A Wood Lathe Speed Calculator determines the optimal RPM for turning wood. It ensures safety and precision in woodworking projects.

Wood Lathe Speed Calculator

Understanding the correct speed for turning a piece of wood on a lathe is vital for both the quality of your work and your safety. Wood lathes vary in their speed capabilities, typically ranging from 500 to 3000 revolutions per minute (RPM).

The right speed will depend on several factors, including the diameter of the wood, the type of cut desired, and the hardness of the wood. Skilled woodworkers know that too fast a speed can cause the wood to burn or a tool to catch, while too slow a speed can lead to rough cuts and ineffective turning. A Wood Lathe Speed Calculator helps by taking into account the specifics of your project to recommend an appropriate RPM, making it an essential tool for both beginners and seasoned artisans.

The Importance Of Correct Lathe Speed

When using a wood lathe, selecting the correct speed is vital. This choice impacts both safety and the quality of your finished product. A Wood Lathe Speed Calculator can serve as an essential guide. Let’s explore why the right lathe speed matters so much.

Safety Concerns

Working at the right speed on a wood lathe keeps you safe. Going too fast can cause wood to splinter or the tool to kickback. This might lead to severe injuries. On the other hand, too slow speeds can make tools catch and jerk, also dangerous. Below are key reasons why a proper speed is critical for safety:

- Avoids wood cracking or breaking, which can lead to accidents.

- Reduces the chance of tools slipping or snagging on the wood.

- Ensures better control over the woodworking process.

Quality Of Work

A project’s success often hinges on precision. The correct lathe speed ensures high-quality results. Too fast, and the wood may burn or get tool marks. Too slow, and the wood may appear rough and unrefined. Find points that emphasize quality:

- Maintain the right speed for a smooth, even finish.

- Prevent unnecessary waste of material due to errors.

- Achieve the desired shape and texture with consistent cutting.

With a speed calculator, you match the optimal speed to the project’s needs.

Basics Of Wood Turning

Delving into the art of wood turning opens up a realm of creativity and craftsmanship. It begins with understanding the machine at the heart of it all: the wood lathe. Knowing your tool and how to control its speed is crucial for creating beautiful, precise works. Let’s explore the essentials of wood turning and the significance of the wood lathe speed calculator.

Wood Lathe Components

Grasping the basics starts with familiarizing yourself with the essential parts:

- Headstock: The drive mechanism that rotates the wood.

- Tailstock: Provides support and stability to the workpiece.

- Bed: The base that connects the headstock and tailstock.

- Tool Rest: Holds chisels and gouges for shaping the wood.

- Spindle: Where the wood is clamped into place for turning.

- Motor: Powers the rotation; speed is adjustable.

This combination allows turners to manipulate wood into desired shapes and sizes.

How A Wood Lathe Works

A wood lathe transforms raw wood into refined pieces by spinning it. Here’s how:

- The motor drives the spindle, making the headstock turn.

- The workpiece is secured between the headstock and tailstock.

- The turner guides tools along the tool rest, shaping the rotating wood.

- The wood lathe speed calculator helps dictate optimal rotation speeds.

Correct speed is vital for the wood’s characteristics and the tool used. Slow speeds work for rough shaping, while faster speeds suit fine, detailed work. The wood lathe speed calculator provides a precise RPM, ensuring top-notch results and safety.

Factors Influencing Optimal Speed

Choosing the right speed for a wood lathe is crucial for quality workmanship. This section delves into factors that affect the optimal speed setting on your wood lathe. Knowing these factors ensures safe, efficient, and precise woodturning operations.

Wood Type And Size

Wood characteristics significantly impact lathe speeds.

- Hardwoods like oak demand slower speeds, reducing chip-out.

- Softwoods like pine can tolerate faster speeds.

- Small pieces can handle higher speeds.

- Larger diameters require slower rotation for safety and control.

Type Of Cut

The cut type determines the ideal lathe speed.

- A rough cut to shape the wood needs a moderate speed.

- Finer cuts for details and finishings require slower, controlled speeds.

- Aggressive cutting can lead to mistakes and is risky at high speeds.

Lathe Capacity

The lathe’s capacity plays a pivotal role in setting the speed.

| Lathe Size | Suggested Speed |

|---|---|

| Mini Lathe | Higher Speeds |

| Full-Size Lathe | Varied Speeds |

| Heavy-Duty Lathe | Lower Speeds for Stability |

Always check the manufacturer’s recommendations. Lathes have limits, and exceeding them can cause accidents and tool damage.

Understanding Rpm

Do you enjoy shaping wood? Then knowing about RPM is key. RPM stands for ‘Revolutions Per Minute’. It tells how fast the wood lathe spins. The right speed shapes wood well and keeps you safe.

What Is Rpm?

