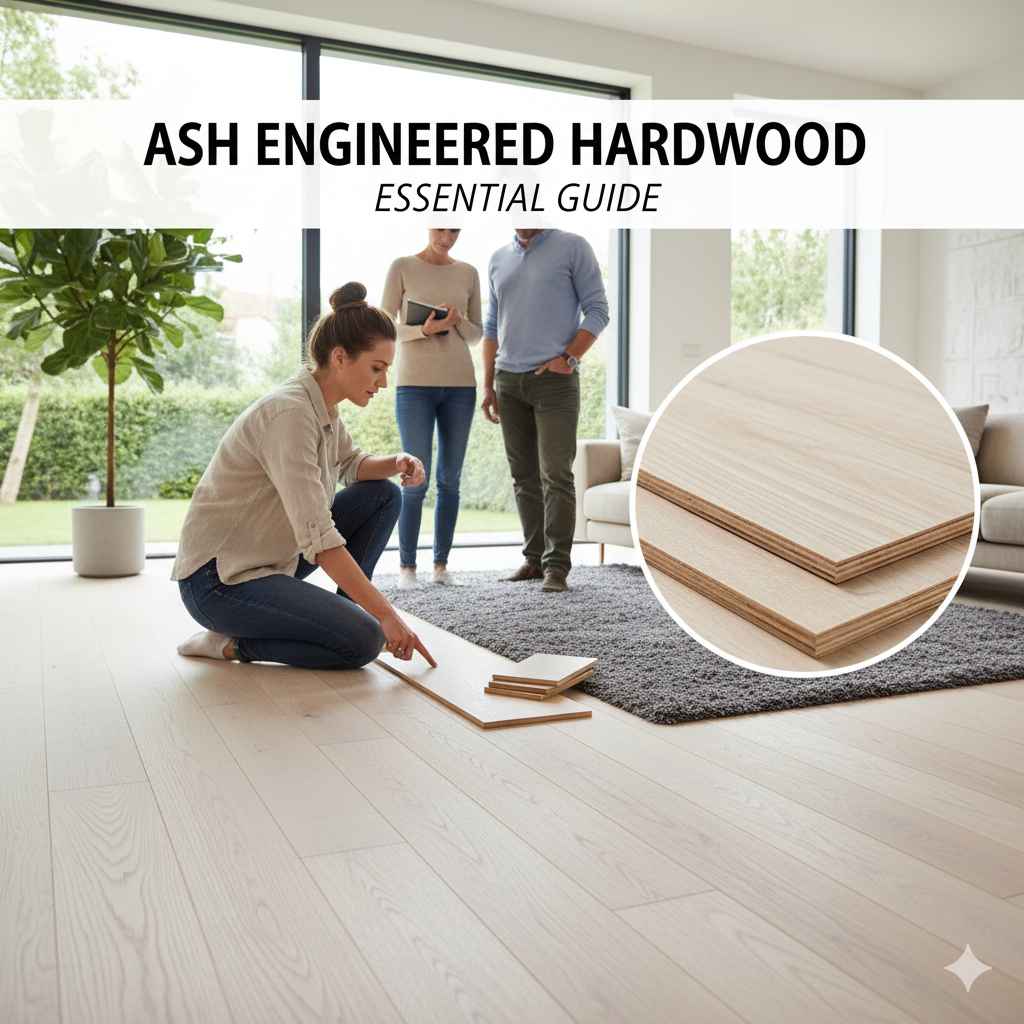

Ash Engineered Hardwood: Essential Guide

Ash engineered hardwood offers a fantastic blend of natural beauty, durability, and a more stable structure than solid wood, making it an excellent flooring choice for many homes. This guide simplifies everything you need to know about choosing, installing, and caring for ash engineered hardwood, ensuring a beautiful and lasting result.

Thinking about new flooring? Ash engineered hardwood is a popular choice, and for good reason! It brings the stunning, natural look of real wood into your home with added benefits that make it a smart investment. But what exactly is it, and how do you choose the best option for your space? Many beginners find the world of flooring materials a bit overwhelming. You might be wondering if it’s as durable as it looks, or how it compares to other wood types. Don’t worry! In this guide, I’ll walk you through everything you need to know about ash engineered hardwood, making it simple and stress-free. We’ll cover what makes it special, how to pick the perfect style, and even touch on installation and upkeep. Let’s get your dream floor started!

