How Good Is Gorilla Glue: Essential Adhesive Guide

Gorilla Glue is an incredibly strong and versatile adhesive, excellent for DIY projects and repairs. It bonds well to various materials like wood, metal, ceramic, and plastic, expanding as it cures to fill gaps and create a durable, waterproof, and impact-resistant bond. If you need a reliable glue for tough jobs, Gorilla Glue is a fantastic choice.

Ever faced a project where only the strongest glue will do? That moment when a simple break promises a world of frustration? We’ve all been there! Dealing with adhesives can be tricky, and finding one that truly lives up to its promise is key to a successful DIY journey. That’s where Gorilla Glue often comes into the spotlight. People rave about its strength, but what makes it so special? Let’s dive deep into what makes Gorilla Glue a go-to for so many woodworkers and home repair heroes. We’ll uncover its strengths, its weaknesses, and how you can use it like a pro for your next project.

What Exactly is Gorilla Glue? A Beginner’s Look

At its heart, Gorilla Glue is a type of polyurethane adhesive. This might sound a bit technical, but think of it as a super-powered glue. Unlike many common glues that simply stick surfaces together, Gorilla Glue works a little differently. When it encounters moisture – even the humidity in the air – it undergoes a chemical reaction. This reaction causes the glue to expand into a foam. This expansion is a key part of its strength; it pushes into tiny crevices and imperfections on your materials, creating an incredibly strong, interlocking bond once it cures. This characteristic makes it particularly effective for bonding porous materials like wood, as well as many other surfaces.

The Magic Behind the Bond: How it Works

The science behind Gorilla Glue’s impressive hold is fascinating. Its polyurethane nature means it reacts with a small amount of water to create a strong, rigid structure. Here’s a simplified breakdown:

- Moisture Activation: A tiny bit of moisture is all it needs. This can come from the air, or you might need to lightly dampen one of the surfaces you’re joining, depending on the material.

- Expansion: As the glue cures, it expands. This is why it’s often called “the expander glue.” This expansion helps it fill gaps and create a more robust connection.

- Curing: Over time, the glue hardens, creating a permanent, super-strong bond. This process usually takes several hours, with its full strength developing over a day or two.

- Waterproof and Durable: Once cured, Gorilla Glue is known for its resistance to water, heat, and impact, making it ideal for both indoor and outdoor applications.

This unique expansion process is what sets it apart. While it means you need to be a bit careful with application (less is often more!), it also guarantees a bond that can withstand a lot more stress than most common household glues.

Gorilla Glue: The Good, The Bad, and The Strong

Like any tool in your workshop, Gorilla Glue has its strengths and weaknesses. Knowing these will help you decide if it’s the right adhesive for your specific task.

What Makes Gorilla Glue So Good? (The Pros)

Let’s start with the impressive reasons why people choose Gorilla Glue:

- Unmatched Strength: This is its superpower. Gorilla Glue creates bonds that are often stronger than the materials themselves, making it perfect for structural repairs and projects demanding high durability.

- Incredible Versatility: It adheres to a wide range of materials, including wood, stone, metal, ceramic, foam, glass, and most plastics. This makes it a true multi-purpose adhesive for various DIY needs.

- Waterproof and Weatherproof: Its cured bond can withstand water, salt water, and extreme temperatures, making it suitable for outdoor furniture, boat repairs, or anything exposed to the elements.

- Fills Gaps: The expanding foam nature means it can effectively fill uneven surfaces and small gaps, creating a solid connection where other glues might fail. Read more about ideal gap-filling adhesives on the [Forest Products Journal].

- Impact Resistance: The cured glue is tough and can absorb shocks and impacts, which is crucial for items that might be dropped or experience vibration.

- Long Shelf Life: When stored properly (cool, dry place), Gorilla Glue has a good shelf life, ensuring it’s ready when you need it.

Where Gorilla Glue Might Fall Short (The Cons)

No glue is perfect, and understanding Gorilla Glue’s limitations is just as important:

- Expansion Mess: The biggest drawback is its tendency to expand. If you use too much, or don’t clamp properly, it can ooze out and create a messy, unsightly foam that’s difficult to clean up once cured.

