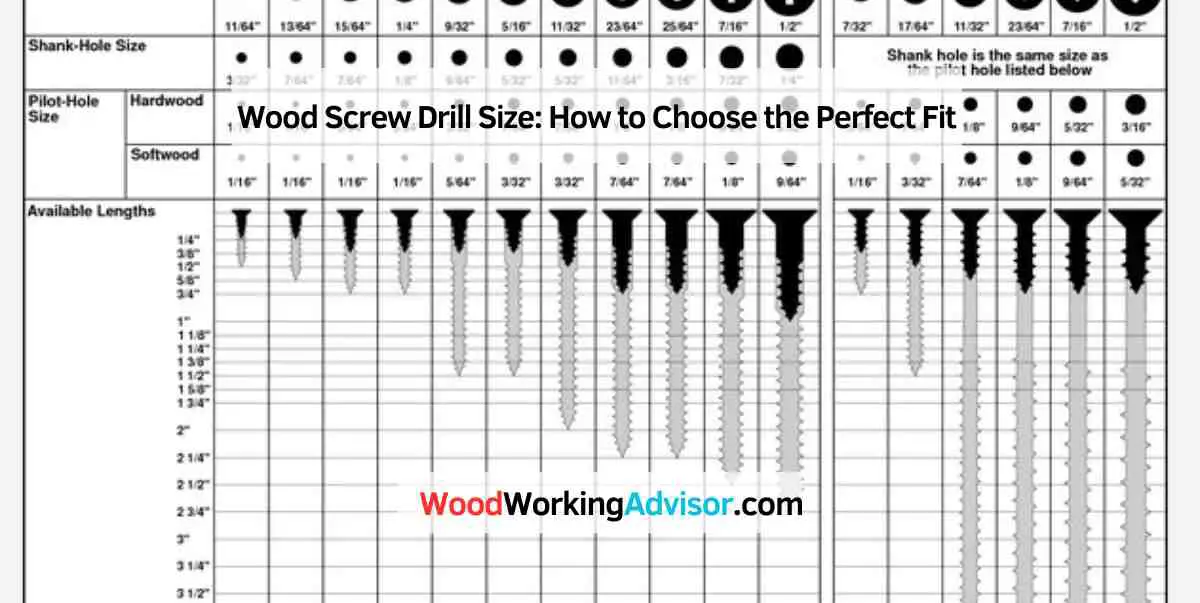

For wood screws, drill size depends on the screw’s diameter. A 3/32-inch drill bit is suitable for #4 wood screws, 7/64-inch for #6, 1/8-inch for #8, 9/64-inch for #10, 5/32-inch for #12, and 3/16-inch for #14 wood screws.

When picking the right wood screw drill size, it’s essential to match the bit to the screw’s diameter to ensure a secure and tight fit. Using the correct drill bit size will help prevent the wood from splitting and ensure the screw holds firmly in place.

By choosing the appropriate drill bit, you can achieve optimal performance and durability for your wood screw applications.

Importance Of Choosing The Right Wood Screw Drill Size

Choosing the right wood screw drill size is crucial to ensure the success of a woodworking project. The size of the drill used for wood screws directly impacts the performance and strength of the connection. Using an incorrect size can lead to a range of issues, from weak joints to damage to the wood material. In this post, we will explore the importance of choosing the right wood screw drill size and the factors that affect it, as well as the impact of an incorrect drill size on screw performance.

Factors Affecting Wood Screw Drill Size

When determining the appropriate drill size for wood screws, several key factors come into play. These include the type and hardness of the wood being used, the screw size and material, as well as the intended load or stress the joint will endure. Each of these factors influences the optimal drill size required to create a strong and secure connection. It’s essential to carefully consider these factors when selecting the appropriate drill size for wood screws to ensure reliable and durable outcomes.

