough layer, shielding the material underneath from everyday wear and tear.

It’s a popular choice for furniture, cabinets, and even car parts because it offers a good balance of looks and protection.

What Is Polyurethane?

Polyurethane itself is a versatile polymer. It’s made through a chemical reaction involving isocyanates and polyols. This reaction creates strong molecular bonds that give polyurethane its strength and flexibility.

For finishes, it’s typically applied as a liquid that cures over time, forming a solid film. This film is what provides the protective barrier.

The curing process is important for the final durability. When the liquid polyurethane dries, it undergoes a chemical change. This change hardens the coating and makes it resistant to scratches, moisture, and stains.

The speed and completeness of this curing process can affect how well the finish performs over time.

Types of PU Finishes

There are different types of PU finishes, each with its own characteristics. Water-based polyurethanes are easier to clean up and have less odor. Oil-based polyurethanes tend to be more durable and offer a richer amber tone over time.

Some PU finishes are also ‘two-part’ or ‘catalytic’ systems, meaning they mix two components before application. These often cure to an extremely hard and durable finish, ideal for high-traffic areas.

The choice between these types depends on the application and desired outcome. Water-based options are good for indoor furniture where strong fumes are a concern. Oil-based ones are great for floors or tabletops that need a very tough shield.

Two-part systems are often used in commercial settings or for items that face extreme wear and tear.

Application and Appearance

PU finishes can be applied by spraying, brushing, or wiping. The method of application can affect the final look and smoothness. Spraying often provides the most even and professional finish, minimizing brush strokes.

Wiping can work for certain oil-based finishes, creating a more natural, less ‘plastic’ look.

