A splitter on a table saw serves the purpose of improving safety during cutting operations. A table saw is a powerful and essential tool in woodworking and construction projects.

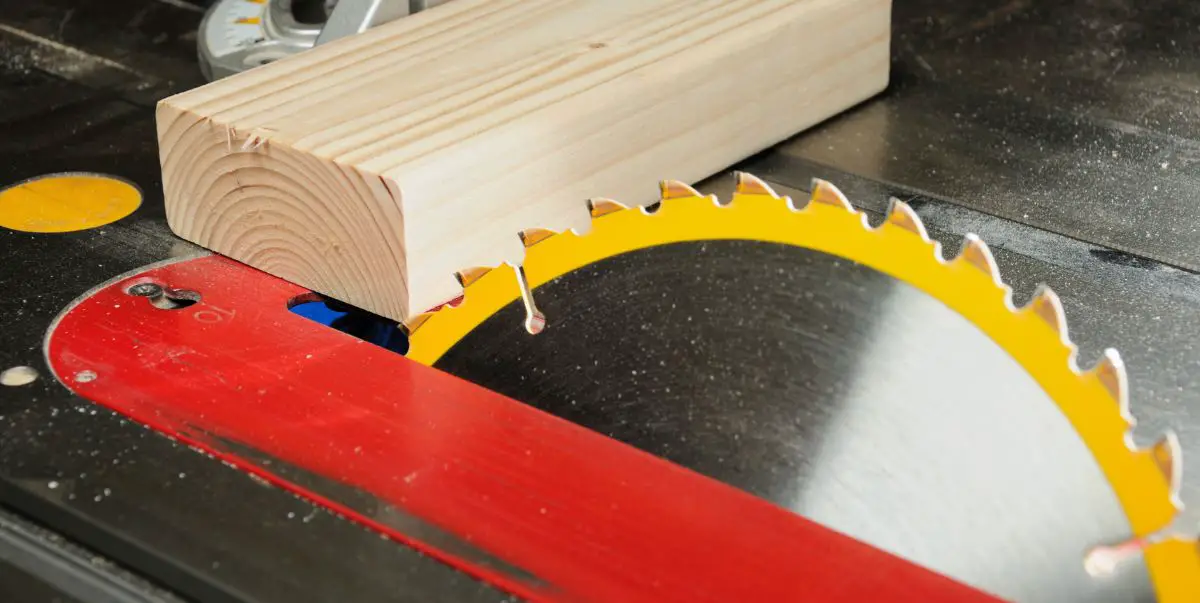

However, it can be dangerous if not used properly. The purpose of a splitter on a table saw is to prevent the occurrence of kickback, which is when the piece being cut suddenly jumps back towards the operator. A splitter is a vertical projection located behind the saw blade, designed to keep the kerf (the width of the cut) open and prevent the material from closing in on the blade.

By keeping the wood parallel to the blade and preventing it from pinching, a splitter ensures a more controlled and safer cutting experience. It helps to reduce the risk of accidents, such as the material getting caught or the blade binding, resulting in a smoother and more accurate cut. So, a splitter is an essential safety feature that should be used whenever operating a table saw.

The Purpose Of A Splitter

When operating a table saw, safety should be the top priority. One essential safety feature that is often included on table saws is a splitter. So, what is the purpose of a splitter? Let’s dive deeper into this question and explore the many benefits that a splitter brings to the table.

Promoting Safety

A table saw splitter plays a crucial role in promoting safety for the user. It is a vertical projection located at the back of the saw blade, aligning with the kerf created by the spinning blade. Its main purpose is to prevent the workpiece from pinching the rear portion of the blade, which could lead to dangerous kickbacks.

But how does a splitter accomplish this? While cutting through the stock, the splitter holds the kerf open, ensuring a safe distance between the two sections of the wood. This prevents the stock from closing back onto the blade, reducing the chances of the lumber binding and causing the saw to kick back.

Preventing Kickback

Kickback is a dreaded occurrence that can happen while using a table saw. It refers to the sudden and violent reaction of the workpiece, propelling it back towards the operator. Kickback can lead to severe injuries, and that’s where a splitter comes into play.

The presence of a splitter significantly reduces the risk of kickback by maintaining a consistent gap on both sides of the blade. This uniform separation between the two sections of the stock minimizes the likelihood of catching or binding, allowing for a smoother and safer cutting experience. By preventing kickback, a splitter provides users with peace of mind and confidence while working with a table saw.

