To cut balsa wood, use a sharp knife or a fine-toothed saw in a slow and steady motion. Balsa wood, known for its lightweight and easy-to-cut nature, can be easily shaped and trimmed using simple tools.

Balsa wood, renowned for its lightweight and versatile properties, is a popular choice among hobbyists, crafters, and model builders. Whether you need precise cuts for architectural models or intricate designs for crafting projects, knowing how to cut balsa wood is essential.

This resilient material offers flexibility and can be easily shaped, making it ideal for various applications. While there are different cutting methods, using a sharp knife or a fine-toothed saw is the most common approach. We will explore the step-by-step process of cutting balsa wood, along with essential tips to ensure a clean and precise outcome. So let’s dive in and discover the art of cutting balsa wood effectively.

Understanding Balsa Wood

Balsa wood is easy to cut and is commonly used in various craft projects and model making. To cut balsa wood, use a sharp knife or a saw with fine teeth, and make sure to measure and mark the wood accurately before cutting to achieve clean and precise cuts.

What Is Balsa Wood?

Balsa wood is a lightweight and versatile material that is widely used in various industries, including woodworking and crafts. It is derived from the Balsa tree (Ochroma pyramidale), which is native to South America but is also cultivated in other parts of the world. Due to its unique characteristics, balsa wood has become a popular choice for both professional artisans and hobbyists.

Properties Of Balsa Wood

Balsa wood is renowned for its exceptional properties that make it an excellent material for various projects. Here are some key properties of balsa wood that you should be aware of:

– Lightweight: Balsa wood is extremely lightweight, with a density ranging from 40 to 340 kg/m³. This makes it easy to handle and work with, making it suitable for intricate designs and delicate structures.

– Softness: Another notable feature of balsa wood is its softness. It is one of the softest commercial hardwoods available, allowing for easy cutting and shaping. Its softness also makes it less prone to splitting and splintering, which is advantageous when working with delicate projects.

– Strength-to-weight ratio: Despite its lightweight nature, balsa wood exhibits impressive strength. It has one of the highest strength-to-weight ratios among all woods, making it ideal for applications where weight is a critical factor.

– Buoyancy: Balsa wood is highly buoyant due to its low density. This property makes it a preferred choice for model aircraft and boats, where buoyancy is essential for proper functioning and stability.

– Easy to work with: Balsa wood can be easily cut, carved, sanded, and shaped using simple hand tools. It is a forgiving material for beginners and allows for precise details in intricate designs.

– Versatility: Balsa wood’s versatility is one of its greatest strengths. It can be used for various applications ranging from architectural models and hobbyist projects to structural elements in bridge-building and aerospace industries.

With these essential properties, balsa wood offers endless possibilities for creativity and innovation. Whether you are a beginner or an experienced woodworker, understanding the characteristics of balsa wood is crucial when it comes to achieving the desired results in your projects. Now that you have a basic understanding of what balsa wood is and its properties, let’s delve into the specifics of cutting this remarkable material.

Tools And Materials

When it comes to cutting balsa wood, having the right tools and materials is crucial for achieving precise and clean cuts. In this section, we will discuss the essential tools as well as additional materials that will make your cutting process easier and more efficient.

Essential Tools For Cutting Balsa Wood

Cutting balsa wood requires a few basic tools that should be a part of every crafter’s toolbox. These tools are:

- Utility Knife: A sharp utility knife with a retractable blade is essential for accurate cutting. Make sure to use a fresh blade for clean cuts.

- Scalpel: A scalpel can be used for intricate and detailed cuts. It provides better control and precision compared to a utility knife.

- Flush-cutting Pliers: These pliers are useful for cutting small and delicate pieces of balsa wood without causing any damage.

- Safety Glasses: Safety should always be a priority when working with sharp tools. Wear safety glasses to protect your eyes from any flying debris.

- Cutting Mat: A self-healing cutting mat is an excellent investment as it provides a stable and safe surface for cutting balsa wood. It also protects your work surface from any scratches.

Additional Materials

In addition to the essential tools, there are a few materials that can further enhance your cutting process:

- Sandpaper: Sandpaper of varying grits is useful for smoothening the edges of the balsa wood after cutting.

- Clamps: Use clamps to secure the balsa wood piece firmly in place, ensuring stability during cutting.

- Ruler or Straight Edge: A ruler or straight edge helps in marking and guiding the cutting lines, ensuring accuracy.

- Painters Tape: Applying painters tape along the cutting line helps prevent the wood from splintering, resulting in cleaner cuts.

- Balsa Wood Strip Cutter: If you frequently work with balsa wood strips of the same width, a balsa wood strip cutter can save you time and effort by providing consistent cuts.

By using the essential tools and additional materials mentioned above, you can ensure a smooth cutting process and achieve precise and clean cuts in your balsa wood projects.

