Tung oil and Danish oil are both natural finishing oils used for woodwork. Tung oil provides a more durable and water-resistant finish, while Danish oil offers a more flexible and easier-to-apply option.

When choosing between the two, consider the specific characteristics of the wood and the desired level of protection and sheen. Tung oil tends to enhance the natural beauty of the wood with a warm, amber hue, while Danish oil provides a richer, deeper color.

Both oils are environmentally friendly and non-toxic when dry. Understanding the differences between Tung oil and Danish oil can help you make an informed decision based on your specific wood finishing needs.

Credit: www.h2ouse.org

Understanding Tung Oil And Danish Oil

Properties And Characteristics Of Tung Oil

Tung oil, also known as China wood oil, is a drying oil derived from the nuts of the tung tree. It is valued for its durability and water-resistant properties, making it an excellent choice for finishing wooden surfaces.

Natural Origin And Composition

- Tung oil is obtained from the seeds of the tung tree, native to East Asia.

- It consists mainly of polyunsaturated fatty acids, specifically alpha-eleostearic acid, which gives it its exceptional drying properties.

Durability And Water Resistance

Tung oil forms a tough, flexible finish that is highly resistant to moisture and water. It penetrates the wood fibers, creating a durable and long-lasting protective layer.

Application And Drying Time

When applying tung oil, it is essential to allow sufficient time for each coat to dry thoroughly. The drying time varies depending on environmental conditions such as temperature and humidity, but typically ranges from 24 to 48 hours.

Properties And Characteristics Of Danish Oil

Danish oil is a mixture of varnish and oil, designed to provide a beautiful, natural-looking finish while offering enhanced protection for wood surfaces.

Ingredients And Formulation

- Danish oil typically comprises a blend of drying oils, resins, and solvents.

- Linen seed oil, tung oil, or polymerized linseed oil are common components, mixed with varnish and thinner to create the formulation.

Versatility And Ease Of Application

Danish oil is known for its ease of application, making it ideal for both novice and experienced woodworkers. It can be applied with a brush, cloth, or foam applicator, and it is versatile enough to be used on various wood species and surfaces.

Finish And Luster

When Danish oil is applied, it enhances the natural grain and color of the wood, resulting in a semi-matte finish with a warm, lustrous appearance. This finish highlights the beauty of the wood while providing a protective layer against wear and tear.

Pros And Cons Of Tung Oil And Danish Oil

When it comes to preserving and enhancing the beauty of wood, many craftsmen and DIY enthusiasts turn to natural oils such as Tung oil and Danish oil. Both of these oils offer their own set of advantages and limitations, making them suitable for different woodworking projects. Understanding the pros and cons of Tung oil and Danish oil can help you make an informed decision when choosing the right finish for your woodwork.

Advantages Of Using Tung Oil

- Enhanced wood grain and color

- Long-term protection and maintenance

- Environmental sustainability

Advantages Of Using Danish Oil

- Quick application and drying

- Versatility on various wood types

- Rejuvenating old wood surfaces

Limitations Of Tung Oil

- Longer curing time

- Odor and VOC concerns

- Vulnerability to heat and chemicals

Limitations Of Danish Oil

- Less long-term durability

- Lack of deep wood penetration

- Potential color inconsistencies

Application And Best Practices

When it comes to finishing wood surfaces, Tung oil and Danish oil are two popular options with their unique properties and application techniques. Understanding the differences between the two oils and knowing the best practices for their application can help you achieve the perfect finish for your woodworking project. In this section, we’ll delve into the application and best practices for using Tung oil and Danish oil.

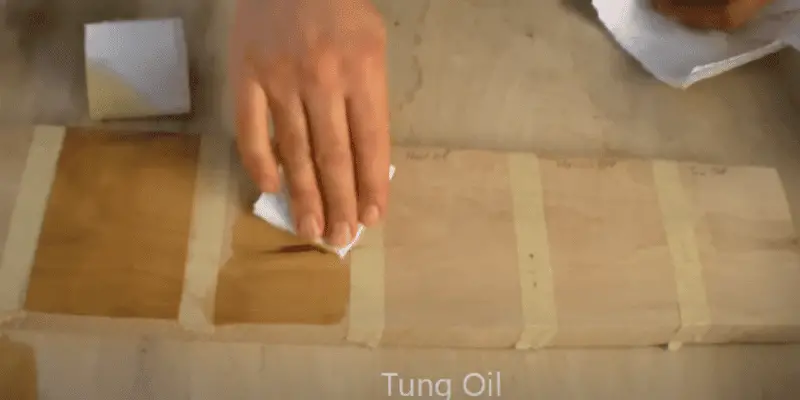

Applying Tung Oil

Surface Preparation And Sanding

Before applying Tung oil, ensure that the wood surface is clean and free from any previous finishes. Sand the surface evenly using 220-grit sandpaper to open up the wood pores and create a smooth base for the oil to penetrate.

Coats And Drying Intervals

- Apply the first coat of Tung oil thinly and evenly using a lint-free cloth or brush.

