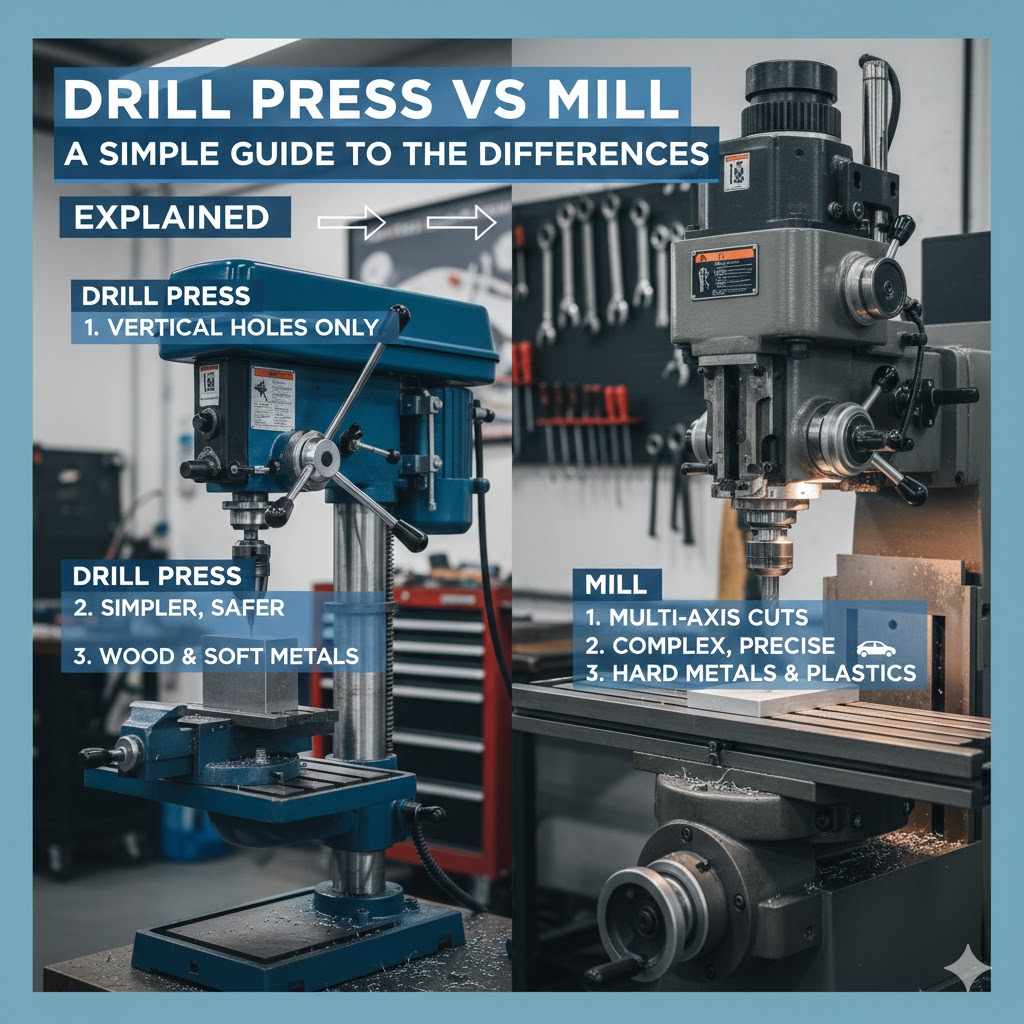

Drill Press vs Mill: A Simple Guide to the Differences

Figuring out the difference between a Drill Press vs Mill: What’s the Difference? can be tricky, especially if you’re just getting into woodworking or metalworking. Many people find the terms confusing because both machines work with materials. Don’t worry, it’s simpler than you might think! This guide will break down the key differences between these tools in a step-by-step way, so you’ll easily grasp their functions and know when to use each one. We’ll start with the basics and move on to their capabilities.