In a nutshell:

- A splitter promotes safety by preventing the workpiece from pinching the rear of the blade.

- It prevents kickback by maintaining a uniform gap between the two sections of the stock.

With its essential functions and safety benefits, a splitter is a must-have feature on a table saw. Its presence ensures that woodworkers can focus on their craft without having to worry about potential accidents caused by kickback. Don’t compromise on safety and always use a table saw equipped with a reliable and efficient splitter.

Understanding Splitter Types

When using a table saw, understanding the different types of splitters is crucial for both safety and performance. A splitter provides a barrier to prevent the workpiece from binding against the rear of the saw blade, reducing the risk of kickback. In this article, we will explore two common types of splitters: the riving knife and the traditional splitter.

Riving Knife

The riving knife is a safety device designed to eliminate kickback by keeping the workpiece separated from the saw blade. Unlike traditional splitters, the riving knife moves up and down with the blade, maintaining a fixed distance from the back of the blade. This ensures that the splitter remains aligned with the kerf, no matter the blade height or angle.

The key advantage of a riving knife is its ability to prevent kickback even when performing non-through cuts, such as dado or groove cuts. This is particularly useful for cutting workpieces that may have internal tension or stress, as the riving knife prevents the workpiece from closing up and pinching the blade.

Traditional Splitter

The traditional splitter, also known as a fixed splitter, is a static element installed on the table saw’s throat plate. It is typically positioned slightly behind the blade and extends vertically, creating a gap just wide enough for the blade to pass through. Similar to the riving knife, the traditional splitter helps prevent kickback by keeping the workpiece from binding against the rear of the blade.

Unlike the riving knife, the traditional splitter does not move with the blade. Therefore, it needs readjustment whenever changing the blade height or angle. It is generally recommended to remove the traditional splitter when performing non-through cuts, as it may interfere with the smooth operation or proper alignment required for these types of cuts.

In summary, understanding the different types of splitters, such as the versatile riving knife and the static traditional splitter, is essential for table saw users. Each type has its advantages and considerations, and choosing the right splitter for the task at hand can greatly enhance both safety and precision in woodworking.

Installation And Adjustment

When it comes to working with a table saw, the installation and adjustment of a splitter play a crucial role in ensuring safety, precision, and efficient operation. Properly aligning the splitter and adjusting its clearance and positioning are essential steps that contribute to the overall performance of the table saw, making it necessary to understand their significance in detail.

Proper Alignment

Proper alignment of the splitter is essential for its effective operation. When installing the splitter, ensure that it is aligned parallel to the blade to prevent binding and kickbacks during cutting. Maintaining precise alignment reduces the risk of the workpiece becoming stuck or spinning away from the fence, resulting in more accurate and safe cuts.

Clearance And Positioning

To optimize the performance of the splitter, clearance and positioning must be carefully adjusted. The splitter should be positioned close to the rear of the blade to prevent the workpiece from rotating into the blade and causing kickback. Additionally, adequate clearance should be provided to accommodate different blade heights and be adjusted as needed for various cutting tasks to ensure smooth and efficient operation.

Effectiveness In Operation

A splitter on a table saw serves the purpose of increasing the effectiveness in operation by preventing kickback and ensuring smooth and safe cutting. It helps maintain accurate and precise cuts while reducing the risk of accidents, making it an essential safety feature for woodworking tasks.

Table saws are widely used in woodworking due to their ability to make precise cuts. To ensure safety and accuracy, table saws are equipped with a device called a splitter. This small but mighty tool serves a crucial purpose in the operation of a table saw, reducing binding risks and enhancing woodworking precision. Let’s delve into these two key aspects to understand the importance of a splitter.

Reducing Binding Risks

Binding occurs when the wood being cut becomes trapped between the blade and the fence, causing the workpiece to jam and potentially kick back towards the operator. This dangerous situation can lead to severe injuries and damage to the equipment. However, with the presence of a splitter, the risk of binding is significantly reduced.

A splitter is a vertical projection located behind the blade, precisely aligned with the blade’s cutting path. As the wood is pushed through the blade, the splitter helps to keep the kerf open, preventing the material from closing in on the blade. By maintaining a consistent distance between the wood and the blade, the splitter ensures a smooth and uninterrupted cutting process, minimizing the chance of binding.