- Allow the first coat to dry for 24 hours before applying subsequent coats.

- Apply additional coats as needed, typically 2-4 coats for a durable finish.

Buffing And Maintenance

After the final coat has dried, buff the surface with a clean cloth to remove any excess oil and achieve a smooth, lustrous finish. Regular maintenance includes wiping the surface with a damp cloth and reapplying Tung oil as needed.

Applying Danish Oil

Surface Preparation And Conditioning

Prior to applying Danish oil, ensure the wood surface is clean, dry, and free from any existing finishes. Conditioning the wood with a sanding sealer can help achieve a more uniform finish.

Application Techniques For Even Finish

- Apply Danish oil liberally using a brush or cloth, ensuring an even coverage across the entire surface.

- Allow the oil to penetrate the wood for approximately 15-20 minutes before wiping off any excess with a clean cloth.

Post-application Care And Maintenance

After applying Danish oil, allow the surface to dry for 24 hours before applying a second coat if desired. Ongoing maintenance includes occasional reapplication of the oil to preserve the finish and protect the wood.

Comparing Finishes On Different Wood Types

When it comes to choosing the right finish for your wood project, understanding how different wood types interact with specific oils is crucial. Comparing Tung Oil and Danish Oil on various wood types can help you make an informed decision based on your specific project needs.

Tung Oil On Hardwoods Vs. Softwoods

Tung oil has distinct effects on hardwoods and softwoods due to their different characteristics. When applied to hardwoods such as mahogany or oak, Tung oil tends to enhance the natural grain patterns and bring out the richness of the wood. On the other hand, when used on softwoods like pine or cedar, Tung oil may not penetrate as deeply, resulting in a more subdued appearance.

Impact On Grain Patterns And Colors

The application of Tung oil on various wood types can have different effects on their grain patterns and colors. On hardwoods, it tends to accentuate the natural grain, enhancing the depth and complexity of the wood’s appearance. Conversely, on softwoods, the impact may be less pronounced, resulting in a more subtle enhancement of the wood’s natural characteristics.

Long-term Aging And Patina

Over time, Tung oil develops a beautiful patina on both hardwoods and softwoods. However, this patina tends to be more pronounced on hardwoods, deepening the richness of the wood and adding to its character. On softwoods, the aging and patina process may be less prominent, but still contribute to the overall appeal of the wood.

Danish Oil On Hardwoods Vs. Softwoods

Similarly, the effects of Danish oil on hardwoods and softwoods vary. When applied to hardwoods, such as cherry or walnut, Danish oil enhances the natural wood characteristics, bringing out the depth of the grain and adding warmth to the color. On softwoods, like cedar or fir, Danish oil can provide a richer appearance, though it may not penetrate as deeply as on hardwoods.

Enhancing Natural Wood Characteristics

The application of Danish oil can highlight the natural wood characteristics on both hardwoods and softwoods. The oil accentuates the grain patterns and colors, bringing out the inherent beauty of the wood. This enhancement process may be more prominent on hardwoods, but still adds visual appeal to softwoods.

Adequacy For Indoor Vs. Outdoor Use

Danish oil is suitable for both indoor and outdoor use, providing a protective finish for wood projects in various environments. Whether used on hardwoods or softwoods, Danish oil offers adequate protection against environmental elements, making it versatile for different applications.

Frequently Asked Questions Of Tung Oil Vs Danish Oil

What Are The Main Differences Between Tung Oil And Danish Oil?

Tung oil and Danish oil differ in their composition and application. Tung oil is a natural oil extracted from the seeds of the tung tree, while Danish oil is a blend of oil and varnish. Tung oil provides a more natural finish, while Danish oil offers a combination of protection and aesthetics.

Can Tung Oil And Danish Oil Be Used On The Same Type Of Wood?

Yes, both Tung oil and Danish oil can be used on the same types of wood, including hardwoods like oak, maple, and walnut. However, the application process and the final appearance may vary. It’s important to consider the specific characteristics of the wood and the desired finish before choosing between the two oils.

How Does Tung Oil Compare To Danish Oil In Terms Of Durability?

Tung oil is known for its exceptional durability and water resistance, making it suitable for indoor and outdoor use. Danish oil provides a moderate level of protection and enhances the natural beauty of the wood. Depending on the intended use and maintenance, both oils can offer long-lasting results.

What Are The Best Application Techniques For Tung Oil And Danish Oil?

Applying Tung oil involves multiple thin coats with thorough drying between each application, while Danish oil can be applied more generously in fewer coats. Both oils require proper surface preparation and sanding for optimal results. Understanding the specific application techniques can help achieve the desired finish and protection.

Conclusion

Both Tung oil and Danish oil have their own unique advantages for wood finishing. Consider the specific needs of your project, such as durability, drying time, and color enhancement. Experimenting with small test pieces can help you determine which oil will best achieve your desired results for a beautiful and long-lasting finish.

2 thoughts on “Tung Oil Vs Danish Oil: Guide to Wood Finishing Options”