- Difficult Cleanup: Wet Gorilla Glue wipes up relatively easily, but once it cures and hardens, it’s very hard to remove. Careful application and immediate cleanup of any squeeze-out are essential.

- Longer Cure Time: While it starts to set relatively quickly, it takes 24 hours for full strength. This means projects may need to be held in place with clamps for an extended period.

- Not for All Plastics: While it works on most plastics, it’s not recommended for polyethylene (like milk jugs) or polypropylene, as it won’t bond well to these waxy surfaces. Always test first!

- Requires Moisture: It needs some moisture to cure. In extremely dry environments, curing might be slower, or you might need to lightly mist one surface with water.

- Appearance: The cured glue is typically a tan or light brown color and can be somewhat rubbery. This might not be ideal for projects where a clear or seamless finish is critical.

Gorilla Glue Varieties: Which One Do You Need?

Gorilla Glue isn’t just one product! They offer a range of specialized glues, each designed for specific tasks. Understanding these can help you pick the perfect one for your DIY needs.

Original Gorilla Glue

This is the classic, the one that started it all. It’s the thick, expanding polyurethane glue known for its incredible strength and versatility across a wide range of materials. Ideal for large projects, outdoor repairs, and situations where maximum strength is needed.

Gorilla Wood Glue

Specifically formulated for woodworking, this glue offers excellent strength and a faster, more controlled set than the original. It cures in a natural color, making it great for visible joints. It’s also weather-resistant, making it suitable for outdoor wood projects. For more on wood adhesives, check out resources from the Building Science Corporation.

Gorilla Super Glue

For quick fixes, Gorilla Super Glue (cyanoacrylate) provides an extremely fast, strong bond on non-porous surfaces like ceramics, some plastics, and metals. It doesn’t expand, making it cleaner to use for small, precise repairs where a tight bond is needed instantly.

Gorilla Construction Adhesive

This is your heavy-duty go-to for building and remodeling. It’s a flexible, gap-filling adhesive designed to bond wood, metal, brick, ceramic, and more. It’s great for projects like attaching molding, subflooring, or other building materials where significant strength and flexibility are required.

Gorilla Clear Glue

If you need a strong bond that’s also visually appealing, Gorilla Clear Glue is the answer. It works on various surfaces, dries clear, and is water-resistant but doesn’t have the same extreme expansion as the original. It’s a good choice for crafts, repairs where appearance matters, and projects involving clear materials or light-colored wood.

How Good is Gorilla Glue: A Comparison Table

To help you visualize the differences, here’s a quick comparison of some popular Gorilla Glue types:

| Feature | Original Gorilla Glue | Gorilla Wood Glue | Gorilla Super Glue | Gorilla Construction Adhesive |

|---|---|---|---|---|

| Primary Use | Heavy-duty, all-purpose, gap-filling | Wood projects, furniture, cabinets | Quick fixes, small repairs, ceramics, plastics | Building, remodeling, heavy-duty projects |

| Key Characteristic | Expands significantly, extremely strong | Strong wood bond, natural color, weather-resistant | Fast-set, no expansion, precise application | Flexible, high strength, gap-filling, weather-resistant |

| Materials Bonded | Wood, stone, metal, ceramic, foam, glass, concrete, leather, fabric, most plastics | Wood (hard & soft) | Ceramics, china, metal, some plastics, paper, leather | Wood, metal, brick, ceramic, stone, drywall, concrete |

| Water Resistance | Excellent (waterproof) | Yes (weather-resistant) | No (not water-resistant) | Excellent (waterproof) |

| Expansion on Cure | High | Low | None | Low |

| Cleanup Challenge (Cured) | Very High | Moderate | High | High |

How to Use Gorilla Glue Effectively: A Step-by-Step Guide

Using Gorilla Glue, especially the original formula, requires a little technique to get the best results and avoid a sticky mess. Follow these steps for a strong, clean bond:

Step 1: Preparation is Key

- Clean Surfaces: Ensure the surfaces you’re bonding are free from dirt, dust, oil, grease, and any loose debris. A clean surface ensures maximum adhesion. For wood, sanding lightly can help create a better profile for the glue to grip.