Impact Of Incorrect Drill Size On Screw Performance

Using an incorrect drill size for wood screws can have significant repercussions on the performance and reliability of the joint. If the drill size is too small, the screw may struggle to penetrate the wood, resulting in a weak connection that is prone to loosening over time. On the other hand, if the drill size is too large, the screw may not achieve sufficient grip, leading to instability and potential failure of the joint. It’s crucial to recognize the impact of an incorrect drill size on screw performance and to prioritize precision in drill selection for optimal results.

Understanding Wood Screw Sizing

Demystifying Screw Gauge And Length

Deciphering the size of wood screws involves understanding both the screw gauge and length.

The screw gauge refers to the thickness of the screw shaft, denoted by a number, with lower numbers indicating thicker shafts.

Meanwhile, the screw length must accommodate the thickness of the material being joined, typically measured in inches.

Influence Of Wood Type On Screw Size Selection

When selecting the right wood screw size, it’s crucial to consider the type of wood you are working with.

Hardwoods like oak may require larger screws, while softer woods such as pine may necessitate smaller ones due to varying densities.

Choosing the appropriate screw size based on the wood type ensures optimal grip and stability for your project.

Selecting The Correct Wood Screw Drill Size

When it comes to woodworking projects, selecting the correct wood screw drill size is crucial. Choosing the right size ensures a secure and reliable fastening, preventing wood from splitting or the screws from becoming loose over time. In this article, we will discuss two essential factors to consider when determining the drill size for wood screws. These factors are determining screw size for different wood thicknesses and matching screw types to drill bit sizes. Let’s dive in!

Determining Screw Size For Different Wood Thicknesses

In order to select the appropriate wood screw drill size, it is important to consider the thickness of the wood you are working with. Using a drill bit that is too large can result in loose screws, while using one that is too small can cause the wood to split. To find the right drill size:

- Measure the thickness of your wood piece using a ruler or caliper.

- Refer to a screw size chart that provides recommendations for specific wood thicknesses.

- Select a drill bit that matches the recommended size.

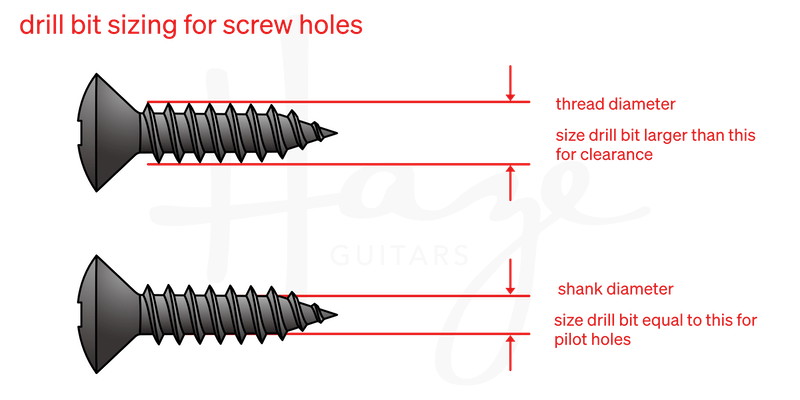

- Remember to consider the shank size of the screw as well, as it determines the width of the pilot hole.

Matching Screw Types To Drill Bit Sizes

In addition to wood thickness, it is also important to match the screw type to the corresponding drill bit size. Different screw types require different pilot hole sizes for optimal performance. Here are some common screw types and their corresponding recommended drill bit sizes:

| Screw Type | Drill Bit Size |

|---|---|

| Flathead Screws | #8 |

| Roundhead Screws | #10 |

| Panhead Screws | #8 |

| Countersunk Screws | #12 |

Matching the correct screw type to the appropriate drill bit size ensures a proper fit and improves the overall strength of the connection. It is important to follow the recommendations provided by the screw manufacturer to achieve the best results.

In conclusion, selecting the correct wood screw drill size is vital for successful woodworking projects. By considering the thickness of the wood and matching the screw type to the appropriate drill bit size, you can ensure a secure and durable fastening. Remember to refer to screw size charts and follow the recommendations provided by the screw manufacturer. Happy woodworking!

