The lumber calculator is a tool used to determine the quantity of lumber required for a project. It accurately calculates the amount of lumber needed based on specific measurements and dimensions provided.

Are you planning a woodworking or construction project and need to know how much lumber you’ll require? If so, the lumber calculator is the perfect tool for you. This handy calculator accurately determines the amount of lumber needed based on the dimensions and measurements you provide.

By inputting the length, width, and height of the project, the calculator quickly calculates the quantity of lumber required. This saves you valuable time and prevents you from purchasing too much or too little lumber for your project. Whether you’re building a deck, a shed, or any other woodworking project, the lumber calculator is an essential tool to ensure an efficient and cost-effective construction process.

The Importance Of Accurate Material Estimation

Accurately estimating the amount of lumber needed for a construction project is crucial for its success. Running out of materials can cause delays and frustration, while buying too much lumber can result in wastage and unnecessary expenses. That’s where a reliable lumber calculator comes in handy. By providing precise calculations, it helps you avoid wastage and cost overruns, while ensuring you have sufficient materials for the project. Let’s dive deeper into the importance of accurate material estimation using a lumber calculator.

Avoiding Wastage And Cost Overruns

Wastage is an unfortunate but common occurrence in construction projects. Without accurate material estimation, you may end up ordering more lumber than necessary, leading to wastage. Additionally, purchasing extra materials that are not required inflates the project’s costs, resulting in cost overruns. Using a lumber calculator removes the guesswork and minimizes the risk of wastage and cost overruns. By providing precise measurements, it ensures you order just the right amount of lumber needed for your project.

Ensuring Sufficient Materials For The Project

Running out of lumber midway through a construction project can bring your progress to a halt. It not only creates delays but also leads to frustration and added expenses. Accurate material estimation using a lumber calculator helps prevent this scenario. By calculating the exact amount of lumber required, you can ensure you have sufficient materials to complete the project without interruptions. It allows you to plan ahead, order the necessary materials, and keep the project running smoothly without any unexpected interruptions.

In conclusion, accurate material estimation is essential for any construction project. Using a lumber calculator eliminates wastage, avoids cost overruns, and ensures there are sufficient materials to complete the project. By investing some time to accurately estimate your lumber needs, you can save time, money, and avoid frustration in the long run.

.png)

Credit: buildbook.co

Understanding Lumber Calculations

When it comes to working with lumber, it’s important to have a clear understanding of how to calculate the amount of material you need for a project. Whether you’re building a bookshelf or a deck, knowing the right measurements can help you avoid costly mistakes and ensure you have enough lumber to get the job done.

Types Of Lumber Cuts

Before diving into lumber calculations, let’s first familiarize ourselves with the different types of lumber cuts. Lumber typically comes in four main cuts, each with its distinct characteristics:

- Plain-sawn lumber: Also known as flat sawn, this cut provides the most affordable option. It has a traditional appearance with cathedral-like grain patterns.

- Quarter-sawn lumber: This cut is known for its stability and straight grain pattern. It is less prone to warping and often used in premium applications.

- Rift-sawn lumber: Rift-sawn boards have a linear grain pattern and are less likely to cup or twist. They are commonly used for fine furniture and cabinetry.

- Live-edge lumber: Live-edge boards retain the natural shape of the tree, including the bark on one or both edges. They add a unique, rustic charm to any project.

Common Measurement Units For Lumber

Now that we know the different types of lumber cuts, let’s explore the common measurement units used in the lumber industry:

| Unit of Measurement | Description |

|---|---|

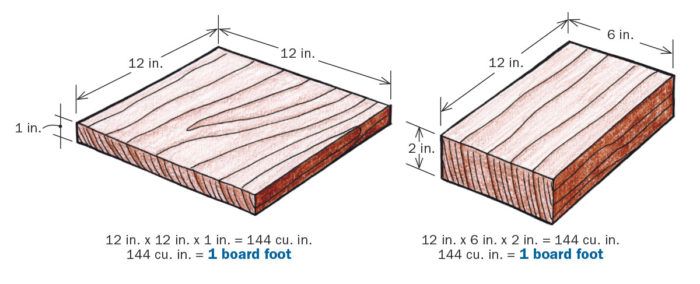

| Board Feet (BDFT) | A board foot is equal to one square foot with a thickness of one inch. It is the most widely used unit of measurement for lumber. |

| Linear Feet (LF) | Linear feet measures the length of the lumber in feet. It is commonly used when purchasing trim or molding. |

| Square Feet (SF) | Square feet measures the surface area of the lumber in square feet. It is often used in flooring projects. |

| Piece Count | When dealing with smaller projects or irregularly shaped pieces, the piece count is used to determine how many individual boards are needed. |

By understanding the different types of lumber cuts and the commonly used measurement units, you’ll have the knowledge required to accurately calculate how much lumber you need for your next project. Whether you’re a woodworking enthusiast or a seasoned carpenter, this information will help you make informed decisions and create beautiful, long-lasting creations.