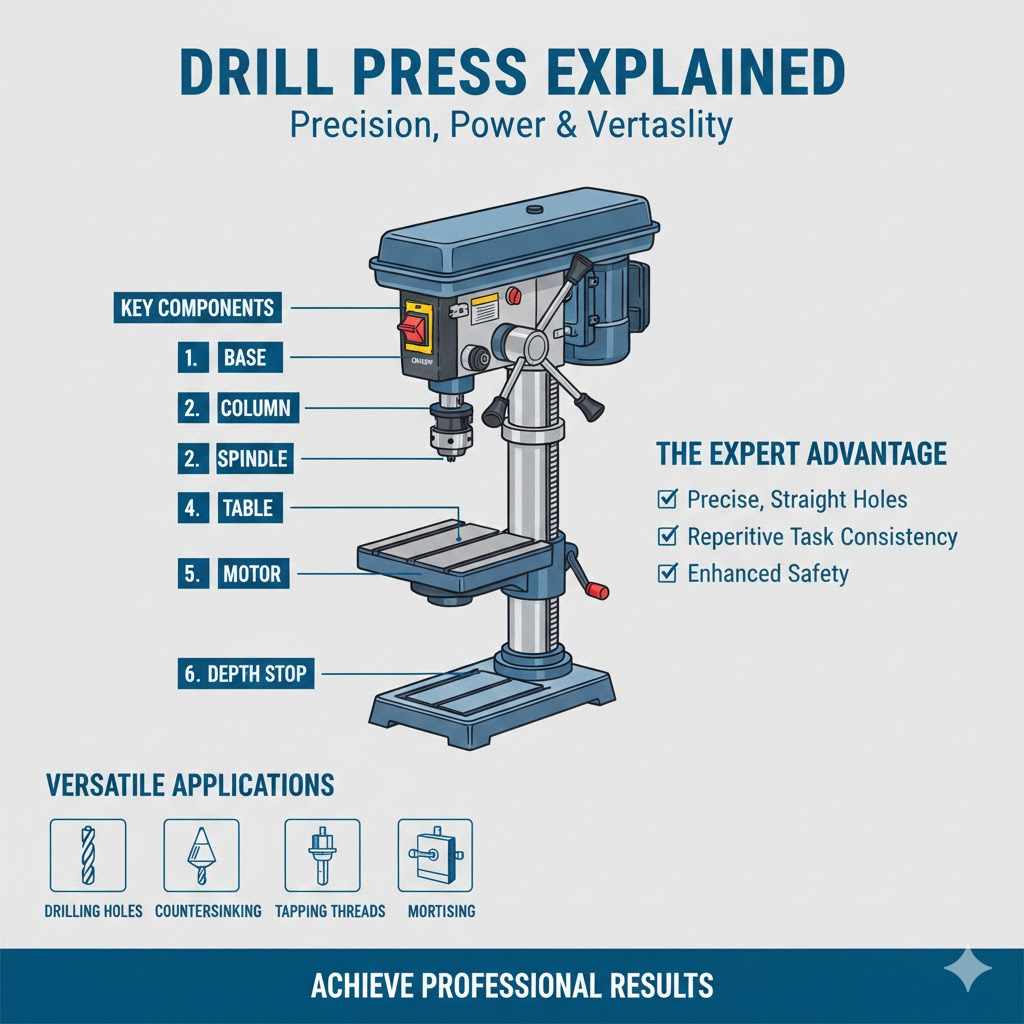

Drill Press Explained

A drill press is a stationary power tool primarily used for creating holes in materials like wood, metal, or plastic. It’s designed to drill precise, straight, and clean holes with ease. Unlike handheld drills, the drill press offers greater control and accuracy because the bit is fixed in place, and the material is clamped down. This allows for perpendicular drilling, something very hard to do freehand. Drill presses are great for repetitive tasks where consistency is important, such as drilling holes for screws or creating patterns.

Key Components of a Drill Press

Understanding the parts of a drill press helps in comprehending its functions. A drill press typically consists of a base, a column, a table (where the material rests), a spindle (that holds the drill bit), and a motor. The motor provides power to the spindle, which spins the drill bit. The table can usually be adjusted in height, and sometimes tilted, to accommodate different-sized workpieces or angled drilling.

- The Base: The bottom part of the drill press, providing stability and support for the entire machine. It’s usually made of cast iron for weight and stability.

- The Column: A vertical structure that supports the head of the drill press, allowing the table to move up and down. The column ensures the drill bit stays aligned.

