How to Fix Warped Plywood: Quick & Easy Solutions

To fix warped plywood, you can use moisture to relax the fibers and then apply weight to flatten it. Alternatively, consider cutting it into smaller pieces and reassembling them properly.

Warped plywood can be a frustrating issue for DIY enthusiasts and professionals alike. This common problem often arises due to moisture exposure or improper storage. Warping can lead to uneven surfaces, making projects challenging. Fortunately, several methods can restore plywood to its original shape.

Understanding how to address warping effectively can save time and materials. This guide will explore practical techniques and tips for fixing warped plywood, ensuring your projects remain on track. Whether you’re a seasoned woodworker or a casual DIYer, these solutions will help you achieve flat, usable plywood once again.

Introduction To Warped Plywood

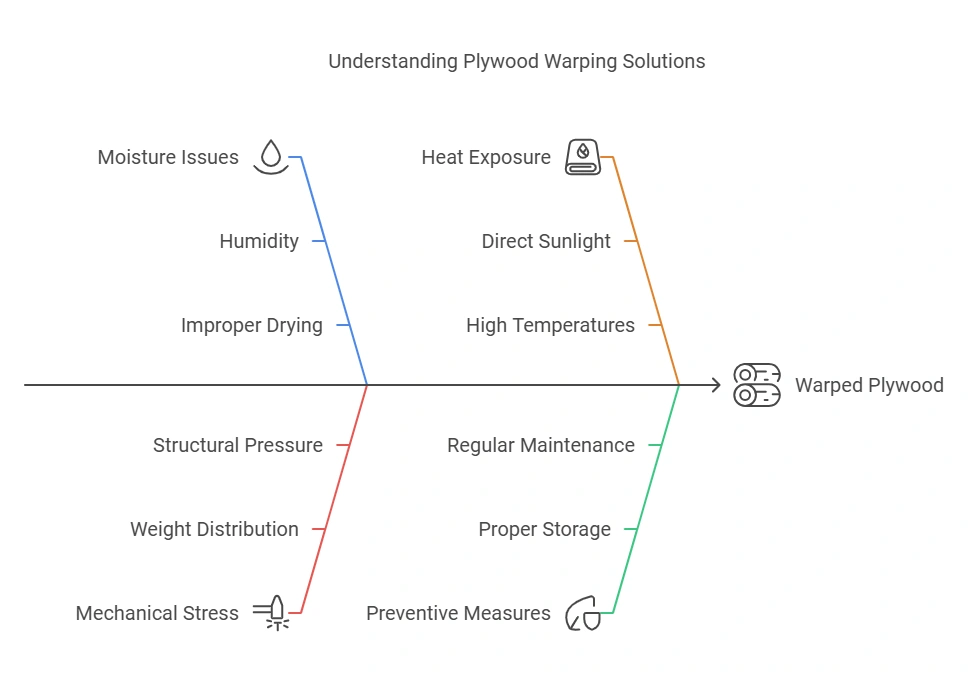

Warped plywood is a common issue in construction. It can happen for many reasons. One major cause is moisture. Plywood absorbs water, causing it to swell and twist. Another reason is temperature changes. Extreme heat or cold can stress the wood.

Improper storage also leads to warping. Stacking sheets incorrectly may create pressure points. Using low-quality plywood can increase the chances of warping too. Age plays a role; older plywood is more likely to warp.

The impact on construction projects can be significant. Warped plywood can cause structural issues in buildings. It may lead to gaps and uneven surfaces. This can result in more costs for repairs.

Identifying Types Of Warpage

Warped plywood can show different types of warpage. Cupping happens when the edges rise while the center dips. This creates a concave shape. Bowing occurs when plywood bends in a curve. It looks like a bow that can be hard to fix.

Twisting is another issue. This happens when corners rotate in different directions. Kinking causes sharp bends in the wood. Both problems make plywood difficult to use. Identifying these types helps in choosing the right fix.

Tools And Materials Needed

Fixing warped plywood requires specific tools and materials. Here are the essential equipment items you need:

- Clamps – To hold the plywood flat.

- Heat Gun – To apply heat gently.

- Wood Glue – For securing the wood.

- Sandpaper – To smooth rough edges.

- Measuring Tape – For accurate measurements.

- Cutting Tool – To trim the plywood if needed.

Safety is very important. Use gloves and goggles to protect yourself. Ensure good ventilation when using tools. Always follow the manufacturer’s instructions for each tool.

Moisture Adjustment Technique

To fix warped plywood, start by controlling humidity levels. Wood absorbs moisture from the air. Keeping the plywood in a balanced environment helps prevent warping.

Use a hygrometer to check humidity. Aim for a range of 30% to 50% humidity. Place the plywood in a room with stable conditions.

Applying moisture evenly is crucial. Use a spray bottle to mist the wood lightly. This helps the plywood to expand evenly.