What is Ash Engineered Hardwood?

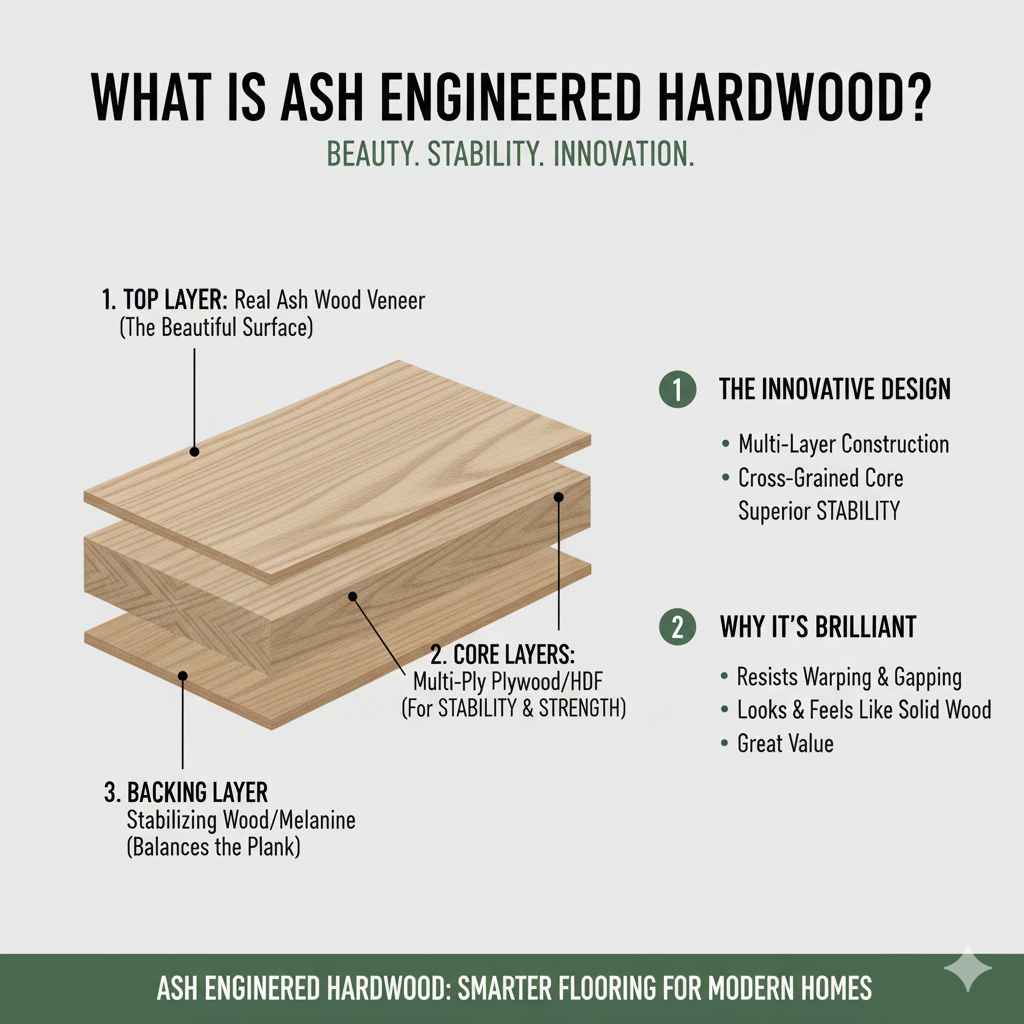

Ash engineered hardwood is a type of flooring designed for beauty and stability. It looks just like solid ash wood, but it’s built differently. This difference makes it more forgiving and versatile for different home environments. Let’s break down its construction.