- The Table: A flat surface that holds the material being drilled. It can be adjusted in height and sometimes tilted to allow for angled drilling.

- The Spindle: The rotating part that holds the drill bit. It’s driven by the motor and spins at various speeds.

- The Motor: The power source of the drill press. It drives the spindle, which then rotates the drill bit to create holes.

Many drill presses also include a depth stop, which lets you control the depth of the hole. This is very important for jobs where consistent hole depths are needed. Using the right drill bit for the material is also critical to get good results. Different types of bits, like twist drills or Forstner bits, are suitable for different applications. Consider the material and the type of hole you need to decide on the proper drill bit.

What You Can Do with a Drill Press

The main function of a drill press is to drill holes. But, it can do a lot more than just that. With the right attachments and bits, a drill press becomes very versatile. It excels at tasks where accuracy and repetition are important, like making multiple holes in a piece of wood for dowels or installing hardware. It’s also handy for countersinking, where you create a recess for screw heads to sit flush with the surface.

- Drilling Holes: This is its primary function. A drill press allows for precise, perpendicular holes.

- Countersinking: Creating a conical recess for screw heads.

- Reaming: Enlarging a hole with greater precision.

- Tapping: Cutting threads inside a hole.

- Mortising: Using a mortising attachment to create square or rectangular holes.

For example, imagine you are building a bookshelf. You will need to drill several holes to hold the shelf supports. A drill press makes this easy. Also, when installing cabinet hinges, the drill press allows you to make perfect holes to mount the hinges.

Understanding Milling Machines

A milling machine, often called a mill, is a more complex and versatile machine tool designed for removing material from a workpiece by using rotating cutters. Unlike a drill press, which focuses on making holes, a mill can create complex shapes, slots, and surfaces. Mills can handle materials like metal, plastic, and wood. They are essential for precision machining tasks in manufacturing, toolmaking, and prototyping.

Milling involves feeding the workpiece into a rotating cutter. This allows for intricate designs and customized parts. The cutters come in various shapes and sizes, which allows them to remove material in many ways. You can shape the material, flatten surfaces, and cut slots, and make complex 3D shapes. Mills are used to create precise components that have tight tolerances for various industries.

How Mills Differ From Drill Presses

The main difference between a drill press and a mill is the range of operations they can perform. While a drill press is limited to drilling holes, a mill can do many other tasks, including shaping, cutting, and creating complex shapes. Mills have more axes of movement, allowing them to move the cutting tool in multiple directions (X, Y, and Z axes). This allows for greater precision and the creation of detailed designs.

- Movement: Mills have movement on multiple axes, allowing for more complex cuts. Drill presses mainly move up and down.

- Cutter Type: Mills use various cutters for shaping and milling. Drill presses use drill bits.

- Capabilities: Mills can create slots, contours, and 3D shapes. Drill presses mostly make holes.

- Precision: Mills usually have more precision due to more adjustment options.

- Cost: Mills are generally more expensive and complex than drill presses.

Consider the process of making a custom metal part. A mill can cut the metal, make specific slots, and shape the edges. A drill press would not be able to do this. A mill can mill flat surfaces, create intricate patterns, and create 3D forms, which a drill press can not.

Key Parts of a Milling Machine

A mill has many parts designed to provide cutting precision and versatility. Key parts include the base, column, knee, saddle, table, spindle, and cutters. Each part plays a critical role in the operation of the mill. The base gives the machine stability, while the column and knee provide support for the table and head. The spindle holds the cutting tools, and the table allows the workpiece to be moved in different directions for precise cuts.

- The Base: Provides a stable platform and support for the entire machine.

- The Column: The vertical structure that supports the head of the mill.

- The Knee: An adjustable part that supports the table.

- The Saddle: Connects the knee to the table, and allows for horizontal movement.

- The Table: Holds the workpiece and can move along the X and Y axes.

- The Spindle: The rotating part that holds the cutting tool.

- Cutters: Various cutting tools used to remove material.

These components allow mills to do many things. The horizontal and vertical movements allow for highly accurate cuts. This versatility makes mills useful in a wide range of industries and projects. Proper maintenance and operation are essential for the longevity and precision of a mill.

