What is Swing on a Lathe: Essential Guide for Machinists

Swing on a lathe measures the maximum diameter that can be turned over the lathe’s bed. It’s crucial for determining the size of the workpiece you can machine.

When working with a lathe, understanding swing is fundamental. It helps you choose the right lathe for your projects. Swing refers to the maximum diameter of the workpiece that can be rotated without hitting the bed. This measurement is vital for both beginners and experienced machinists.

Knowing the swing ensures that you can safely and efficiently machine parts. Whether you are crafting small components or larger pieces, the swing on a lathe dictates the size of materials you can work with. In this blog, we will delve deeper into what swing on a lathe means and why it is important for your machining projects.

Introduction To Lathe Swing

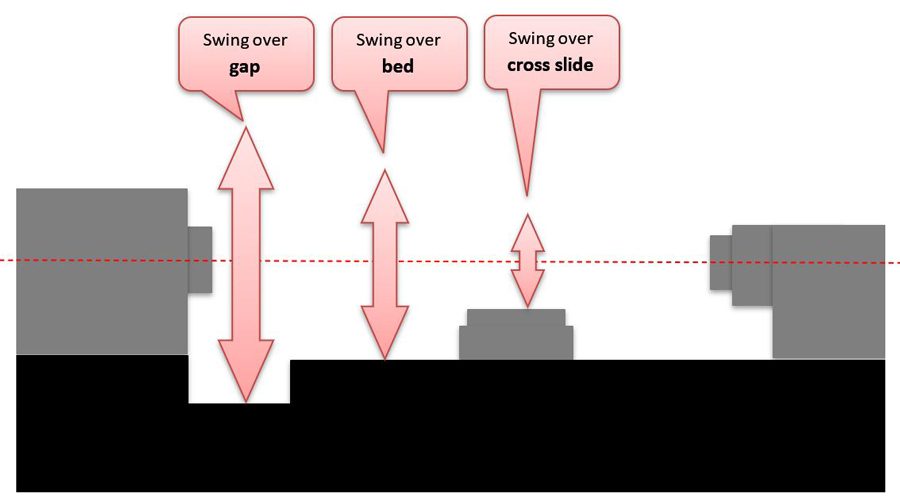

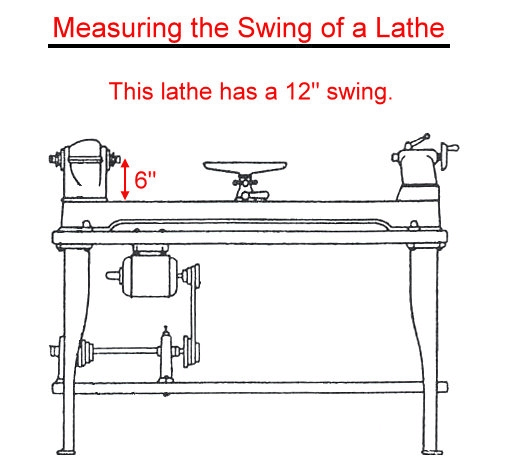

Lathe swing is the distance across the largest circle the lathe can turn. It is measured from the bed of the lathe to the center of the spindle. This measurement is then doubled. It shows the maximum diameter of workpiece that can be turned on the lathe.

The lathe swing is crucial in machining. It determines the size of the workpieces you can work on. Larger swing means bigger parts can be machined. This allows for more versatility in projects. It also impacts the type of work you can do. Understanding your lathe’s swing helps you choose the right machine for your tasks.

Components Of Lathe Swing

The headstock is the part of the lathe that holds the main spindle. It provides power to turn the workpiece. This component is very important for the lathe’s function. The headstock is usually on the left side of the lathe.

The tailstock supports the other end of the workpiece. It helps keep the workpiece steady while turning. The tailstock can move along the bed for different lengths of workpieces. It is also used for drilling operations.

The bed is the base of the lathe. It supports all other components. The bed has a flat or V-shaped guideway. This helps in accurate movement of the carriage and tailstock. The bed must be very strong and rigid.