Enhancing Woodworking Precision

Woodworking demands precision, and a table saw equipped with a splitter can greatly enhance the accuracy of cuts. The splitter acts as a support for the wood, preventing the material from flexing or vibrating during the cutting process.

By keeping the workpiece stable, the splitter enables the blade to make cleaner and more precise cuts. This is especially important when working with narrow or thin pieces of wood that are prone to bending or wobbling. With the use of a splitter, woodworkers can achieve straighter cuts, resulting in seamless joints and professional-looking finished products.

In addition to stability, the splitter also helps in reducing tear-out. Tear-out, where wood fibers tear instead of being cut cleanly, can mar the surface of the material. The splitter acts as a barrier, supporting the wood fibers and reducing the likelihood of tear-out, resulting in cleaner and smoother cuts.

In conclusion, a splitter plays a vital role in the operation of a table saw. Its effectiveness lies in reducing binding risks and enhancing woodworking precision. By preventing binding, the splitter ensures a safer working environment, while also contributing to cleaner cuts and improved accuracy. Whether you are a professional woodworker or a hobbyist, understanding the purpose and benefits of a splitter is essential for achieving optimal results in your woodworking projects.

Maintenance And Best Practices

Regular cleaning and proper maintenance of your table saw splitter are crucial for ensuring both its longevity and effectiveness. By following a few simple best practices, you can keep your splitter in optimal condition and maintain a safe working environment.

Regular Cleaning

Cleaning your table saw splitter should be a routine part of your woodworking maintenance. Sawdust, resin, and other debris can easily accumulate on the splitter, causing it to become less efficient and potentially compromising the safety of your work.

To clean your splitter, follow these steps:

- Disconnect the table saw from the power source.

- Remove the throat plate covering the splitter and set it aside.

- Using a brush or compressed air, carefully remove any debris from the splitter, making sure to reach all the nooks and crannies.

- Inspect the splitter for any signs of damage or wear. Replace if necessary.

- Reattach the throat plate and ensure it is securely in place.

Regular cleaning not only improves the efficiency of your splitter but also ensures the accuracy and quality of your cuts.

Choosing The Right Splitter

When it comes to choosing a table saw splitter, there are a few factors to consider to ensure you select the right one for your needs. Here are some tips:

- Check the compatibility: Make sure the splitter is compatible with your table saw model. Different saws may require different types or sizes of splitters.

- Quality and material: Look for a splitter made of high-quality materials that are durable and long-lasting. This is important for the longevity and effectiveness of the splitter.

- Adjustability: Consider a splitter that offers adjustability options, allowing you to adapt it to different types of cuts and materials.

- Installation: Look for a splitter that is easy to install and adjust on your table saw. This will save you time and effort in the long run.

By choosing the right splitter, you can enhance your woodworking experience and achieve better results with your table saw.

Frequently Asked Questions Of What Is The Purpose Of A Splitter On A Table Saw?

What Is The Splitter Used For On The Table Saw?

A splitter is used on a table saw to prevent wood from binding and causing kickback. It helps to keep the material aligned and prevents the saw blade from getting pinched. This safety feature is essential for protecting the user and achieving accurate cuts.

What Is The Purpose Of The Splitter On The Table Saw To Prevent Lumber From?

The purpose of the splitter on a table saw is to prevent lumber from pinching or binding against the blade during cutting. It helps to maintain a consistent cutting path, reducing the risk of kickback and ensuring a safer and smoother woodworking experience.

What Is The Difference Between A Splitter And A Riving Knife?

A splitter prevents kickback by keeping wood from closing in on the blade. A riving knife also prevents kickback but moves up and down with the blade to maintain a consistent distance.

Do You Really Need A Riving Knife?

Yes, you really need a riving knife. It helps prevent dangerous kickback by keep the wood from pinching the saw blade. A riving knife also ensures smoother and more accurate cuts. It’s an important safety feature for your table saw.

Conclusion

A splitter on a table saw is essential for ensuring safety and accuracy in woodworking. By preventing kickback and maintaining a straight and smooth cut, it plays a crucial role in protecting the user and producing high-quality results. Understanding the purpose and function of a splitter is key to maximizing the potential of a table saw and achieving professional-grade craftsmanship.