Drill Press vs Mill: Applications and Examples

When comparing a Drill Press vs Mill: What’s the Difference? it’s helpful to consider their applications in real-world scenarios. Each tool is designed for certain tasks, and knowing when to use which tool can improve efficiency and results. A drill press excels at hole-making tasks, while a mill shines when complex shapes and precise machining are needed. Understanding their capabilities will help you make the right choice.

When to Use a Drill Press

A drill press is perfect for tasks that need accurate holes. It’s a great choice for drilling straight, clean holes in wood, metal, or plastic. It’s also ideal for repetitive jobs, where you need to drill many holes with consistent depth and size. A drill press offers better control and accuracy. This makes it perfect for DIY projects, woodworking, and small metalworking tasks where precision is key.

- Drilling holes for dowels in woodworking projects. Using a drill press will create accurate holes, ensuring a strong and correct connection.

- Installing hardware, such as hinges on cabinets. The drill press is great for making the required holes in the precise spots.

- Creating multiple holes for screws in assembly jobs. The drill press makes the process quick and uniform.

- Countersinking holes for screws to sit flush with the surface. This creates a professional look and a neat finish.

For example, if you’re building a simple wooden bench, a drill press would be the best tool for drilling the holes for the legs and the seat. You’ll be able to create accurate holes that ensure a strong and long-lasting bench. You can drill at specific depths using the depth stop. This is better and faster than trying to do it by hand.

When to Use a Milling Machine

A milling machine is the tool to use when you need more detailed operations, like cutting complex shapes, creating slots, or shaping surfaces. Mills are essential for projects needing high precision. They are common in metalworking, toolmaking, and manufacturing. Mills are needed for building custom parts and when precise dimensional accuracy is needed.

- Creating custom parts for machinery. A mill can make components with precise dimensions and complex shapes.

- Making molds and dies. Mills are essential for shaping the tools.

- Shaping metal or plastic for a custom project. With mills, it’s possible to create unique shapes and designs.

- Prototyping. Mills provide the ability to create prototypes with precision.

For example, if you are creating a custom bracket for an engine. You’ll use a mill to cut the metal to the correct size, shape, and create mounting holes. This level of precision cannot be achieved with a drill press. When building custom parts, a mill’s capabilities are often needed.