Factors Impacting Lumber Calculation

Project Design And Complexity

The design and complexity of your project have a significant impact on the amount of lumber needed. Intricate designs or custom specifications may require additional cutting and shaping of the lumber, resulting in more waste and potentially a higher overall lumber requirement.

Accounting For Waste And Imperfections

When calculating lumber needs, it’s crucial to account for waste and imperfections. Purchasing extra lumber to accommodate for cutting errors, warped pieces, or knots can ensure that the project can be completed without delays or compromises in quality. Additionally, accounting for waste and imperfections helps minimize the risk of running short on materials.

Introduction To How Much Lumber Calculator

Calculating the right amount of lumber needed for a project is essential for both DIY enthusiasts and professionals. The How Much Lumber Calculator is a valuable tool that simplifies this process, enabling users to accurately estimate the quantity of lumber required for their projects.

Features And Functionality

- Input dimensions of the project

- Automatic calculation of lumber quantity

- Customizable settings for different types of lumber

- Visual representation of the project layout

Advantages For Diy Enthusiasts And Professionals

- Saves time and effort in manual calculations

- Reduces wastage by providing precise measurements

- Helps in budgeting by estimating lumber costs accurately

- Enhances project planning and organization

Utilizing The How Much Lumber Calculator

Construction projects can become overwhelming when guessing the amount of lumber needed. That’s where the How Much Lumber Calculator comes into play! By understanding how to properly utilize this tool, you can streamline your project planning.

Entering Project Specifications

Simply input your project details into the calculator to get accurate estimates.

- Start by entering the dimensions of your project, such as length, width, and height.

- Specify the type of lumber needed, whether it’s softwood, hardwood, or composite.

- Enter any additional details, like cutting angles or waste allowance, to refine the results further.

Interpreting The Calculated Results

Once the calculator processes your input, the calculated results are presented for your project.

- Review the total board feet required for your project.

- Check the breakdown of lumber pieces needed, like boards, studs, or joists.

- Ensure to account for any additional materials like fasteners or finishing products for a comprehensive project overview.

Credit: www.finewoodworking.com

Best Practices For Material Estimation

Accurately estimating the amount of lumber needed for a project is essential to avoid material shortages or excess, as both can lead to unnecessary expenses or project delays. Utilizing a lumber calculator can streamline this process, but it’s crucial to incorporate best practices for material estimation to ensure project success.

Double-checking The Calculations

Ensure that all input measurements and calculations in the lumber calculator are accurate. Double-checking the numbers can help you catch any potential errors before ordering or purchasing the lumber. Inaccurate calculations can result in either a surplus or a shortage of materials, leading to additional costs.

Considering Contingencies And Additional Allowances

It’s important to consider contingencies and include additional allowances when estimating lumber. Factors such as waste due to trimming, mistakes, or unexpected changes in the project scope should be taken into account. Including a buffer for such contingencies can help prevent material shortages and reduce the likelihood of project delays.

Common Errors In Lumber Estimation

Estimating lumber amounts can be challenging due to common errors. Utilizing a reliable how much lumber calculator helps in accurate estimation. These errors can lead to material shortages or excess, affecting project timelines and budget.

Accurately estimating the amount of lumber needed for a project is essential to ensure a smooth construction process. However, many DIY enthusiasts and even professionals often make common errors that can lead to wasted resources and increased costs. To help you avoid these pitfalls, we have highlighted two crucial factors that are frequently overlooked when measuring the required lumber: underestimating wastage and overlooking special project requirements.

Underestimating Wastage

One of the most significant errors in lumber estimation is underestimating the amount of wastage that typically occurs during construction. Whether it’s due to inaccurate cuts, flaws in the wood, or unexpected changes in project design, wastage is an inevitable part of any woodworking project. Ignoring this aspect can result in frustration and delays, as you may find yourself scrambling to purchase additional lumber at the last minute.