Considerations For Drill Size And Pilot Holes

When choosing the right drill size for wood screws, it’s essential to consider the thickness of the material and the size of the screw. Ensuring a proper fit by using the correct pilot hole diameter will prevent the wood from splitting and enhance the overall structural integrity of the joint.

In woodworking, the right drill size and pilot holes play a crucial role in achieving accurate and professional results. Considering these factors can greatly impact the stability, appearance, and usability of your finished project. Here, we will explore the importance of pilot holes in woodworking and delve into the effect of drill bit material on pilot hole accuracy.

Importance Of Pilot Holes In Woodworking

When drilling into wood, especially hardwoods or softwoods prone to splitting, using a pilot hole is essential. A pilot hole is a small-diameter hole drilled before inserting a screw. It helps guide the screw precisely and prevents the wood from splitting or cracking under the pressure of the screw.

Using a pilot hole also ensures that the screw is inserted at the desired angle and depth, resulting in improved overall stability of the wood joints. By reducing the chances of splitting and allowing for smoother screw insertion, pilot holes contribute to the longevity and durability of your woodworking projects.

Effect Of Drill Bit Material On Pilot Hole Accuracy

The choice of drill bit material can significantly affect the accuracy of pilot holes. Different materials offer varying levels of durability, sharpness, and precision. It is crucial to choose the right type of drill bit that suits your specific woodworking needs.

High-speed steel (HSS) drill bits are a popular choice due to their versatility and affordability. They can effectively drill pilot holes in most wood types, making them a reliable option for general woodworking projects.

Cobalt drill bits, on the other hand, offer enhanced strength and durability, making them suitable for harder wood species or materials like metals. They can maintain their sharpness for more extended periods, resulting in cleaner and more precise pilot holes.

For more specialized woodworking tasks, such as drilling holes in laminate or composite materials, carbide-tipped drill bits are ideal. These bits are designed to last longer and withstand high temperatures, ensuring consistent performance and accurate pilot holes.

By selecting the appropriate drill bit material, you can achieve greater precision, efficiency, and longevity in your woodworking projects. Consider the type of wood or material you are working with to determine the most suitable drill bit for your pilot holes.

Remember, take your time when drilling pilot holes, and ensure that the bit size matches the screw size you intend to use. These seemingly small considerations can have a significant impact on the overall quality and success of your woodworking endeavors.

Strategies For Testing Wood Screw And Drill Fit

When dealing with wood screws, it’s crucial to ensure the compatibility between the screw size and drill size for a secure and sturdy fit. Testing the fit between the screw and the pilot hole is essential to avoid issues like stripping or splitting the wood.

Methods For Testing Screw And Pilot Hole Compatibility

- Use a scrap piece of wood to test the screw and drill fit

- Insert the screw into the pilot hole with a screwdriver

- Observe if the screw goes in smoothly without too much resistance

- If the screw struggles to go in, the drill size may be too small

- If the screw goes in too easily, the drill size may be too large

- Make adjustments to the drill size accordingly

Adjusting Drill Size For Optimal Grip

- Choose a drill bit slightly smaller than the wood screw diameter

- Test the fit before driving the screw into the wood

- Consider the wood type and thickness when selecting the drill size

Choosing The Right Drill Bit Type For Wood Screw Installation

When it comes to woodworking projects, choosing the right drill bit type is crucial for ensuring clean and effective wood screw installation. The drill bit you use can greatly impact the outcome of your project, affecting the flushness of the screws, the stability of the joints, and the overall appearance of your workpiece. In this article, we will explore different types of drill bits and their suitability for wood screw installation, helping you make an informed decision for your next woodworking project.