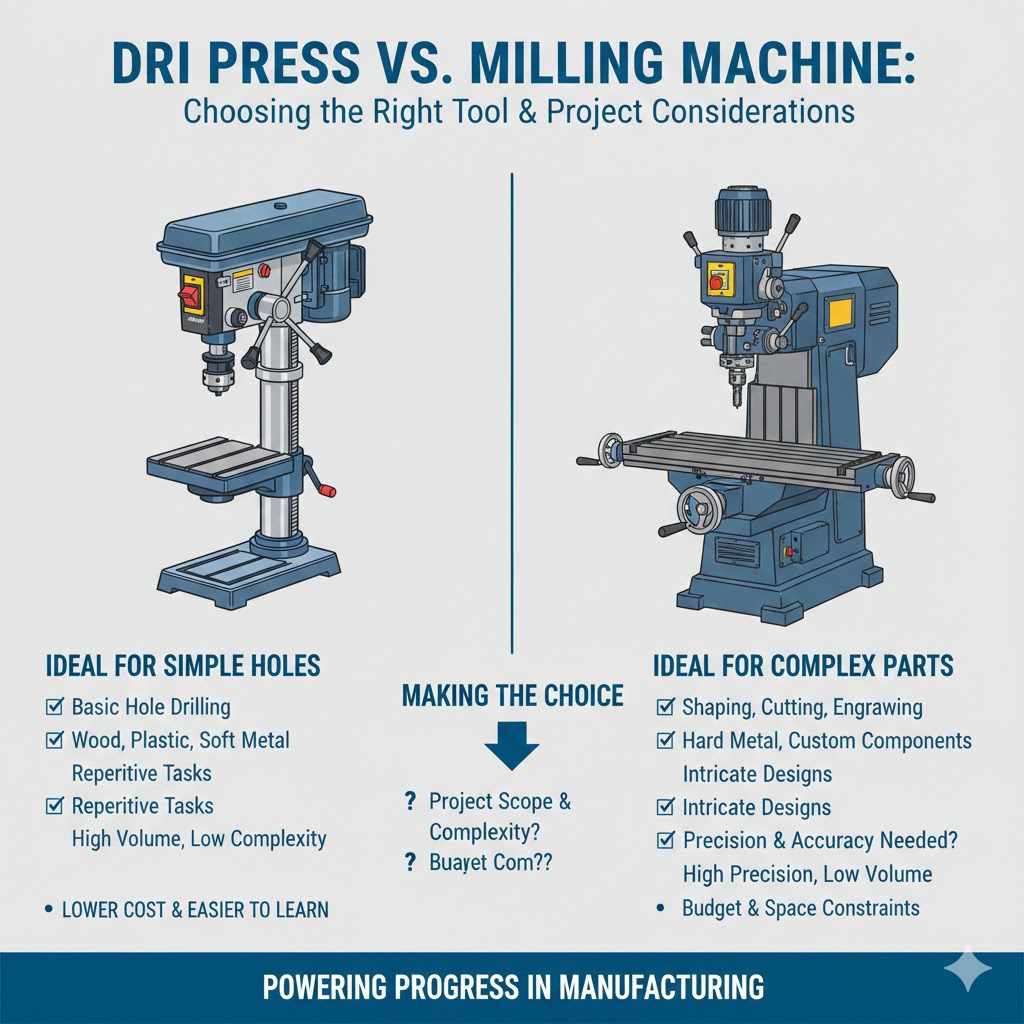

Choosing the Right Tool

Selecting the right tool depends on the project. Considering the main differences in function and cost is very important. The drill press is the easier and more affordable option for basic hole-making. The mill offers more versatility and precision for advanced projects.

Factors to Consider

Many factors come into play when deciding. Consider the kind of tasks you will be doing, your budget, and the level of precision needed. For straightforward hole-drilling jobs, a drill press is enough. However, if your projects involve complex shapes, intricate designs, or high-precision parts, a mill is the better choice. Think about the material and the complexity of the project.

- Project Scope: The drill press is ideal for simple projects. Mills are better for complex designs.

- Precision: Mills offer greater precision. Drill presses do their job but lack many of the adjustments.

- Budget: Drill presses are less expensive than mills. Mills can range in price, based on size and features.

- Space: Drill presses are smaller than mills, which means a mill needs more space.

- Skill Level: Drill presses are easier to learn to operate. Mills require more skill and practice.

For example, if you are building a birdhouse, a drill press is enough to drill the necessary holes. However, if you are building a metal part, you will want a mill for its accuracy and versatility.

Making the Right Choice

The right tool depends on your project’s needs. If you need to make holes and do simple tasks, a drill press is a great choice. If you need to create complex shapes or custom parts, a mill will give you the precision you need. Knowing the differences and considering your projects helps you make the most informed decision.

A study by the U.S. Bureau of Labor Statistics found that machinists, who often work with mills, earn a median annual wage of $49,070 in May 2022. This shows the importance of mills in the manufacturing industry.

Frequently Asked Questions

Question: What’s the main function of a drill press?

Answer: The primary function of a drill press is to create accurate and straight holes in various materials.

Question: Can a milling machine cut curves?

Answer: Yes, a milling machine can cut curves and complex shapes because it can move in multiple axes.

Question: Which tool is better for making a slot in a piece of metal?

Answer: A milling machine is the best tool for creating slots, due to its ability to remove material precisely and control the shape.

Question: Are drill presses good for beginners?

Answer: Yes, drill presses are generally easier for beginners to use, as they focus on drilling holes.

Question: What materials can a milling machine work with?

Answer: Milling machines can work with many materials, including metal, wood, plastic, and composites.

Final Thoughts

The main thing to keep in mind is the difference between a Drill Press vs Mill: What’s the Difference? A drill press is best for creating precise holes, and a mill is more about creating complex shapes and removing material. The drill press is easier to learn and generally more affordable. A mill requires more skill, but also gives you more capabilities. Considering the kind of projects you typically work on and your budget makes it easier to choose. Whether you’re a beginner wanting to make simple projects or a more seasoned woodworker or metalworker, each tool has its own key purpose. Armed with this knowledge, you are ready to explore the world of woodworking and metalworking. Now you can confidently start your next project, knowing which tool to use.