It is advisable to factor in an additional 10% to 15% of lumber to account for wastage. This extra allowance ensures that you have enough materials to address any unexpected contingencies. By considering potential wastage upfront, you can better plan your budget, reduce stress, and maintain a smooth workflow. Additionally, it allows you to keep your project on track, even if you encounter sudden changes or errors along the way.

Overlooking Special Project Requirements

Another common error when estimating lumber needs is overlooking special project requirements. Each construction project comes with unique specifications, such as the need for specialty cuts, additional support beams, or intricate design elements. Failing to incorporate these special requirements into your lumber calculations can lead to inadequate materials and a compromised project outcome.

To avoid this issue, carefully review the plans and project specifications before calculating the necessary lumber. Take note of any specific requirements that may deviate from standard measurements or materials. Consider the different project stages and identify any non-standard elements that may require additional support or customized lumber dimensions.

A helpful tip is to create a detailed checklist of all the special project requirements and cross-reference it with your lumber calculations. This checklist will serve as a reliable reference throughout the construction process, ensuring that you have the correct materials on hand when you need them, and minimizing the risk of unexpected surprises or costly delays.

Improving Accuracy With Advanced Techniques

When it comes to estimating lumber quantities for your projects, accuracy is key. Advanced techniques can greatly enhance the precision of your calculations, saving you time and money in the long run. In this article, we will explore two powerful methods that can help you improve the accuracy of your lumber calculations.

Using Digital Models And Software

In today’s digital age, leveraging technology can revolutionize your lumber estimating process. By utilizing digital models and software, you can take advantage of powerful features that greatly enhance accuracy.

With the help of digital models, you can create a virtual representation of your project, allowing you to visualize the dimensions and layout in a realistic 3D environment. This not only gives you a clearer understanding of the materials you’ll need but also helps identify any potential issues or discrepancies before the construction phase begins.

Moreover, by using specialized software specifically designed for lumber calculations, you can streamline the process and eliminate manual errors. These tools often come equipped with comprehensive databases of lumber sizes, types, and prices, making it easier to select the right materials for your project.

By inputting the necessary project dimensions into the software, it can then generate accurate material quantities and even create detailed cutting lists. This precision allows for better material planning, reducing waste and optimizing your budget.

Applying Industry-standard Formulas

Another effective technique for improving accuracy is by applying industry-standard formulas. These formulas have been developed and refined over time to ensure reliable and consistent results.

One such formula is the “Board Foot” calculation, which measures lumber based on its volume. By multiplying the width, thickness, and length of a piece of lumber and dividing by 144, you can determine the number of board feet it contains. This universal unit of measurement enables easy comparison and estimation of lumber quantities.

Additionally, industry-standard formulas account for common factors such as trimming, waste, and spacing. By factoring these variables into your calculations, you can ensure you have enough materials for the job while minimizing excess waste.

When implementing industry-standard formulas, it’s important to stay up to date with any changes or updates in the industry. Building codes, regulations, and standards can evolve over time, and staying informed will help you maintain accuracy in your estimates.

In conclusion, improving accuracy in lumber calculations is essential for any construction or woodworking project. By using digital models and software, as well as applying industry-standard formulas, you can enhance precision, save time, and optimize your materials. Embracing these advanced techniques will not only lead to more successful projects but also improve your overall efficiency as a builder or craftsman.

Credit: www.amazon.com

Frequently Asked Questions Of How Much Lumber Calculator

What Is A Lumber Calculator And How Does It Work?

A lumber calculator is a tool used to estimate the amount of lumber needed for a project based on specific measurements. It helps users calculate the quantity of wood required, minimizing waste and ensuring accurate planning.

Why Should I Use A Lumber Calculator For My Projects?

Using a lumber calculator enhances project efficiency by accurately determining the amount of wood needed. It prevents over or underestimation, saving time, money and reducing material waste.

How Can A Lumber Calculator Help Me Save On Costs?

By precisely calculating the required lumber amount, a lumber calculator prevents unnecessary purchases, reducing expenses. It optimizes project planning, leading to cost-efficiency and budget control.

Conclusion

In the age of DIY projects and home improvement, a lumber calculator is an invaluable tool. By using accurate measurements, it helps you estimate the amount of lumber needed for various projects. With the convenience and efficiency it offers, it’s no wonder that it has become a must-have for any DIY enthusiast.

Make sure to bookmark our lumber calculator for all your future projects.