Comparison Of Twist, Spade, And Brad Point Bits

There are various drill bit types available for wood screw installation, but among the most commonly used are twist, spade, and brad point bits. Let’s compare these three types to better understand their characteristics and applications:

| Drill Bit Type | Characteristics | Applications |

|---|---|---|

| Twist Bits | Helical flutes for efficient chip removal Available in various materials and lengths |

Ideal for general-purpose drilling in wood |

| Spade Bits | Flat, paddle-like design Large cutting surface |

Perfect for drilling large-diameter holes in wood |

| Brad Point Bits | Sharp, pointed tip for precise starting Clean and accurate holes |

Excellent for drilling dowel and pilot holes in wood |

Selecting Countersink Bits For Wood Screw Flushness

Ensuring that wood screws are flush with the surface is essential for achieving a professional and neat finish. Countersink bits help create recessed holes to accommodate the screw heads, allowing them to sit flush with or below the wood surface. Different countersink bit styles are available, such as:

- Single-flute countersink bit: Commonly used for larger screw heads

- Multi-flute countersink bit: Suitable for various screw sizes and materials

The choice of countersink bit depends on factors like screw size, wood type, and personal preference. Remember to select a countersink bit that matches the size and shape of your screw heads for optimal flushness.

Tips For Maintaining Screw And Drill Bit Compatibility

“Tips for Maintaining Screw and Drill Bit Compatibility”

When it comes to woodworking, ensuring screw and drill bit compatibility is essential for clean and effective results. Proper maintenance is crucial to prevent stripped screws and ensure clean drill bit performance.

To avoid stripped screws, follow these preventative measures:

- Choose the correct drill bit size by referring to manufacturer guidelines or using a drill bit gauge.

- Pre-drill pilot holes to accommodate the screw size, avoiding excessive force that can strip the wood or the screw itself.

- Invest in high-quality wood screws that are less likely to strip compared to lower-grade alternatives.

Maintain clean drill bit performance by following these regular maintenance tips:

- Regularly clean drill bits with a wire brush to remove debris and ensure smooth drilling.

- Inspect drill bits for damage, such as dull or chipped edges, and replace them promptly to maintain precision and prevent damage to the screws or wood.

- Use lubricants or wax on drill bits to reduce friction and heat buildup, prolonging their lifespan and maintaining their sharpness.

Final Considerations For Perfect Wood Screw And Drill Fit

Balancing Grip Strength With Wood Material Integrity

Before choosing the drill size for your wood screw, consider the balance between grip strength and wood material integrity.

A larger drill size may provide a stronger grip but can compromise the wood’s structural integrity.

Always match the wood screw drill size with the thickness of the wood to prevent splits or cracks.

- Choose a larger drill bit diameter for hardwoods to ensure a secure grip without damaging the wood.

- For softwoods, opt for a slightly smaller drill size to maintain wood integrity while still achieving a tight fit.

Seeking Professional Input For Challenging Projects

When facing challenging woodworking projects, seek professional advice for the best wood screw and drill fit.

Professional woodworkers can offer valuable insights into the most suitable drill sizes for specific wood types and project requirements.

Consulting with experts can help prevent costly mistakes and ensure a successful outcome for your woodworking project.

Remember: The right wood screw drill size is crucial for a secure and durable connection in woodworking projects.

Credit: hazeguitars.com

Frequently Asked Questions For Wood Screw Drill Size

What Is The Recommended Drill Size For Wood Screws?

For inserting wood screws, it’s advisable to use a drill bit that closely matches the screw diameter to ensure a proper fit and grip in the wood material. Choosing the right drill size is crucial for the stability and strength of the screw connection.

How Do I Determine The Correct Wood Screw Size For My Project?

To find the appropriate wood screw size, consider the thickness of the wood material you are working with and the weight-bearing capacity required. A general rule is to use a screw approximately three-quarters of the wood thickness for optimal performance and durability.

Why Is Matching The Drill Size To The Wood Screw Important?

Matching the drill size to the wood screw prevents the wood from splitting and ensures a secure attachment. Using the correct size also enhances the overall integrity of the project and minimizes the risk of structural damage or loosening over time.

Conclusion

Selecting the right wood screw drill size is crucial for successful woodworking projects. By understanding the importance of choosing the correct size, you can ensure sturdy and durable connections. Remember to match the screw to the size of the hole for optimal performance and project longevity.

Make informed choices for better results.