- Gather Your Tools: You’ll need your chosen Gorilla Glue, clamps (essential for most jobs!), a damp cloth or paper towel for cleanup, and possibly a small brush or applicator if you’re using the original formula.

- Work Area: Protect your work surface with newspaper or drop cloths, as Gorilla Glue can be tricky to remove if it spills.

Step 2: Apply the Glue (Less is More!)

- Original Gorilla Glue: If working with very dry materials (like some woods), lightly dampen one of the surfaces with a fine mist of water. This helps the glue start expanding. Then, apply a small amount of glue to just one surface. Remember, it will expand considerably, so a thin bead or a few small dots is usually enough. Over-application is the number one cause of a messy job.

- Other Gorilla Glues: For Super Glue or Wood Glue, apply a thin, even layer to one surface. For Construction Adhesive, apply in a bead along the joint or as a series of dots.

Step 3: Join the Surfaces

- Bring the two surfaces together as quickly as possible after applying the glue.

- Press them firmly into place.

Step 4: Clamp It!

This is a critical step, especially for the original Gorilla Glue. Clamps hold the pieces securely while the glue cures and also help to control the expansion slightly by redistributing the pressure. Make sure your clamps are positioned so they don’t get glued to your project!

How long to clamp: Check the product instructions, but for the original Gorilla Glue, clamping for at least a few hours is often recommended. Other types may require shorter clamping times.

Step 5: Clean Up Any Squeeze-Out IMMEDIATELY

As soon as you’ve clamped your pieces, use a damp cloth or paper towel to wipe away any excess glue that has squeezed out from the edges. If you wait until the glue has started to cure, you’ll be in for a tough cleanup job.

Step 6: Allow to Cure Fully

Gorilla Glue requires time to reach its full strength. For the original formula, this is typically 24 hours. While it might feel set sooner, give it the full cure time for the strongest possible bond. For other types, consult the product label, as cure times can vary significantly.

Tips for Perfect Gorilla Glue Application

Here are some pro tips to make your Gorilla Glue projects even more successful:

- Ventilation: Always use Gorilla Glue in a well-ventilated area. The vapors can be irritating.

- Wear Gloves: Gorilla Glue can stick to skin very quickly and is difficult to remove. Always wear disposable gloves during application and cleanup.

- Test First: If you’re unsure how Gorilla Glue will react with a specific material, test it on a scrap piece first. This is especially important for plastics.

- Use the Right Amount: This bears repeating – less is more with Gorilla Glue. Start with a small amount and learn how much you need for your specific application.

- Dampen Appropriately: For the original Gorilla Glue, understand when to dampen. Too much water can cause excessive foaming. For most wood applications, a light mist is sufficient.

- Consider Clear Tape: For very light-duty clamping or to hold small pieces in place while the glue sets, sometimes strong packing tape can be useful in conjunction with light clamping or pressure.

- Storage: Keep the cap on tightly and store the glue in a cool, dry place. Refrigeration can extend shelf life further.

