Engineered wood and plywood are both durable and versatile materials commonly used in construction and furniture making. While engineered wood is made by combining various wood layers with adhesive under high heat and pressure, plywood is made by stacking thin veneers of wood together and bonding them with glue.

These materials offer similar benefits in terms of strength, durability, and resistance to moisture and warping. However, engineered wood may have a higher dimensional stability and uniformity due to its manufacturing process, while plywood may have a slightly higher strength due to the cross-grain orientation of its veneers.

Understanding the differences and considering specific project requirements can help in choosing the most suitable option.

Key Differences Revealed

When it comes to choosing the right type of wood for your construction or interior design projects, it’s important to understand the key differences between engineered wood and plywood. Both materials are popular choices due to their versatility and durability, but they have distinct characteristics that set them apart.

Composition And Manufacturing

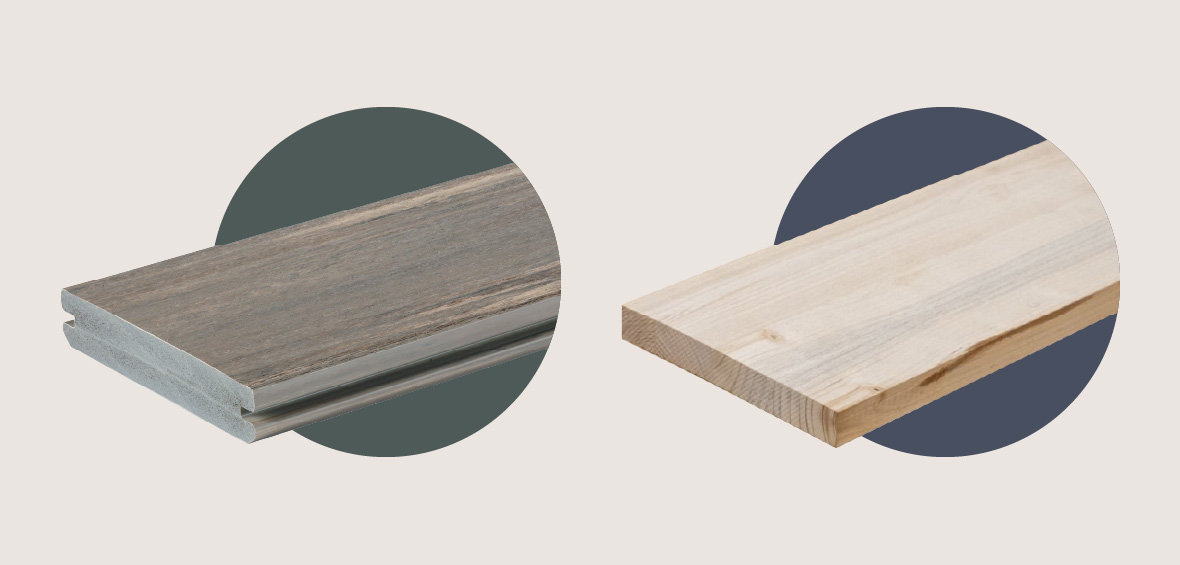

Engineered wood, also known as composite wood or manufactured board, is made by bonding several layers of wood veneers together using adhesives under high heat and pressure. This process creates a strong and stable material with enhanced resistance to warping and cracking. On the other hand, plywood is made by gluing together layers of thin wood veneers, with each layer positioned at a right angle to the previous one. This cross-grain construction method gives plywood excellent strength and stability.

Appearance And Aesthetics

Engineered wood typically features a uniform and smooth surface, as it is created by pressing and bonding wood fibers, particles, or strands together. It offers a consistent look, making it ideal for applications where a sleek and modern appearance is desired. In contrast, plywood retains the natural grain pattern of the wood veneers used in its construction. This results in a more rustic and organic look, displaying the beauty and character of the wood species used.

Durability And Performance

Both engineered wood and plywood are durable materials that can withstand the test of time. However, engineered wood tends to have better dimensional stability and resistance to moisture compared to plywood. This makes engineered wood a suitable choice for environments with high humidity or fluctuations in temperature. Plywood, on the other hand, is known for its strength and impact resistance, making it a preferred option for structural applications and heavy-duty use.

Sustainability And Environmental Impact

In terms of sustainability, both engineered wood and plywood have their advantages. Engineered wood is often made from recycled wood fibers or byproducts of the lumber industry, reducing waste and utilizing resources efficiently. It also requires fewer trees to produce compared to solid wood. Plywood, on the other hand, is typically made from logs that are sustainably harvested and replanted. Both materials can contribute to LEED certification and green building practices.

Cost Comparison

When it comes to cost, engineered wood is generally more affordable compared to plywood. The manufacturing process of engineered wood allows for better utilization of raw materials, reducing production costs. Plywood, on the other hand, requires more intensive manufacturing processes, including cutting and stacking of wood veneers, which increases its production costs. However, the cost difference may vary depending on the specific type and grade of engineered wood or plywood.