The heart of woodworking with a lathe is RPM. It measures how many times your wood lathe turns in one minute. Think of it as the speed of your car. But here, you shape wood not travel!

Rpm And Woodworking

In woodworking, RPM matters a lot. A slow turn might not cut wood. But too fast can be dangerous. You need a balanced speed. This is where a calculator helps you find the perfect RPM.

Let’s break down why this matters:

- Different woods need different speeds. Hard wood like oak needs slower RPM. Soft wood like pine can handle faster RPM.

- Tool control improves with the right RPM. It’s easier to make smooth cuts and avoid mistakes.

- Safety first: the correct RPM keeps the lathe steady. Steady means fewer chances for accidents.

Using a wood lathe speed calculator, you find the safe and effective speed. You enter the size of your project and type of wood. The calculator does the rest. It gives you a speed that matches your project needs.

Remember, the right RPM can make or break your woodworking project. It’s a simple number with big importance. It’s like knowing the right amount of sugar for your cookies!

Calculating The Perfect Speed

Finding the right speed for your wood lathe can make all the difference. It affects the quality of your work and the safety of your operation. The perfect speed depends on several factors, such as the type of wood and the size of your workpiece. Let’s learn how to calculate the ideal speed for your woodworking projects with precision.

Using Formulas

Understanding some basic principles is essential for calculating lathe speed. A common formula involves the diameter of your workpiece and a standard RPM (revolutions per minute) range. The formula is:

RPM = (Recommended Speed (in feet per minute) × 12) / (π × Diameter (in inches))

- Diameter: Measure the widest part of your workpiece in inches.

- Recommended Speed: This is a suggested speed based on the type of wood you’re working with.

To make this easier, here’s an example:

| Workpiece Diameter (in inches) | Recommended Speed (in feet per minute) | RPM |