Preparation

Learn how to cut balsa wood effectively with these simple steps. Increase precision and achieve smooth edges with proper preparation techniques.

Before you begin cutting balsa wood, it’s important to properly prepare the material. With the right techniques, you can achieve clean and precise cuts for all your woodworking projects.

Measuring And Marking

To ensure accurate cuts, start by measuring and marking your balsa wood. Use a ruler or a measuring tape to determine the desired length, width, or shape of your cuts. Once you have your measurements, mark the wood with a pencil or a fine-tip marker. By marking the wood, you create a guide that will help you stay on track while cutting.

Remember to make your marks clear and visible, especially if you’re working with intricate or complex designs. This will help prevent any confusion or mistakes during the cutting process.

Securing The Wood

Securing the balsa wood is crucial to ensure it remains stable and safe during cutting. There are several methods you can use to secure the wood, depending on your preference and the tools you have available.

One common method is to use clamps to hold the wood in place. Simply position the wood on a stable surface and use clamps to firmly secure it. Make sure the clamps do not interfere with the cutting line to avoid damaging the wood or the blade.

Alternatively, you can use double-sided tape or adhesive to attach the wood to a cutting mat or a stable workbench. This method provides stability and minimizes movement while cutting. Just be cautious when removing the tape to avoid splintering or damaging the wood.

Whichever method you choose, always ensure that the wood is securely held to prevent any accidents or mistakes while cutting.

Cutting Techniques

When it comes to cutting balsa wood for various crafting or hobby projects, there are several techniques you can use. Each method has its own advantages and considerations, depending on factors such as the intricacy of the design and the level of precision required. In this blog post, we will explore the cutting techniques using a hobby knife, a laser cutter, a scroll saw, and a CNC machine.

Using A Hobby Knife

One of the most common and accessible ways to cut balsa wood is by using a hobby knife. This method is ideal for simple and small projects that don’t require intricate cuts. To cut balsa wood with a hobby knife, follow these steps:

- Begin by marking the desired cut line on the balsa wood using a ruler and a pencil.

- Hold the balsa wood firmly and position the hobby knife at the starting point of the cut line.

- Apply gentle pressure and slowly guide the knife along the marked line, making multiple light passes if necessary.

- Continue cutting until you have reached the end of the marked line, ensuring to maintain a steady and controlled motion.

- After finishing the cut, sand the edges of the balsa wood with sandpaper to smooth out any roughness.

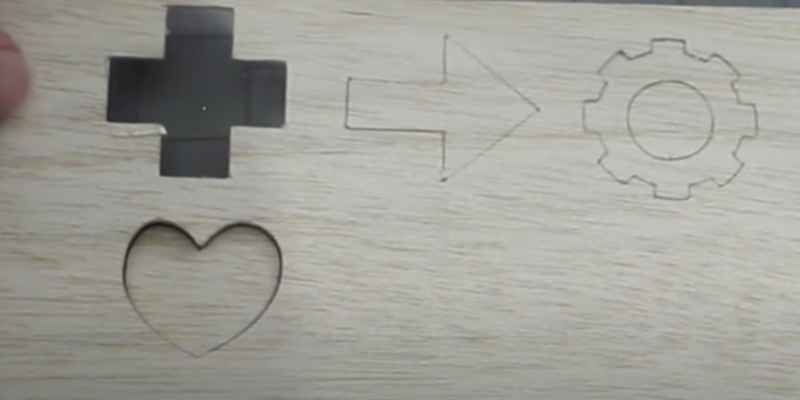

Using A Laser Cutter

If you’re looking for more precise and intricate cuts, using a laser cutter is an excellent option. Laser cutters use a concentrated beam of light to vaporize the material they come into contact with, resulting in smooth and clean cuts. Here’s how you can cut balsa wood using a laser cutter:

- Prepare your design on a computer software and save it in a format compatible with your laser cutter.

- Secure the balsa wood onto the cutting bed of the laser cutter, ensuring that it is flat and stable.

- Set the laser cutter to the appropriate power and speed settings based on the thickness of the balsa wood.

- Upload your design file to the laser cutter and align it with the balsa wood.

- Activate the laser cutter and let it precisely cut out your design, making sure to monitor the process to ensure accuracy.

- Once the cutting is complete, carefully remove the balsa wood from the cutting bed, and you’ll have a perfectly cut piece ready for further refinement.

Using A Scroll Saw

When dealing with thicker balsa wood or projects that require curved or intricate cuts, a scroll saw can be your best tool. This powered saw features thin blades that move up and down rapidly, allowing for detailed cutting. Follow these steps to achieve precise cuts with a scroll saw:

- Secure the balsa wood onto the table or workbench, making sure it won’t move or vibrate during the cutting process.