Credit: www.timbertech.com

Strengths Of Engineered Wood

Engineered wood is a versatile and reliable material that offers numerous advantages over traditional plywood. From enhanced stability to resistance against moisture and heat, engineered wood stands out as a top choice for a wide range of applications. In this section, we will explore the strengths of engineered wood in more detail.

Versatility In Applications

One of the key strengths of engineered wood lies in its versatility. This engineered material is suitable for various applications, making it a favorite among architects, builders, and homeowners alike. Whether it’s used for flooring, furniture, cabinetry, or even structural purposes, engineered wood delivers excellent performance and aesthetic appeal.

Superior Stability

Engineered wood exhibits superior stability compared to plywood, thanks to its layered construction. Unlike solid wood or plywood, which can expand or contract with changes in temperature and humidity, engineered wood remains more dimensionally stable. This stability reduces the risk of warping, buckling, or cracking, ensuring longevity and durability.

Enhanced Lifespan

The composition of engineered wood contributes to its remarkable lifespan. By combining layers of real wood with adhesives and resins, engineered wood gains added strength and protection against wear and tear. This enhanced lifespan translates into a cost-effective choice, as it requires fewer repairs or replacements over the years.

Resistance To Moisture And Heat

Engineered wood showcases excellent resistance to moisture and heat, making it an ideal option for areas prone to humidity or temperature fluctuations. The layered structure and protective coatings used in engineered wood help prevent moisture absorption and minimize the risk of warping, swelling, or mold growth. Its ability to withstand high temperatures also ensures it retains its structural integrity in challenging environments.

Ease Of Installation

Another advantage of engineered wood is its ease of installation. With tongue and groove or click-lock systems, engineered wood boards can be quickly and efficiently installed, saving time and labor costs. Whether you are a homeowner embarking on a DIY project or a professional contractor, the straightforward installation process of engineered wood makes it a favorite choice.

When Plywood Wins

While engineered wood offers many advantages over plywood in terms of its strength, durability, and eco-friendliness, there are still certain situations where plywood comes out on top. Let’s explore some of the classic uses of plywood, along with its flexibility and bending capabilities, higher impact resistance, repair and maintenance advantages, and affordability factor.

Classic Plywood Uses

Plywood has been a popular choice in construction and woodworking for decades due to its versatility. It is commonly used for various applications such as:

- Interior and exterior walls

- Furniture construction

- Cabinetry and shelving

- Subfloors and underlayment

- Roofing and sheathing

This diverse range of uses makes plywood a reliable choice for both structural and decorative purposes, ensuring its continued popularity in the industry.

Flexibility And Bending Capabilities

One of the key benefits of plywood is its flexibility and bending capabilities. Unlike engineered wood, plywood can be easily bent and shaped to fit curved surfaces, making it ideal for projects that require custom designs or unconventional forms. This inherent flexibility allows plywood to adapt to various architectural and design needs, giving it an edge in certain applications.

Higher Impact Resistance

Plywood is known for its exceptional impact resistance, which makes it a preferred choice in high-traffic areas or locations prone to heavy use. Its multi-layered structure consisting of cross-laminated sheets enhances its strength and durability, enabling it to withstand substantial impacts without significant damage. Whether it’s flooring in busy commercial spaces or heavily used furniture, plywood’s superior impact resistance ensures longevity and reliability.

Repair And Maintenance Advantages

When it comes to repair and maintenance, plywood offers distinct advantages. In the event of damage, plywood can be easily patched or replaced, providing a cost-effective solution to keep structures functional. Its laminated layers allow for individual sheet replacement without the need for extensive repairs. Additionally, the natural wood grain of plywood makes any marks or scratches less noticeable compared to engineered wood, maintaining its aesthetic appeal with minimal effort.

Affordability Factor

One of the key factors that make plywood a popular choice in many projects is its affordability. Compared to engineered wood, plywood comes at a lower price point, making it a cost-effective option for those working on a tight budget. Its widespread availability and ease of production contribute to its affordability while still offering satisfactory performance and versatility.

Engineered Wood: Unveiling The True Power

When it comes to the world of construction materials, traditional wood has always been a staple. However, with technological advancements paving the way for innovative alternatives, engineered wood has emerged as a game-changer. In this article, we will unravel the true power that engineered wood holds in the construction industry. From its technological advancements to its comprehensive comparison with traditional wood products, let’s dive deeper into why engineered wood is making waves.

Technological Advancements

Engineered wood is not just your ordinary wood. It is a result of cutting-edge technology and scientific advancements that bring out the best in this material. Unlike traditional wood, engineered wood is made by layering thin sheets of wood veneers together to form a composite material. These veneers are then bound together using powerful adhesives and subjected to intense heat and pressure, resulting in a highly durable and versatile product.