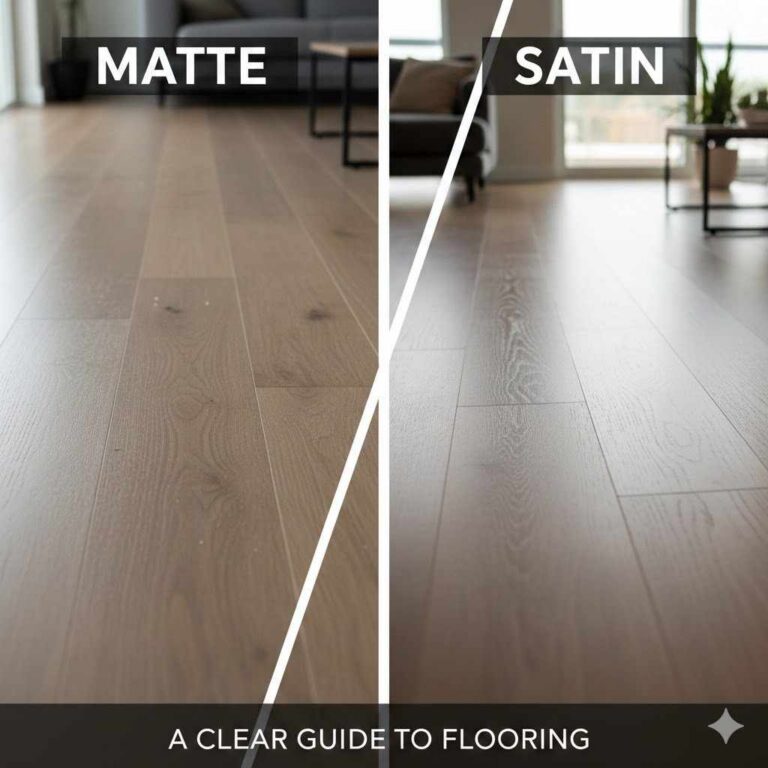

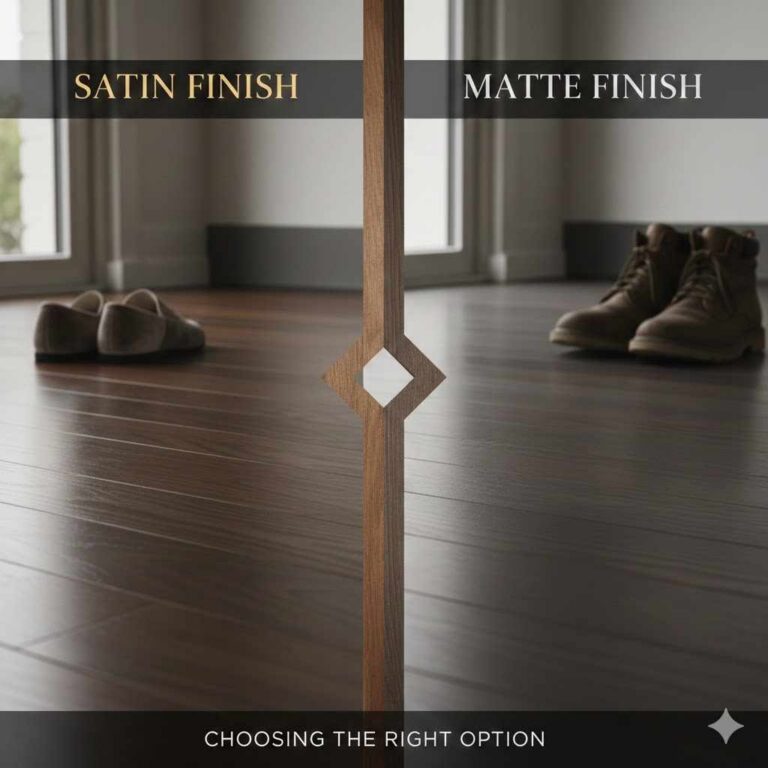

Visually, PU finishes can range from a matte, natural look to a high-gloss, reflective surface. This versatility allows designers and homeowners to achieve different aesthetic effects. A matte finish can hide minor imperfections better, while a gloss finish can make a space feel brighter and more modern.

The appearance is a significant factor in why people choose PU finishes for their projects.

Pros and Cons of PU Finish

-

Pros

PU finishes offer excellent durability against scratches and general wear. They are also highly resistant to moisture and stains, making them easy to clean and maintain. The wide range of sheen options allows for aesthetic flexibility, from subtle matte to striking gloss.

This makes them a good choice for items that need to look good and last a long time.

-

Cons

Some PU finishes, especially oil-based ones, can emit strong odors during application and curing. They can also yellow slightly over time, particularly when exposed to UV light. While durable, they can be prone to chipping or cracking if subjected to extreme impacts or significant temperature fluctuations.

Repairing a damaged PU finish can sometimes be challenging, often requiring sanding and reapplication.

Understanding Laminate

Laminate is a material made by pressing together multiple layers of paper or plastic, bonded with resin. The top layer is usually a printed decorative sheet, designed to mimic wood, stone, or other textures. This sheet is then protected by a clear wear layer.

Laminate is often used for flooring, countertops, and furniture surfaces because it’s affordable and can look very realistic.

How Laminate Is Made

The creation of laminate involves high pressure and heat. A core layer, often made from particleboard or medium-density fiberboard (MDF), is topped with a decorative layer and then a transparent overlay. These layers are fused together under immense pressure, creating a single, strong sheet.

This process makes laminate a stable and durable material for many uses.

The ‘wear layer’ on top is crucial. It’s typically made of melamine resin and aluminum oxide. This layer is what gives laminate its resistance to scratches, stains, and fading.

The thickness and quality of this wear layer significantly impact the overall durability of the laminate product.

Types of Laminate

There are different types of laminate, primarily categorized by their construction and intended use. High-pressure laminate (HPL) is the most durable. It’s made by bonding multiple layers of kraft paper saturated with phenolic resin, with a decorative paper and overlay bonded on top under high heat and pressure.

Low-pressure laminate (LPL), also known as melamine, uses a single layer of particleboard or MDF with a decorative paper and overlay fused directly to it.