|---|---|---|

| 6″ | 900 | Calculate using the formula |

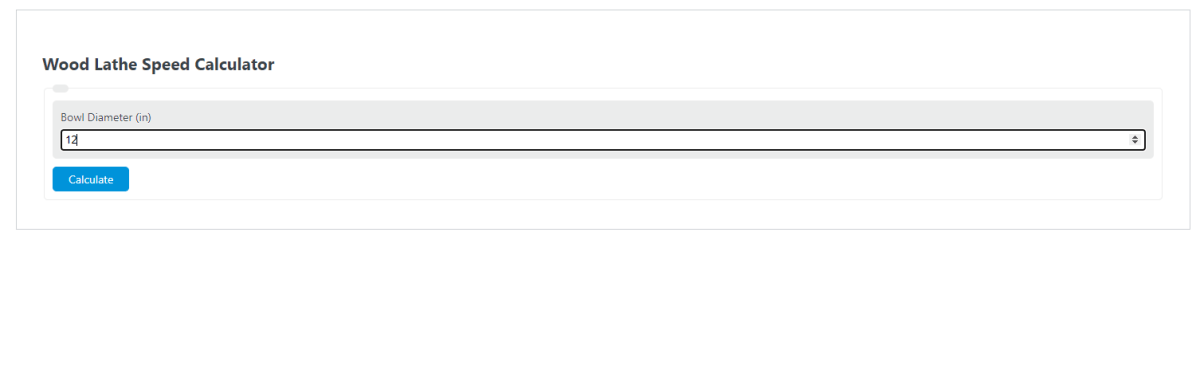

Commercial Calculators

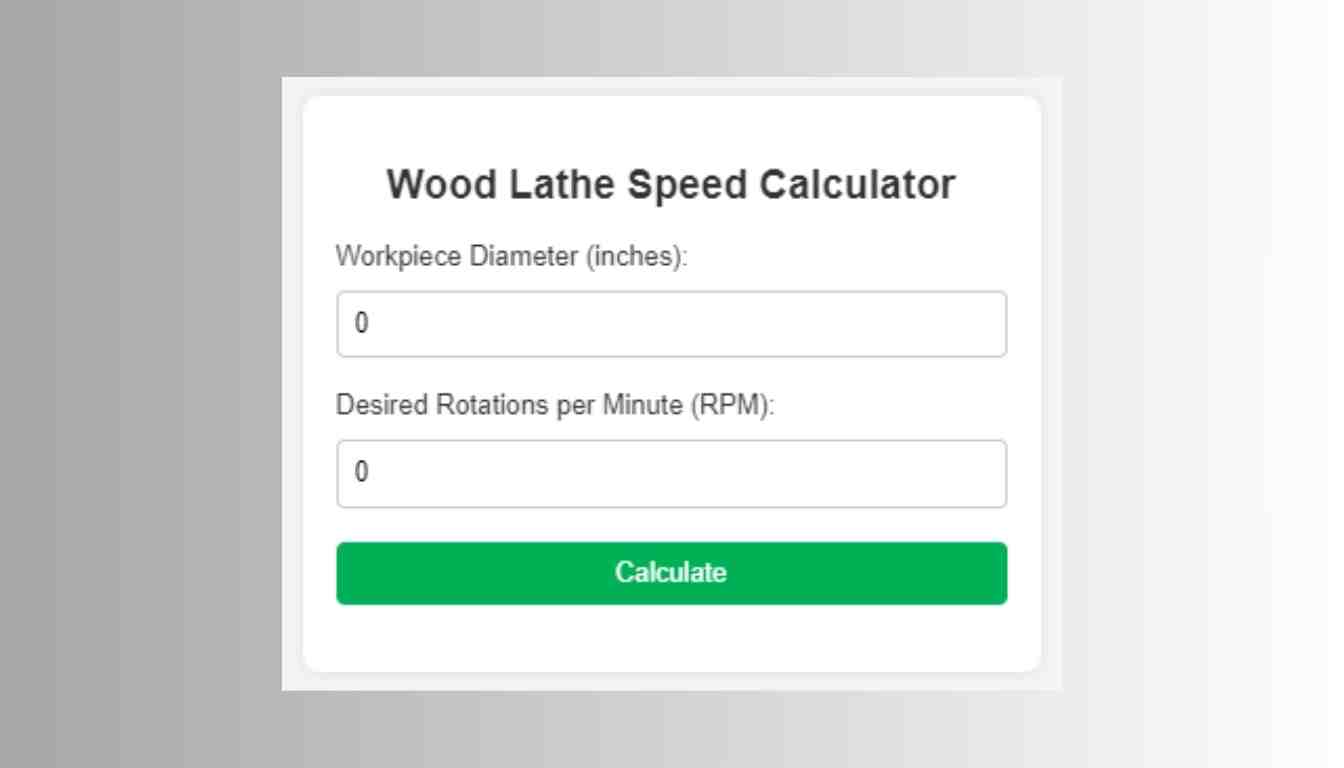

For those who prefer a quicker solution, various commercial calculators exist. These tools take the guesswork out of the equation. They come with pre-set values for different wood types and sizes. All you need to do is:

- Enter the diameter of your workpiece.

- Select the type of wood.

- Hit calculate to get the perfect speed.

Certain calculators also offer advanced features such as adjusting for specific lathe types or cutting tools.

Credit: turnawoodbowl.com

Dialing In Your Wood Lathe

Every woodturner knows precision is key. The right speed on your wood lathe can make or break a project. Finding this perfect speed isn’t just guesswork; it’s both an art and a science. Let’s explore how to dial in that mystical RPM for your wood lathe. With the help of a wood lathe speed calculator, getting it just right is easier than ever.

Setting Up

Start by understanding your lathe’s capabilities. Know the maximum and minimum RPM it can achieve. Once you’ve got this down, you’ll need to consider the diameter of the workpiece. Here’s a simple guide to follow:

- Smaller diameters usually allow for higher speeds.

- Larger pieces require slower speeds.

It’s vital to check for any wobble or imbalance in your material. A balanced piece means a safer and smoother operation.

Adjusting Speed

With your setup complete, it’s time to adjust the speed. Use the wood lathe speed calculator to input the diameter of your workpiece. The calculator will suggest an optimal speed. Refer to the below table as a starting point:

| Diameter | Recommended Speed (RPM) |

|---|---|

| Less than 2 inches | 1000-3000 RPM |

| 2 to 4 inches | 700-2000 RPM |

| 4 to 8 inches | 500-1500 RPM |

| 8 inches and above | 250-1000 RPM |

Remember to start at a lower speed and gradually increase it. Keep an eye on the wood’s response as you go. Look for vibrations, and if they occur, slightly reduce the RPM.

Finally, ensure you’re wearing proper safety gear. A face shield, safety glasses, and dust mask are your best friends here. Now, you’re set to turn your masterpiece with confidence and precision!

Troubleshooting Common Issues

Using a wood lathe speed calculator helps you work with precision. But sometimes, things can go wrong. Let’s fix these issues together. Easy steps can make your lathe run smoothly again.

Vibration And Wobble

Vibration and wobble in a lathe can ruin your work. Often, these issues are due to an unbalanced piece of wood or improper setup. Here’s a quick checklist:

- Check if the wood is properly mounted.

- Ensure the tool rest is secure and not too far from the wood.

- Adjust the lathe’s feet for a level setup.

- Inspect belts and pulleys for wear and tear.

Use a wood lathe speed calculator to choose the right speed. This prevents excessive wobble.

Chattering And Burning

Chattering happens when the tool touches the wood unevenly. Burning occurs due to high friction. Solutions include:

- Sharpen your tools; dull ones cause problems.

- Reduce the lathe’s speed for delicate operations.