Understanding the Layers

Engineered hardwood flooring consists of multiple layers, fused together under heat and pressure. This construction is key to its performance:

- Top Layer (Veneer): This is a thin slice of real ash wood. It’s the part you see and feel, giving your floor its authentic wood grain and color. The quality of this veneer determines the floor’s appearance.

- Core Layers: Beneath the veneer is a core made from plywood or HDF (High-Density Fiberboard). These layers are cross-grained, meaning the wood fibers run in different directions. This cross-graining is what adds stability and strength to the plank.

- Backing Layer: The bottom layer often made of a stabilizing material like a thin layer of wood or a melamine coating. This layer helps balance the plank and provides additional support.

Because of this layered design, engineered ash wood is less likely to expand or contract with changes in temperature and humidity compared to solid wood. This makes it a great choice for areas like basements or kitchens where moisture levels can fluctuate.

Why Choose Ash Engineered Hardwood?

Ash wood itself is known for its strength and distinctive grain patterns. When engineered, these qualities are enhanced by the flooring’s construction. Here’s why it stands out:

Pros of Ash Engineered Hardwood

- Durability & Stability: The layered construction makes it very stable. It resists warping, buckling, and gapping caused by humidity changes better than solid wood. This is a huge plus for maintaining a beautiful floor over the years.

- Aesthetic Appeal: Ash wood has a beautiful, light to medium brown color with prominent, attractive grain patterns. It offers a classic, natural look that can brighten up any room. It’s often compared to oak but with a softer, more subtle figure.

- Versatility in Installation: Due to its stability, ash engineered hardwood can be installed in more places than solid wood. This includes below-grade levels (basements) and over subfloors with radiant heating systems, as long as proper underlayment is used. Learn more about proper installation techniques from the Building Science Corporation.

- Can Be Refinished (Limited): While solid wood can be sanded and refinished multiple times, engineered wood can only be refinished once or twice, depending on the thickness of the top ash veneer. Thicker veneers offer more refinishing potential.

- Environmental Considerations: Engineered wood often uses less premium wood for its core layers, making it a more efficient use of forest resources.

Potential Cons to Consider

While ash engineered hardwood is a great option, it’s good to know about any potential downsides:

- Refinishing Limitations: As mentioned, the veneer thickness limits how many times you can sand and refinish the floor. If you plan to refinish your floors frequently, solid hardwood might be a better long-term choice.

- Cost: High-quality engineered ash wood, especially with a thick wear layer, can be as expensive as good quality solid ash or oak flooring.

- Wood Variation: Like all natural wood, each plank will have unique grain patterns and color variations. This is part of its charm, but it’s important to embrace this natural beauty.

Types of Ash Engineered Hardwood

When you’re shopping, you’ll find ash engineered hardwood in different styles and finishes. Understanding these will help you find the perfect match for your home’s décor.

Wear Layer Thickness

This is one of the most critical factors in engineered wood. The wear layer is the actual thickness of the real ash veneer on top.

| Wear Layer Thickness | Description | Best For |

|---|---|---|

| 0.5mm – 1mm (approx. 1/32″ – 1/25″) | Thin veneer. Offers a cost-effective way to get real ash. | Low-traffic areas, budget-conscious projects. Limited refinishing potential. |

| 2mm – 4mm (approx. 1/12″ – 1/6″) | Medium thickness. Offers good durability and a bit more flexibility for refinishing. | General residential use, hallways, living areas. |

| 4mm+ (approx. 1/6″ or more) | Thick veneer. Provides excellent durability and maximum refinishing potential. | High-traffic areas, commercial applications (sometimes), and if you want to refinish multiple times. |

Finishing Options

The finish protects the wood and dictates its appearance. Common finishes for ash engineered hardwood include:

- Urethane/Polyurethane: This is the most common and durable finish. It offers excellent protection against scratches, spills, and wear. It can be clear or tinted.

- Hardwax Oil: A more natural finish that penetrates the wood. It offers a matte, authentic look and feel. It requires more regular maintenance but is easier to spot-repair.

- Lacquer: Less common for residential flooring, lacquer offers a smooth, hard finish but can be more prone to chipping.