HPL is commonly used for countertops and tabletops that experience heavy use. LPL is more often found on furniture, cabinets, and shelving where the demands are less intense. The distinction is important because HPL offers a much higher level of resistance to impact and abrasion than LPL.

Application and Appearance

Laminate is typically available in sheets or planks and is often installed using glues or interlocking systems. For countertops, it’s usually glued to a particleboard or MDF substrate. For flooring, it often features a click-lock system for easy DIY installation.

The appearance of laminate can be very convincing. Advanced printing technologies allow for highly realistic reproductions of natural materials like wood grains, marble, and granite. This visual appeal, combined with its affordability, makes laminate a popular choice for achieving a high-end look without the high cost of the real thing.

The decorative layer can be customized to virtually any pattern or color.

Pros and Cons of Laminate

-

Pros

Laminate is generally very affordable, making it an accessible option for many budgets. It’s quite resistant to scratches, stains, and fading, especially HPL. It’s also easy to clean with just soap and water.

The variety of designs available means you can find a look to match almost any decor. Installation can also be simpler and quicker compared to some other materials.

-

Cons

While resistant to surface damage, laminate is not waterproof. If water seeps into the seams or core material, it can swell and warp. It can also be prone to chipping or denting if heavy objects are dropped on it.

Unlike solid wood or stone, laminate cannot typically be refinished or repaired if significantly damaged; it usually needs to be replaced.

PU Finish vs Laminate Durability Comparison

When we talk about durability, we’re looking at how well a surface holds up to daily use over time. This includes resistance to scratches, dents, moisture, stains, and general wear and tear. Both PU finishes and laminate have their strengths in different areas, and understanding these differences is key to making the right choice for your project.

Scratch Resistance

PU finishes, especially those with a hard topcoat, can offer good scratch resistance. However, a sharp object can still gouge or scratch the coating. The depth of the scratch depends on the hardness of the PU and the force applied.

A lower sheen finish might show minor scratches less than a high-gloss one.

Laminate, particularly HPL with its aluminum oxide wear layer, is often considered more scratch-resistant than many PU finishes. This wear layer is designed to be extremely hard, making it difficult to scratch with everyday objects like keys, coins, or pet claws. However, a very sharp knife or a heavy, abrasive object could still potentially mark the surface.

| Material | Scratch Resistance | Notes |

|---|---|---|

| PU Finish | Good to Very Good | Depends on PU type and sheen. Can be gouged by sharp objects. |

| Laminate (HPL) | Excellent | Aluminum oxide wear layer is very hard. Can still be marked by extreme force. |

Moisture and Stain Resistance

PU finishes are generally resistant to moisture and stains. Spills can usually be wiped away easily without causing damage to the coating. However, prolonged exposure to standing water, especially on unsealed edges or in very humid environments, can potentially compromise the finish over time.

The quality of the application and the type of PU also play a role.

Laminate’s resistance to moisture is more limited. While the surface itself is non-porous and resists liquid penetration, water can seep into the seams between planks or at edges. This can cause the core material (MDF or particleboard) to swell and delaminate.

For this reason, laminate is often not recommended for very wet areas like bathrooms or laundry rooms, unless specifically designed for that purpose with enhanced water resistance. Stains are usually not an issue on the surface itself, as they can be wiped off.

One study found that water exposure for 24 hours could cause swelling in up to 15% of the thickness of some common laminate flooring core materials, while PU-finished wood showed minimal swelling. This highlights a key difference in how they handle moisture.

Impact and Dent Resistance

PU finishes themselves do not typically dent. However, if the underlying material is soft, like some woods, heavy impacts can cause dents in the wood which might show through the finish. The PU coating itself is more likely to chip or crack under a very sharp, heavy impact rather than dent.

Laminate is more prone to chipping and denting, especially at the edges and corners. A heavy object dropped on laminate can cause the decorative layer to chip off or create a noticeable dent in the core material. This damage is usually permanent and cannot be easily repaired.

The density and construction of the core material significantly influence how well laminate resists dents.