Ensure the moisture is not too much. Excess water can lead to more warping. After misting, let it sit in a well-ventilated area.

| Humidity Level | Effect on Plywood |

|---|---|

| Below 30% | Wood dries out and can crack |

| 30% – 50% | Ideal for balanced moisture |

| Above 50% | Wood absorbs too much moisture |

Mechanical Correction Methods

Using weights and clamps is an effective way to fix warped plywood. Place the warped plywood on a flat surface. Add heavy weights on the warped areas. This helps to flatten the wood over time. Use clamps to hold the plywood in place. Make sure the clamps apply even pressure.

For temporary framing solutions, build a simple frame. Use straight wood pieces to create a rectangle. Attach the warped plywood to the frame using screws. This keeps the plywood flat while you work. Check the frame regularly to ensure it stays straight. This method works well for small projects.

Heat Treatment Process

To fix warped plywood, using direct heat is effective. This method helps straighten the wood. A heat gun or hair dryer works well for this task. Keep the heat source moving to avoid burns.

Always wear heat-resistant gloves for safety. It protects hands from burns. Work in a well-ventilated area to prevent inhaling fumes. Make sure the plywood is dry before applying heat. Wet wood can cause more warping.

After applying heat, place weights on the plywood. This helps to keep it flat as it cools. Check the plywood regularly to see if it is straightening. Repeat the process if necessary.

Alternative Fixes For Minor Warps

Fixing minor warps in plywood can be simple. Adhesives work well for quick fixes. Use a strong glue that dries clear. Apply the glue to the warped area. Press the wood flat and let it dry. This can help restore its shape.

Reinforcing with backing boards is another effective method. Cut a piece of plywood to match the warped area. Secure it to the back with screws or glue. This adds strength and support to the warped board. It can help prevent future warps.

Preventive Measures For Future

Proper storage and handling of plywood can greatly reduce warping. Keep plywood flat and elevated off the ground. Use supports to prevent bending or twisting.

Store plywood in a dry area away from moisture. Use a dehumidifier if necessary. Cover sheets with a tarpaulin to protect from dust and moisture.

Choosing quality plywood is essential. Look for sheets with a smooth surface and no visible defects. Grade matters; higher grades are less likely to warp.

Consider plywood thickness. Thicker sheets usually resist warping better than thinner ones. Buy from reputable suppliers to ensure quality materials.

When To Call A Professional

Assessing the severity of warping is crucial. Small warps can often be fixed at home. Major warps may need professional help. Check for signs of extreme bending or cracks. If the plywood feels soft or unstable, it’s time to call an expert.

Professional services offer several advantages. Experts have the right tools and skills. They can provide a long-lasting solution. Professionals also save time and reduce stress. Their experience helps avoid further damage.

Consider hiring a professional if:

- The plywood is part of a structural element.

- DIY methods fail to correct the issue.

- You lack the necessary tools or knowledge.

Conclusion: Restoring Plywood’s Integrity

Restoring plywood’s integrity is important for its longevity. Effective solutions include applying heat to reshape warped plywood. Moisture control is crucial. Keeping plywood in a dry area helps prevent warping.

Using weights can also help. Place heavy objects on warped areas to flatten them. Clamping plywood can provide additional pressure and restore its shape.

Always ensure proper storage. Store plywood flat, avoiding direct sunlight and dampness. Regular checks can catch issues early, preserving its quality.

| Solution | Description |

|---|---|

| Heat Application | Use heat to reshape warped areas. |

| Moisture Control | Keep plywood in a dry environment. |

| Weight Application | Place heavy objects to flatten warped spots. |

| Clamping | Use clamps for added pressure to restore shape. |

Frequently Asked Questions

How Can I Tell If Plywood Is Warped?

You can identify warped plywood by checking its surface for unevenness. Place a straightedge along the board’s length to spot gaps. Also, inspect the corners; if they do not align properly, the plywood is likely warped. Look for signs of moisture damage, which can exacerbate warping.

What Causes Plywood To Warp?

Plywood warps mainly due to moisture imbalance and temperature changes. Excess humidity can cause the wood fibers to swell, while dry conditions can make them shrink. Poor storage conditions and inadequate sealing also contribute to warping. Understanding these factors can help prevent future issues with your plywood.

Can Warped Plywood Be Fixed?

Yes, warped plywood can often be fixed using various methods. Applying moisture to the concave side may help it return to shape. You can also use weights to flatten it. In severe cases, replacing the plywood might be more practical for achieving a flat surface.

How Do I Prevent Plywood From Warping?

To prevent plywood from warping, store it in a dry, climate-controlled area. Ensure it is sealed with a protective finish to block moisture. Periodically check for humidity levels and adjust conditions accordingly. Proper handling and storage techniques will extend the life of your plywood and maintain its shape.

Conclusion

Warped plywood can be frustrating, but it’s fixable. By following the right techniques, you can restore its shape and functionality. Regular maintenance and proper storage can prevent warping in the future. Take these steps to ensure your projects remain strong and reliable.

A little effort now can save you time later.