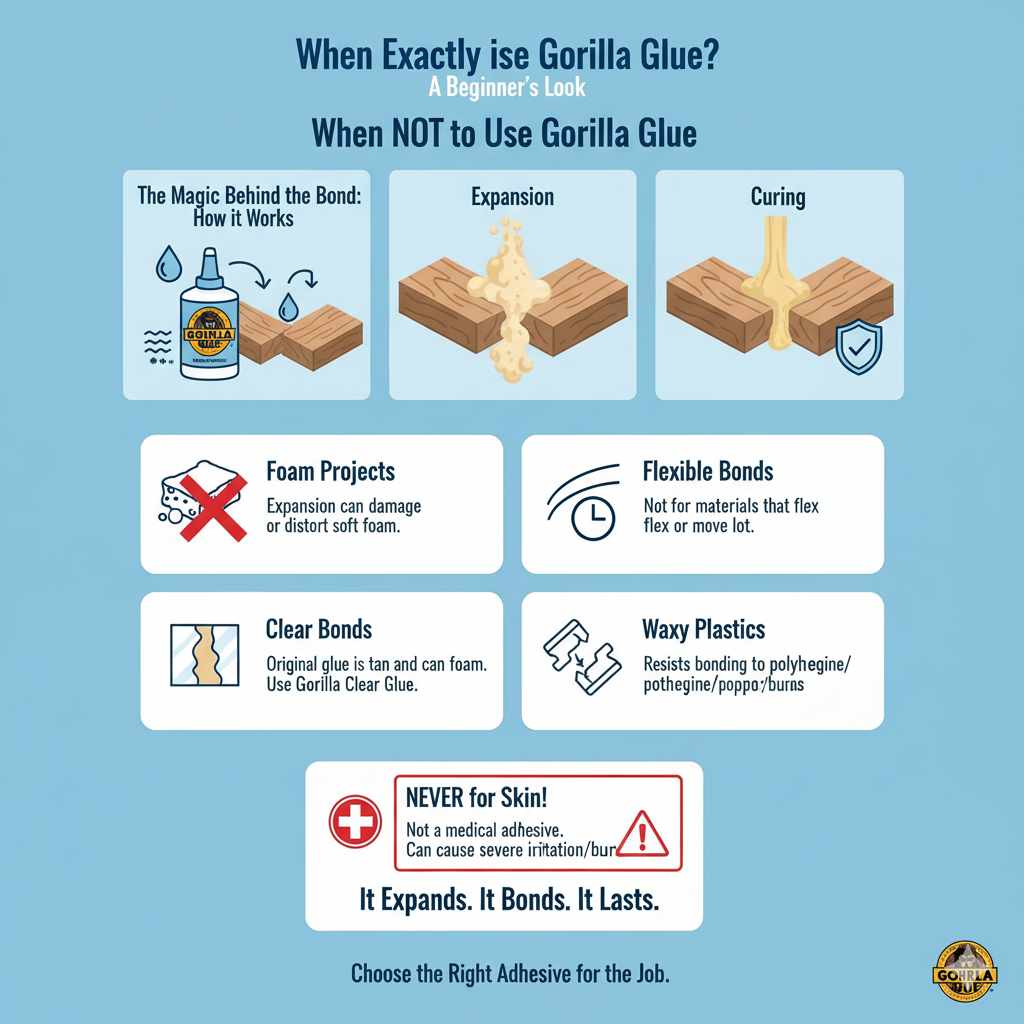

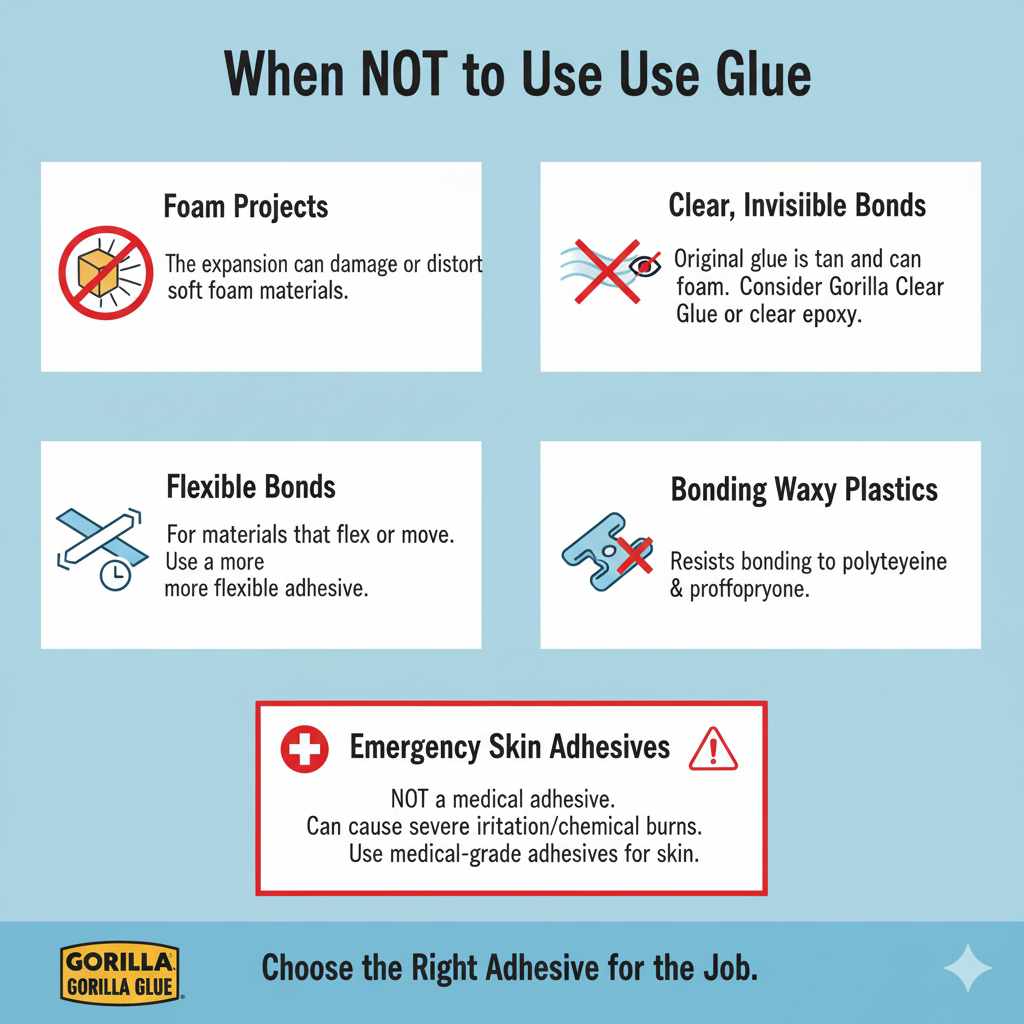

When NOT to Use Gorilla Glue

While incredibly strong, Gorilla Glue isn’t the best choice for every scenario:

- Foam Projects: The expansion can damage or distort soft foam materials.

- When a Flexible Bond is Needed: For materials that flex or move a lot, a more flexible adhesive like a silicone or specific construction adhesive might be better.

- Clear, Invisible Bonds: If the bond line absolutely must be invisible or transparent, the original Gorilla Glue’s tan color and potential for foam strings might not suffice. Consider Gorilla Clear Glue or a specialized clear epoxy.

- Bonding Waxy Plastics: As mentioned, polyethylene and polypropylene resist Gorilla Glue.

- Emergency Skin Adhesives: While some DIYers might consider this out of desperation, Gorilla Glue is NOT a medical adhesive. It can cause severe irritation or chemical burns. Always use products specifically designed for skin. For more on safe bonding practices, explore OSHA’s guidelines on workplace safety and materials.

Frequently Asked Questions about Gorilla Glue

Q1: How do I remove uncured Gorilla Glue?

A: Wipe away uncured glue immediately with a dry cloth, then use a damp cloth. For stubborn spots, rubbing alcohol or mineral spirits can sometimes help, but test in an inconspicuous area first.

Q2: How do I remove cured Gorilla Glue?