Color and Grain

Ash wood naturally ranges from creamy white to light brown, sometimes with pinkish or darker brown streaks. You’ll find:

- Natural/Muted Tones: These highlight the wood’s inherent color variations and subtle grain.

- Stained Finishes: Ash wood takes stains well, allowing for a wide spectrum of colors, from dark ebony to lighter grays or even whitewashed looks.

- Brushed/Distressed Finishes: These processes add texture and a rustic feel, often mimicking the look of aged wood.

What to Look for When Buying Ash Engineered Hardwood

Selecting the right flooring involves more than just picking a pretty color. Here’s a checklist to help you make an informed decision:

- Veneer Thickness: As discussed, this impacts durability and refinishing potential. For most homes, a wear layer of 2mm or more is recommended.

- Core Construction: Look for multi-ply hardwood plywood or dense HDF cores. These provide better structural integrity and moisture resistance.

- Finish Quality: A good finish will have multiple protective coats. Ask about the number of coats or certifications for durability.

- Plank Size and Style: Wider planks (5 inches or more) can make a room feel more spacious, while narrower planks offer a more traditional look. Be sure the style matches your home’s aesthetic.

- Installation Method: Most engineered hardwoods can be glued down, stapled (if suitable subfloor), or floated (clicked together). Ensure the product matches your desired installation method. Floating floors are often the most beginner-friendly.

- Brand Reputation and Warranty: Choose reputable brands known for quality. Check the warranty details to understand what’s covered and for how long.

Ash Engineered Hardwood vs. Other Flooring Options

How does ash engineered hardwood stack up against other popular choices? Here’s a quick comparison:

| Flooring Type | Pros | Cons | Best For |

|---|---|---|---|

| Ash Engineered Hardwood | Stable, beautiful wood look, versatile installation, good durability. | Limited refinishing, can be pricey. | Homes with fluctuating humidity, basement installations, aesthetic focus. |

| Solid Ash Hardwood | Looks great, can be refinished many times. | Sensitive to humidity changes, can warp/buckle, not for basements. | Dry climates, upper floors, traditional homes. |

| Oak Engineered Hardwood | Very durable, stable, popular choice, wide variety of finishes. | Can be more expensive than ash, grain is bolder. | High-traffic areas requiring extreme durability. |

| Laminate Flooring | Affordable, very durable surface, easy to install. | Not real wood, can sound hollow, susceptible to water damage (many types). | Budget projects, high-traffic areas where real wood isn’t feasible. |

| Luxury Vinyl Plank (LVP) | Highly water-resistant, durable, realistic wood-look options, often more affordable. | Not real wood, can be dented by heavy furniture. | Kitchens, bathrooms, basements, pets, and kids. |

Installation Basics for Ash Engineered Hardwood

Installing engineered hardwood can be a rewarding DIY project, especially if you choose a floating floor system. Always follow the manufacturer’s specific instructions, as they are the ultimate authority for their product.

Preparation is Key

Before you even open a box of flooring, proper preparation is crucial:

- Acclimate the Flooring: This is vital! Let the unopened boxes sit in the room where they will be installed for at least 48-72 hours. This allows the wood to adjust to the room’s temperature and humidity, preventing warping after installation.

- Subfloor Check: Your subfloor must be clean, dry, perfectly level, and structurally sound. Uneven subfloors will cause your new floor to creak and shift. You may need to repair or level it. For detailed subfloor preparation guidance, check out resources from organizations like the National Association of Home Builders.

- Gather Tools and Materials: You’ll need a tape measure, utility knife, pencil, tapping block, pull bar, spacers, safety glasses, and potentially a saw (miter saw, jigsaw, or circular saw for cutting planks). You might also need underlayment and adhesive if your installation method requires it.

Common Installation Methods

- Floating Floor (Click-Lock): This is the most popular DIY method. Planks simply click or lock into each other. The floor is not attached to the subfloor but rests on an underlayment. This is generally the easiest and fastest method.

- Glue-Down: Planks are glued directly to the subfloor. This creates a very solid feel and is often recommended for wider planks or certain subfloor types. Requires specific flooring adhesive.