Wear and Tear Over Time

Over many years, PU finishes can develop a patina, which can be seen as attractive aging by some. However, they can also show signs of wear like dulling of the sheen, minor scratches, and potential fading if exposed to direct sunlight. Regular cleaning and occasional waxing or polishing can help maintain their appearance.

Laminate is designed to be wear-resistant for its intended lifespan. The wear layer helps prevent the decorative pattern from wearing away. However, once this wear layer is compromised, the underlying pattern can be damaged, and the material may start to look worn.

Because it cannot be refinished, the only way to refresh worn laminate is replacement.

For instance, a busy kitchen countertop with a PU finish might show some fine scratches after a decade, but the overall look could remain appealing with care. The same countertop in laminate might show chipped edges or areas where the wear layer has started to peel, making it look worn out.

Real-World Applications and Examples

To truly grasp the differences, let’s look at how PU finish and laminate perform in everyday situations. These examples will show where each material shines and where its limitations might become apparent.

Kitchen Countertops

In kitchens, countertops face a lot of action: spills, hot pans (sometimes), cutting (hopefully not directly on the surface!), and general daily use. A PU finish on a solid wood countertop can offer a beautiful, natural look. It resists stains well, but users must be careful about using trivets for hot items and cutting boards for chopping.

If a scratch does occur, a skilled woodworker can often sand and reapply the PU finish to restore it.

Laminate countertops are a very popular budget-friendly option. They offer a wide range of styles, from mimicking granite to wood. They are easy to clean and resist common kitchen stains.

However, they are susceptible to heat damage – placing a hot pot directly on laminate can melt or discolor the wear layer. Also, deep scratches or chips are usually permanent, meaning the entire countertop might need replacement if significant damage occurs.

A common scenario involves a family that cooks daily. A PU-finished maple countertop might develop a few faint knife marks over five years, but the wood’s natural beauty is still apparent. A laminate countertop in the same kitchen might have a small chip on the front edge from a dropped pan and a slightly dulled appearance in the main working area due to constant use.

Furniture

For furniture like tables, desks, and cabinets, both PU and laminate are frequently used. A PU finish on a wooden table provides a smooth, protective layer that is resistant to spills and can be wiped clean easily. This makes it ideal for dining tables where food and drinks are common.

The ability to repair minor damage is a significant advantage for wood furniture with PU finishes.

Laminate furniture is often found in offices, schools, and as a more affordable option for home use. A laminate desk surface is very durable against everyday wear from typing and writing. It’s easy to clean up coffee spills.

However, placing very hot items directly on a laminate desk can cause damage, and dragging heavy office chairs across it might scratch the surface over time.

Consider a child’s desk. A desk with a PU-finished wood top can withstand crayon marks and juice spills with easy cleanup. If a deep scratch occurs, it might be repairable.

A laminate desk surface can also handle these messes, but a significant scratch or gouge is likely permanent, potentially making the desk look unsightly.

Flooring

Laminate flooring has become incredibly popular due to its affordability and ease of installation. Modern laminate floors can convincingly mimic the look of hardwood or tile. They offer good scratch resistance, making them suitable for homes with pets and children.

However, their main weakness is their susceptibility to water damage. Spills need to be wiped up quickly, and they are generally not recommended for full bathrooms or basements prone to flooding.

While less common than laminate, PU finishes can be applied to wood floors for protection. These finishes create a durable, sealed surface that resists stains and moisture. They can be refinished multiple times over the life of the floor, extending its lifespan significantly.

The cost is typically higher for a PU-finished wood floor compared to laminate, and installation can be more complex.

In a busy hallway that sees a lot of foot traffic, laminate flooring might show some wear in high-traffic zones after several years, but generally holds up well against scuffs. A hardwood floor with a high-quality PU finish in the same hallway would also resist wear, but the key advantage is that it can be sanded and recoated to look brand new, whereas the laminate would have to be replaced in damaged sections.