Calculating Lathe Swing

To measure lathe swing, check the distance from the lathe’s bed to the spindle’s center. This distance is the swing radius. Multiply the swing radius by two to get the swing diameter. The swing diameter shows the largest piece the lathe can handle.

Common tools include calipers and rulers for accurate measurements. Use a tape measure for larger distances. Micrometers help with precise measurements. Each tool ensures the correct swing calculation.

Credit: www.youtube.com

Types Of Lathe Swing

The standard swing on a lathe measures the largest diameter of the workpiece that can be rotated. It is the distance from the bed to the center of the spindle. This measurement is crucial for determining the size of the workpiece. Larger standard swing allows for bigger workpieces. Smaller lathes have a limited standard swing.

The gap bed swing allows for turning larger diameters. It has a removable section in the lathe bed. By removing this section, the swing increases. This feature is helpful for working on larger projects. The gap bed swing is versatile and adds flexibility. It is commonly found in many lathes.

Choosing The Right Swing

Understanding your project’s needs is key. Think about the size of your workpiece. Larger pieces need a bigger swing. Small projects might be okay with a smaller swing. This helps in getting the right tool for the job.

The material you work with matters. Harder materials need a sturdy lathe. Softer materials might not need as much power. Choose a lathe that fits the material best. This ensures better results and longer tool life.

Common Mistakes With Lathe Swing

Taking wrong measurements is a big problem. Precision is key. If the part is too big, it won’t fit. If it’s too small, it might break. Recheck measurements often. Always use the right tools for the job. A small mistake can ruin the whole project.

Every material has a limit. Pushing beyond this is risky. Metals and woods have different strengths. Ignoring these can cause damage to the lathe. Always know the material’s capacity. This keeps your tools safe and working well.

Improving Machining Accuracy

Choosing the right tool is key. Quality tools ensure better cuts and fewer errors. Sharp tools reduce the load on the machine. This helps in producing precise parts. Always pick tools made for your specific material. The right tool gives clean results and extends machine life.

Keeping the lathe well-maintained is crucial. Lubricate moving parts regularly. This helps in smooth operation. Check for wear and tear frequently. Replace worn parts promptly. Clean the machine after each use. Dirt and debris can cause inaccuracies.

Credit: ozarktoolmanuals.com

Advanced Tips For Machinists

Regular maintenance keeps your lathe running well. Always check the alignment of your machine. This helps in making precise cuts. Use proper lubrication to reduce wear. Clean the lathe after every use. Remove any metal shavings. Inspect the tool bits for wear and replace if needed. Properly sharpened tools make better cuts.

Use the right speed for the material. Slow speeds for harder materials. Faster speeds for softer ones. Always check the manufacturer’s guidelines. Adjust the feed rate for smoother finishes. Use coolant to reduce heat and tool wear. Regularly check the machine’s balance. An unbalanced machine causes vibrations. These vibrations affect the quality of your work.

Wear safety glasses at all times. They protect your eyes from flying debris. Never wear loose clothing. It can get caught in the machine. Tie back long hair. Always use the machine’s guards. They protect you from moving parts. Keep the work area clean. Remove any clutter. Clutter can cause accidents. Always follow the manufacturer’s safety guidelines.

Credit: schoolofwoodwork.com

Frequently Asked Questions

What Does Swing On A Lathe Mean?

Swing on a lathe refers to the maximum diameter of the workpiece that can be rotated on the lathe without hitting the bed.

How Is Lathe Swing Measured?

Lathe swing is measured from the lathe bed to the center of the spindle. It is then doubled to get the diameter.

Why Is Swing On A Lathe Important?

Swing on a lathe is important because it determines the maximum size of the workpiece that can be machined.

What Is The Typical Swing Range For Lathes?

The typical swing range for lathes varies from 6 inches to 40 inches, depending on the type and size of the lathe.

Conclusion

Understanding the swing on a lathe is crucial for precision work. It helps determine the maximum diameter of workpieces. Proper knowledge ensures safety and efficiency. Always consider swing capacity when choosing a lathe. This saves time and avoids mistakes. Learning about swing enhances your lathe skills.

Keep practicing for better results. Your projects will benefit greatly. Now, you’re ready to utilize your lathe effectively. Happy machining!