- Staple/Nail-Down: Planks are secured to a wooden subfloor using staples or nails. This is more common for thicker engineered wood or solid hardwood and requires a specialized flooring nailer or stapler.

Safety First! Always wear safety glasses when cutting wood or using tools. If you’re unsure about any step, consult a professional. Working safely ensures a successful and rewarding project.

Caring for Your Ash Engineered Hardwood Floor

With proper care, your ash engineered hardwood floor will remain beautiful for years to come. The key is regular, gentle maintenance.

Daily and Weekly Care

- Sweep or Vacuum Regularly: Use a soft-bristle broom or the hard floor attachment on your vacuum cleaner. This removes dirt, grit, and pet hair that can scratch the finish over time.

- Clean Spills Immediately: Blot up any liquid spills with a soft, absorbent cloth. Don’t let them sit, as they can seep into the seams or damage the finish.

- Use Damp (Not Wet!) Mops: For a deeper clean, use a pH-neutral floor cleaner specifically designed for hardwood floors. Lightly dampen a microfiber mop – never saturate the floor with water. Excess water is the enemy of any wood floor.

Protecting Your Floor

Prevention is just as important as cleaning:

- Use Furniture Pads: Place felt pads under the legs of all furniture (chairs, tables, sofas) to prevent scratches when they are moved. Replace them regularly as they can wear down.

- Area Rugs: Place rugs in high-traffic areas like entryways, hallways, and living areas. Choose rugs made of natural or synthetic fibers that won’t trap moisture.

- Avoid Harsh Chemicals: Never use abrasive cleaners, ammonia-based products, or excessive water on your engineered hardwood.

- Control Humidity: Aim to keep indoor humidity levels between 30-50%. A hygrometer can help you monitor this, and a humidifier or dehumidifier can be used as needed. This is crucial for maintaining the stability of engineered wood.

Frequently Asked Questions

Q1: Is ash engineered hardwood good for kitchens?

Yes, ash engineered hardwood can be a good choice for kitchens, especially those with a sturdy wear layer and a durable finish. However, it’s crucial to clean up spills immediately and maintain a consistent humidity level to prevent moisture damage.

Q2: How does ash engineered hardwood differ from solid ash hardwood?

The main difference is construction. Engineered wood has a core of cross-laminated veneer or HDF topped with a thin layer of real ash. Solid ash is made from a single piece of ash wood. Engineered wood is more stable and can be installed in more areas, while solid wood can be refinished more times.

Q3: Can I install ash engineered hardwood myself?

Yes, especially if you choose a floating floor system with a click-lock mechanism, which is very beginner-friendly. As long as you prepare the subfloor properly and follow the manufacturer’s instructions, it’s a manageable DIY project.

Q4: How many times can I refinish ash engineered hardwood?

This depends entirely on the thickness of the top ash veneer (the wear layer). Thin veneers (under 2mm) may not be refinishable at all, while thicker veneers (4mm+) might allow for one or two sandings and refinishings. Always check the product specifications.

Q5: Is ash engineered hardwood more or less expensive than oak engineered hardwood?

Typically, ash engineered hardwood is often slightly less expensive than comparable oak engineered hardwood, but prices can vary greatly based on quality, brand, finish, and veneer thickness. Both are considered mid-to-high-end flooring options.

Q6: What is the best way to clean ash engineered hardwood floors?

The best method is regular sweeping or vacuuming (with a hard floor attachment). For deeper cleaning, use a pH-neutral hardwood floor cleaner and a lightly damp microfiber mop. Avoid excessive water and harsh chemicals.

Conclusion

Ash engineered hardwood offers a beautiful, durable, and stable flooring solution that can enhance the look and feel of your home. By understanding its construction, appreciating its unique aesthetic, and knowing what to look for when purchasing, you can confidently select the perfect ash engineered hardwood for your space. Whether you decide to tackle the installation yourself or hire a professional, remember that proper preparation and ongoing care are your best allies in ensuring your new floor looks stunning for years to come. Embrace the natural grain and warm tones of ash, and enjoy the timeless beauty it brings to your home.