Choosing the Right Material for Your Needs

The decision between PU finish and laminate ultimately depends on what you prioritize. Do you need the absolute toughest surface for a high-impact area, or is a good balance of looks, cost, and decent durability enough? Thinking about these questions will guide you to the best choice.

Budget Considerations

Laminate is almost always the more budget-friendly option. The raw materials are less expensive, and the manufacturing process is generally more cost-effective. This makes it a great choice when you need to cover a large area, like a whole room of flooring or multiple furniture pieces, without breaking the bank.

PU finishes, especially when applied to quality wood or metal, tend to be more expensive. The cost of the finish itself, plus the labor involved in proper application and preparation, adds to the overall price. However, this higher initial cost can sometimes be offset by the longevity and repairability of the material.

Aesthetics and Style

Aesthetically, both offer a wide range of options. Laminate excels at mimicking other materials with great realism. You can get almost any look you desire, from exotic woods to natural stone patterns, at an affordable price.

The consistency of laminate patterns can be a plus for a uniform look.

PU finishes on materials like wood allow for the natural beauty and unique grain of the material to show through. They can be tinted to achieve various colors and are available in different sheens, offering a more natural and often more premium feel. The depth and character of real wood with a good PU finish are hard to replicate exactly with laminate.

Maintenance and Repair

For daily cleaning, both are relatively easy. Spills on laminate can be wiped up with a damp cloth and mild soap. PU finishes can also be cleaned with similar methods.

The key difference lies in repair. Minor scratches on PU finishes can often be buffed out or repaired with a touch-up kit or by re-sanding and recoating a small area.

Laminate damage, such as chips or deep scratches, is typically permanent and requires replacement of the damaged section or the entire piece. This can be a significant drawback if durability is paramount and you expect potential for damage.

Long-Term Value

When considering long-term value, it’s a trade-off. Laminate offers good value upfront due to its low cost and decent durability for its price point. It can last many years if treated with care.

PU finishes on quality materials often represent a higher initial investment but can provide a longer service life and retain their appearance better over decades, especially if repairability is factored in. A refinishable surface often holds its value longer.

For example, a high-quality laminate countertop might last 10-15 years in a moderate-use kitchen before showing significant wear. A solid wood countertop with a PU finish, if maintained and occasionally refinished, could potentially last 30-50 years or more, retaining much of its original beauty.

Frequently Asked Questions

Question: Is PU finish waterproof?

Answer: PU finishes are highly water-resistant, meaning they can handle spills and typical household moisture without immediate damage. However, they are not completely waterproof, and prolonged submersion or exposure to standing water can eventually compromise the finish and the underlying material.

Question: Can laminate be repaired if it gets scratched?

Answer: Minor surface scratches on laminate might be difficult to repair completely. Deep scratches or chips are generally not repairable and require replacement of the damaged part or the entire surface.

Question: Which is better for a bathroom PU finish or laminate?

Answer: For areas prone to high moisture, like bathrooms, a PU finish on a properly sealed material is often a better choice than laminate. Laminate’s core material can swell and warp if it gets wet, whereas a good PU finish provides a better barrier against moisture.

Question: Can I put hot pans on a PU finished table?

Answer: It is not recommended to place hot pans directly on most PU finished surfaces, especially wood. The heat can damage the finish, causing discoloration or softening. Always use trivets or hot pads.

Question: Is laminate flooring more durable than PU finished wood flooring?

Answer: For scratch resistance on the surface, high-quality laminate can often outperform PU finished wood. However, PU finished wood floors can be refinished, giving them a longer potential lifespan and the ability to look new again, which laminate cannot offer.

Summary

When comparing PU finish and laminate for durability, each has strengths. PU finishes offer good protection and are often repairable, especially on wood. Laminate, particularly HPL, provides excellent scratch resistance at a lower cost but is vulnerable to water damage and cannot be refinished.

Choose PU for repairability and natural beauty, and laminate for budget-friendly, tough surfaces where moisture is not a major concern.