- Apply gentle, steady pressure.

- Check the wood’s moisture content.

Burning can also mean that your speed is too high. Use the calculator to adjust it.

Advancing Your Wood Turning Skills

Are you ready to take your woodturning to new heights? Perfecting your craft involves understanding not only your tools but also the best ways to use them. A Wood Lathe Speed Calculator can be a game-changer. Let’s unlock the secrets of master woodturners and elevate your skills to the next level.

Learning From Experience

The path to expertise in woodturning is paved with practice. Each project brings valuable lessons. Make each experience count:

- Track your progress: Keep a notebook detailing your projects, including speeds used and results achieved.

- Analyze outcomes: Identify what works and replicate it in future projects.

- Adjust on the fly: Learn to alter lathe speeds based on the feel of the material and the tool.

Success comes from reflecting on each project and adapting techniques accordingly.

Advanced Techniques

Mastering advanced woodturning techniques demands precision and practice. A Wood Lathe Speed Calculator enhances the process. Here are techniques to consider:

- Segmented Turning: Assemble intricate designs with precision.

- Multi-Axis Turning: Create complex shapes by shifting the axis of rotation.

- Thermal Bending: Use heat to bend and shape wood on the lathe.

With each technique, the right speed is crucial. A Wood Lathe Speed Calculator helps you find the sweet spot for your project, reducing trial and error and enhancing the final product.

Useful Accessories And Upgrades

Exploring the world of woodturning reveals the importance of precise speed control. A wood lathe speed calculator becomes a woodworker’s best ally in achieving perfect cuts every time. But, what enhances the functionality of this essential tool even further? Let’s dive into some must-have accessories and upgrades that ensure optimum results and ease of use.

Chucks And Jaws

Chucks are pivotal in holding your workpiece securely. Upgrade your lathe with a high-quality chuck to improve grip and precision. Scroll chucks offer versatility for various projects.

- Self-centering chucks simplify the process of aligning your workpiece.

- Jaws come in diverse shapes and sizes, tailored for specific tasks.

Selecting the right set of chucks and jaws dramatically enhances your lathe’s functionality.

Upgrading Your Lathe

Enhancements such as a variable speed control can offer better speed regulation. Consider these key upgrades:

| Upgrade | Benefit |

|---|---|

| Tool Rest | Provides stability and control. |

| Bed Extension | Increases the maximum length of the workpiece. |

| Steady Rest | Reduces vibration for long or heavy items. |

A well-chosen upgrade not only improves performance but also elevates the entire woodturning experience.

Credit: calculator.academy

Maintaining Your Wood Lathe

For woodturning enthusiasts, a wood lathe is a key to creating beautiful projects. Proper maintenance ensures precision and extends your lathe’s life. Let’s explore how to keep your wood lathe in excellent shape with regular checks and long-term care.

Regular Checks

Keeping a wood lathe functioning well involves consistent attention. Here’s what to do:

- Clean after use: Remove wood shavings and dust.

- Inspect belts: Check for cracks or fraying.

- Check screws: Tighten any loose screws.

- Verify spindle: Ensure it runs true with no play.

- Oil moving parts: Apply lubricant to reduce wear.

Long-term Care

Wood lathes also need periodic detailed maintenance. Here’s a guide for long-term upkeep:

| Task | Frequency |

|---|---|

| Lubricate bearings | Every 6 months |

| Replace worn parts | As needed |

| Check electrical components | Annually |

| Polish bed ways | Every year |

Record these tasks in a maintenance log to track your lathe’s health.

Credit: calculator.academy

Frequently Asked Questions On Wood Lathe Speed Calculator

What Is A Wood Lathe Speed Calculator?

A Wood Lathe Speed Calculator is a tool to determine the optimal spinning speed for woodturning. It factors in the diameter of the wood piece and suggests safe rotations per minute (RPM).

How Does Lathe Speed Affect Woodturning?

Proper lathe speed is crucial; it affects the quality of the cut and safety. Too fast can lead to vibrations and potential chipping, while too slow might result in rough cuts and inefficient turning.

Why Use A Speed Calculator For Wood Lathes?

Using a speed calculator helps prevent guesswork, ensuring optimal speed for different wood diameters. This maximizes efficiency and safety, reducing risks of accidents or poor-quality outcomes.

Can Incorrect Lathe Speeds Damage Wood?

Yes, incorrect lathe speeds can cause damage. Excessive speeds might burn or crack the wood, while slower speeds can lead to uneven surfaces or tear-out during the turning process.

Conclusion

Mastering the correct speed on your wood lathe is essential for outstanding results. Utilize our Wood Lathe Speed Calculator to ensure your craftsmanship benefits from precision and safety. Embrace this tool for efficiency in your woodworking projects, and watch as it enhances the quality of each creation.

Happy turning!