This process allows engineered wood to possess exceptional strength and stability, making it resistant to warping, twisting, and shrinking. Moreover, it eliminates the inherent flaws and defects often found in natural wood, ensuring consistent quality throughout the entire piece. With this remarkable combination of technology and craftsmanship, engineered wood sets a new standard in the realm of construction materials.

The Future Of Engineered Wood In Construction

Engineered wood is not just a passing trend; it signifies the future of construction. As sustainability becomes increasingly important, the use of engineered wood aligns perfectly with the goal of reducing carbon footprint. Engineered wood is made from renewable resources and promotes responsible forest management, as it requires less natural wood compared to traditional timber products.

Additionally, engineered wood’s superior strength and stability make it an ideal choice for modern construction projects. It can withstand heavy loads and offers excellent structural integrity, making it suitable for a wide range of applications such as flooring, framing, and even tall buildings. Furthermore, its uniform composition and consistent quality ensure easier and more precise installation, saving time and money for builders.

Comprehensive Comparison With Traditional Wood Products

Now, let’s delve into a comprehensive comparison of engineered wood and traditional wood products. The following table breaks down the key differences:

| Aspect | Engineered Wood | Traditional Wood |

|---|---|---|

| Strength and Stability | Highly stable and resistant to warping, twisting, and shrinking. | Susceptible to warping, twisting, and shrinking. |

| Consistency | Uniform composition and consistent quality throughout the entire piece. | Natural wood may have inherent flaws and defects. |

| Eco-Friendliness | Uses renewable resources and promotes responsible forest management. | Can result in deforestation and unsustainable practices. |

| Applications | Suitable for a wide range of applications, including large-scale construction projects. | May have limitations in terms of load-bearing capacity and structural integrity. |

As the table illustrates, engineered wood surpasses traditional wood products in various aspects, proving its superiority in construction applications.

Making The Right Choice

When it comes to selecting the right material for your woodworking projects, making an informed decision is crucial. Two popular options that often come up for consideration are engineered wood and plywood. While both have their merits, understanding the differences and assessing your project needs can help you make the right choice for your specific requirements.

Assessing Project Needs

Before diving into the pros and cons of engineered wood and plywood, it is important to evaluate your project needs. Consider factors such as the intended use of the finished product, budget constraints, and the desired level of durability. By assessing these needs, you can better determine which material will be the most suitable for your project.

Weighing The Pros And Cons

To make an informed decision, let’s delve into the pros and cons of both engineered wood and plywood:

| Engineered Wood | Plywood |

|---|---|

|

|

|

|

The Importance Of Quality

In any woodworking project, the quality of the materials used plays a significant role in the final outcome. When comparing engineered wood and plywood, it is essential to consider the quality of the specific product you are considering. Look for reputable brands and suppliers that offer reliable warranties and certifications. Investing in high-quality materials ensures durability and longevity in your finished project.

Expert Recommendations

While there is no one-size-fits-all answer for which material is better, experts often recommend considering the specific project requirements and personal preferences. For intricate designs that demand precision, engineered wood may be the preferred choice due to its consistency and stability. However, if cost-effectiveness and versatility are the primary concerns, then plywood might be the better option. Consulting with experienced woodworkers or seeking advice from industry professionals can provide invaluable insights for your decision-making process.

Frequently Asked Questions On Engineered Wood Vs Plywood

Which Is Better Engineered Wood Or Plywood?

Engineered wood is better than plywood due to its durability, strength, and cost-effectiveness. Its layers are firmly bonded, making it less likely to warp or splinter. Additionally, engineered wood is made from renewable materials, reducing environmental impact. Its versatility suits various applications, ensuring its popularity in construction and furniture industries.

What Are The Disadvantages Of Engineered Wood Furniture?

Engineered wood furniture has some drawbacks. It is prone to water damage and swelling, difficult to repair scratches, and may emit formaldehyde gas. Additionally, it has a shorter lifespan compared to solid wood and is harder to refinish.

Is Engineered Wood Strong?

Engineered wood is indeed strong due to its construction. It’s made with layers of wood fibers glued together, providing enhanced durability and stability compared to solid wood. This makes it suitable for various applications, such as flooring and furniture, offering strength without compromising on aesthetics.

Which Is Better Particle Board Or Engineered Wood?

Particle board and engineered wood have their own advantages. Particle board is affordable and lightweight, while engineered wood is stronger and more durable.

Conclusion

Both engineered wood and plywood have their own advantages and disadvantages. Engineered wood offers greater stability, versatility, and sustainability, while plywood provides strength and affordability. When choosing between the two, it is important to consider the specific application and requirements.

Ultimately, the decision should be based on factors such as budget, aesthetics, and desired performance. Having a clear understanding of these differences will help you make an informed choice for your project.

8 thoughts on “Engineered Wood Vs Plywood: Unveiling the True Power”