- Position the scroll saw blade near the edge of the balsa wood, aligning it with the marked cut line.

- Switch on the scroll saw and gently guide the wood towards the blade, moving it along the marked line.

- Continue cutting, allowing the saw to do most of the work, and maintain a steady pace to ensure accuracy.

- Once the cut is complete, turn off the scroll saw and carefully remove the balsa wood piece.

- Inspect the cut edge and use sandpaper to smoothen any rough areas.

Using A Cnc Machine

For intricate designs and complex projects, a CNC (Computer Numerical Control) machine provides unmatched precision and efficiency. CNC machines are programmed to follow a specific design, and they use rotating cutting tools to achieve highly detailed cuts in balsa wood. Here’s how you can cut balsa wood using a CNC machine:

- Create or download a digital design file compatible with the CNC machine software.

- Secure the balsa wood onto the CNC machine’s cutting bed using clamps or other suitable methods.

- Import the design file into the CNC machine software and ensure proper alignment and positioning.

- Set the necessary cutting parameters such as depth and speed.

- Activate the CNC machine and allow it to meticulously cut out your design, while closely monitoring the process.

- Once the cutting is complete, remove the balsa wood from the machine, and you’ll have a precisely cut piece ready for use or further refinement.

Finishing And Safety Tips

When it comes to cutting balsa wood, it’s not just about getting the right tools and techniques. Finishing and safety are equally important aspects to consider. In this section, we’ll explore some essential tips for sanding and smoothing the wood, applying a finish, and taking necessary safety precautions to ensure a successful and protected woodworking experience.

Sanding And Smoothing

Sanding and smoothing balsa wood is a crucial step in achieving a polished and professional look for your project. Here are some tips to help you get the best results:

- Start with a coarse-grit sandpaper, like 80 or 100 grit, to remove any rough surfaces or imperfections.

- Gradually progress to finer grits, such as 220 or 320, to achieve a smoother finish. Remember to sand parallel to the grain to avoid damaging the wood.

- Consider using a sanding block or sponge to maintain consistent pressure and prevent uneven sanding.

- After sanding, wipe away any dust using a clean, dry cloth or a tack cloth specifically designed to remove debris.

- Inspect the wood for any remaining imperfections and repeat the sanding process if necessary.

Applying A Finish

Applying a finish to balsa wood not only enhances its appearance but also protects it from moisture and wear. Here’s how to apply a finish effectively:

- Clean the wood surface thoroughly, ensuring it is free from any dust or debris.

- Choose a suitable finish for balsa wood, such as a clear varnish, lacquer, or polyurethane. Consider testing a small area beforehand to ensure compatibility.

- Apply the finish in thin, even coats using a brush, sponge, or cloth. Allow each coat to dry completely before applying the next.

- After the final coat, lightly sand the surface with fine-grit sandpaper to achieve a smooth and polished finish.

- Wipe away any dust and debris with a clean cloth, and your balsa wood project is ready to shine!

Safety Precautions

Woodworking should always be conducted with safety in mind. Here are some essential safety precautions to follow when cutting balsa wood:

- Wear protective goggles to shield your eyes from flying debris and a dust mask to protect your respiratory system from fine particles.

- Use a sharp blade or cutting tool to minimize the risk of accidents. Dull blades can cause the wood to splinter or slip.

- Remember to work in a well-ventilated area to prevent inhaling harmful fumes from adhesives or finishes.

- Ensure your work surface is stable and secure to prevent the wood from shifting during cutting.

- Keep your fingers and hands clear of the cutting path, and always use clamps or a vice to hold the wood securely.

By following these simple tips and guidelines, you can achieve excellent results when cutting balsa wood while ensuring your safety throughout the process.

Frequently Asked Questions On How To Cut Balsa Wood

Can You Use Scissors To Cut Balsa Wood?

Yes, you can use scissors to cut balsa wood. Scissors provide a precise and easy cutting tool for balsa wood projects. Remember to apply gentle pressure and have a sharp pair of scissors for the best results.

Is Balsa Wood Hard To Cut?

Cutting balsa wood is easy due to its softness, making it a popular choice for crafting and model building. Its low density and fine grain allow for clean and precise cuts.

Can You Cut Balsa Wood With An Exacto Knife?

Yes, an Exacto knife can be used to cut balsa wood. It is important to handle the knife with care to ensure accurate and precise cuts.

Can I Cut Balsa Wood With Cricut?

Yes, you can cut balsa wood with Cricut.

Conclusion

Cutting balsa wood is a straightforward process that can be accomplished with a few simple tools and techniques. By following the steps outlined in this blog post, you can achieve clean, precise cuts in your balsa wood projects. Remember to use the right tools, take safety precautions, and practice your cutting skills.

With a little practice, you’ll be able to create beautiful creations with balsa wood. Happy cutting!