A: Cured Gorilla Glue is very difficult to remove. You can try to carefully scrape it away with a razor blade or putty knife, or mechanically abrade it (sand it down). For some surfaces, strong solvents might work, but always test first and be aware that they can also damage the surrounding material.

Q3: Can I use Gorilla Glue for repairing broken dishes or ceramics?

A: Yes, but the original Gorilla Glue is not ideal because its expansion can be messy and the tan color might be noticeable. Gorilla Super Glue or Gorilla Clear Glue are much better choices for ceramic repairs, offering a fast, strong, and less conspicuous bond.

Q4: Is there a difference between Gorilla Glue and Super Glue?

A: Yes! Gorilla Glue (the original) is a polyurethane adhesive that expands and requires moisture to cure, creating a very strong, durable bond over a longer curing time. Super Glue (cyanoacrylate) cures instantly with no expansion, offering a quick bond but is generally more brittle and not waterproof.

Q5: Will Gorilla Glue hold metal to wood?

A: Absolutely. The original Gorilla Glue, Gorilla Wood Glue, and Gorilla Construction Adhesive all bond well to both metal and wood, creating a very strong connection.

Q6: How much will Gorilla Glue expand?

A: The original Gorilla Glue expands to about 3-4 times its original volume. This is why it’s crucial to use it sparingly and be prepared for squeeze-out.